Mastering CNC Workholding: Secure Parts for Flawless Results

TL;DR

CNC workholding refers to any device or method used to securely fasten a workpiece in a fixed, stable position during the machining process. It is absolutely essential for counteracting the immense cutting forces generated by a CNC machine. Proper workholding ensures the part remains immobile to achieve high precision, prevent tool breakage, guarantee the quality of the final product, and maintain operator safety. Common examples include vises, clamps, chucks, and custom fixtures.

The Fundamentals of CNC Workholding: Definition and Importance

In the world of CNC machining, you can have the most advanced machine and a perfectly programmed toolpath, but without effective workholding, the entire operation is destined for failure. Workholding is the critical discipline of securing a workpiece—the stock material being machined—in a precise and rigid location. As explained in a guide from Purdue University, parts don't just float in 3D space as they do in a CAD model; something must physically hold them against the powerful forces of cutting tools.

The primary importance of workholding is to counteract the physical forces exerted during machining. When a spinning end mill or a lathe tool cuts into metal, plastic, or wood, it generates significant pressure, vibration, and torque. If the workpiece were unsecured, it would be thrown from the machine, creating a dangerous projectile and ruining the part. A robust workholding setup absorbs these forces, ensuring the workpiece does not shift, vibrate, or deflect. This stability is the foundation of all precision and accuracy in CNC machining.

Furthermore, proper workholding is directly linked to the quality and repeatability of the finished parts. Even a microscopic shift during a cut can cause dimensional inaccuracies, poor surface finish, and features that are out of tolerance. As noted by manufacturing experts at Fictiv, if you attempt to machine multiple parts with a poor setup, each part will be significantly different from the rest, resulting in low precision. For any kind of production run, the ability to place each new piece of stock in the exact same position repeatedly is key to achieving consistent results.

Finally, safety cannot be overstated. A workpiece that breaks free from its restraints can cause catastrophic damage to the cutting tool, the machine spindle, and the enclosure. More importantly, it poses a severe risk to the machine operator. A thoughtfully designed workholding solution is a non-negotiable aspect of a safe and efficient machining environment, preventing accidents and costly damage.

A Comprehensive Guide to Workholding Devices and Methods

The method chosen to secure a workpiece depends heavily on the part's geometry, material, and the specific machining operations. A wide array of devices and techniques have been developed, ranging from simple mechanical clamps to sophisticated custom fixtures. Understanding the most common options is the first step toward selecting the right solution for your project.

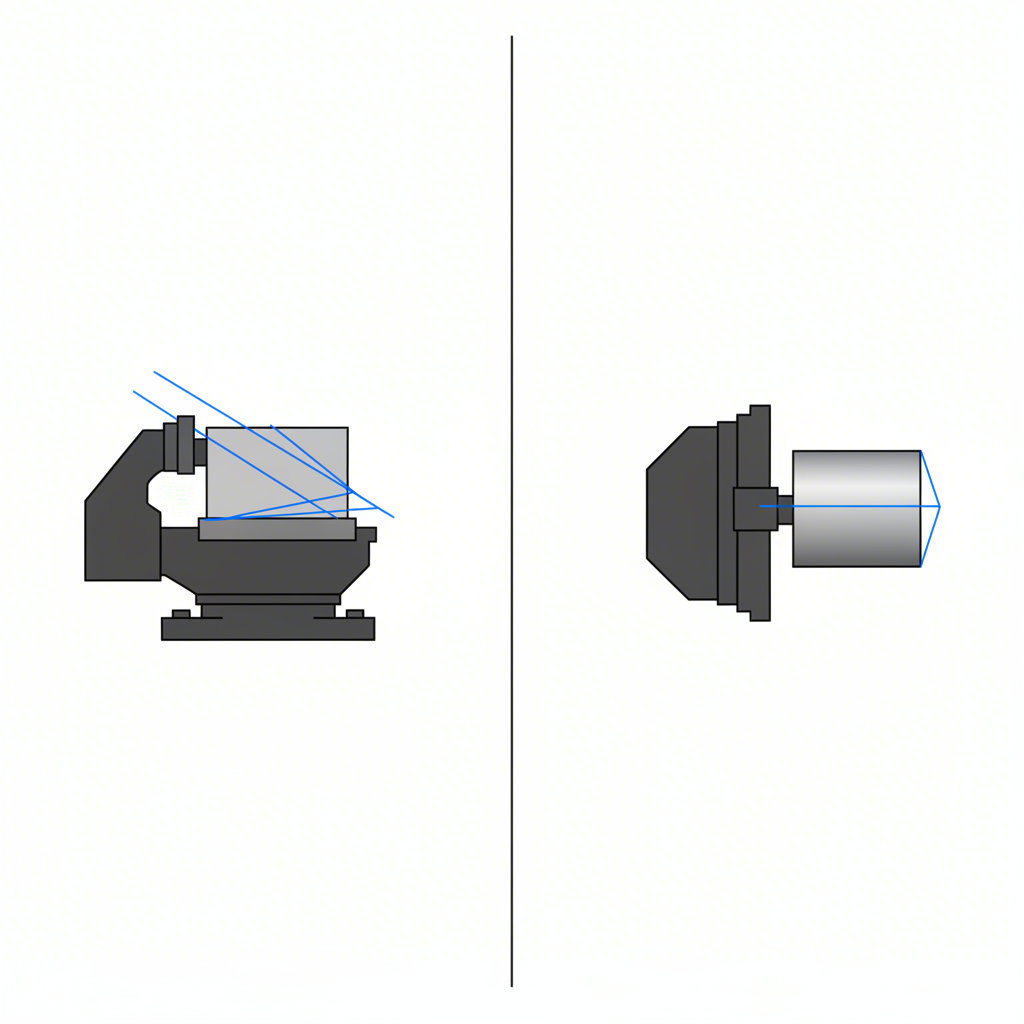

Vises: The machinist's vise is arguably the most common workholding device on a CNC mill. It uses two jaws—one fixed and one movable—to clamp onto parts with parallel sides. Vises are fast to set up, highly rigid, and provide excellent repeatability. For parts with irregular shapes, machinists often use 'soft jaws,' which are custom-machined aluminum jaw inserts that are cut to perfectly match the profile of the workpiece.

Clamps: For large or unusually shaped parts that don't fit in a vise, various clamping systems are used. Step clamps (or toe clamps) bolt directly to the machine's T-slotted table and hold the workpiece down from the top or sides. This method is highly versatile but can be more time-consuming to set up than a vise.

Chucks and Collets: Primarily used on lathes for turning operations, chucks and collets are designed to grip cylindrical workpieces. A three-jaw chuck is common for quickly centering round or hexagonal stock, while a four-jaw chuck allows for independent jaw adjustment to hold irregular shapes. Collets offer a higher degree of precision and gripping force for specific diameters.

Fixtures and Jigs: A fixture is a custom-built workholding solution designed specifically for one part or a family of similar parts. As detailed by CNC Cookbook, fixtures are where machinists often make their money on production jobs by enabling faster loading and more secure holding of complex parts. A jig performs the same holding function but also guides the cutting tool, a feature more common in manual machining than in CNC.

Other Methods: For delicate or thin materials, other methods are employed. Vacuum tables use suction to hold flat sheets of material down without clamps. Adhesives like special waxes, hot glue, or even double-sided tape can be effective for low-force applications. For high-volume production, services like XTJ offer advanced CNC milling with expertise in designing optimal workholding for complex, precision-engineered components, ensuring quality and efficiency. You can discover how XTJ can transform your designs with their tailored services.

To help clarify these options, here is a summary of common workholding devices:

| Device Type | Primary Use Case | Pros | Cons |

|---|---|---|---|

| Machinist's Vise | General-purpose milling of square or rectangular parts. | Fast setup, high rigidity, good repeatability. | Limited by jaw opening size; requires parallel surfaces. |

| Clamps (Toe/Step) | Large, flat, or irregularly shaped workpieces. | Highly versatile, strong clamping force. | Slower setup, can obstruct tool access. |

| 3-Jaw Chuck | Holding round or hex stock on a lathe. | Self-centering, quick to use. | Less accurate for non-perfectly round parts. |

| Custom Fixture | High-volume production of a specific part. | Maximum repeatability, speed, and process security. | High upfront cost and design time; not versatile. |

| Vacuum Table | Machining thin, flat sheets of non-porous material. | Uniform pressure, no side clamps to obstruct toolpaths. | Holding force depends on surface area; not for small parts. |

Workholding Solutions for CNC Milling vs. Turning (Lathes)

While the core principle of workholding—keeping the part still relative to the tool—is universal, the strategies and devices differ significantly between CNC milling and CNC turning. The fundamental difference lies in what is moving: in milling, the tool spins and moves, while the workpiece is stationary. In turning, the workpiece spins while a stationary tool cuts it.

Workholding for CNC Milling

On a CNC mill, the workpiece is typically mounted on a stationary table that moves along the X and Y axes. The primary challenge is to resist the multi-directional forces from the rotating end mill. The most common solution is a machinist's vise bolted to the machine table. For larger plates or parts with complex shapes, a tooling plate with a grid of threaded holes and dowel pin locations is used. This allows for the use of various clamps, such as toe clamps, to secure the workpiece directly to the plate, providing repeatable and precise positioning.

Workholding for CNC Turning (Lathes)

On a CNC lathe, the workpiece rotates at high speed, so the workholding must provide a balanced, secure grip to handle the centrifugal forces in addition to the cutting forces. The standard device is a chuck, typically with three or four jaws. A three-jaw chuck is self-centering and ideal for quickly gripping round stock. A four-jaw chuck has independently adjustable jaws, allowing it to hold square or irregular shapes concentrically. For high-precision work or holding smaller diameter stock, collets are used. A collet is a sleeve that contracts around the workpiece, providing a very tight, concentric grip along a greater surface area than a chuck.

Key Considerations for Selecting the Right Workholding Method

Choosing the optimal workholding solution is a critical decision that impacts efficiency, accuracy, and cost. There is no single best method; the right choice depends on a careful analysis of the project's specific requirements. An inappropriate setup can lead to scrapped parts, broken tools, or even machine damage. Before starting any CNC job, a machinist should consider the following factors.

First, evaluate the Workpiece Geometry and Material. Is the part a simple block with parallel sides, or does it have a complex, organic shape? A simple vise is perfect for the former, while the latter may require custom-machined soft jaws or a dedicated fixture. The material is also crucial. Hard metals like steel require extremely rigid clamping to withstand high cutting forces, whereas soft plastics or thin-walled parts could be damaged or warped by excessive clamping pressure, making a vacuum chuck or a lighter touch necessary.

Next, consider the Required Precision and Tolerances. High-precision jobs with tight tolerances demand workholding that is not only rigid but also highly repeatable. A custom fixture plate with dowel pins or a high-quality vise ensures that every part is located in the exact same position, which is critical for consistency across a production run. Less precise work, like roughing out a wood carving, might be adequately secured with simpler methods like screws or T-track clamps, as described by Sienci Labs.

The Production Volume is a major economic driver in workholding selection. For a one-off prototype, a standard vise or a quick clamp setup is the most efficient choice. Investing time and money into a custom fixture would not be cost-effective. However, for a production run of hundreds or thousands of identical parts, a custom fixture that holds multiple parts at once can dramatically reduce cycle times and operator effort, providing a significant return on investment.

Finally, analyze the Machining Operations and Tool Access. The workholding must secure the part without getting in the way of the cutting tool. If a part needs features machined on five of its six sides, a standard vise will require multiple setups. In contrast, a dovetail fixture or a custom 'tombstone' on a 4th or 5th-axis machine might allow all features to be cut in a single operation, drastically improving efficiency.

Checklist for Choosing Your Workholding:

- Geometry: Is the part square, round, or complex?

- Material: Is it hard and strong, or soft and delicate?

- Tolerances: How precise does the final part need to be?

- Volume: Are you making one part or one thousand parts?

- Access: Can the tool reach all necessary surfaces without hitting the clamps?

Frequently Asked Questions About CNC Workholding

1. What is the difference between a jig and a fixture in workholding?

While often used interchangeably, there is a technical difference. A fixture is a device that holds a workpiece in a specific location and orientation for a machining operation. A jig does the same thing but also includes features to guide the cutting tool. In modern CNC machining, the machine's G-code provides the primary guidance for the tool path, which is why many custom workholding devices are fixtures. However, jigs, which also guide the tool, are still commonly used to provide additional support and precision for specific operations.

2. Can you use magnets for CNC workholding?

Yes, magnetic chucks are a common workholding solution, particularly for grinding and light milling operations on ferrous materials (materials that contain iron). A magnetic chuck uses powerful electromagnets or permanent magnets to hold the workpiece securely. They are excellent for providing unobstructed access to five sides of a part but are only suitable for materials that are magnetic and may not provide enough holding force for heavy roughing cuts.

3. How does workholding affect surface finish?

Workholding has a direct and significant impact on surface finish. Any vibration or chatter during the cutting process will be transferred to the part's surface, leaving a poor finish. A rigid, stable workholding setup dampens these vibrations, allowing the cutting tool to make a clean, smooth cut. Insufficient clamping force or a setup that allows the part to resonate will almost always result in a rough or wavy surface.

-

Posted in

cnc machining, CNC milling, CNC turning, manufacturing, workholding