Essential Steps for Getting a Fast CNC Machining Quote

TL;DR

To get a CNC machining quote, you must first have a 3D CAD file of your part. You then upload this file to an online CNC service provider's website, specify your requirements like material, quantity, and finish, and you will receive an instant or manual price quote. This streamlined process allows for rapid and efficient pricing of custom-manufactured parts.

Understanding the CNC Quoting Process: From Design to Price

A CNC machining quote is a detailed price estimate for manufacturing a custom part based on a digital design. Modern manufacturing platforms have revolutionized this process. Instead of lengthy manual calculations, most online services like Protolabs and Xometry use powerful algorithms to provide an instant quote. You simply upload a 3D CAD file, and the software analyzes its geometry for manufacturability, calculates machine time, and generates a price in seconds. This contrasts sharply with traditional manual quotes from local machine shops, which can take days but may offer more personalized feedback.

The price of a CNC machined part is determined by several key factors. The primary driver is machining time—the longer a machine has to run to create your part, the higher the cost. This is directly influenced by part complexity, such as intricate curves, deep pockets, or thin walls. Material choice is another significant factor; common materials like Aluminum 6061 are cost-effective, while specialized alloys or high-performance plastics like PEEK are more expensive. Other critical inputs include the order quantity (higher volumes typically reduce the price-per-part), the required tolerances (tighter tolerances demand more precision and time), and any specified surface finishes.

Online quoting platforms offer immense benefits in speed and accessibility, allowing you to get pricing from anywhere at any time. However, a local machine shop might provide a deeper collaborative relationship and more hands-on guidance. For complex projects, leveraging a service that offers robust engineering support can be invaluable. For instance, some providers offer Design for Manufacturability (DFM) feedback to optimize your design for efficiency and cost-effectiveness. When seeking a partner for prototypes or production, considering a provider like XTJ's comprehensive formative manufacturing services can accelerate development with expert feedback and a wide range of material options.

Before you begin, ensure you have everything prepared to streamline the process. A clear understanding of your project requirements is essential for receiving an accurate and useful quote. Here is a high-level checklist of what to have ready:

- Completed 3D CAD Model: The non-negotiable starting point for any quote.

- Material Selection: A specific choice of metal or plastic for your part.

- Order Quantity: The number of parts you need to be manufactured.

- Critical Tolerances: Any specific dimensional requirements that must be met.

- Surface Finish Requirements: Desired final look and feel (e.g., as-machined, anodized).

- Technical Drawing (Optional but Recommended): A 2D drawing to clarify tolerances, threads, and other special features.

Step 1: Preparing Your 3D CAD Model and Technical Drawings

The foundation of any CNC machining quote is a high-quality 3D Computer-Aided Design (CAD) file. This digital blueprint contains all the geometric information a machine needs to create your part. Without it, an automated quoting engine cannot analyze the part's complexity or calculate the toolpaths required for manufacturing. The accuracy and quality of your CAD model directly impact the accuracy of the quote and the success of the final product.

Online CNC services accept a variety of file formats, but some are preferred for their universality and data richness. The most widely accepted format is STEP (.stp, .step), as it is a neutral format that preserves the 3D model's integrity across different CAD systems. Other common formats include IGES, SLDPRT (SolidWorks), and sometimes STL, though STL is more commonly associated with 3D printing and can lack the precise data needed for machining. Always check the specific requirements of the service you are using, such as JLCCNC, to ensure compatibility.

Beyond the file format, applying Design for Manufacturability (DFM) principles is crucial. DFM involves designing parts in a way that makes them easier and more cost-effective to manufacture. Simple DFM considerations include using standard drill sizes for holes, adding generous radii to inside corners to accommodate the cutting tool, and avoiding unnecessarily deep pockets or thin walls that are prone to vibration and breakage. Incorporating these practices not only lowers your quote but also improves the structural integrity of the machined part.

While a 3D model is essential, supplementing it with a 2D technical drawing provides an extra layer of clarity that automated systems might miss. This is especially important for communicating critical information that isn't always captured in a 3D file alone.

| Submission Type | Pros | Cons |

|---|---|---|

| 3D Model Only | Fastest for instant quoting; sufficient for simple parts with standard tolerances. | Lacks clarity on specific tolerances, threads, surface finishes, and critical features. |

| 3D Model + 2D Drawing | Provides complete manufacturing intent; clearly defines tolerances, threads, and special instructions. | Requires extra preparation; may necessitate a manual review, slowing down the initial quote. |

Before you hit 'upload,' run through this final pre-upload checklist to prevent common errors that can delay your quote or lead to manufacturing issues:

- Check for Errors: Ensure your model is a single, solid body with no open surfaces or geometric faults.

- Confirm Scale: Verify the model is exported at a 1:1 scale in the correct units (e.g., mm or inches).

- Include All Features: Double-check that all necessary holes, fillets, and chamfers are present in the model.

- Define Critical Tolerances: If you have specific tolerance requirements, make sure they are clearly noted on an accompanying 2D drawing.

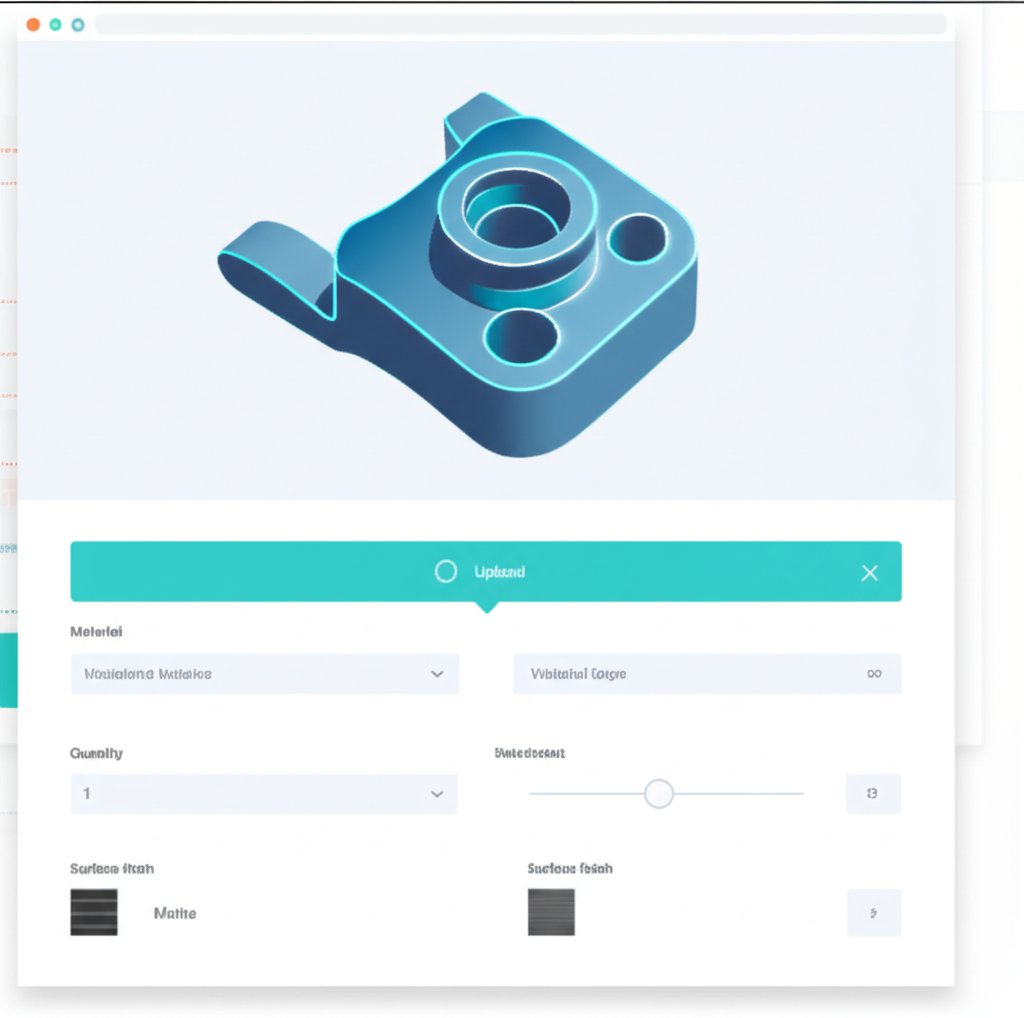

Step 2: Submitting Your Design and Specifying Requirements

Once your CAD file is prepared, the next step is to upload it to an online CNC quoting platform. This process is designed to be straightforward across most major services, including Hubs (now Protolabs Network) and others. The user interface typically guides you through a series of selections to define the exact specifications for your part, which allows the system to generate an accurate, real-time price.

The submission process generally follows a consistent, logical workflow. While the exact layout may vary slightly between providers, the core steps remain the same. This structured approach ensures all necessary information is captured efficiently, translating your digital design and requirements into a manufacturable reality.

- Navigate to the Instant Quote Page: Locate the "Get a Quote" or "Upload File" button, which is prominently displayed on the service provider's homepage.

- Upload Your Prepared CAD File(s): Drag and drop or select your 3D model (e.g., a STEP file) and any accompanying 2D technical drawings.

- Select Your Material: Choose the desired material from a comprehensive dropdown menu that lists various metals and plastics.

- Specify the Desired Quantity: Enter the number of parts you need. The price-per-part will often decrease as the quantity increases due to economies of scale.

- Choose a Surface Finish: Select any post-processing finishes required, such as anodizing, bead blasting, or powder coating.

- Add Notes or Special Instructions: Use a dedicated field to communicate any critical information not captured elsewhere, such as assembly requirements or specific inspection criteria.

Selecting the right material and finish is critical to your part's function and appearance. Online platforms provide a wide array of options to suit nearly any application, from prototyping to end-use production. Below are some common examples you will encounter.

| Category | Common Examples | Typical Applications |

|---|---|---|

| Materials | Aluminum 6061, Stainless Steel 304, ABS, POM (Delrin) | General-purpose prototyping, structural components, functional parts. |

| Finishes | As-Machined, Anodized (Type II), Bead Blasted | Standard finish, corrosion resistance and color, matte non-reflective surface. |

To ensure the most accurate quote, double-check all your inputs before submission. A simple error in material selection or quantity can significantly alter the price. Pay close attention to the units (e.g., inches vs. millimeters) and confirm that the automated 3D viewer on the platform renders your part correctly. Taking a moment to verify these details can save you time and prevent costly mistakes down the line.

Key Considerations for an Accurate Quote

Securing an accurate CNC machining quote is more than just uploading a file; it's about providing clear and complete information to the manufacturer. The core principle is to eliminate ambiguity. A well-prepared design file and detailed specifications lead to a price that reflects the true cost of production, preventing unexpected charges or delays. Remember that the quality of your input directly determines the quality of your output.

Your primary goal should be to ensure your design is optimized for manufacturing. Applying DFM principles is the most effective way to manage costs. Simplify geometries where possible, use standard tool sizes for internal corners, and specify tolerances only as tight as absolutely necessary. Every complex feature and every tight tolerance adds machining time and, therefore, cost. A thoughtful design can achieve the same function for a fraction of the price.

Finally, leverage the tools and resources provided by online platforms. Their automated DFM feedback can highlight potential issues before you even place an order. By following the structured steps of preparing your CAD file, specifying your requirements accurately, and reviewing your submission carefully, you can navigate the quoting process with confidence and turn your digital design into a physical part efficiently and cost-effectively.

Frequently Asked Questions

1. How to estimate CNC machining time?

Estimating CNC machining time involves calculating the total time a cutting tool is engaged with the workpiece. A basic formula is: Machining Time = (Length of Cut × Number of Passes) / (Feed Rate × Spindle Speed). However, this calculation is complex in practice, as it must account for tool changes, machine setup, part complexity, and material type. For this reason, online quoting platforms use sophisticated algorithms to analyze a CAD model's geometry and simulate toolpaths to provide a much more accurate time and cost estimate automatically.

2. What is the typical CNC cutting design price?

The price of CNC machining is not based on a single factor but is often simplified to an hourly rate for quoting purposes. These rates vary significantly by region, machine complexity, and shop overhead. For example, average hourly costs can range from $70 to over $150 in the United States and Europe. However, this rate is only one part of the total cost, which also includes material costs, setup fees, and any secondary processing. The final price of a part is determined by the total machining time, material cost, quantity ordered, and required finishes.

-

Posted in

CAD model, cnc machining, instant quote, manufacturing, prototyping