Is Stainless Steel Magnetic? A Quick Reference By Common Grades

Magnetism in Stainless Steel Made Simple

Ever wondered why sometimes a magnet sticks to your stainless steel fridge, but other times it just slides right off? The answer to "is stainless steel magnetic" isn’t as black and white as you might think. In fact, whether or not stainless steel is magnetic depends on its specific grade and how it’s been processed. Here’s what you need to know before you reach for a magnet to test that kitchen appliance, fastener, or cookware.

Quick Answer to Is Stainless Steel Magnetic

Most austenitic stainless steels—like the well-known 304 and 316 grades—are typically non-magnetic in their original, annealed state. However, ferritic and martensitic stainless steels (think 400-series, such as 410 or 430) are generally magnetic. But there’s a twist: even non-magnetic grades can become slightly magnetic after processes like cold working or welding. So, the classic “magnet test” is helpful but not foolproof for identifying stainless steel types or quality. The real answer to “is stainless steel magnetic” depends on both the alloy’s family and its processing history.

Why Magnets Sometimes Stick and Sometimes Don’t

Imagine you’re testing different stainless steel items. Sometimes, magnets stick firmly; other times, there’s no pull at all. This variation is normal and comes down to the internal structure of the steel and how it was made. For example, a 304 stainless steel sink may feel non-magnetic in flat areas but show a weak pull near bends or welds. That’s because mechanical work can change the crystal structure, making even austenitic stainless steels slightly magnetic after forming or machining.

-

Myth: All stainless is non-magnetic.

Fact: Only some types—mainly austenitic—are non-magnetic, and even these can become weakly magnetic after processing. -

Myth: Stainless steel that attracts a magnet is low quality.

Fact: Magnetism is not an indicator of corrosion resistance or quality. -

Myth: The magnet test can always identify stainless steel.

Fact: The magnet test is a clue, not a guarantee; composition and processing matter most.

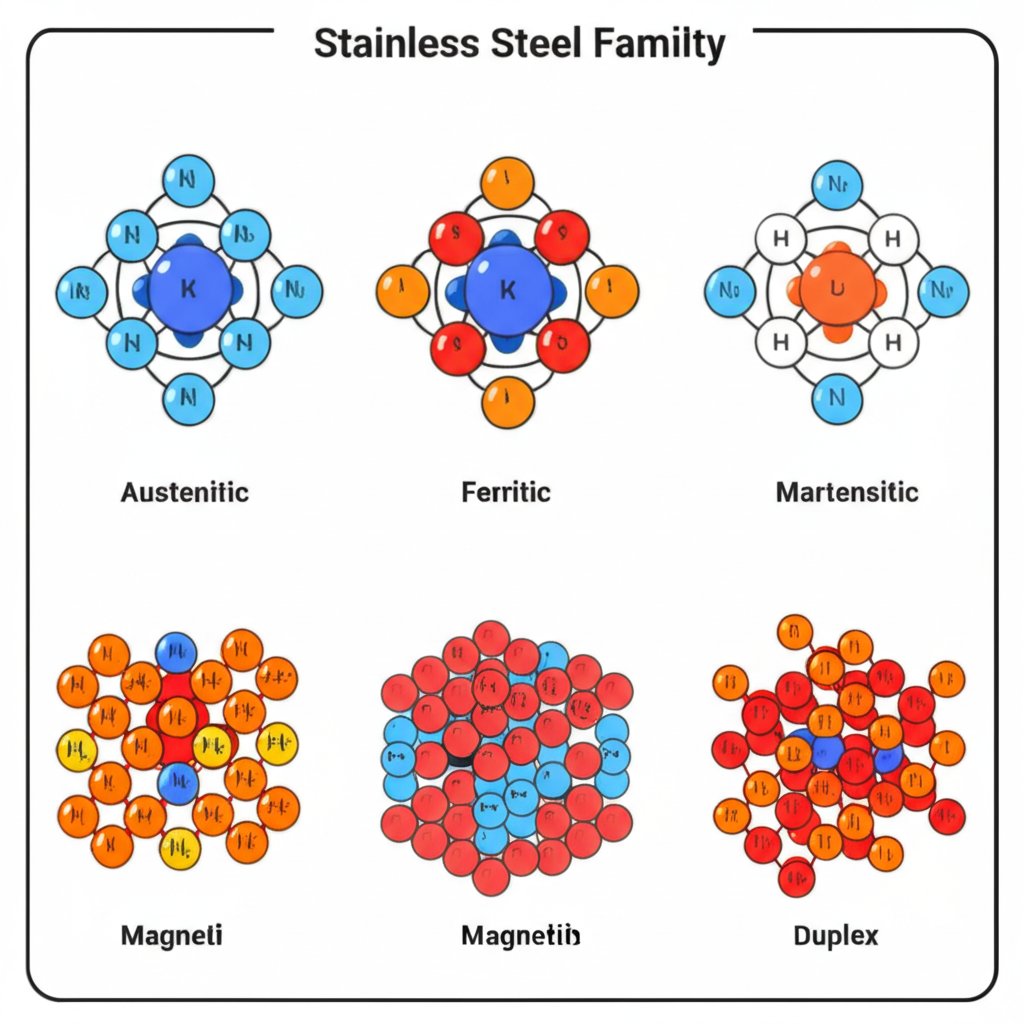

Stainless Families at a Glance

| Stainless Family | Typical Magnetic Response | Common Grades |

|---|---|---|

| Austenitic (300-series) | No (can be weak after cold work) | 304, 316 |

| Ferritic (400-series) | Yes | 430 |

| Martensitic (400-series) | Yes | 410, 420 |

| Duplex | Moderate/Yes | 2205 |

Copy-paste takeaway: "Stainless steel magnetic response depends on grade and processing—most 300-series are non-magnetic, 400-series are magnetic, and cold work can induce weak magnetism in non-magnetic grades."

So, next time you ask, "is stainless steel magnetic," remember: the answer changes with the family and how the steel was handled. The magnet test is a helpful first check, but understanding the grade and its processing is key to making the right call. This quick overview sets the stage for a deeper dive into what makes each stainless steel family unique—and why your own experience with magnets and stainless steel might be different from your neighbor’s.

How Stainless Families Drive Magnetic Behavior

What Stainless Steel Is Made Of

When you hear "stainless steel," think of an iron-based metal mixed with enough chromium—usually at least 10.5%—to resist rust and staining. But that’s just the start. Stainless steel often includes other elements like nickel and molybdenum, which tweak its structure and performance. These small changes in recipe are what make stainless steel is magnetic or not, and why it’s used in everything from kitchen sinks to medical devices.

Ferrous vs Non Ferrous Explained

Let’s break it down: ferrous metals contain iron, while non ferrous metals do not. Stainless steel is a classic example of a ferrous metal, since iron is its main ingredient. Most ferrous metals—including many stainless steels—are magnetic, but there are exceptions. Non ferrous metals like aluminum or copper are not magnetic and are often chosen where weight or electrical conductivity matters more than strength. Understanding the difference between ferrous and non ferrous metals helps you predict which materials will respond to a magnet.

Austenitic, Ferritic, Martensitic in Plain English

Here’s where it gets interesting. Stainless steels fall into families based on their atomic structure, which is shaped by those added elements:

- Austenitic Stainless: These are the 300-series grades (like 304 and 316). Their structure is called "face-centered cubic" (FCC), which makes them tough and usually non-magnetic in the annealed state. But if you bend or cold-work them, a small amount of martensite can form, making even austenitic stainless steel magnetic—just a little. That’s why your magnet might weakly stick to a well-used kitchen sink.

- Ferritic Stainless: These 400-series grades have a "body-centered cubic" (BCC) structure and are magnetic by nature. They’re often used in appliances and automotive trim where magnetic properties are needed.

- Martensitic Stainless: Also part of the 400-series, these steels are magnetic and can be heat treated for extra hardness. Think of them in cutlery and some medical tools.

- Duplex Stainless: These are a mix of austenitic and ferritic structures, offering moderate magnetism and high strength.

| Family | Typical Magnetic Response | Corrosion Resistance | Common Uses |

|---|---|---|---|

| Austenitic | Non-magnetic (can be weakly magnetic after cold work) | High | Food processing, medical equipment, piping |

| Ferritic | Magnetic | Moderate | Automotive trim, appliances, industrial parts |

| Martensitic | Magnetic | Lower than austenitic/ferritic | Cutlery, surgical instruments, valves |

| Duplex | Moderately magnetic | Very high | Marine, chemical processing, pressure vessels |

Why Structure Matters: A Quick Visual

Imagine the atoms in steel as a grid. In austenitic stainless (FCC), atoms are packed in a way that resists magnetism. In ferritic and martensitic (BCC), the arrangement allows magnetic fields to flow more easily, making these stainless steel ferrous metals magnetic by default. So, when someone asks, "is stainless steel is magnetic?"—the answer is all about the structure.

Copy-paste takeaway: "Austenitic stainless steel magnetic response is usually weak or absent, while ferritic and martensitic types are strongly magnetic—structure and composition are key."

Understanding these families and their stainless steel magnetic properties lets you predict whether a magnet will stick—and helps you choose the right grade for your job. Next, let’s look at which specific grades are most likely to be magnetic, and how processing can change what you feel in the field.

Grade by Grade Magnetic Quick Reference

Ever grabbed a magnet to check if a fastener or appliance is really stainless steel, only to get mixed results? The answer depends on the specific grade—and how it’s been processed. Here’s your practical, grade-by-grade guide to stainless steel magnetic behavior, so you know what to expect before you buy, specify, or test.

What to Expect from Popular Grades

| Grade | Family | Typical Magnetic Response | Notes on Processing Effects |

|---|---|---|---|

| 304 | Austenitic (300-series) | Non-magnetic in annealed state; can become weakly magnetic after cold work | Cold working (bending, forming, machining) or welding can induce slight magnetism, especially at edges or welds. "304 stainless steel magnetic" only after significant deformation. |

| 316 | Austenitic (300-series) | Non-magnetic in annealed state; may show weak magnetism after heavy cold work | Similar to 304, but even less prone to magnetism. "316 stainless steel magnetic" response is rare, but possible with severe mechanical work. |

| 303 | Austenitic (300-series, high sulfur) | Generally non-magnetic; may show variable weak magnetism after machining | Machining and cold work can induce localized magnetism. Sulfur content may cause more variability. |

| 430 | Ferritic (400-series) | Magnetic | Remains magnetic regardless of processing. Used where magnetic properties are needed (e.g., appliance panels). |

| 410 | Martensitic (400-series) | Magnetic | Magnetic in both annealed and hardened states. Used in cutlery, fasteners, and tools. |

| 17-4 | Precipitation-Hardened Martensitic | Magnetic | "17-4 stainless steel magnetic" in all conditions; strength and magnetism increase after heat treatment. |

When Austenitic Becomes Slightly Magnetic

If you’re wondering, “is 304 stainless steel magnetic?” or “is 316 stainless steel magnetic?”—the answer is usually no for new, annealed material. But after bending, welding, or machining, you might notice a weak magnetic pull, especially near worked edges. This is due to small amounts of martensite forming from mechanical stress. The effect is more pronounced in 304 than 316, and is almost always weak compared to ferritic or martensitic grades (source).

Ferritic and Martensitic Quick Cues

For grades like 430, 410, and 17-4, the story is simple: they’re magnetic, regardless of processing. If you need a stainless steel that will reliably attract a magnet—say, for magnetic separation or clamping—these are your go-to choices. In particular, “is 430 stainless steel magnetic?” and “is 410 stainless steel magnetic?” Both are a definite yes.

- If you’re unsure about a part’s grade, try these tips:

- Check for grade markings or mill certificates on packaging or the part itself.

- Use a magnet to test several areas—edges, welds, and flat surfaces may respond differently.

- Contact your supplier for documentation if the magnetic response doesn’t match your expectations.

- Remember: surface finish, thickness, and cold work can all influence what you feel with a magnet.

Key takeaway: “304 stainless steel magnetic” and “316 stainless steel magnetic” responses are weak and only show up after significant deformation. Ferritic and martensitic grades (like 430, 410, and 17-4) are reliably magnetic—making them easy to identify with a magnet.

Understanding these quick cues will help you match your expectations to real-world testing. Up next, we’ll explore how processing steps—like cold work and welding—can change magnetism and what you can do to control it in your specifications.

How Processing Changes Stainless Magnetism

Cold Work and Induced Magnetism in 304

Ever wondered why a magnet might weakly stick to a bent stainless steel bracket, even though you know austenitic stainless is supposed to be non-magnetic? The answer lies in what happens during manufacturing. When austenitic stainless steels like 304 are bent, rolled, formed, or even machined, their internal structure can partially transform from austenite to martensite—a phase that is stainless steel ferromagnetic. This process, known as martensitic stress-induced transformation (MSIT), means that even grades labeled as non-magnetic can show a noticeable pull after cold work.

For example, 304 stainless steel in its original, annealed state is nearly non-magnetic. But after thread rolling, wire drawing, or forming, you’ll notice that a household magnet may stick weakly—especially at edges, threads, or bends. The more intense the cold working, the more martensite forms, and the stronger the magnetic response. This is why is 304 stainless magnetic is sometimes answered with, “It depends on how it was made.”

Annealing and Solution Treatment Effects

If you need to reduce or eliminate unwanted magnetism, solution annealing is your best tool. This heat treatment restores the austenitic structure by dissolving the martensite and relieving stresses, returning the steel to its non-magnetic state. However, there’s a trade-off: annealing can also reduce tensile strength and may cause distortion, especially in thin or complex parts. For applications where cosmetic appearance or strict non-magnetic properties are critical, specifying a final solution-annealed condition is essential. Remember, without this treatment, does stainless steel magnetize after cold work? Yes—sometimes enough to pick up a paperclip or small screw.

Welding Heat Zones and Partial Magnetism

Welding introduces high localized heat, which can also alter the magnetic behavior of stainless steel. In austenitic grades, heat-affected zones (HAZ) near welds may experience microstructural changes—sometimes forming small amounts of martensite or even magnetic ferrite, especially if the weld is poorly controlled or the alloy is high in carbon. This can lead to weak magnetism along weld seams, even if the rest of the part remains non-magnetic. If you’re specifying parts where magnetism must be minimized, it’s wise to call out inspection of weld areas separately.

Temperature Exposure During Processing and Service

While most changes in stainless steel magnetism happen during manufacturing, prolonged exposure to high temperatures during service can also subtly shift behavior. Severe heating and cooling cycles may promote phase changes that either increase or decrease magnetism, depending on the alloy and environment. However, under typical service conditions, these effects are minor compared to cold work or welding.

- Spec Clause Example: Final condition: solution-annealed austenitic stainless; limit magnet attraction to weak/negligible in non-formed areas. Verify per Test Protocol A.

- Spec Clause Example: Process control: minimize cold work in cosmetic surfaces where weak magnetism is unacceptable.

- Inspection Note: Inspect weld zones for localized magnetism; document any areas where magnets attract with more than weak force.

- Design Reminder: If some magnetism is acceptable, clarify acceptable locations and levels in your drawings or purchase orders.

Key trade-off: Taming magnetism through annealing or minimal cold work may reduce strength or increase cost—balancing magnetism, strength, and corrosion resistance is part of every good stainless steel specification.

So, can stainless steel be magnetised? Absolutely—especially if it’s austenitic stainless that’s been cold worked or welded. Does stainless steel magnetize permanently? Unless you re-anneal, those changes can last for the life of the part. Understanding these effects helps you write better specs and get the right performance from your stainless steel, every time. In the next section, we’ll see how temperature and environment in real-world use can further influence magnetic response.

How Service Conditions Impact Stainless Steel Magnetism

Service Temperature and Magnetic Response

Ever noticed a magnet sticks firmly to a stainless panel in your workshop, but seems weaker or not at all on the same part after it’s been in service near heat? That’s no accident. The magnetic properties of stainless steel—especially for ferritic and martensitic grades—can change with temperature. When stainless steel is heated toward its critical “Curie temperature,” it loses its ability to attract a magnet. Once the steel cools back down, the magnetism typically returns. This is why you might find that magnetic stainless steel cookware works perfectly on an induction stove at room temperature, but its magnetic pull can fade when the pan gets very hot. For most household and industrial uses, though, these effects are temporary and reversible.

Curie Concepts in Practical Terms

The “Curie point” is the temperature where a magnetic material loses its magnetism entirely. For stainless steels, this varies by grade and structure. Ferritic and martensitic types have Curie points well above typical service temperatures, but in high-heat environments—like ovens, kilns, or process lines—magnetism can noticeably decrease. Austenitic stainless steels, already weakly magnetic or non-magnetic, show little change since their magnetic permeability of stainless steel is low to begin with. If you need precise numbers for your application, check the alloy datasheet or material standards for that grade.

Gaps, Coatings, and Surface Condition

It’s not just heat that changes what you feel with a magnet. The presence of any gap—like a layer of paint, oxide, or even a thin sheet of paper—can significantly reduce the apparent magnetic pull. This is why is sheet metal magnetic sometimes gets a “sort of” answer: the steel itself may be magnetic, but coatings or non-metallic layers weaken the effect. Even a thin oxide layer or a fingerprint can make a strong magnet seem weak. The same goes for thickness—the thinner the metal, the less magnetic force it can transmit. And don’t forget prior cold work: a spot that’s been bent or hammered may show a different response than a flat, untouched area.

- Temperature: High heat can reduce or temporarily remove magnetism, especially near or above the Curie point.

- Gap/Coating: Paint, oxides, or non-metallic layers weaken the pull between magnet and steel.

- Magnet Strength: Stronger magnets reveal weak magnetism better than small fridge magnets.

- Thickness: Thicker steel transmits magnetic force more effectively.

- Prior Cold Work: Areas that have been bent, formed, or welded may have altered magnetism compared to untouched regions.

| Variable | Effect on Magnetic Response |

|---|---|

| High Temperature (near Curie point) | Reduces or eliminates magnetic attraction; returns on cooling |

| Coating/Gap | Weakens perceived magnetism, even if steel is magnetic |

| Steel Thickness | Thicker = stronger magnetic pull; thin sheet may feel weak |

| Prior Cold Work | May increase local magnetism in austenitic grades |

Always test stainless steel magnetism in the condition and environment where it will actually be used—shop results and field results can be very different.

Understanding these environmental and physical variables helps explain why stainless steel permeability and steel magnetic permeability can seem inconsistent. The next time you’re evaluating a material for an application—whether it’s a kitchen, a plant, or a lab—remember to consider temperature, coatings, and real-world conditions, not just the grade. Up next: how to test and document magnetic response so your results are reliable and repeatable.

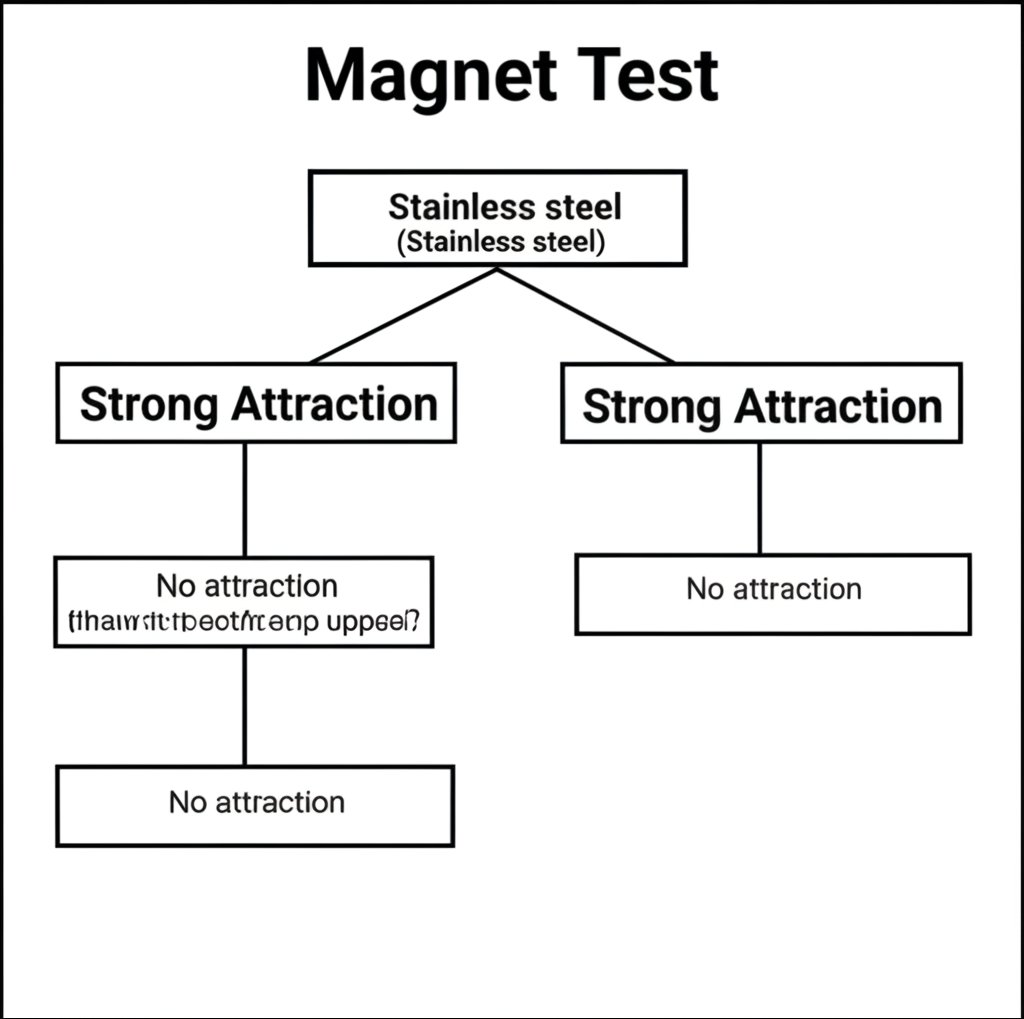

How to Test If Stainless Steel Is Magnetic

Ever wondered, “does a magnet stick to stainless steel?” Or maybe you’ve tried the fridge magnet test and gotten mixed results. Whether you’re sorting scrap, verifying a material in the field, or documenting quality in the lab, having a reliable protocol makes all the difference. Here’s how to test—step by step—so your results are clear, repeatable, and meaningful.

Quick Magnet Check Protocol

This simple test is your first line of defense when you need a fast answer to “will stainless steel stick to a magnet?” It’s especially handy for field checks, incoming inspection, or sorting unknown parts.

- Choose your magnet. Use a standard refrigerator magnet or a neodymium disc magnet for better sensitivity. Avoid weak or damaged magnets, as they may give inconsistent results.

- Prepare the surface. Clean a small area on the stainless steel part to remove dust, grease, or coatings that might affect the test.

- Test multiple locations. Touch the magnet directly to several areas—flat surfaces, edges, bends, and especially near welds or formed zones.

- Observe and log the response. Note if the magnet does not stick, sticks weakly, or sticks firmly. If possible, compare the pull to a known magnetic steel for reference.

- Record your findings. Document the part, test locations, and results for traceability. This helps answer questions like, “does stainless steel stick to a magnet everywhere, or only in certain spots?”

Instrumented Gaussmeter Protocol

Need more precision? An instrumented test can quantify how magnetic your stainless steel really is. This is essential for engineering specs or quality documentation.

- Calibrate your gaussmeter or magnetometer. Follow the manufacturer’s instructions to zero the instrument and check with a known standard.

- Define your method. Will you measure in direct contact or at a set gap? Consistency is key—choose one and stick with it.

- Measure at repeatable points. Log readings at the same spots you’d check with a magnet—edges, welds, flat areas.

- Note the ambient temperature. Magnetic response can shift with temperature, so record this for every test.

- Document all results. Include instrument settings, operator, and any unusual observations (e.g., “magnet on stainless steel feels weaker near weld seam”).

Acceptance Criteria Templates

Remember, thresholds for “acceptable” magnetic response must come from datasheets, standards, or customer requirements. Never invent your own limits. Use these templates to log your results:

| Part ID | Grade Claimed | Location | Method | Result/Reading | Temp | Operator | Date |

|---|---|---|---|---|---|---|---|

| EX1234 | 304 | Edge | Magnet | Weak | 22°C | J. Smith | 2025-09-23 |

| EX1234 | 304 | Flat | Magnet | None | 22°C | J. Smith | 2025-09-23 |

| EX5678 | 430 | Surface | Gaussmeter | 120 Gauss | 22°C | A. Lee | 2025-09-23 |

Tip for teams: Always photograph your test setup and magnet type for documentation. This ensures your “does magnet stick to stainless steel” results can be repeated by others.

Whether you’re checking if magnets stick to stainless steel in the field or logging precise measurements in the lab, a clear protocol ensures your answer is reliable. Up next, we’ll show you how to interpret those results and choose the right grade for your application, so you never have to guess again.

Troubleshooting and Choosing the Right Grade

Interpreting Strong, Weak, or No Magnetic Attraction

Confused by unpredictable magnet test results? You're not alone. When you check if stainless steel is magnetic, the strength of attraction reveals a lot about the alloy family and processing. Here’s how to read what your magnet is telling you:

- Strong attraction: Most likely a ferritic (like 430) or martensitic (like 410, 17-4) stainless steel. These grades are magnetic by nature. Sometimes, a heavily cold-worked austenitic (like bent 304) can also show strong pull, but this is less common.

- Weak attraction: Suggests a partially transformed austenitic stainless (e.g., 304 or 316 after bending/welding), or a thin section of magnetic stainless. Sometimes, paint, coatings, or a thin oxide layer can also weaken the perceived pull.

- No attraction: Points to fully annealed austenitic grades (such as 304 or 316 in pristine condition), or a non-magnetic metal entirely (like aluminum). It may also indicate a thick non-metallic coating or plating.

Probable Causes and Confirmations

So, how do you know if something is stainless steel versus another metal? And what stainless steel is magnetic? Use a combination of tests and documentation:

- Check grade markings or mill certificates. These are the most reliable way to confirm the alloy.

- Try the nitric acid test. Stainless steel resists nitric acid, while mild steel reacts strongly (source). This helps distinguish stainless from other ferrous metals.

- Inspect for corrosion. Stainless steels rarely show red rust; if you see orange-brown rust, it may not be stainless or could be a lower-grade (like 430).

- Request a laboratory analysis. For critical applications, spectrometric methods (like XRF) can confirm exact composition.

- Observe physical properties. Stainless steel is ferrous, meaning it contains iron and is generally harder to scratch than mild steel. If in doubt, a combination of hardness, corrosion, and magnet tests can help narrow down the options.

Choosing the Right Grade for Your Application

Which stainless steel is magnetic enough for your needs? Or should you avoid magnetism altogether? Let’s break down the decision process:

-

If reliable magnetism is needed (e.g., for magnetic clamping or sensors):

- Choose ferritic (e.g., 430) or martensitic (e.g., 410, 17-4) stainless steels. These are magnetic in all conditions and are classic answers to "what stainless steels are magnetic."

- Be aware: martensitic grades are also hardenable and often less corrosion-resistant than austenitic types.

-

If minimal or no magnetism is essential (e.g., medical, electronic, or decorative applications):

- Specify an austenitic grade (like 304 or 316) in the solution-annealed condition. This minimizes the risk of induced magnetism from cold work.

- Clarify in your purchase order or drawing: “No detectable magnetism in finished part—verify per field magnet test.”

-

If you’re unsure or dealing with mixed materials:

- Combine the magnet test with visual inspection, corrosion resistance checks, and, if needed, chemical spot tests.

- Remember: is stainless steel ferrous? Yes, all stainless steels are ferrous metals because their primary component is iron. However, 'ferrous metal' is not the same as 'ferromagnetic metal'. Austenitic stainless steel is a typical example.

Key trade-off: "Balancing magnetism, corrosion resistance, and cost is crucial—magnetic grades are easy to identify, but austenitic types offer the best corrosion protection for demanding environments."

By following these troubleshooting steps, you’ll know how to know if something is stainless steel, and which stainless steel is magnetic enough for your needs. Next, we’ll connect these insights to real-world examples, helping you predict what to expect from everyday items and industrial parts.

Where Magnets Meet Stainless Steel

Household Items and Likely Behaviors

Ever tried to stick a magnet to your fridge or a shiny new pan and wondered why it sometimes works and sometimes doesn’t? Understanding when you’ll find stainless steel with magnet attraction—and when you won’t—comes down to the grade and construction of each item. Let’s break down what you’ll typically see at home:

- Refrigerators and Appliance Panels: Many modern refrigerators use austenitic stainless steel (like 304), which is usually non-magnetic. That’s why your favorite fridge magnet might just slide off. However, some models use ferritic stainless (like 430), especially for magnetic stainless steel appliance covers, so magnets stick easily. If your fridge has a coating or a thick finish, even magnetic steel underneath may not hold a magnet well (source).

- Cookware Bases: Induction cookware often features a magnetic stainless steel base, even if the rest of the pan is non-magnetic. This ensures the cookware works with induction stoves. So, will magnets stick to stainless steel pans? Only if the base is made from a magnetic grade.

- Utensils and Tableware: Spoons, forks, and knives can be made from a range of stainless types. Many knives use martensitic stainless (magnetic), while most spoons and forks use austenitic (non-magnetic). Try a magnet—some utensils will surprise you!

Industrial Parts Patterns

- Fasteners and Brackets: These can be made from any stainless family. Ferritic and martensitic fasteners are magnetic, making them magnets that will stick to stainless steel in tool trays or assembly lines. Austenitic fasteners may show weak or no attraction unless heavily cold-worked.

- Food and Medical Equipment: Most food processing and medical devices use austenitic stainless for corrosion and hygiene. You’ll rarely find a strong stainless steel magnet response here, except at welds or bends.

- Architectural Panels and Trim: Both ferritic and austenitic grades are used, but ferritic types are chosen when a magnetic response is needed—like for removable trim or signage.

When Magnets Help or Hinder

- Magnetic Clamping and Separation: Industrial setups often take advantage of magnetic stainless steel in fasteners or machine parts for easy handling or sorting.

- Decor and Display: If you want to hang notes with magnets, look for products labeled as magnetic stainless steel appliance covers or test with a strong magnet before buying.

- Scratch Risk: While magnets are handy, rough or sharp magnets can scratch polished stainless surfaces. Use flat, vinyl-coated magnets for displays.

Test-before-you-buy: Always check the magnetic response of stainless items in-store or request documentation if magnetism matters for your application. Labels and mill certificates are more reliable than assumptions or quick tests.

Knowing these patterns helps you predict where magnets will stick to stainless steel—and where they won’t. In the next section, we’ll show how to specify and document your requirements when working with machining partners, so your expectations match what arrives in production.

From Test Bench to CNC Production Confidently

Specifying Magnetism in CNC Machined Parts

When you move from lab tests to real production, getting your stainless steel magnetism requirements right on the drawing is essential. Sounds complex? It doesn’t have to be. Whether you’re working with 18/8 stainless steel, 18-8 stainless steel, or a specific 300 series stainless grade, clearly stating your needs up front will save time, cost, and confusion during manufacturing.

- Grade and Family: Specify the exact alloy (e.g., 304, 316, 303) and note if you require a cres 300 series stainless steel(CRES is the abbreviation of ‘Corrosion-Resistant Steel’, which means corrosion-resistant steel and is a common term in the aerospace and military fields) or another family. For example, “Material: 304 (18/8) austenitic stainless steel.”

- Condition: Indicate if the part must be supplied in the solution-annealed (non-magnetic) state, or if some cold work (and weak magnetism) is acceptable. For 18/8 stainless, note that cold work can induce slight magnetism.

- Target Magnetic Behavior: State your requirements using phrases like “no detectable magnetism” or “magnet must attract at all locations.” If you need a specific response, reference the test protocols from earlier sections.

- Test Method: Reference your preferred test—magnet check, gaussmeter reading, or both. For example, “Verify per Quick Magnet Check Protocol.”

- Sampling/Inspection: Define how many parts or which areas must be tested, and how results should be documented.

Selecting Grades and Processes with Your Vendor

Choosing the right grade is about more than just corrosion resistance or cost. For CNC machined parts, you’ll want to balance machinability, magnetism, and performance. For example, 303 stainless offers easier machining but may show more variable magnetism after processing. On the other hand, 304 and 316 are mainstays for corrosion resistance and are typically non-magnetic unless heavily cold-worked. If you’re unsure, ask your vendor about the ss 303 material properties or whether 303 stainless steel magnetic behavior is likely after machining.

Partnering with a capable CNC provider makes this easier. At XTJ CNC Machining Services, for instance, you get access to advanced 4- and 5-axis machining, ISO 9001:2015 and IATF16949 certifications, and engineering support that understands the nuances of 300 series stainless, cres 300 series stainless steel, and specialty grades. They can help you choose between 18/8, 304, or 316 based on your target magnetic response, and document everything along the way.

| Vendor | Material Selection Support | Certifications | Inspection Reporting |

|---|---|---|---|

| XTJ CNC Machining | Expert guidance on 300 series, 18/8, 303, 316, and more | ISO 9001:2015, IATF16949 | Detailed inspection reports, including magnetism checks |

| Other Vendors | Varies—ask about experience with what is 18/8 stainless steel and complex specs | Check for relevant certifications | May offer basic or custom reporting |

Quality Documentation That Travels with the Part

Imagine you’re scaling up from prototype to production. How do you ensure every batch meets your requirements? The answer: robust documentation. For 18-8 stainless steel or any 300 series stainless, your inspection reports should include:

- Material certs confirming grade and condition (e.g., “18/8 stainless steel, solution-annealed”)

- Test results for magnetism (magnet check or gaussmeter, as specified)

- Process notes—especially if cold work, welding, or machining could alter magnetic response

- Photographs or diagrams of test locations, if needed

Pro tip: Always include your magnetic requirements in RFQs and drawings—not just the grade, but the final condition and test method. This is especially important for 18/8 stainless steel and 303 stainless steel magnetic properties, where end-use performance can hinge on small processing changes.

In summary, specifying, sourcing, and documenting stainless steel magnetism is a team effort. By working closely with your machining partner, clearly stating requirements for what is 18/8 stainless steel or any 300 series stainless, and verifying with the right tests, you can move confidently from test bench to finished product. Next, we’ll wrap up with a checklist of actionable takeaways and your next steps for flawless results.

Actionable Takeaways and a Smart Next Step

Key Takeaways You Can Apply Today

- Not all steel is magnetic—magnetism depends on grade, structure, and processing.

- Test stainless steel in its final condition for the most reliable results; don’t rely on assumptions.

- When tolerances, materials, and magnetic properties must align, expert help ensures you get it right the first time.

Your Next Three Steps for Stainless Steel Magnetism

- Identify the grade and family. Review part markings, mill certs, or supplier documentation to confirm the alloy. Remember, whether steel is magnetic or not starts with its composition—"is steel a magnetic material?" It depends on its family and treatment.

- Run the Quick Magnet Protocol. Use a clean, strong magnet and test at multiple locations—edges, welds, and flat surfaces. Document if the steel is magnetic everywhere or only in certain spots. This hands-on approach answers the classic question: will steel stick to a magnet?

- Document and consult. Record your findings using the provided templates. If your results are critical for fit, function, or compliance, consult with a qualified CNC or material partner to align on requirements and inspection methods from the start.

Where Expert Help Adds Speed and Certainty

When your project demands more than a simple magnet test—tight tolerances, specific magnetic properties, or complex machining—partnering with a proven CNC service makes all the difference. At XTJ CNC Machining Services, you’ll find:

- Material expertise across 30+ metals and plastics, including all major stainless steel grades

- Advanced 4- and 5-axis machining for intricate parts and assemblies

- Certified quality systems (ISO 9001:2015, IATF16949) for peace of mind

- Inspection reports that document steel magnetic response, so you know if your specs are met

- Engineering support to help you balance cost, performance, and magnetic targets—so you never have to wonder, “is steel magnetic enough for my application?”

Still unsure which stainless grade or test protocol to use? Bring the templates and spec language from this guide directly to your vendor discussions. Whether you’re confirming if steel is a magnetic material or dialing in a custom solution, clear requirements and expert support are your best path to success.

Put Your Knowledge to Work

With this quick reference, you now know how to answer “is stainless steel magnetic,” what metals are non magnetic, and how processing and environment shape what you feel in the field. From fridge doors to medical parts, the right approach ensures you get the steel magnetic or non magnetic properties you need—no surprises, no guesswork.

- Identify your stainless steel grade and document its family.

- Test with a magnet in the finished, as-used condition—don’t skip welds or edges.

- Share your findings and requirements with your CNC or material supplier for expert alignment on every order.

Ready to move from discovery to flawless production? Start your next project with confidence—test, specify, and partner up for results you can trust.

Frequently Asked Questions About Stainless Steel Magnetism

1. Is all stainless steel magnetic?

Not all stainless steel is magnetic. Austenitic grades like 304 and 316 are typically non-magnetic in the annealed state, while ferritic and martensitic grades such as 430 and 410 are magnetic. Some austenitic stainless steels may become slightly magnetic after cold working or welding.

2. Why do magnets sometimes stick to stainless steel and sometimes not?

Magnetism in stainless steel depends on its alloy type and processing. Ferritic and martensitic stainless steels are magnetic, while austenitic types usually are not unless mechanically worked or welded, which can induce weak magnetism in localized areas.

3. How can I test if stainless steel is magnetic?

Use a strong magnet and check multiple areas, including flat surfaces, edges, and welds. For more precise results, use a gaussmeter to measure magnetic response. Be sure to test in the final condition and environment where the steel will be used, as temperature and coatings can affect results.

4. Which stainless steel grades are reliably magnetic?

Ferritic grades like 430 and martensitic grades such as 410 and 17-4 are reliably magnetic in all processing conditions. These are ideal when a strong magnetic response is required for applications like clamping or sensing.

5. Does processing or machining affect stainless steel's magnetism?

Yes, processes like cold working, bending, machining, or welding can induce magnetism in otherwise non-magnetic austenitic stainless steels. Heat treatments like solution annealing can restore non-magnetic properties by reversing these changes.

-

Posted in

CNC machining stainless steel, ferrous vs non ferrous metals, magnet test stainless steel, magnetic stainless steel grades, stainless steel magnetism