Best CAD Software for CNC: A Practical Comparison

TL;DR

Choosing the best CAD software for your CNC depends on your goals. For most hobbyists and small businesses, Autodesk Fusion 360 is the top all-in-one choice, combining powerful CAD and CAM features at an affordable price. If your work is artistic, like woodworking or sign-making, the Vectric ecosystem (Aspire or VCarve Pro) is unparalleled. For professional engineers who need maximum precision, SolidWorks remains the industry standard, though it requires a separate CAM program.

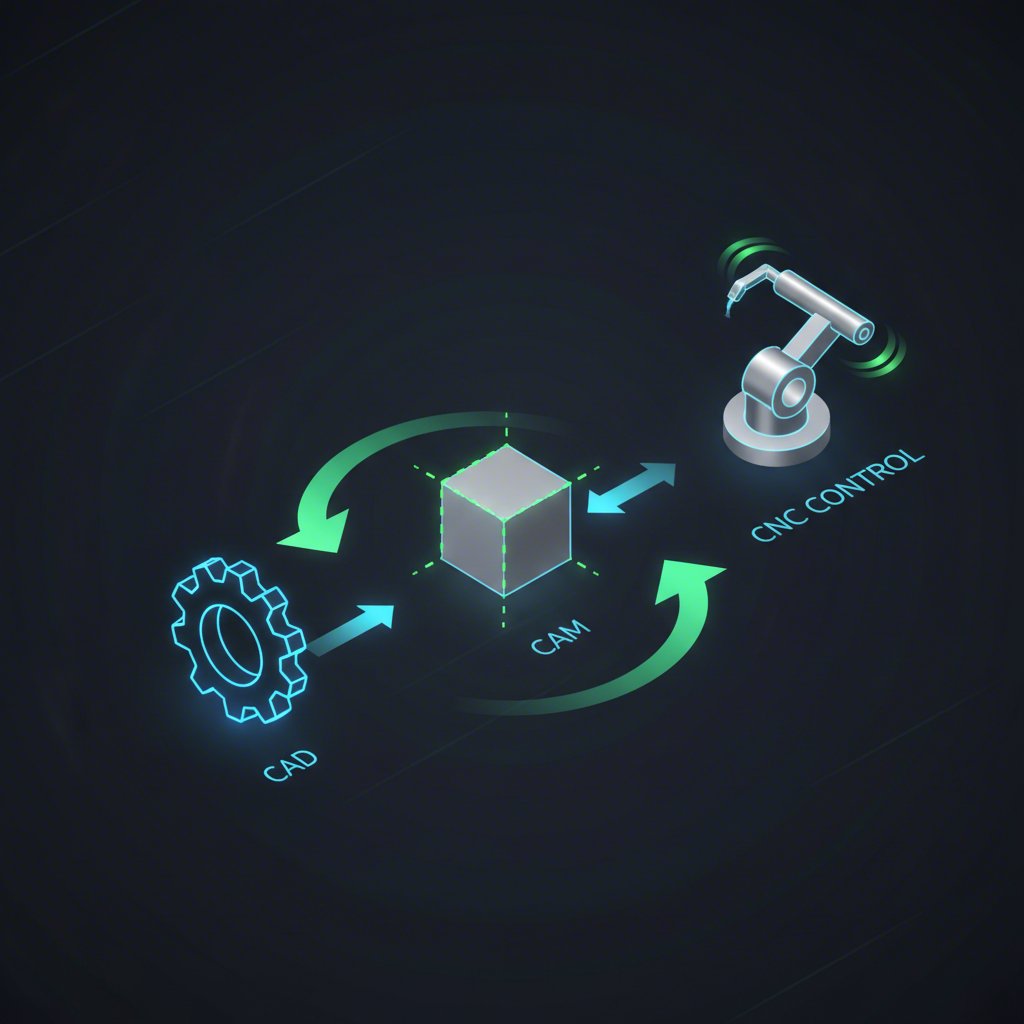

The CNC Software Workflow: CAD, CAM, and Control Explained

Before diving into specific software, it's crucial to understand the three distinct stages of the CNC process. Many newcomers are confused by the alphabet soup of CAD, CAM, and control software, but the workflow is logical. Each step uses a different type of software to take your idea from a digital concept to a physical object.

First is CAD (Computer-Aided Design). This is where your project begins. In CAD software, you create the 2D or 3D model of the part you want to make. Think of it as your digital drawing board. You define shapes, set dimensions, and assemble components. Popular examples of pure CAD software include SolidWorks and AutoCAD, though many modern programs integrate this step with the next one.

Next comes CAM (Computer-Aided Manufacturing). Once your design is complete, CAM software takes over. Its job is to translate your 3D model into instructions the CNC machine can understand. It does this by generating toolpaths—the exact routes the cutting tool will follow. In this stage, you'll define parameters like tool selection, cutting speed, and cut depth. The output of CAM software is a file of G-code, the universal language of CNC machines.

Finally, there is the CNC Control Software. This software acts as the interface between your computer and the CNC machine itself. It reads the G-code file generated by your CAM program and sends the precise motion commands to the machine's motors, directing the tool to cut your part. Examples include Mach4 and LinuxCNC. Many modern solutions, especially for beginners and hobbyists, offer an integrated CAD/CAM experience in a single package, which simplifies this workflow significantly.

The All-in-One Champion: Autodesk Fusion 360

For a vast number of users, from beginners to seasoned professionals, Autodesk Fusion 360 is the go-to recommendation. Its immense popularity stems from its integrated approach, combining CAD, CAM, CAE (Computer-Aided Engineering), and PCB design into a single, cloud-based platform. This eliminates the friction of moving designs between separate programs, creating a seamless workflow from initial sketch to final G-code.

Fusion 360's strength lies in its versatility. It offers robust parametric modeling, allowing you to create complex 3D parts and assemblies with ease. When you're ready to machine your part, you simply switch to the "Manufacture" workspace. Here, you'll find a comprehensive suite of CAM tools that support everything from simple 2.5-axis milling and turning to more complex 3-axis and 5-axis machining. This integration makes it an incredibly efficient tool for iterative design and prototyping.

One of its most significant advantages, particularly for hobbyists and startups, is its pricing model. Autodesk offers a free personal use license, but it comes with significant limitations, including a maximum of 10 active documents and restrictions on advanced CAM features and common file export types. The cloud-based nature facilitates collaboration, allowing teams to work on the same project from different locations. While this requires a stable internet connection, it ensures your files are always synced and accessible. More information on its capabilities can be found on the official Autodesk website.

Pros & Cons of Fusion 360

| Pros | Cons |

|---|---|

| Fully integrated CAD and CAM workflow | Steep learning curve for advanced features |

| Free for personal, non-commercial use | Cloud-based platform requires internet access |

| Powerful 2D, 3D, and multi-axis CAM | Can be resource-intensive on older computers |

| Strong community and abundant tutorials | Occasional bugs or performance issues after updates |

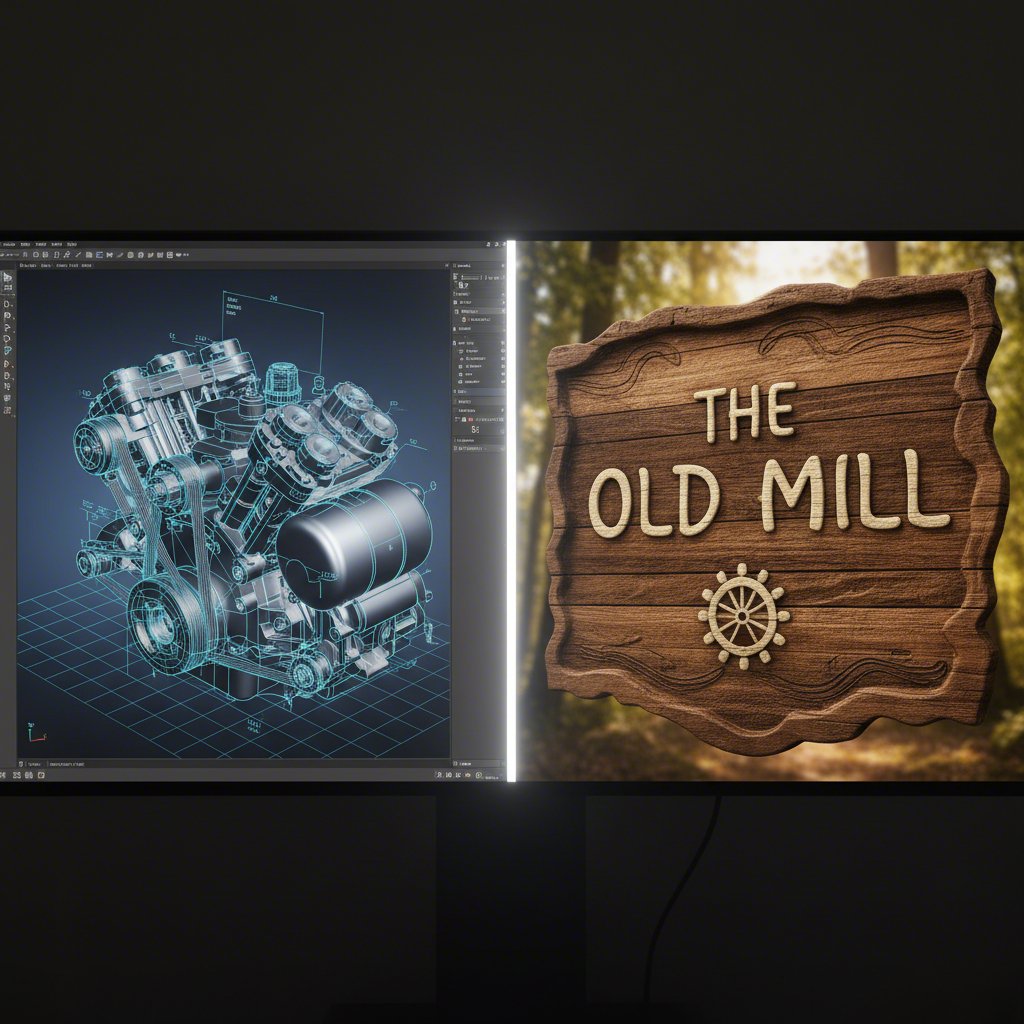

For Artistic CNC: The Vectric Ecosystem (Aspire & VCarve Pro)

While Fusion 360 excels at mechanical parts, the Vectric software suite is the undisputed leader for artistic and decorative applications, especially on CNC routers. If your work involves intricate carvings, detailed sign-making, or ornate furniture, Vectric's products are designed specifically for you. Their intuitive interface and powerful toolsets are tailored for woodworkers, artists, and creators.

The two most popular offerings are VCarve Pro and Aspire. VCarve Pro is the perfect tool for 2D and 2.5D work. It excels at creating toolpaths for cutting out shapes, pocketing, drilling, and, as the name suggests, V-carving for text and graphics. It also allows you to import and machine single 3D models, making it a versatile choice for a wide range of projects. Many users find it significantly easier to learn than more engineering-focused programs.

Aspire includes all the features of VCarve Pro and adds a complete 3D modeling toolset. This is the key difference: with Aspire, you can design and build your own complex 3D relief models from scratch. You can sculpt organic shapes, add textures, and create intricate 3D components directly within the software. This makes it the ideal choice for users who need to create custom 3D artwork rather than just machining existing models. As a leading choice for artistic CNC, Vectric's offerings are detailed on their official site.

VCarve Pro vs. Aspire

| Feature | VCarve Pro | Aspire |

|---|---|---|

| Primary Use | 2D/2.5D design and machining, importing 3D models | Full 3D design, sculpting, and machining |

| 3D Modeling | None (can only import and machine) | Full 3D component design and sculpting tools |

| Ideal User | Sign-makers, hobbyists, cabinet makers | Artisans, furniture makers, 3D modelers |

| Price | Lower | Higher |

The Engineering Standard: SolidWorks for Professionals

When precision, reliability, and advanced simulation are non-negotiable, professionals in engineering and product design turn to SolidWorks. It is widely regarded as the industry standard for parametric CAD. Its focus is purely on design, and it provides an incredibly powerful and robust environment for creating complex mechanical parts, large assemblies, and production-ready drawings with exacting tolerances.

Unlike Fusion 360 or Vectric, SolidWorks does not include CAM in its base package, but it becomes an integrated CAD/CAM solution with official add-ons. It is a dedicated design tool. To generate G-code for a CNC machine, you need a separate CAM plugin or standalone software. Popular choices that integrate with SolidWorks include CAMWorks and Mastercam. This modular approach allows specialists to use the best-in-class tool for each job, but it also adds complexity and cost to the overall software package.

SolidWorks is overkill for hobbyists and most small businesses due to its high cost and steep learning curve. However, for professionals in aerospace, automotive, or industrial manufacturing, its advanced features for simulation, stress analysis, and motion studies are indispensable. If your business revolves around designing and validating high-performance parts, SolidWorks is the proven solution. For those designing such complex parts but seeking manufacturing partners, leveraging advanced CNC milling services from XTJ can be a strategic choice, offering rapid production with tight tolerances and a wide range of materials without the overhead of in-house machining.

Pros & Cons of SolidWorks

| Pros | Cons |

|---|---|

| Extremely powerful and precise parametric modeling | Very expensive license and maintenance fees |

| Industry standard for professional engineering | Requires a separate CAM program for CNC |

| Robust simulation and analysis tools | Steep learning curve for new users |

| Large ecosystem of third-party plugins | Overkill for simple or artistic projects |

Getting Started: Top Free and Budget-Friendly Options

For those just starting with CNC or operating on a tight budget, the high cost of professional software can be a major barrier. Fortunately, there is a vibrant ecosystem of free and low-cost software that is more than capable of producing excellent results. These tools are a fantastic way to learn the fundamentals of CAD and CAM without a significant financial investment.

According to guides like one from Carbide 3D, some of the most popular free options include FreeCAD, Carbide Create, and Easel. FreeCAD is a powerful, open-source parametric 3D modeler. It is highly capable for designing engineering parts but comes with a notoriously steep learning curve. Carbide Create is a simple 2D CAD/CAM program that is very easy to learn, making it perfect for beginners designing signs and simple mechanical parts. Similarly, Easel by Inventables is a browser-based, user-friendly CAD/CAM solution designed to get new users cutting parts as quickly as possible.

While these free tools are excellent starting points, they have limitations. Simpler programs like Easel and Carbide Create lack the advanced features of paid software, and you may outgrow them as your skills and project complexity increase. FreeCAD is powerful but can be less polished and more difficult to master than commercial alternatives. They represent a trade-off between cost, power, and ease of use.

Comparison of Free CNC Software

| Software | Cost | Primary Function | Ideal User |

|---|---|---|---|

| FreeCAD | Free (Open Source) | Parametric 3D CAD with CAM workbench | Tinkerers, engineers on a budget |

| Carbide Create | Free | Integrated 2.5D CAD/CAM | Absolute beginners, 2D project makers |

| Easel | Free (Pro version available) | Browser-based 2.5D CAD/CAM | Hobbyists, educators, beginners |

Choosing the Right CNC Software for You

Ultimately, the "best" CAD software for CNC is the one that best fits your specific needs. There is no single answer for everyone. Before you commit, take a moment to evaluate your primary goals. Are you focused on creating precise, functional parts for engineering projects, or are you more interested in artistic expression through wood or other materials? Your answer will point you in a clear direction.

Your budget and willingness to learn are also critical factors. Don't be afraid to start with a free option like Carbide Create or the personal use version of Fusion 360 to get a feel for the workflow. As your skills grow and your projects become more ambitious, you can always invest in more specialized or powerful software. The key is to choose a tool that empowers you to bring your ideas to life without creating unnecessary frustration.

Frequently Asked Questions About CNC Software

1. Is FreeCAD good for CNC?

Yes, FreeCAD can be an excellent choice for CNC, especially for users on a budget who need to design mechanical parts. It is a powerful parametric 3D modeler with a dedicated CAM workbench that can generate G-code. However, it has a very steep learning curve compared to more user-friendly commercial software, and its interface can feel less polished. It is best suited for those with some technical background or a high degree of patience.

2. Can I use SketchUp for CNC?

While SketchUp is a popular and easy-to-use 3D modeling program, it is not ideal for CNC work out of the box. It was primarily designed for architectural and conceptual visualization, not for manufacturing. To create G-code from a SketchUp model, you will need to use third-party plugins or extensions, which can add complexity to the workflow. It's possible, but dedicated CAD/CAM software is generally a more direct and reliable path.

3. What is the most popular CAD CAM software?

The answer depends on the industry. In professional manufacturing, Mastercam is often cited as the most widely used CAM software, while SolidWorks is a leader in professional CAD. However, in the broader market that includes hobbyists, small businesses, and education, Autodesk Fusion 360 has become immensely popular due to its integrated CAD/CAM capabilities and accessible pricing, making it one of the most popular all-in-one solutions available today.

-

Posted in

cad software, CAM software, cnc machining, fusion 360, vectric