Essential Rules for Designing CNC Internal Radii

TL;DR

Designing internal radii for CNC machining is critical because standard rotating tools cannot create sharp 90-degree internal corners. As a best practice, your internal corner radius should be at least one-third of the cavity's depth. For optimal results and cost-efficiency, make the radius slightly larger than the cutting tool's radius—ideally around 130%—to ensure manufacturability, reduce tool stress, and improve the final surface finish.

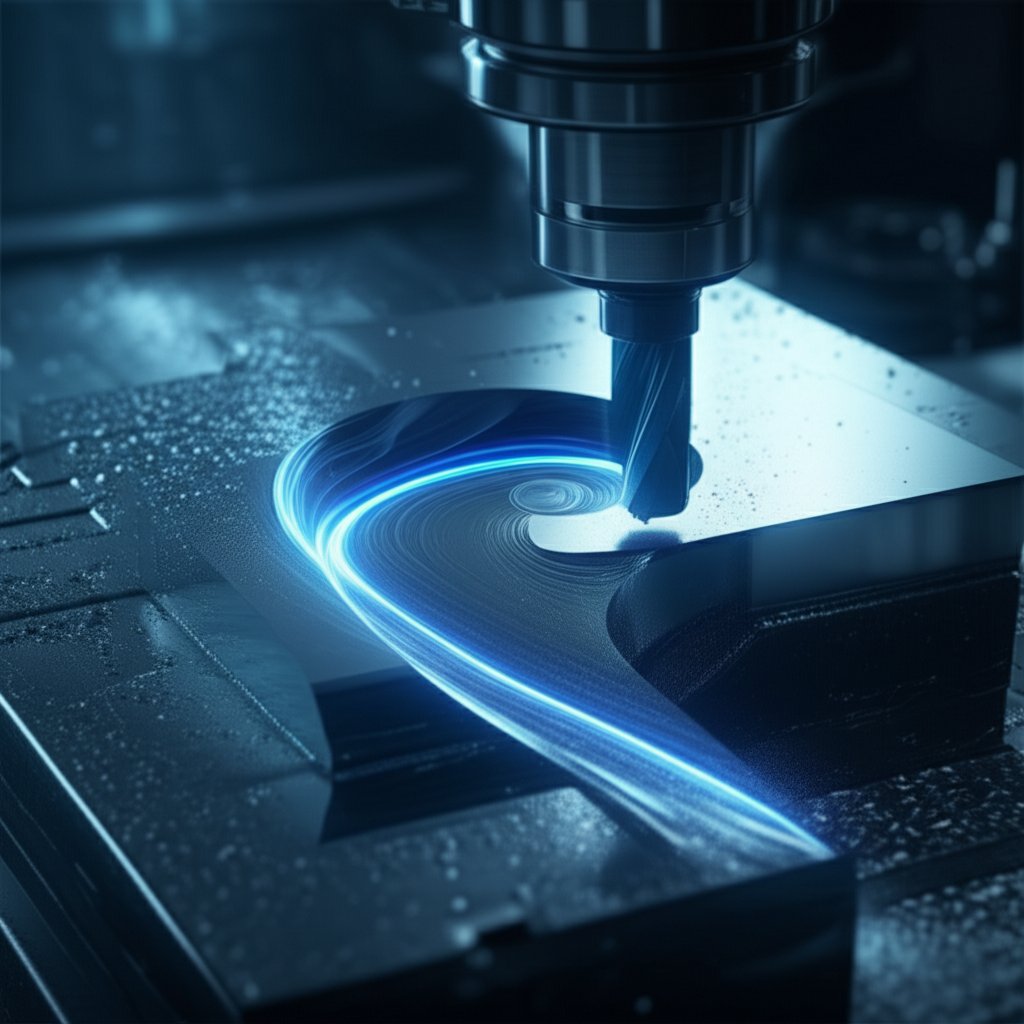

The Fundamental Constraint: Why Sharp Internal Corners Are Impossible

A core principle in designing for CNC machining is understanding the physical limitations of the tools. The primary reason that perfectly sharp, 90-degree internal corners cannot be machined is due to the geometry of the cutting tools themselves. CNC mills and drills are cylindrical, and as a rotating, round tool moves into a corner, it will invariably leave behind a radius that matches its own. Forcing a tool into a sharp corner path would cause it to stop, pivot, and restart, leading to excessive tool wear, potential breakage, and a poor surface finish marked by vibrations, often called chatter. This is a fundamental mechanical constraint that designers must account for from the very beginning of the CAD process.

Think of it like trying to fit a round peg into a square hole; the peg simply cannot fill the sharp corners of the hole. Similarly, an end mill cannot clear out material to create a perfectly square internal pocket. While other, more specialized and expensive processes like Electrical Discharge Machining (EDM) can achieve sharp corners, standard subtractive CNC machining cannot. Therefore, incorporating an appropriate internal radius is not just a recommendation but a necessity for successful and efficient manufacturing. Ignoring this constraint leads to designs that are either impossible to produce as drawn or require significant, costly adjustments by the machinist.

Core Design Rules for CNC Internal Radii

To ensure your parts are manufacturable and meet quality standards, follow these established best practices for designing internal radii. These rules help balance design intent with the practical realities of the CNC machining process, leading to better outcomes and lower costs.

- Relate Radius to Cavity Depth: A widely accepted rule of thumb is that the radius of an internal corner should be at least one-third of the cavity's depth. As detailed by Protolabs (formerly Hubs), following this guideline helps maintain tool rigidity. Machining a deep pocket with a very small radius would require a long, thin tool, which is prone to deflection and vibration, ultimately compromising the part's accuracy and surface finish.

- Make the Radius Larger Than the Tool: To optimize the machining process, design the internal radius to be slightly larger than the tool radius. A common recommendation is to make the part's radius about 130% of the tool's radius. For example, if a 10mm diameter (5mm radius) end mill is used, a 6.5mm internal radius is ideal. Xometry suggests adding at least 0.02" to 0.05" to the radius to give the tool clearance to make a smooth turn without stopping, which reduces machining time and prevents chatter.

- Use Standard Tool Sizes: Whenever possible, design your radii to correspond with standard end mill diameters (e.g., 6mm, 8mm, 10mm, 12mm). This allows the machine shop to use common, off-the-shelf tools, which are more cost-effective than custom tooling. Aligning your design with available tools simplifies the manufacturing setup and reduces overall project costs.

- Specify Minimums When Necessary: While larger is better, sometimes a design requires a small radius. It's important to know the minimums a manufacturer can achieve. For instance, JLCCNC notes they can achieve a minimum radius of 0.5mm for depths up to 3mm, but this requires smaller, more fragile tools and increases machining costs. Always specify the largest radius your design can tolerate.

Optimizing Radius Design for Cost, Speed, and Quality

The design of internal radii is one of the most significant factors influencing the cost, speed, and quality of a CNC machined part. Strategic choices in this area can lead to substantial savings and superior results. The fundamental relationship is straightforward: larger radii allow for the use of larger, more robust cutting tools. These larger tools can remove material at a much higher rate (higher feed rates) and with greater stability, which drastically reduces machining time and, consequently, lowers the cost. A larger tool is also less likely to break and produces a better surface finish due to reduced vibration.

Conversely, designing small, tight radii forces the use of smaller, more delicate end mills. These tools must run at slower speeds to avoid breaking and may require multiple shallow passes to achieve the desired depth. This significantly increases machining time and drives up the cost. As explained by Protocase, the tool's engagement with the material increases dramatically in a tight corner, putting stress on both the tool and the workpiece, which can degrade the surface finish. Therefore, a critical part of the design process is to ask: is this small radius functionally essential, or can it be enlarged to optimize for manufacturability?

For teams looking to streamline this process, leveraging expert feedback can be invaluable. To accelerate your product development, consider services like those offered by XTJ for comprehensive formative manufacturing. Partnering with an experienced team provides access to crucial Design for Manufacturability (DFM) feedback, helping you optimize features like internal radii before production begins. This expert analysis ensures your design is perfected for efficiency, quality, and cost-effectiveness from the start.

Design Choices and Their Consequences

| Design Choice | Required Tool | Relative Machining Time | Relative Cost | Surface Finish Quality |

|---|---|---|---|---|

| Large Radius (e.g., 10mm) | Large, rigid end mill | Low | Low | Excellent |

| Small Radius (e.g., 1mm) | Small, fragile end mill | High | High | Fair to Poor |

| Radius = Tool Radius | Standard end mill | Moderate | Moderate | Poor (chatter likely) |

| Radius > Tool Radius | Standard end mill | Low | Low | Good to Excellent |

Frequently Asked Questions About Designing Internal Radii

1. What happens if I design a part with sharp 90-degree internal corners?

If you submit a design with sharp internal corners, the manufacturer cannot produce it as-is using standard CNC milling. They will typically contact you to discuss modifications. The most common solution is to add the smallest possible radius their tools can create, which may not meet your design's functional needs and will likely increase the cost. In some cases, they may suggest alternative manufacturing methods like EDM, which is significantly more expensive.

2. How can I create a pocket for a square part to fit into?

When a mating part with sharp corners needs to fit into a machined pocket, you cannot use a simple rounded internal corner. The solution is to design reliefs, often called "dog-bone" or "T-bone" fillets. A dog-bone fillet involves machining a circular pocket at each corner, extending past the main pocket boundary. This clears the corner area completely, allowing the square part to fit perfectly while still using a standard round cutting tool.

3. Does the same radius rule apply to both vertical and horizontal corners?

The rules discussed primarily apply to vertical internal corners (the corners at the bottom of a pocket's walls). Horizontal corners, or floor radii, where the vertical wall meets the floor of a pocket, are also a consideration. If possible, design parts without a floor radius, as this allows a flat-bottomed end mill to create a clean 90-degree transition. If a floor radius is required, it's best to make it smaller than the vertical corner radius so the same ball-end or bull-nose tool can machine both features efficiently.