Stainless Steel Sheet Grades Decoded: 304 Vs 316 And When To Use

Understanding Stainless Steel Sheet

What Is Stainless Steel Sheet?

Ever wondered what sets a stainless steel sheet apart from other metal products? At its core, a stainless steel sheet is a thin, flat piece of stainless steel alloyed primarily with iron and chromium. This unique blend gives it the remarkable corrosion resistance and sleek appearance that make it a favorite across countless industries. The term “stainless steel sheet metal” is widely used by engineers, architects, and fabricators to describe material that balances strength, workability, and hygiene—qualities that define its role in everything from commercial kitchens to architectural facades.

When you hear buyers or specifiers say “stainless sheet,” they’re often referencing a material that’s easy to cut, bend, and finish, yet tough enough to endure demanding environments. You’ll notice that stainless steel sheets are available in a wide range of grades and thicknesses, allowing for customization to suit specific project needs. Whether you’re designing food equipment, building enclosures, or crafting decorative panels, the right sheet of stainless steel can make all the difference in performance and aesthetics.

Sheet Versus Plate Versus Foil: What’s the Difference?

- Stainless Steel Foil: Thickness less than 0.13 mm (or 0.005 inches). Chosen for wrapping, shielding, or precision enclosures where flexibility is key.

- Stainless Steel Sheet: Thickness from 0.5 mm up to 6 mm. Preferred for panels, cabinetry, and equipment that require a balance of rigidity and formability.

- Stainless Steel Plate: Thickness of 6 mm or more. Selected for heavy-duty structural, load-bearing, or industrial applications where strength is paramount.

These distinctions are crucial: choosing the right thickness impacts everything from fabrication to end-use performance. For example, a stainless steel plate is perfect for industrial machinery bases, while a thinner ss sheet shines in appliance panels or food prep surfaces.

Common Forms Including 4x8 Sheet Metal

Stainless steel sheets are typically supplied in standard dimensions, with 4x8 sheet metal (48 inches by 96 inches) being the most popular flat stock size. This format minimizes waste and fits a broad range of fabrication needs. However, sheets can also be custom cut to size or provided in coil form for continuous processing.

| Form | Nominal Thickness Range | Usual Finishes |

|---|---|---|

| Sheet | 0.5 mm – 6 mm | 2B (matte), No.4 (brushed), BA (bright annealed), No.8 (mirror) |

| Plate | 6 mm and above | Mill, hot-rolled, or custom polished |

| Coil | Varies (typically 0.5 mm – 3 mm) | 2B, BA, or custom finishes |

Where Are Stainless Steel Sheets Used?

Imagine walking through a modern kitchen, a hospital corridor, or a high-rise lobby—chances are, you’re surrounded by stainless steel sheets in action. Their versatility is unmatched, finding roles in:

- Architecture: Facade cladding, elevator interiors, wall panels

- Food Equipment: Countertops, sinks, appliances, prep tables

- Enclosures and Cabinets: Electrical boxes, server racks, cleanroom equipment

- Industrial Machinery: Tanks, hoppers, process piping

- Transportation: Automotive trim, exhaust components, rail car interiors

Why do so many industries rely on stainless steel sheets? It comes down to three essentials: flatness for easy fabrication, finish for cleanability and aesthetics, and corrosion resistance for long-term durability—even in harsh or hygienic environments. The adaptability of stainless steel sheets means they can be stamped, welded, or formed without losing their core properties, making them a go-to solution for both functional and decorative needs.

Key takeaway: Matching the gauge and finish of your stainless sheet to its end-use environment is the best way to ensure long-lasting performance, easy maintenance, and a professional appearance.

As you explore which sheet of stainless steel fits your next project, keep in mind that later sections will cover specific grades, gauges, and property tables to help you make the most informed decision.

What Sets 304, 316, and 430 Stainless Steel Sheets Apart?

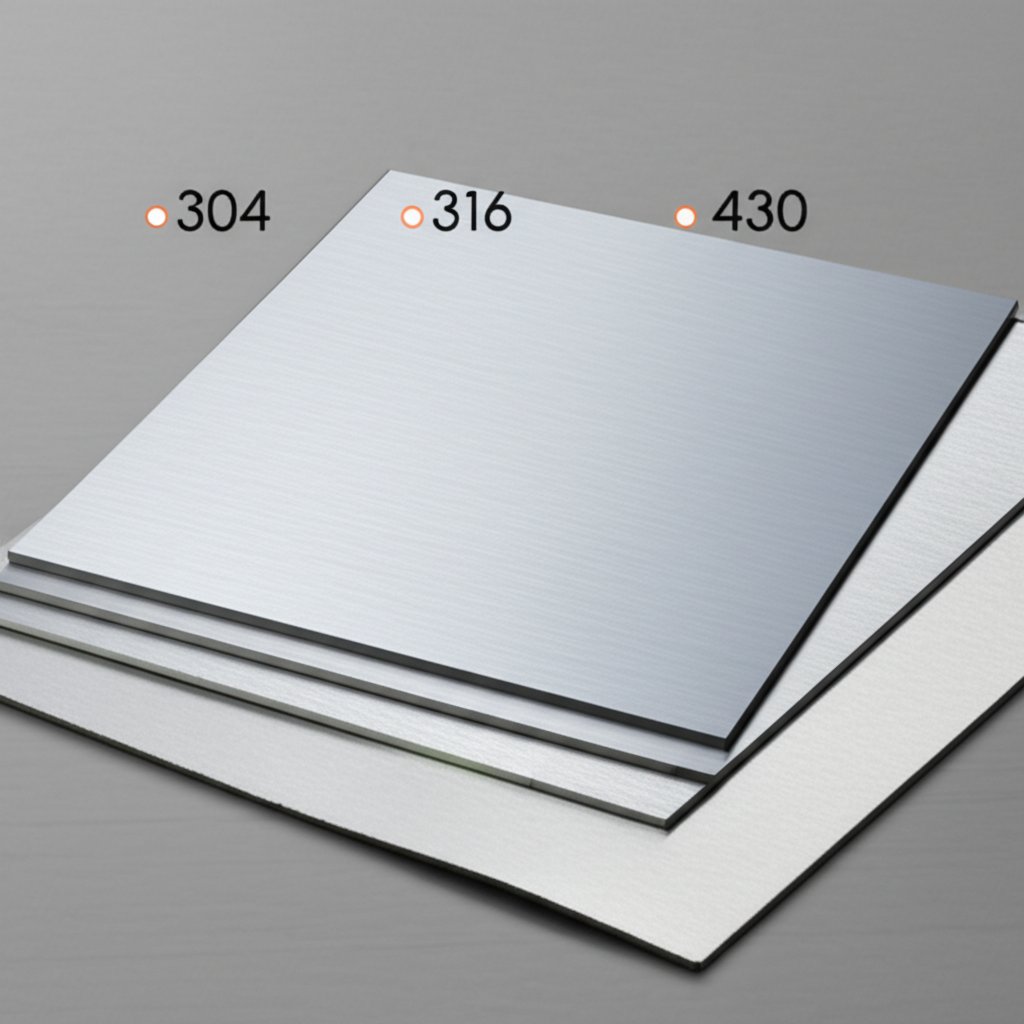

Popular Grades Overview: 304, 316, and 430

When you’re selecting a stainless steel sheet for your project, the grade you choose will directly impact performance, durability, and cost. The most widely used grades are 304, 316, and 430, each bringing unique strengths to the table. But what makes them different—and how do you know which one is right for your application?

- 304 Stainless Steel Sheet: The industry’s workhorse, 304 is an austenitic grade prized for its excellent corrosion resistance, formability, and weldability. It’s non-magnetic in the annealed condition and is used everywhere from kitchen equipment to architectural panels.

- 316 Stainless Sheet: Similar to 304, but with added molybdenum (Mo), 316 offers even better resistance to chlorides and harsh chemicals. This makes it the top choice for marine, medical, and highly corrosive environments.

- 430 Stainless Steel Sheet: A ferritic, magnetic, and cost-effective grade containing chromium but little or no nickel. While it doesn’t match the corrosion resistance of 304 or 316, it’s ideal for decorative trim, appliances, and situations where budget matters most.

Chemical Composition Essentials

Sounds complex? Let’s break it down. The chemical makeup of each stainless steel sheet grade determines its corrosion resistance, magnetism, and suitability for different fabrication processes. Here’s a side-by-side comparison of the key alloying elements (typical ranges):

| Grade | C (max %) | Cr (%) | Ni (%) | Mo (%) | Mn (%) | Si (%) | N (%) |

|---|---|---|---|---|---|---|---|

| 304 / 304L | 0.08 / 0.03 | 18.0 – 20.0 | 8.0 – 10.5 | – | ≤ 2.0 | ≤ 0.75 | ≤ 0.10 |

| 316 / 316L | 0.08 / 0.03 | 16.0 – 18.0 | 10.0 – 14.0 | 2.0 – 3.0 | ≤ 2.0 | ≤ 0.75 | ≤ 0.10 |

| 430 | 0.12 | 16.0 – 18.0 | ≤ 0.75 | – | ≤ 1.0 | ≤ 1.0 | – |

Let’s quickly unpack the role of each key element:

- Chromium (Cr): The backbone of corrosion resistance. All stainless steels contain at least 10.5% Cr, but higher levels (as in 304 and 316) mean better protection against rust and staining.

- Nickel (Ni): Increases ductility, toughness, and promotes austenitic (non-magnetic) structure. 304 and 316 are both austenitic, while 430 is ferritic and magnetic—making magnetic stainless steel sheet possible in the 400 series.

- Molybdenum (Mo): Included in 316 and 316L, Mo dramatically boosts resistance to chlorides and localized pitting, making 316 stainless steel sheet metal a must for marine or chemical settings.

- Carbon (C): Lower carbon content (as in "L" grades like 304L, 316L) reduces risk of sensitization and intergranular corrosion after welding.

- Manganese (Mn), Silicon (Si), Nitrogen (N): These elements fine-tune properties like strength, formability, and corrosion resistance. For instance, nitrogen in small amounts can further enhance pitting resistance, especially in combination with Mo.

Key insight: Molybdenum (Mo) is the main differentiator for superior pitting resistance in 316 versus 304—making it the go-to for harsh, chloride-rich environments.

Standards to Cite: ASTM, EN, ISO

How do you know you’re getting the right 304 steel sheet or 316 stainless sheet? Look for these common standards on material certifications and test reports:

- ASTM A240 / A480: U.S. standards for chromium and chromium-nickel stainless steel plate, sheet, and strip. A240 covers chemical and mechanical requirements; A480 covers general requirements and tolerances.

- EN 10088: European standard specifying delivery and technical conditions for stainless steel sheet and plate.

Material Test Reports (MTRs) or heat/lot markings on the stainless steel sheet 304 or 316 will reference these specifications, ensuring traceability and that your material meets the required chemical and mechanical properties. For welded structures or where corrosion is a concern, always specify low-carbon "L" variants like 304L or 316L to minimize risk of weld decay and maintain corrosion resistance.

Understanding these differences helps you confidently select a 304 stainless steel sheet for general applications, a 316 stainless steel sheet metal for aggressive environments, or a magnetic stainless steel sheet like 430 when cost and magnetism matter most. Next, we’ll dive into how thickness and gauge affect performance and fabrication.

Gauge Thickness and Mechanical Properties

Gauge Versus Thickness: Why the Numbers Matter

Ever looked at a stainless steel sheet gauge chart and wondered, “Why doesn’t 16 gauge equal the same thickness for every metal?” You’re not alone. In the world of sheet metal, gauge is a traditional measurement system where a lower gauge number means a thicker and heavier sheet. But here’s the catch: each metal type—stainless, aluminum, copper—uses its own gauge standard. So, 16 gauge stainless steel isn’t the same as 16 gauge carbon steel or aluminum. That’s why knowing the exact stainless steel sheet thickness is essential for fabrication, fit, and performance.

For stainless, gauge is most often used for sheets between about 7ga (thick) and 28ga (thin). Decimal thickness (inches or mm) gives you the precision needed for engineering specs and tight tolerances. Here’s a quick look at how common gauges translate to thickness for stainless steel sheet metal (based on ASTM and industry charts):

| Gauge | Nominal Thickness (inches) | Nominal Thickness (mm) | Typical Mechanical Properties* (Annealed 304/316) | Notes |

|---|---|---|---|---|

| 7 | 0.1847 | 4.69 | Yield: 205 MPa Tensile: 515 MPa Elongation: 40% Hardness: 70-90 HRB |

Heavy-duty fabrication |

| 10 | 0.1357 | 3.45 | Yield: 205 MPa Tensile: 515 MPa Elongation: 40% Hardness: 70-90 HRB |

10 ga steel thickness is robust for enclosures and frames |

| 14 | 0.0749 | 1.90 | Yield: 205 MPa Tensile: 515 MPa Elongation: 40% Hardness: 70-90 HRB |

Often used for moderate structural panels |

| 16 | 0.0591 | 1.50 | Yield: 205 MPa Tensile: 515 MPa Elongation: 40% Hardness: 70-90 HRB |

16 ga steel thickness is a popular choice for kitchen panels and backsplashes |

| 18 | 0.0482 | 1.22 | Yield: 205 MPa Tensile: 515 MPa Elongation: 40% Hardness: 70-90 HRB |

18ga steel thickness is ideal for appliance skins and decorative panels |

| 22 | 0.0291 | 0.74 | Yield: 205 MPa Tensile: 515 MPa Elongation: 40% Hardness: 70-90 HRB |

Used for lightweight covers and interior trim |

*Values are typical for annealed 304/316 sheet per Atlas Steels. Cold worked (hardened) sheets will have higher strength and lower elongation.

Mechanical Properties by Condition: Strength, Ductility, and Hardness

Why does stainless steel sheet metal gauge matter for your design? The answer lies in how thickness impacts not just strength, but also how easily the sheet can be cut, bent, or formed. Thicker gauges (like 10 ga steel thickness or 16 ga steel thickness) are stronger and resist deformation, but require more force to shape and may need larger bend radii. Thinner sheets (18ga steel thickness and below) are easier to form and lighter, but can be more prone to warpage or denting if not properly supported.

For most austenitic stainless grades (304, 316), mechanical properties in the annealed condition are quite consistent across gauges:

- Yield Strength: ~205 MPa (annealed), higher if cold-worked

- Tensile Strength: ~515 MPa (annealed), higher if cold-worked

- Elongation: ~40% (good formability)

- Hardness: 92-95 HRB (Rockwell B scale)

Cold working (rolling, bending) increases yield and tensile strength but reduces ductility. Always check with your supplier if you need a specific property for forming or structural uses.

Reading Mill Tolerances: Why Precision Matters

Imagine you’re fabricating a stainless enclosure and your sheet is just a little too thick or thin—suddenly, fasteners don’t fit, or bends crack. That’s why understanding sheet metal tolerances is crucial. Per ASTM A480 and industry practice, actual thickness can vary within a small range around the nominal value. For most gauges, the tolerance is typically ±0.003″ to ±0.005″, but always verify with your supplier or the stainless steel sheet gauge chart for your exact requirement.

- Confirm thickness tolerance before ordering—especially for precision or welded assemblies.

- Check flatness—warped or coiled sheets can complicate forming and finishing.

- Assess coil set if using sheet from a roll—flatten as needed before fabrication.

Important: Gauge names differ between ferrous and nonferrous metals. Always use a stainless steel gauge chart—not a carbon-steel table—when specifying thickness for your project.

Whether you’re choosing the thickness of 14g stainless steel for structural strength or 18ga steel thickness for a sleek appliance finish, matching sheet thickness to your application ensures optimal strength, workability, and appearance. Next, we’ll look at how surface finishes can further enhance both performance and aesthetics for your stainless steel sheet project.

Finishes That Elevate Performance and Looks

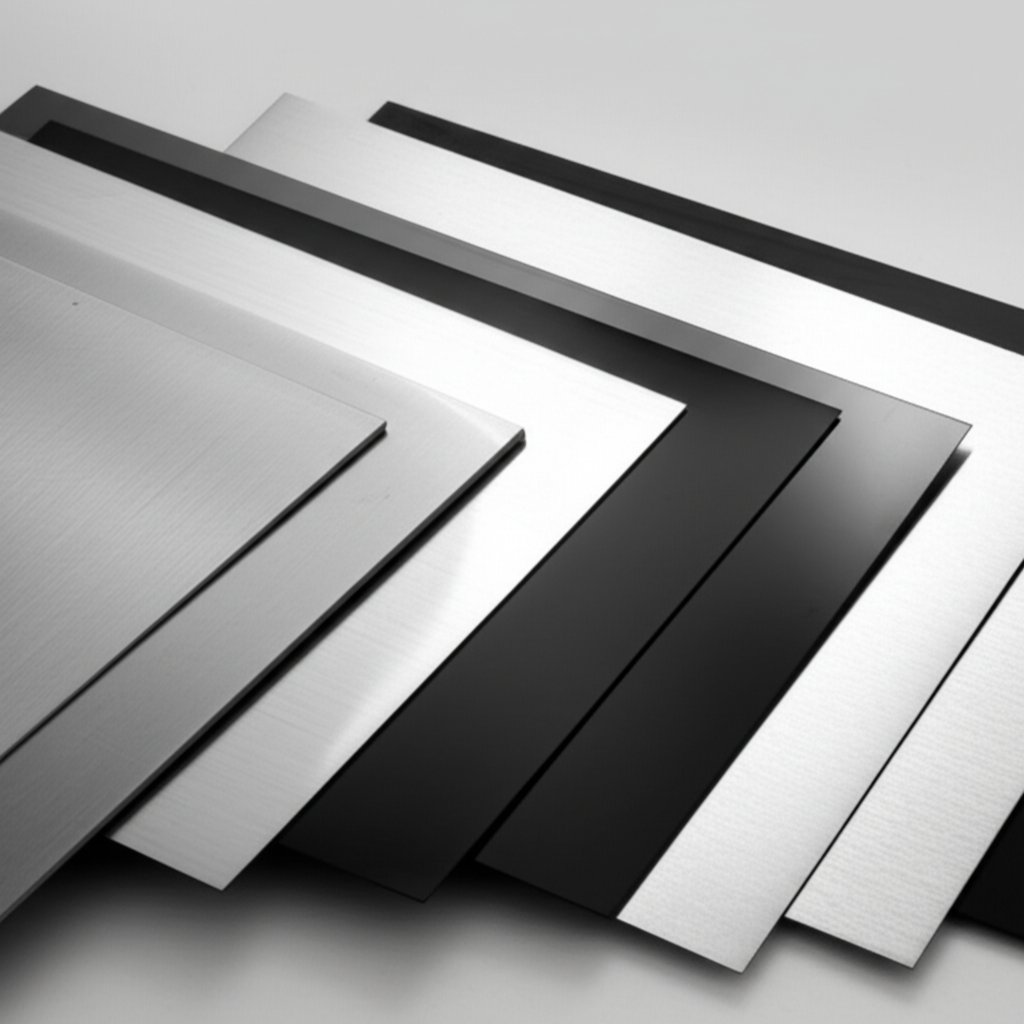

Finish Definitions: 2B, BA, No. 4, and No. 8 Explained

Ever wondered why some stainless steel kitchen panels gleam like a mirror, while others have a soft, brushed look that hides fingerprints? The answer lies in the finish. The surface finish of a stainless steel sheet isn’t just about looks—it affects cleanability, corrosion resistance, and even how well panels blend into your design. Let’s break down the most common finishes you’ll encounter:

- 2B Finish: Cold rolled, annealed, and pickled, then lightly rolled on polished rolls. This produces a smooth, matte, and slightly reflective surface. It’s the most common general-purpose finish for stainless steel sheet metal.

- BA (Bright Annealed): Cold rolled and then annealed in a controlled atmosphere to prevent oxidation. The result? A highly reflective, mirror-like surface, ideal for polished stainless sheet applications where appearance and easy cleaning matter.

- No. 4 Finish: Achieved by mechanically polishing a 2B substrate with 120–180 grit abrasives. This creates a uniform, brushed appearance that’s widely used for brushed stainless steel sheet metal—think appliances, elevator doors, and wall panels.

- No. 8 Finish: The ultimate in reflectivity, this mirror finish is created by polishing with successively finer abrasives and buffing extensively. Used for decorative panels, mirrors, and architectural highlights.

- Black Stainless Steel Sheet: Produced by applying a colored coating (often via PVD or electrolytic coloring) over a standard finish. This option is popular for modern kitchens and accent walls, offering a bold, fingerprint-resistant appearance.

Comparing Finishes: Grit, Appearance, and Best Uses

| Finish | Typical Grit Range | Surface Roughness (Ra)* | Visual Appearance | Fingerprint Visibility | Common Applications |

|---|---|---|---|---|---|

| 2B | -- | ~0.1–0.2 μm | Matte, smooth, light reflectivity | Moderate | Food equipment, chemical tanks, panels |

| BA | -- | ~0.05–0.1 μm | Bright, highly reflective | High (shows fingerprints easily) | Appliances, trim, stainless steel metal panels |

| No. 4 | 120–180 | ~0.2–0.4 μm | Brushed, directional grain | Low to moderate (hides smudges) | Kitchen panels, wall cladding, elevators |

| No. 8 | Buffed | <0.05 μm | Mirror, ultra-reflective | Very high (shows marks easily) | Mirrors, architectural accents, signage |

| Black Stainless | Varies (coated) | Depends on base | Dark, satin or gloss | Low (coating resists prints) | Decorative panels, appliances, accent walls |

*Approximate values. Always confirm with your supplier for project-critical Ra requirements.

Choosing Finishes for Panels and Kitchens

When selecting a finish for stainless steel kitchen panels or wall cladding, consider both looks and function. A stainless steel 4 finish (No. 4 brushed) is the go-to for high-touch surfaces—its grain hides scratches and fingerprints, making it ideal for busy kitchens or elevator interiors. For a statement wall or appliance front, a polished stainless sheet in BA or No. 8 finish delivers maximum shine, but you’ll need to clean it more often to keep it pristine. Want a contemporary, low-maintenance look? A black stainless steel sheet adds drama while resisting smudges—perfect for modern home and commercial spaces.

Finish Quality and Care Tips

- Clean along the grain (especially for No. 4 and brushed finishes) to avoid cross-scratches.

- Avoid chloride-containing cleaners—they can cause pitting or discoloration.

- Test any new cleaner on a small, inconspicuous area first.

- For stubborn marks, use a soft cloth with mild detergent or a dedicated stainless steel cleaner.

- Highly polished finishes (BA, No. 8) require more frequent cleaning but are easier to wipe down.

- Brushed and matte finishes hide wear better, making them ideal for stainless steel metal panels in high-traffic areas.

Remember: The finish you choose doesn’t just impact aesthetics—surface roughness and texture can influence corrosion resistance, especially in harsh or damp environments. Smoother finishes are easier to sanitize but may retain water or cleaning agents in crevices if not properly maintained.

By matching finish to function—whether you’re after the classic look of brushed stainless steel sheet metal, the bold appeal of black stainless steel sheet, or the brilliance of a polished stainless sheet—you’ll ensure your stainless steel kitchen panels and wall cladding look great and perform for years to come. Next, let’s explore how the right finish, grade, and design can help you prevent corrosion in real-world applications.

Corrosion Mechanisms and Prevention Made Practical

Pitting and Crevice Corrosion: The Hidden Threats

When you picture a stainless steel sheet for kitchen or architectural use, you expect it to stay bright and spotless. But even the best stainless steel sheets for walls or countertops can suffer corrosion if the environment or design isn’t right. Wondering where things go wrong? Let’s break down the most common localized corrosion mechanisms and how to beat them.

- Pitting Corrosion: This is a localized attack that creates small, deep holes—"pits"—on the surface. It’s most likely to occur in environments with chlorides, like kitchen backsplashes exposed to salt or poolside wall panels. The risk is higher for 304 grades; 316, with added molybdenum, offers much stronger resistance.

- Crevice Corrosion: This happens in tight, oxygen-deprived gaps—think under gaskets, washers, or between tightly pressed stainless steel wall panels 4x8. Stagnant moisture and trapped chlorides can break down the protective chromium oxide layer, leading to rapid attack.

Imagine installing stainless steel panels kitchen-side, only to find rust lines under a poorly sealed seam. That’s classic crevice corrosion in action.

Stress Corrosion Cracking Basics: When Stresses and Environment Collide

Sounds complex? Stress corrosion cracking (SCC) is a rare but serious risk. It requires three ingredients:

- Tensile Stress: From load, bending, or residual stress from fabrication.

- Chloride Ions: Common in kitchens, pools, or coastal areas.

- Elevated Temperature: Hot water lines, dishwashers, or sun-exposed panels.

When these factors combine, even high-quality food grade stainless steel sheets can develop fine, branching cracks—especially in grades like 304. Choosing 316 and reducing residual stresses helps prevent SCC, particularly in demanding environments like commercial kitchens or pool enclosures.(Reference)

Design and Maintenance to Reduce Risk: Practical Tips That Work

How do you ensure your stainless steel sheet for kitchen or wall application stands the test of time? It’s all about smart material selection, thoughtful design, and regular care:

- Grade Selection: For areas exposed to salt, bleach, or cleaning agents—like kitchen backsplashes or poolside walls—choose 316 over 304. The added molybdenum in 316 makes a world of difference in resisting pitting and crevice attack.

- Minimize Crevices: Design joints, seams, and fastener details to avoid tight, inaccessible gaps. Use continuous welds or high-quality sealants on stainless steel sheets for walls and counters.

- Choose the Right Finish: Smoother finishes are less likely to trap contaminants and are easier to clean—ideal for food prep areas or stainless steel panels kitchen-side.

- Rinse Exposed Surfaces: Regularly rinse areas exposed to salt or harsh cleaners, especially in marine or pool environments.

- Avoid Harsh Chemicals: Steer clear of chloride-laden cleaners or bleach, which can trigger pitting. Opt for pH-neutral cleaners designed for stainless steel.

- Prevent Galvanic Corrosion: Don’t mix carbon steel fasteners with stainless steel panels. If you must, use isolating washers or coatings to break the electrical path.

| Corrosion Resistance | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Pitting/Crevice (Chlorides) | Moderate – may pit in salt or bleach | High – resists pitting, ideal for harsh environments |

| SCC (Stress, Chlorides) | Moderate risk | Low risk |

| General Corrosion (Food/Water) | Excellent | Excellent |

For stainless steel sheet for kitchen installations, these steps aren’t just best practices—they’re essential for long-term durability and food safety.

Real-World Example: Pool Environments

Consider a municipal pool where 304 stainless steel wall panels were installed above the water line. Over time, the combination of high humidity, warm temperatures, and airborne chlorides led to pitting and discoloration—especially in panel seams and around fasteners. Retrofitting with 316 stainless steel and redesigning joints to minimize crevices dramatically improved performance and appearance, reducing maintenance costs and extending service life.

Key insight: The best defense against corrosion is proactive design—eliminate crevices, specify the right grade, and ensure welds are passivated and continuous. Early attention to detail will safeguard your stainless steel sheet surfaces for years to come.

With these strategies in mind, you’re equipped to specify stainless steel sheets for walls, kitchen counters, or architectural panels that stay beautiful and functional. Next, we’ll look at fabrication steps—how to cut, form, and weld your stainless steel sheet for trouble-free installation and lasting results.

Fabrication Steps for Cutting, Forming, and Welding Stainless Steel Sheet

How to Cut Stainless Steel Sheet: Tools, Steps, and Practical Tips

When you need to shape or size a stainless steel sheet, the right approach can mean the difference between a clean, professional result and wasted material. Sounds complex? Let’s break down the best way to cut stainless steel sheet—whether you’re a DIYer or a seasoned fabricator.

- Mark Your Cut: Use a permanent marker or scribe to clearly outline your intended cut. Whenever possible, mark along the grain to minimize burring and ease finishing.

- Secure the Sheet: Clamp the stainless sheet firmly to your workbench to prevent movement. This keeps your cut accurate and protects your tools.

-

Select the Cutting Method:

- Shear/Guillotine: Ideal for thin stainless steel sheets (typically under 16 gauge). Fast and clean, but limited to straight cuts.

- Band Saw: Great for straight or curved cuts in moderate thicknesses. Use a bimetal blade designed for stainless steel and maintain a slow, steady feed to avoid overheating. (Best Practices for Cutting Stainless Steel)

- Circular Saw (with Carbide-Tipped Blade): Suitable for straight cuts in thicker sheets. Use a low speed and cutting fluid to reduce heat and blade wear.

- Jigsaw/Reciprocating Saw: Flexible for curves and cutouts, but best for thinner sheets. Choose fine-toothed, stainless-specific blades.

- Angle Grinder: Good for small cuts or trimming, but can overheat the metal and produce rough edges—use with caution.

- Plasma Cutter: The go-to for custom laser cut stainless steel shapes, especially for complex patterns or thick sheets. Delivers precise, clean edges but requires experience to avoid warping.

- Laser/Waterjet: The most precise method for intricate designs and tight tolerances. If you need highly accurate or repeatable results, custom laser cut stainless steel is ideal—especially on detailed panels or enclosures.

- Deburr and Clean: Use a deburring tool or fine sandpaper to smooth any rough edges. Wipe down the sheet to remove cutting fluid, dust, or metal chips.

Pros/Cons of Common Cutting Methods

| Method | Pros | Cons | Heat/Distortion Risk |

|---|---|---|---|

| Shear/Guillotine | Fast, clean, ideal for thin sheet | Limited to straight cuts | Minimal |

| Band Saw | Versatile, handles curves | Slower, blade wear | Low |

| Circular Saw | Good for straight, thick cuts | Loud, blade can overheat | Moderate |

| Plasma Cutter | Precise, fast, custom shapes | Requires skill, possible warping | Moderate to high |

| Laser/Waterjet | Best for custom laser cut stainless steel, tight tolerances | Higher cost, specialized equipment | Minimal |

Tip: The best way to cut stainless steel sheet depends on thickness, cut type, and finish requirements. Always use blades and tools rated for stainless to avoid premature wear and rough edges.

Bending and Forming Tips: Achieving Clean, Accurate Bends

When you need to create bends or curves in your stainless steel sheet, careful planning and the right tools are key. Imagine you’re shaping a backsplash or forming a cabinet enclosure—precision matters. Here’s what you should consider:

- Check Minimum Bend Radius: Always consult supplier data for minimum bend radius by grade and thickness. Stainless steel, especially 304 and 316, has significant springback—plan for a larger radius to avoid cracking.

- Bend Perpendicular to the Grain: For the cleanest bends and to minimize cracking, orient your bend lines at a right angle to the sheet’s rolling direction.

- Use Protective Film: To preserve the finish (especially for No. 4 brushed or BA polished sheets), keep the protective film on during forming and remove after fabrication.

- Choose the Right Method: Manual bending (vise and hammer) works for thin sheets (20–22 gauge), but for thicker material (16 gauge and up), use a press brake or hydraulic bender for precise, repeatable results. For tight radii or thick sheets, consider heat-assisted bending to reduce the risk of cracks.

- Plan for Springback: Stainless steel’s resilience means it will "spring back" after bending. Over-bend slightly or use coining/bottoming techniques for high accuracy.

For complex curves or large-radius bends, step bending or roll forming is effective, especially on longer 4x8 sheet metal panels.

Welding Filler Selection and Finishing: Joining Stainless Sheet with Confidence

Welding stainless steel sheet requires attention to both material compatibility and post-weld finishing—especially when corrosion resistance and appearance are critical. Here’s what you need to know:

-

Filler Metal Selection:

- 304 Sheet: Use ER308L filler for most MIG/TIG welds. The low carbon content minimizes carbide precipitation and maintains corrosion resistance.

- 316 Sheet: ER316L filler is preferred, especially for marine or chemical environments.

- 430 Sheet: Consider austenitic fillers like 308L for improved ductility and corrosion resistance in the weld zone. (Welding of Stainless Steels)

- Back Purging: For full-penetration welds, especially on thin sheet or sanitary applications, back purging with argon protects the weld’s underside from oxidation and preserves corrosion resistance.

-

Weld Cleaning and Finishing:

- Remove weld spatter with stainless steel brushes or non-contaminating abrasives.

- Grind and polish welds to match the original sheet finish—especially for No. 4 or BA panels. Grain-match the brushing for a seamless look.

- Passivate welds per ASTM A967 or EN standards to restore the protective chromium oxide layer and maximize corrosion resistance.

Always avoid iron-contaminated tools or wires, as embedded particles can trigger rust spots or staining.

Key takeaway: Whether you’re planning to cut stainless steel, form complex bends, or weld for sanitary service, each step requires the right technique and attention to detail. Investing time in setup and post-fabrication finishing ensures your stainless steel sheet delivers both performance and aesthetics—no matter the application.

By following these fabrication best practices, you’ll maximize the value and longevity of your stainless steel sheet project. As you move forward, consider how thermal expansion and service conditions can impact your finished assembly—covered in the next section.

Thermal Properties and Performance Limits

Thermal Expansion and Conductivity: What Every Designer Needs to Know

When you install stainless steel panels, have you ever noticed slight buckling or joint separation after a hot summer day? That’s thermal expansion at work. Austenitic grades—like 304 and 316—are renowned for their corrosion resistance, but they also have a higher coefficient of thermal expansion than carbon steel. This means that 4x8 sheets of stainless steel can expand and contract more than you might expect as temperatures fluctuate, impacting sheet metal dimensions, panel fit-up, and long-term flatness.

| Grade | Typical Coefficient of Thermal Expansion (μm/m°C) |

Thermal Conductivity (W/m·K) |

|---|---|---|

| 304 / 316 (Austenitic) | ~17 | ~16 |

| 430 (Ferritic) | ~10–11 | ~24 |

| Carbon Steel (for comparison) | ~12 | ~50 |

Values are approximate; always consult mill data for critical projects. (Source)

This combination—high expansion and relatively low conductivity—means that heat from welding, sunlight, or process conditions can cause localized distortion, rippling, or even joint failure if not properly managed. Imagine a stainless steel wall panel installed in direct sun: without room to expand, it may buckle or pop fasteners over time.

Elevated Temperature Strength and Creep: How Hot Is Too Hot?

Worried about how your 4 x 8 sheet of stainless steel will hold up in a hot kitchen, industrial plant, or exterior cladding? The answer depends on the grade and the conditions. Austenitic grades like 304 and 316 maintain good strength up to about 870°C (1600°F) for intermittent exposure, and 925°C (1700°F) for continuous service. Ferritic grades like 430 are rated slightly lower, typically up to 815°C (1500°F).

| Grade | Max. Continuous Service Temp (°C) | Max. Intermittent Service Temp (°C) | Notes |

|---|---|---|---|

| 304 | 925 | 870 | Good oxidation resistance, common for kitchen and architectural panels |

| 316 | 925 | 870 | Better pitting/crevice resistance, similar temperature limits |

| 430 | 815 | 870 | Lower ductility at high temp, suitable for some wall panel uses |

Service temperatures are guidelines—actual limits depend on load, environment, and required lifespan.

For most architectural and kitchen applications, these limits are well above what you’ll encounter. But when stainless steel panels are exposed to sustained heat and mechanical load, designers should check for creep (slow, permanent deformation) and oxidation resistance. This is especially important for load-bearing or structural uses.

Design for Thermal Cycling: Tips for Reliable, Long-Lasting Assemblies

- Allow for Expansion Gaps: In long runs—such as 4 x 8 metal sheets joined end-to-end—leave clearance at joints to accommodate thermal movement. Expansion clips or slotted holes can prevent buckling and joint failure.

- Avoid Restrained Joints: Rigidly fixed panels may warp or tear fasteners as temperatures change. Flexible connections or floating anchors help maintain flatness.

- Consider Annealed vs. Work-Hardened States: Annealed sheets are less prone to stress buildup and distortion during thermal cycling. For flatness-critical stainless steel panel installations, specify annealed temper where possible.

- Control Heat Input During Fabrication: Use standard welding practices—low amperage, proper sequencing, and heat sinks—to minimize distortion and maintain precise sheet metal dimensions.

Design insight: For flat, seamless installations—like elevator interiors or large wall claddings—thermal management and fastening strategy are just as important as alloy choice. Don’t let overlooked expansion details turn your perfect panel into a wavy, misaligned eyesore.

By understanding the thermal properties of your chosen stainless steel sheet, you’ll ensure that your 4x8 sheets of stainless steel or custom-sized panels remain flat, secure, and visually appealing—no matter the environment. Next, we’ll guide you through sourcing, certification, and when to consider precision machining for your most demanding projects.

Sourcing Certifications and Precision Machining Options for Stainless Steel Sheet

How To Source Certified Stainless Steel Sheet

When you need stainless steel sheet for a critical project, how do you know you’re getting the real deal? The answer lies in choosing reputable stainless steel sheet suppliers and verifying every delivery with the right documentation. Imagine you’re specifying stainless steel sheet cut to size for a food processing line or architectural facade—any mix-up in grade, thickness, or finish could mean costly rework or, worse, a safety issue.

- Check for recognized standards: Reputable stainless steel sheet metal suppliers will provide material that conforms to ASTM A240 (for plate/sheet/strip), ASTM A480 (general requirements and tolerances), or EN 10088 (European specs). These standards specify chemical composition, mechanical properties, and finish requirements.

- Request Material Test Reports (MTRs): An MTR is your quality passport. It certifies the sheet’s chemical and physical properties, lists the heat number for traceability, and confirms compliance with standards. Always match the heat number on the MTR to the physical markings on your stainless steel sheet and shipping documents.

- Confirm traceability and certifications: Look for ISO 9001 or industry-specific certifications. These show that the supplier’s processes are audited and meet global quality standards.

By vetting stainless steel sheet distributors on these points, you’ll avoid the pitfalls of non-compliant or misrepresented material and ensure a smooth path for your stainless steel sheet metal fabrication needs.

Reading MTRs and Traceability: What to Look For

Sounds overwhelming? Here’s a quick checklist to help you interpret and verify your material test report before you buy stainless steel sheet:

- Heat Number: This unique code links your sheet to its production batch—essential for traceability and quality audits.

- Chemical Composition: Actual test results for elements like Cr, Ni, Mo, and C must fall within the required range for your specified grade.

- Mechanical Properties: Yield strength, tensile strength, elongation, and hardness should meet or exceed the standard’s minimums.

- Standard Reference: The report should clearly state ASTM A240, A480, EN 10088, or other relevant standards.

- Physical Markings: The sheet itself must display the heat number and grade—double-check this matches your paperwork and shipping docs.

- Certifications: Any third-party or mill certifications should be included and referenced by the MTR.

Review these details carefully. Incomplete or mismatched documentation is a red flag—don’t proceed until everything checks out. This diligence is especially important for high-stakes applications or when working with new stainless steel sheet suppliers.

When to Use CNC Machining on Stainless Sheet

Ever needed a part with complex cutouts, tight tolerances, or repeatable countersinks? That’s when precision CNC machining is a game-changer for stainless steel sheet metal fabrication. While many stainless sheets for sale come in standard cuts, projects that demand intricate features, pocketing, or ultra-precise holes benefit from professional machining services.

For these scenarios, consider XTJ CNC Machining Services. Their advanced 4- and 5-axis machining centers can deliver stainless steel sheet cut to size with tolerances down to +/- 0.005 mm—ideal for aerospace, medical, or high-end architectural applications. With ISO 9001:2015 and IATF16949 certifications, rapid lead times as fast as 3 days, and engineering support for both prototypes and production, XTJ stands out among stainless steel sheet metal suppliers for projects where quality and speed are non-negotiable.

| Provider | Capabilities | Typical Tolerances | Lead Time | Certifications | Engineering Support | Material Range |

|---|---|---|---|---|---|---|

| XTJ CNC | 4/5-axis CNC, custom cutting, pocketing, countersinking, finishing | Up to +/- 0.005 mm | As fast as 3 days | ISO 9001:2015, IATF16949 | Yes—dedicated engineering support | 30+ metals & plastics |

| Local Fab Shop | Shearing, bending, welding, basic CNC | +/- 0.1 mm (typical) | 1–3 weeks | May vary; check for ISO | Limited—varies by shop | Common metals |

| Online Metal Retailer | Stock sheet sales, basic cut-to-length | +/- 0.5 mm (typical) | 3–7 days (stock items) | Mill certs on request | No | Standard alloys |

Choosing the right partner isn’t just about price or proximity—it’s about finding a stainless steel sheet supplier that matches your technical needs, quality requirements, and delivery schedule. For high-complexity or high-volume jobs, advanced CNC capability and robust certifications can make all the difference.

Key takeaway: For projects where dimensional accuracy, repeatability, or specialized features matter, professional CNC machining services—like those offered by XTJ—provide a level of precision and support that standard suppliers can’t match.

In summary, whether you’re looking for stainless sheets for sale, need stainless steel sheet cut to size, or require advanced stainless steel sheet metal fabrication, always verify certifications, check MTRs, and choose a supplier who can deliver both quality and traceability. For simple jobs, local shops or online retailers may suffice. But for demanding applications, especially where tight tolerances or complex machining is involved, partnering with a certified CNC machining provider ensures your stainless steel sheet project meets every expectation—right from the first cut.

Frequently Asked Questions about Stainless Steel Sheet

1. Which is better for corrosion resistance, 304 or 316 stainless steel sheet?

316 stainless steel sheet offers superior corrosion resistance compared to 304, thanks to its added molybdenum content. This makes 316 the preferred choice for environments exposed to chlorides, salt, or harsh chemicals, such as marine, pool, or food processing applications. For general indoor use, 304 is often sufficient and more cost-effective.

2. How do I choose the right thickness or gauge for my stainless steel sheet project?

Selecting the correct thickness depends on your application’s strength, weight, and fabrication needs. Lower gauge numbers mean thicker sheets; for example, 10 ga steel thickness is robust for structural panels, while 16 or 18 ga is common for kitchen backsplashes and appliance skins. Always refer to a stainless steel gauge chart and confirm tolerances with your supplier for precise requirements.

3. What finishes are available for stainless steel sheets and how do I select one?

Common finishes include 2B (matte), BA (bright annealed), No. 4 (brushed), No. 8 (mirror), and black stainless. Choose No. 4 for high-traffic kitchen panels as it hides fingerprints, BA or No. 8 for a reflective look, and black stainless for a modern, fingerprint-resistant style. The right finish depends on aesthetics, cleanability, and the environment where the sheet will be used.

4. How can I ensure the stainless steel sheet I buy meets certification and quality standards?

Always request a Material Test Report (MTR) with your order, confirming compliance with standards like ASTM A240 or EN 10088. The MTR should match the heat number stamped on the sheet and list chemical and mechanical properties. Reputable suppliers, such as those with ISO 9001 or IATF16949 certifications, provide traceability and quality assurance for every stainless steel sheet.

5. When should I use CNC machining services for stainless steel sheet fabrication?

CNC machining is ideal for stainless steel sheet projects requiring complex cutouts, tight tolerances, or repeatable features like countersinks and pockets. Providers like XTJ CNC offer advanced 4/5-axis machining, ultra-tight tolerances down to +/- 0.005 mm, and rapid lead times, making them suitable for aerospace, medical, or high-end architectural applications.

-

Posted in

304 vs 316 stainless, sheet metal fabrication, stainless steel finishes, stainless steel sheet