Does Stainless Steel Rust Or Corrode? Choose The Right Grade

Does Stainless Steel Rust?

When you invest in stainless steel, you expect a material that stands up to rust and corrosion. But does stainless steel rust? The short answer is: stainless steel resists rust far better than ordinary carbon steel, but it is not completely immune. Under certain conditions, even this renowned metal can show stains, pits, or rust-like discoloration. To understand why, let’s break down what makes stainless steel stainless and why it sometimes fails.

Does stainless steel rust and why the passive film matters

Rust is a specific form of corrosion—mainly iron oxide—that forms when iron reacts with oxygen and moisture. In regular steel, this process is rapid and destructive. Stainless steel, on the other hand, contains at least 10.5% chromium. This chromium reacts swiftly with oxygen in the environment, forming a thin, invisible layer of chromium oxide on the surface. This is called the passive film. It's what gives stainless steel its famous corrosion resistance.

Think of this passive film as a clear raincoat for the metal. If it’s scratched or damaged, the chromium in the steel reacts with oxygen to heal itself—so long as the environment isn’t too harsh. That’s why stainless steel is often called “self-healing.” However, if aggressive chemicals (like chlorides from salt) or stagnant water keep attacking the surface, the raincoat analogy breaks down: the film can’t repair fast enough, and rust or stains may appear.

- Chloride exposure: Salt and chlorides can break down the passive layer, especially in coastal or de-icing environments.

- Stagnant moisture: Water that sits on the surface blocks oxygen, preventing the film from repairing itself.

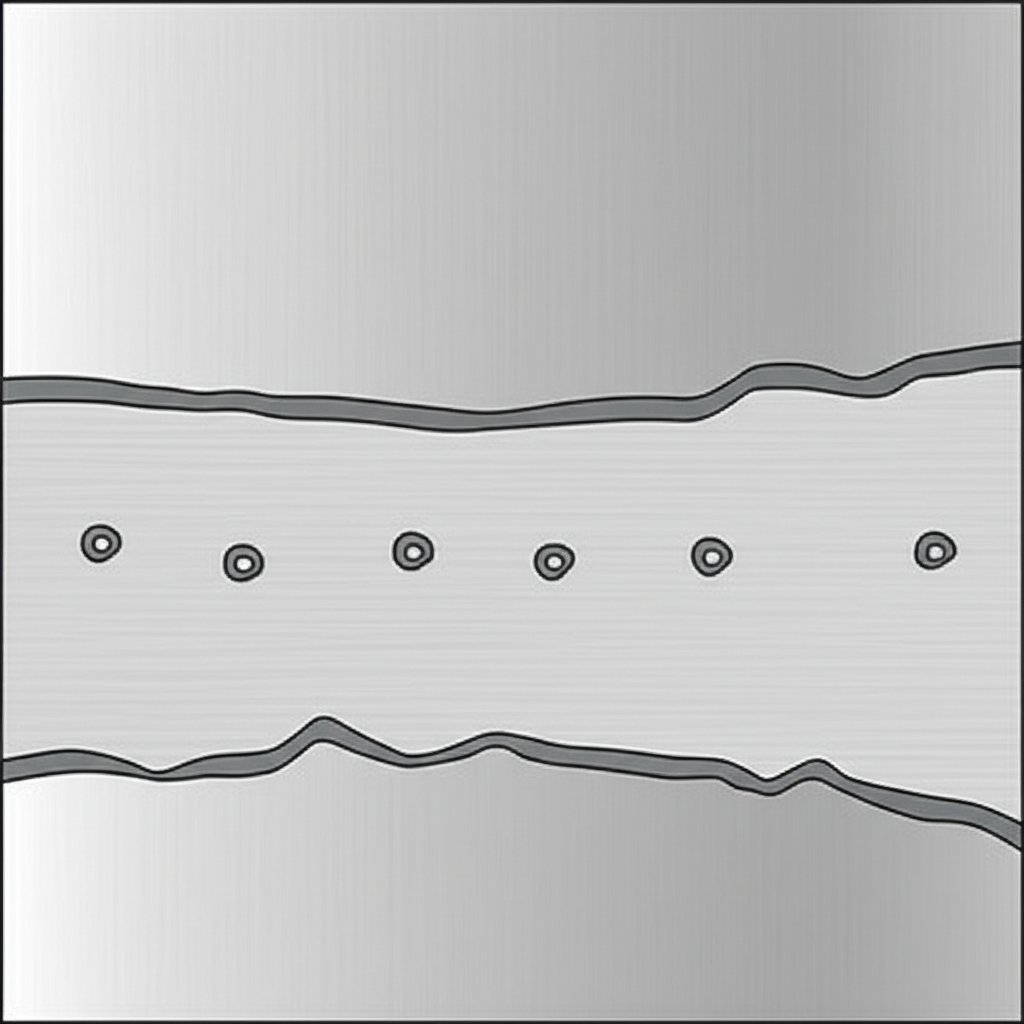

- Tight crevices: Gaps and overlaps trap moisture and contaminants, creating micro-environments where the passive layer fails.

- Contamination from carbon steel: Iron particles from tools or nearby steel can seed rust spots on stainless surfaces.

- Abrasive damage: Scratches or rough handling can strip away the protective film, making the metal vulnerable.

When stainless behaves like ordinary steel

Can stainless steel rust? Yes—if the passive layer is compromised and the environment is aggressive enough. For example, stainless steel rusting is common in areas exposed to road salt, pool chemicals, or trapped water. In these scenarios, the difference between rust vs corrosion becomes important: while corrosion is a broad term for metal deterioration, rust refers specifically to iron oxide. Stainless steel rarely forms deep, flaky rust like mild steel, but it can develop surface stains, pitting, or even localized corrosion if neglected.

So, will stainless steel rust? In most everyday conditions, it stays clean and bright thanks to its self-healing film. But in tough environments—or with poor design and maintenance—it can lose its edge. Understanding what makes stainless steel stainless helps set realistic expectations and guides smarter choices for design, cleaning, and grade selection.

Stainless steel resists rust—yet in salty, oxygen-poor, or dirty conditions, even premium grades can stain or pit if design, finish, and maintenance are overlooked.

Why Stainless Resists And When It Fails

Ever wondered why stainless steel stays shiny in your kitchen but can spot or pit near the ocean? To answer why does stainless steel rust in some places but not others, it helps to break down the science of rust vs corrosion and see how stainless steel’s unique defenses can still be overcome. Let’s make sense of these terms and explore what really happens when stainless steel corrosion shows up.

Corrosion vs rust and what that means for stainless

Sounds complex? Here’s the simple version: corrosion is the gradual destruction of a material (usually metal) by chemical or electrochemical reaction with its environment. Rust, on the other hand, is a specific type of corrosion—one that only happens to iron and steel, forming reddish-brown iron oxides. So, while all rust is corrosion, not all corrosion is rust [AMPP].

Stainless steel stands apart because of its corrosion resistance. What makes stainless steel stainless is the formation of a thin, self-healing chromium oxide film on its surface. This barrier protects the underlying metal from reacting with water and oxygen, preventing both rust and most types of corrosion. But even with this shield, stainless can still suffer localized attack—meaning one spot can corrode or pit while the rest looks perfectly fine.

How chlorides trigger pitting and crevice attack

So, do stainless rust? Not like regular steel, but in the right (or wrong) conditions, trouble can still start. Here’s how it happens:

- Passivation and stainless steel oxidation: Imagine the chromium oxide film as a clear, self-repairing raincoat. As long as oxygen is present, this "coat" heals itself. But if the surface is covered by stagnant water or buried under dirt, oxygen can’t reach it. The result? The protective layer breaks down, and stainless steel oxidation can begin, making the metal more vulnerable.

- Pitting: Picture tiny, needle-sized wormholes forming under salty droplets (think: seawater spray, de-icing salt). Pitting of stainless steel is highly localized—like a pinprick in an otherwise perfect raincoat. These pits can grow, leading to deep damage even when most of the surface looks untouched.

- Crevice corrosion: Trapped moisture in tight spaces—like under gaskets or between overlapping parts—acts like a mini salt battery. These “salt basins” never dry, starving the area of oxygen and letting corrosive ions concentrate. Even if the rest of the metal is pristine, these hidden spots can corrode rapidly.

- Galvanic attack: When stainless fasteners are paired with more reactive metals (like aluminum or carbon steel) and exposed to water, a tiny electrical current can flow. The less noble metal corrodes faster—so if isolation isn’t used, you’ll notice unexpected, localized damage. It’s like a battery forming right at the joint.

Each of these mechanisms can turn a small flaw or design oversight into a significant problem. For example, a single drop of seawater left under a bolt head can trigger pitting, while a rough weld or tight joint can create a crevice that defeats even the best corrosion resistance of stainless steel.

To minimize risk, consider these immediate steps:

- Choose smoother finishes for areas exposed to splashing or salt spray—fewer nooks mean less chance for crevice corrosion or pitting.

- Avoid tight joints or overlaps that trap water and debris.

- Clean away deposits before they become chloride hotspots—especially after storms or heavy use.

Local defects drive local damage in stainless steel: even the best alloy can become corroded metal if design and maintenance are ignored. Prioritize smooth surfaces, smart joints, and regular cleaning for lasting protection.

Understanding these failure points sets the stage for choosing the right stainless grade for your environment—because sometimes, upgrading the alloy or the finish is the best way to stop corrosion before it starts.

Stainless Grades For Real World Environments

Imagine you’re planning a project—maybe a kitchen, an outdoor sculpture, or a marine railing. You know stainless steel is the answer for durability, but which type is right for your environment? Does 304 stainless steel rust, or is 316 always the safer bet? Here’s a clear pathway to help you pick the right grade and avoid surprises down the line.

Choosing 304 versus 316 for your environment

Let’s start with the basics: both 304 and 316 are austenitic steel grades, celebrated for their formability, strength, and stainless steel corrosion resistance. But the difference lies in the details. Grade 304 contains about 18% chromium and 8% nickel, making it an excellent all-purpose choice for most indoor and mild outdoor settings. It’s the most widely used stainless steel worldwide for a reason—affordable, easy to clean, and dependable.

However, if your application faces regular exposure to salt (think coastal areas, de-icing salts, or pool environments), 316 steps up with its added molybdenum. This small change offers a big upgrade in resisting chlorides and acids. It’s why 316 is the go-to for marine hardware, food processing, and chemical washdown areas. So, will 304 stainless steel rust if exposed to salt or standing water? Over time, yes—especially if cleaning is neglected or the finish is rough. Meanwhile, 316 holds up much better in these aggressive conditions, though even it is not invincible if water and chlorides are allowed to linger.

Using PREn and standards to compare corrosion resistance

How do you compare grades when the environment is tough or the risks are high? Enter PREn—the Pitting Resistance Equivalent Number. This value estimates how well a stainless alloy resists pitting from chlorides, using its chromium, molybdenum, and nitrogen content. While PREn isn’t a guarantee, it’s a handy way to rank options within the same stainless family. Higher PREn means better performance in salty or chemical-rich settings. For most projects, you’ll also want to check ASTM or ISO standards to ensure the grade meets your design and fabrication needs.

To make your choice easier, here’s a quick decision matrix. Notice how finish and maintenance matter just as much as the grade itself—especially where crevices or stagnant water could form.

| Environment | 304 | 316 | Duplex |

|---|---|---|---|

| Indoor, dry | Standard finish; periodic cleaning | Usually not required | Over-spec; not needed |

| Inland outdoor | Smooth finish; rinse after winter salts; avoid crevices | Extra margin in polluted/urban zones | Rarely needed |

| Coastal splash / marine | Risk of staining; will 304 stainless steel rust in water? Yes, especially with rough finish | Preferred; mirror or electropolished finish; regular rinsing | For severe or submerged use |

| Chemical washdown | May corrode; frequent inspection | Preferred; hygienic finish; avoid stagnant water | Consider for harsh chemicals |

| Food service | Common; smooth finish; clean regularly | For brine/salt use | Rarely needed |

| High temperature | Check grade for scaling resistance | Better at higher temps | Specialty grades only |

- Design tips: In splash zones or coastal areas, prefer electropolished or mirror finishes. Avoid tight joints and crevices that trap water—these are hotspots for corrosion, even with the best alloys.

- Maintenance: Regular cleaning and rinsing, especially after salt exposure, extends life and keeps surfaces bright.

Still wondering, does stainless steel rust in water? Both 304 and 316 can corrode if water is allowed to stagnate and oxygen can’t reach the surface. Will stainless steel rust in water? The answer depends on grade, finish, and maintenance—but neglect any of these, and even the best alloy can show stains or pits over time.

Finally, always consider availability, fabrication constraints, and compliance with ASTM or ISO standards when selecting your grade. Sometimes, a more corrosion-resistant grade is worth the initial investment for long-term savings and peace of mind.

Design And Installation To Prevent Corrosion

Ever wondered why some outdoor stainless installations shine for decades, while others develop stains or corrosion in just a few seasons? The answer often lies not in the material itself, but in the details of design and installation. Even corrosion resistant steel like stainless needs smart planning to keep its defenses strong—especially in harsh environments where water, salt, and dissimilar metals can create hidden risks.

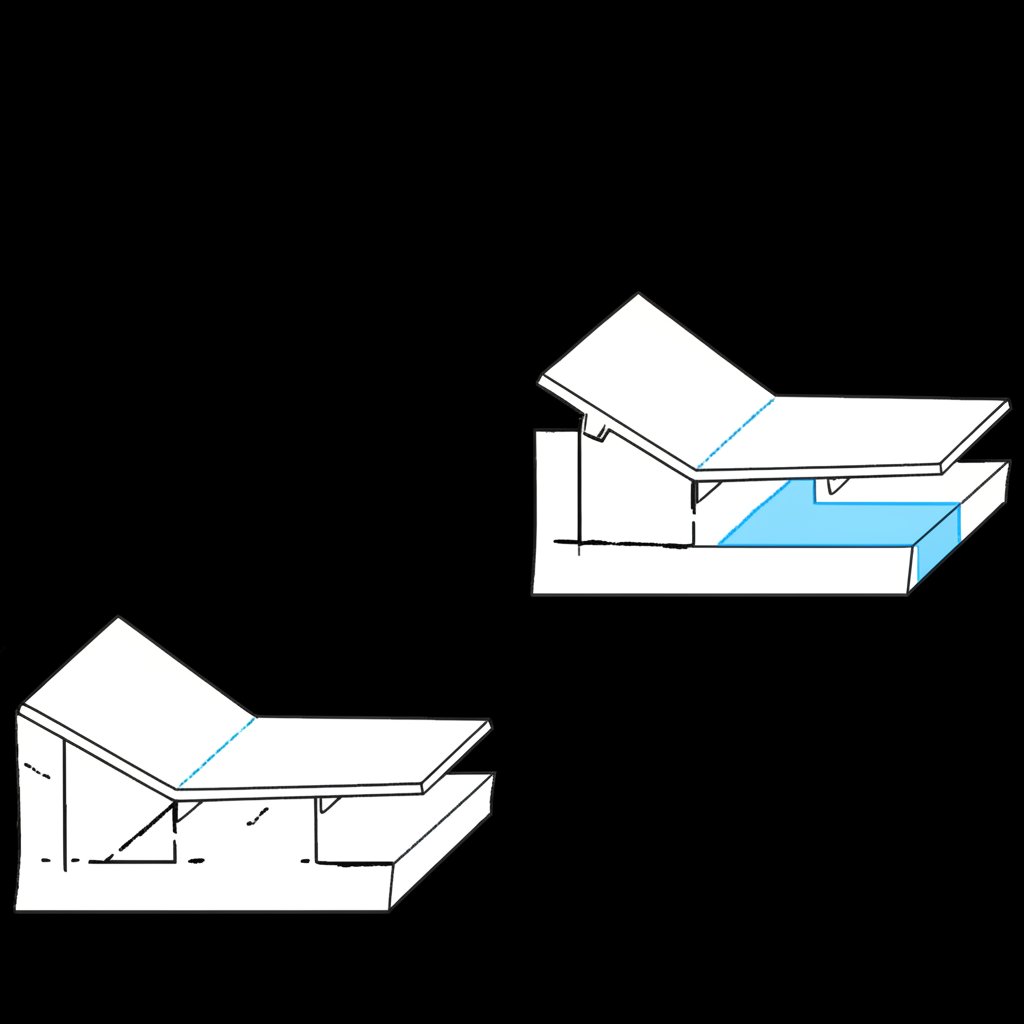

Designing out crevices and water traps

When you’re designing with stainless steel for exterior use, think like water: Where will rain collect? Where might debris or salt-laden runoff get trapped? If you want to prevent issues like stainless steel rusting outside, it’s critical to remove opportunities for moisture to linger and concentrate.

- Drainage and slope: Break up long, flat runs with slope or drip edges so water runs off quickly. Avoid horizontal surfaces where puddles can form.

- Ventilation and access: Allow airflow behind panels and inside enclosures. Make sure joints, seams, and overlaps are accessible for cleaning and inspection.

- Welds and finishes: Use continuous, smooth welds and grind them flush to the parent metal. Avoid undercuts, pinholes, or rough areas—these are prime sites for crevice corrosion. For food or medical use, blend to a hygienic finish.

- Fasteners and isolation: Always match or exceed the corrosion resistance of the fastener to the component. Use nylon or polymer washers to electrically isolate dissimilar metals, and apply sealants to keep out water.

- Avoid cross-contamination: Never use carbon steel tools on stainless. Grinding or brushing with the wrong tool can embed iron particles, seeding rust. Protect surfaces during fabrication and installation.

- Gasket and seal design: Choose non-absorbent, closed-cell gaskets that won’t soak up and hold chlorides. Avoid materials that trap moisture against the metal.

Imagine a railing with flat horizontal bars: rainwater pools, dirt builds up, and soon you see brown stains or pits. Now picture the same railing with sloped tops and open joints—rain washes it clean, and maintenance is a breeze. Simple choices like these can make all the difference in whether stainless steel rusts outside or stays pristine for years [Nickel Institute].

Pairing stainless with other metals the smart way

Mixing metals in a project? Stainless steel aluminum corrosion is a classic pitfall. When stainless and aluminum (or zinc-coated steel) are joined and exposed to water—especially in marine or coastal environments—a galvanic cell can form. This means the less noble metal (aluminum or zinc) will corrode preferentially, often rapidly, while the stainless remains protected. The result: ugly corrosion, loose fasteners, or even structural failure.

- Insulate dissimilar metals: Always use non-conductive barriers—nylon, rubber, or plastic washers and gaskets—between stainless and aluminum. Specialized coatings or paints can also help isolate the metals.

- Surface area matters: If you must use stainless fasteners with aluminum, make sure the aluminum area is much larger than the stainless. The reverse (small aluminum fasteners in large stainless panels) greatly increases the risk of corrosion aluminum stainless steel problems.

- Regular inspection: In harsh environments, check joints for signs of staining or pitting. Replace gaskets or coatings if they degrade over time.

For example, using stainless bolts to secure large aluminum panels is often safe with proper isolation. But joining small aluminum screws to a big stainless frame? That’s asking for trouble, especially outdoors or near salt water.

If water can sit, salts will concentrate—and concentrated salts defeat stainless.

By addressing these design and installation details up front, you’ll dramatically reduce the risk of stainless steel and aluminum corrosion, and ensure your project stands the test of time. Next, we’ll look at coatings and treatments that can add another layer of protection—especially when upgrading the alloy isn’t practical.

Coatings And Treatments That Actually Help

When you’re weighing the options between a better alloy or adding a stainless steel coating, it’s not always a simple call. Is stainless steel rust proof by itself, or do you need extra protection? Let’s break down the real-world choices for boosting corrosion resistance—especially in tough environments where water, salts, or abrasion are a concern.

When a Higher Grade Beats a Thicker Coating

Imagine you’re facing a harsh marine environment, or your equipment needs to withstand aggressive cleaning chemicals. In these cases, simply adding a thicker coating may not be enough. Sometimes, upgrading to a more corrosion-resistant grade is the best long-term investment. Why? Because coatings—no matter how advanced—can wear, chip, or get breached at edges, fasteners, or joints. Once water gets underneath, corrosion proof steel becomes a myth: hidden crevices trap moisture and defeat even the best barrier.

-

Upgrade the alloy when:

- Exposure to chlorides, acids, or high humidity is constant.

- Maintenance access is limited, making re-coating impractical.

- Precision parts require dimensional stability and minimal buildup.

- Cleanability and hygiene are top priorities (think food, pharma, or medical settings).

-

Consider coatings when:

- Components face mechanical abrasion, impact, or chemical attack incompatible with available alloys.

- Retrofit or repair is needed on existing installations.

- Visual customization or color-coding is required.

Remember, corrosion resistant metals like stainless steel owe their performance to a self-healing oxide layer. If this layer is damaged and not allowed to recover, even rust resistant steel can show signs of attack—especially in crevices or under failed coatings.

Passivation, Electropolish, and Protective Clear Coats

Let’s compare the most common treatments and coatings for stainless steel, so you can match the solution to your needs:

-

Passivation

Pros

- Removes free iron, boosting the natural passive film.

- Minimal change to appearance or dimensions.

- Enhances corrosion resistance, especially after fabrication or machining.

- Low maintenance—just periodic cleaning.

Cons

- Not permanent; may require re-passivation over time.

- Does not provide a physical barrier against abrasion or chemicals.

-

Electropolishing

Pros

- Smooths out micro-peaks and removes embedded contaminants.

- Improves cleanability and reduces sites for corrosion initiation.

- Ideal for high-purity, food, or medical applications.

Cons

- Requires specialized equipment and post-treatment passivation for best results.

- Does not add a thick physical barrier.

-

Clear Polymer Sealers

Pros

- Add hydrophobicity—great for splash zones or outdoor fixtures.

- Easy to apply and often transparent.

Cons

- Require periodic reapplication, especially in high-wear areas.

- May not withstand aggressive chemicals or UV long-term.

-

Epoxy/Polyurethane Paint Systems

Pros

- Provide a thick, durable barrier for industrial or buried service.

- Wide range of colors and finishes available.

Cons

- Repairs can be tricky; edges and joints are vulnerable to underfilm corrosion.

- Surface preparation and application quality are critical for success.

-

Anodized Coatings

Note

- Primarily used for aluminium, stainless steel can also be anodised to change its surface properties through specific processes such as using a strong alkaline electrolyte, but this is not a mainstream application.

-

Black Chromate

Note

- It is primarily used as a post-treatment for zinc plating. Although it is possible to achieve a similar appearance by applying a black oxide treatment directly to stainless steel, this is different from the mechanism by which a black chromate film is formed on zinc.

For a detailed look at passivation versus coating, Stanford Advanced Materials offers a clear summary: passivation enhances the metal’s own oxide film, while coatings create a physical barrier. The best choice depends on your environment, maintenance plans, and required durability.

One crucial point: coatings cannot stop crevice attack if moisture or salts are trapped underneath. No matter how corrosion-resistant or rust resistant steel claims to be, trapped water will eventually defeat any surface barrier. That’s why design and maintenance—like keeping joints clean and surfaces dry—are as important as the coating itself.

Protecting edges, fasteners, and joints often matters more than flat surfaces. Focus your efforts where water or debris can hide, and you’ll extend the life of even the best corrosion resistant metals.

Next up: let’s dive into cleaning and maintenance strategies to keep your stainless finish looking and performing its best, no matter what the environment throws at it.

How to Get Rust Off Stainless Steel Sink and Surfaces

Notice orange stains on your stainless sink or appliances and wonder, “Why is there rust on stainless steel?” You’re not alone. Even though stainless is engineered for corrosion resistance, small missteps in cleaning or exposure to water and contaminants can lead to unsightly stains or even damage. The good news? With the right approach, you can remove rust from stainless steel and stop stainless steel rusting before it spreads. Let’s break down safe, effective routines and troubleshooting tips that work for homes, food service, and facility teams alike.

Remove Orange Stains and Tea Staining Without Damage

When you see rust from stainless steel—whether it’s faint tea staining or more stubborn spots—start with gentle cleaning methods. Here’s how to get rust off stainless steel sink surfaces and restore their shine:

-

Routine Clean

- Rinse the surface with warm water to remove loose debris.

- Apply a mild detergent (like dish soap) using a microfiber cloth.

- Wipe along the grain of the steel—this helps avoid micro-scratches.

- Rinse thoroughly and dry with a clean towel to prevent water spots.

-

Surface Stain Removal

- For light rust or tea stains, use a non-chloride stainless cleaner or make a paste of baking soda and water.

- Apply the paste with a soft nylon pad (never steel wool, which can worsen rust).

- Scrub gently with the grain until the stain lifts.

- Rinse thoroughly and dry.

- For persistent spots, use a stainless passivation gel as directed by the manufacturer. This helps restore the protective chromium oxide layer.

Safety First: Always wear gloves and eye protection, and ensure good ventilation when using commercial cleaners or gels. Avoid chlorine bleach and steel wool—they can damage the surface and accelerate rusting.

Stop Future Staining With Simple Habits

Once you’ve cleaned away the rust on stainless steel, a few routine habits will help you learn how to stop stainless steel from rusting and keep that finish bright for years:

- After exposure to water—especially in coastal or food service settings—rinse and dry surfaces promptly. Does stainless steel rust with water? Only if it sits and blocks oxygen from reaching the protective layer.

- Don’t let metal utensils, cast iron pans, or wet sponges sit on stainless surfaces for long periods.

- Wipe up spills and clean away salt, food residue, or cleaning chemicals quickly.

- Inspect regularly for signs of staining, especially around joints, fasteners, and seams.

Want to know how to prevent stainless steel from rusting? It’s all about keeping the surface clean, dry, and free from contaminants. Even high-grade stainless can develop rust from stainless steel if exposed to stagnant water or aggressive cleaning agents.

Troubleshooting Common Stains and Rust Patterns

- Orange smears that wipe off easily: Usually mean contamination from nearby carbon steel (like tools or wire racks). Clean thoroughly and monitor for recurrence.

- Tiny pinpoints or brown halos: Suggest chloride pitting—common in salty or humid environments. Clean, rinse, and inspect regularly to stop stainless steel rusting from spreading.

- Rainbow discoloration: Often a result of heat tint or residue from cleaning agents. Buff gently and clean before deposits build up.

If you’re wondering how do you get rust off of stainless steel in a kitchen or industrial setting, remember: start with the mildest method and only move to stronger cleaners if stains persist. Overly harsh abrasives or chemicals can do more harm than good.

Key Habits for Long-Term Protection

- Rinse after salt or chemical exposure.

- Keep surfaces dry whenever possible.

- Schedule periodic inspections to catch early signs of rust or staining.

With these simple routines, you’ll know exactly how to get rust off stainless steel sink surfaces and how to prevent stainless steel from rusting, whether you’re caring for a home kitchen or a busy facility. Up next, we’ll explore inspection templates that help you track and maintain stainless performance for the long haul.

Inspection Templates For Lasting Performance

Ever wondered if a little stain on your stainless steel is just cosmetic—or the start of a bigger problem? Catching issues early is the key to keeping your investment looking and performing its best. Let’s break down how to make inspection a routine, not a reaction, so you can stop rusting stainless steel before it spreads and turns into costly repairs.

Inspection Checklist for Indoor, Outdoor, and Coastal Environments

Not all environments challenge stainless steel the same way. The risk of rusty stainless steel increases with exposure to moisture, salt, and pollutants. That’s why your inspection routine should match the setting. Use this checklist to guide your walk-throughs and maintenance sessions:

| Area | What to Check | Frequency (by Exposure) |

|---|---|---|

| Surfaces | Look for water traps, tea staining, biofilm, or discoloration. Is there evidence of rusting stainless steel or surface roughness? | Low: Occasionally Moderate: Regularly High: Frequently, plus after salt events |

| Joints & Edges | Check under gaskets, overlaps, and seams for residue or trapped moisture. Does rust spread from these points? | Low: Occasionally Moderate: Regularly High: Frequently |

| Fasteners | Confirm correct grade match and that isolation washers or coatings are intact. Look for early signs of corrode and rust. | Low: Occasionally Moderate: Regularly High: Frequently |

| Finish | Feel for roughness or buildup. Re-finish or clean as needed to maintain passivation. | All: As needed, but more often in harsh zones |

| Environment | Note any new sources of chlorides (landscaping salts, de-icing agents) or increased pollution. Document changes. | All: Each inspection |

Tip: For high-exposure settings (coastal, splash zones), pair inspections with rinse routines after heavy salt exposure. For low-risk, indoor dry environments, focus on periodic visual checks and keep a log of any changes you notice.

What to Look for Before Staining Becomes Corrosion

Imagine you spot a faint orange streak or a rough patch on a handrail—should you worry? Here’s how to tell if it’s time for action, and what causes corrosion to take hold:

- Tea staining or light discoloration: Usually cosmetic, but a signal that moisture or salts are lingering. Rinse and dry, then monitor for changes.

- Pinpoint rust or pitting: Indicates chloride attack or oxygen deprivation. Clean and re-passivate the area; if pits deepen, consult a specialist.

- Residue under gaskets or overlaps: Trapped water can corrode and rust underlying metal. Disassemble, clean, and replace seals if needed.

- Loose or mismatched fasteners: Accelerate rusting stainless steel, especially if isolation is lost. Replace with proper grade and re-inspect regularly.

- Surface roughness or buildup: Holds contaminants, making it easier for rust to start and does rust spread if left unchecked. Polish or clean to restore smoothness.

Document your findings with photos and notes. Tracking changes over time helps separate harmless stains from early warning signs of deeper issues. If you’re unsure how long does it take steel to rust in your setting, remember that localized corrosion can progress quickly—especially in salty or humid environments. Early intervention is always easier than a full restoration.

Routine Tiers: Match Inspection to Exposure

- Low Exposure (Indoor, Dry): Occasional checks—look for dust, spills, or accidental contamination.

- Moderate Exposure (Inland Outdoor): Regular checks—focus on rain, pollution, and seasonal salt use.

- High Exposure (Coastal, Splash Zones): Frequent checks—after storms, salt spray, or cleaning events. Rinse and dry surfaces as part of your routine.

And if you notice pitting, deep discoloration, or structural concerns, don’t wait: consult a corrosion specialist. Early, minor cleaning and re-passivation can halt most issues, but advanced damage to load-bearing parts requires expert assessment and repair.

Catch the first specks—early action saves far more effort than restoring rusty stainless steel later.

By making inspections a habit, you’ll not only answer the question “stainless steel does it rust?” with confidence, but also extend the life and beauty of your investment. Next, we’ll connect these inspection strategies to fabrication best practices—so your corrosion resistance starts from day one.

From Design To CNC Parts Without Corrosion Surprises

Ever wondered why some stainless steel parts last decades, while others show early signs of corrosion—even when made from the same grade? The answer often lies in what happens between design and delivery. Let’s explore how smart fabrication and precision machining can preserve stainless steel’s corrosion resistance, and what you should specify to avoid surprises down the line.

Fabrication Practices That Preserve the Passive Layer

Stainless steel’s corrosion resistance depends on its thin, self-healing chromium oxide layer. But fabrication missteps—like rough machining, iron contamination, or improper finishing—can damage this layer and trigger premature corrosion. So, can you use metal on stainless steel tools or mix metals in fabrication? Only if you’re careful: cross-contamination from carbon steel or aluminum can seed rust spots and accelerate stainless steel to aluminum corrosion, especially in moist or salt-laden environments.

Here’s how to keep your stainless parts at their best:

- Specify tight tolerances: Precision machining reduces crevices and gaps where water or debris can collect and oxidize stainless steel. Fewer crevices mean fewer corrosion risks.

- Use dedicated stainless tooling: Tools previously used on carbon steel can transfer iron particles, undermining corrosion resistance. Always use separate, clean tools for stainless work.

- Request proper finishes: Directional, polished, or electropolished finishes reduce surface roughness, making it harder for contaminants to stick and easier to clean. Smooth finishes also help the passive layer form evenly.

- Insist on post-machining cleaning and passivation: After cutting or welding, thorough cleaning removes embedded particles. Chemical passivation treatments restore the protective oxide film, ensuring long life—even in tough environments.

When to Lean on Precision CNC for Clean, Corrosion-Smart Parts

If you need stainless parts that look great and last, choosing the right manufacturing partner is critical. For example, XTJ CNC Machining Services specializes in high-precision, corrosion-aware production. Their advanced 4 and 5-axis machining centers deliver ultra-tight tolerances down to +/- 0.005mm, which is key for minimizing crevices where corrosion could start. With a broad material selection—including stainless, aluminum, and copper—and ISO 9001:2015 and IATF16949 certifications, they support projects where longevity and quality matter most.

- Ultra-tight tolerances help eliminate water traps and rough joints.

- Dedicated stainless handling avoids iron contamination.

- Multiple finishing options—directional grain, polished, electropolished—enhance cleanability and corrosion resistance.

- Fast lead times (as quick as 3 days) support urgent or iterative projects.

- ISO-certified quality and engineering support for peace of mind.

| Provider | Material Handling | Finish Quality | Tolerances | Lead Time | Certifications |

|---|---|---|---|---|---|

| XTJ CNC | Dedicated stainless tools, no cross-contamination | Polished, electropolished, or custom finish | +/- 0.005mm | As fast as 3 days | ISO 9001:2015, IATF16949 |

| In-house job shop | Mixed-use tools may risk contamination | Standard or rougher finish, limited options | Typically +/- 0.05mm or looser | 1-3 weeks or more | Varies; not always certified |

Whether you’re designing for marine, medical, or architectural use, aligning your grade choice, design details, and machining quality is the best way to ensure your stainless steel parts resist corrosion and deliver a long, reliable service life. Want to know how long does stainless steel last? With proper fabrication and maintenance, decades are achievable—even in challenging environments.

Frequently Asked Questions About Stainless Steel Rust

1. Will stainless steel rust if I shower with it?

Stainless steel is highly resistant to rust and safe for use in wet environments like showers. However, prolonged exposure to water, especially if combined with soap residue or body oils, can lead to surface staining over time. Rinsing and drying stainless steel jewelry or fixtures after showering helps preserve their shine and prevents any potential discoloration.

2. How fast does stainless steel rust?

The speed at which stainless steel rusts depends on environmental factors such as exposure to salt, moisture, and contaminants. In most indoor or mild outdoor settings, stainless steel can remain rust-free for decades. However, in harsh environments like coastal areas or locations with de-icing salts, surface staining or pitting can appear within months if not properly maintained and cleaned.

3. Does stainless steel rust with water?

Stainless steel can resist rust even when exposed to water, thanks to its self-healing chromium oxide film. However, if water is stagnant or contains chlorides (like salt), the protective film may break down, increasing the risk of rust or staining. Regular rinsing and drying are key to preventing rust when stainless steel is frequently exposed to water.

4. What causes stainless steel to corrode or rust?

Stainless steel can corrode or rust when its protective chromium oxide layer is damaged or overwhelmed. Common causes include exposure to chlorides (salt), trapped moisture in crevices, contamination from carbon steel tools, abrasive damage, and lack of oxygen. Proper design, maintenance, and grade selection are essential to minimize these risks.

5. How can I stop stainless steel from rusting?

To prevent stainless steel from rusting, keep surfaces clean and dry, rinse after exposure to salt or chemicals, and avoid using carbon steel tools on stainless. Regular inspection, prompt removal of stains, and choosing the right alloy for your environment also help maintain corrosion resistance and extend the lifespan of your stainless steel items.

-

Posted in

corrosion resistance, metal fabrication, rust prevention, stainless steel maintenance, stainless steel rust