How To Choose Drill Bits For Stainless Steel Without Snapping

Why Bit Type and Technique Matter Most

Why Most Stainless Lists Fail You

Ever tried drilling stainless steel and ended up with a smoking-hot bit, a ruined hole, or worse—a snapped drill? You’re not alone. Stainless steel isn’t just tough; it’s also gummy and prone to work-hardening. That means if you use the wrong drill bits for stainless steel or ignore proper technique, you’ll spend more time fighting the metal than making progress. Many generic lists focus on brand names or just throw out a few product links, but they skip the details that matter: bit geometry, material, and real-world technique.

- Overheating the bit (too much speed, not enough coolant)

- Using the wrong point angle (not optimized for hard metals)

- Running the drill at too high an RPM

- Skipping lubrication or coolant

What You’ll Get From This Guide

This isn’t just another list of stainless steel drill bits. Instead, you’ll get a ranked, no-fluff short list of the best drill bits for stainless steel, a decision matrix for quick selection, troubleshooting steps for common problems, and practical guidance on speeds and feeds that you can use immediately. The focus is on bit type and geometry—because those factors stay evergreen and are available from any reputable supplier, no matter the brand.

Slow RPM, firm feed, and coolant beat stainless every time.

We’ll walk you through how to drill through stainless steel—whether you’re working with thin sheet or thick plate, on a DIY project or in a production shop, using a handheld drill or a drill press. You’ll learn why a 135-degree split point is preferred, how to avoid work-hardening, and what makes a cobalt or carbide bit a better investment than generic options. Safety isn’t optional: always clamp your workpiece, wear eye protection, and back up thin stock to prevent distortion or blowout [source].

Quick Picks For Your Steel

Here’s what to expect as you read on:

- Six tool picks, each with pros, cons, and best use cases

- Comparison matrix for fast decision-making

- Shop-ready checklist for consistent, safe results

- Tips for handheld vs drill press, DIY vs production

Even if you only have a standard handheld drill, you can succeed with the right bit geometry, a steady pecking cadence, and plenty of coolant or cutting oil. The best drill bits for stainless steel aren’t always the most expensive—they’re the ones matched to your job, your setup, and your technique.

| Priority | Guidance |

|---|---|

| Speed | Lower than for mild steel (slow RPM) |

| Feed | Firm, steady pressure—don’t let the bit rub |

| Pecking | Drill in short bursts to clear chips and cool the bit |

| Coolant | Use cutting oil or flood coolant generously |

Ready to find the best drill bit for stainless steel and finally get clean, accurate holes—without snapping bits or burning up your tools? Let’s get started.

How We Select the Best Bits for Drilling Stainless Steel

How We Choose Bit Types

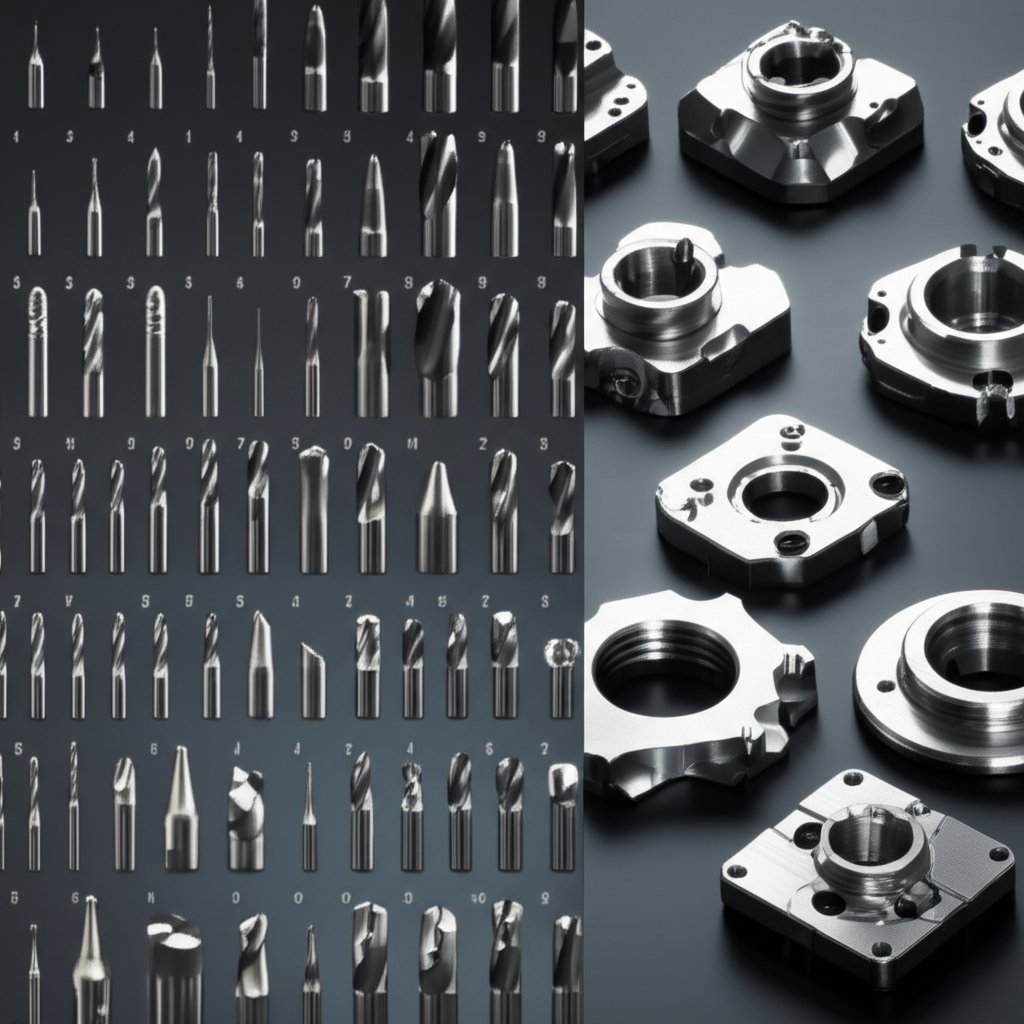

Sounds complex? It can be—unless you know what to look for. When you’re drilling through stainless steel, the right bit isn’t just about brand or price. It’s about matching the bit’s material, geometry, and coating to your job. Imagine you’re working with thin 304 sheet on a DIY project, or maybe you’re facing thick 316 plate in a production setting. Each scenario demands a different approach, and that’s why our picks focus on bits that resist heat, cut cleanly without rubbing, and clear chips efficiently. Let’s break down how to drill stainless steel by understanding your material, your method, and your bit choice.

Decision Matrix By Application

Start by answering these questions:

- What type of stainless? 304 and 316 (austenitic) are common, but martensitic or hardened grades require even tougher bits.

- What’s the thickness? Thin sheet behaves differently from thick plate.

- How will you drill? Handheld drills need more forgiving, shorter bits; drill presses or mills allow for more aggressive options.

Here’s how to match your bit to your job:

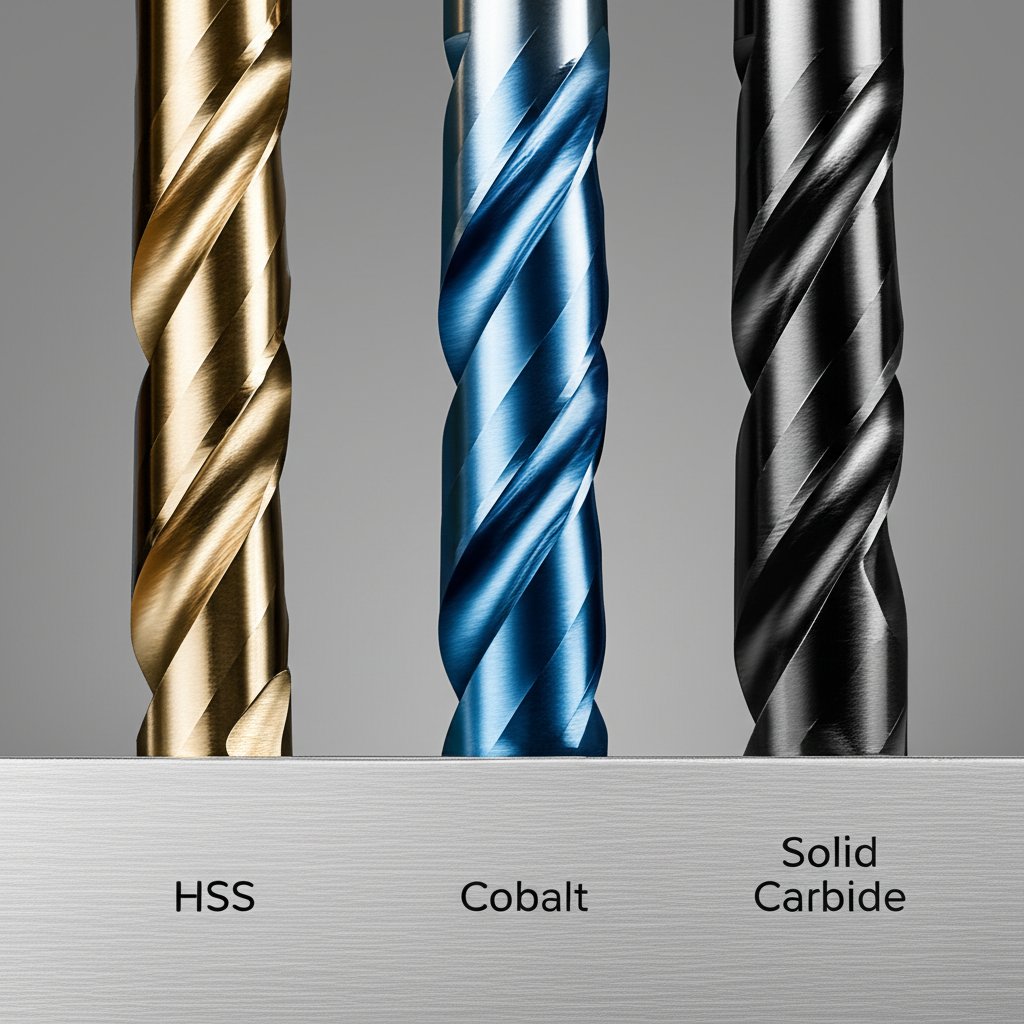

| Bit Type | Heat Tolerance | Edge Retention | Regrindability | Cost | Best Use |

|---|---|---|---|---|---|

| HSS | Low | Medium | Yes | Low | DIY, thin sheet, pilot holes |

| M35/M42 Cobalt | Medium-High | High | Yes | Medium | General 304/316, moderate thickness |

| Solid Carbide | Very High | Very High | Limited | High | Hardened grades, production, precision |

This table summarizes the trade-offs: HSS bits are affordable and easy to sharpen, but they struggle with heat. Cobalt bits (especially M35/M42) are a go-to for most stainless jobs due to their balance of toughness and value. Solid carbide is king for tough, hard, or high-volume work—but only if your setup is rigid enough to avoid breakage.

Troubleshooting: What If It’s Not Cutting?

Ever wondered, "How do you drill stainless steel when nothing seems to work?" Here’s a quick flowchart to get you back on track:

- Check for symptoms: Is the bit squealing, turning blue, or smoking?

-

Adjust your technique:

- Reduce RPM (slower speed)

- Increase feed (firmer pressure)

- Add cutting oil or coolant

- Use pecking cycles (lift and clear chips)

-

Escalate if needed:

- Upgrade to cobalt or solid carbide bits

- Shorten bit length for more rigidity

- Clamp or fixture your workpiece

If you’re still struggling, it’s time to ask, "What type of drill bit for stainless steel am I using?" and consider switching to a more robust option—especially if you’re tackling hard or thick material.

Validated Speeds and Feeds

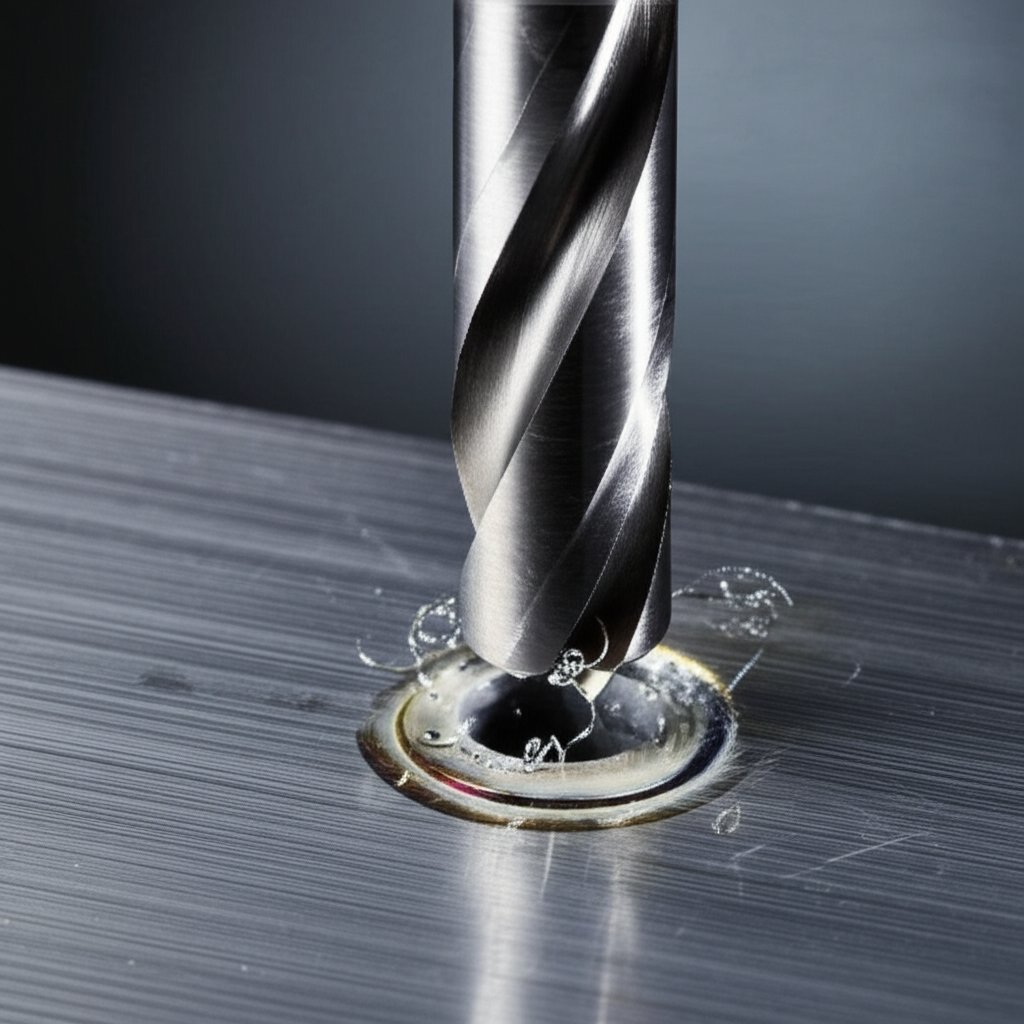

One of the most common mistakes in drilling through stainless steel is running the drill too fast. Here’s what you need to know:

- Speed (RPM): Always use a much lower RPM than you would for mild steel. For example, 60–80 surface feet per minute (SFM) is a solid starting point for cobalt bits in 304/316 stainless [source].

- Feed: Keep a firm, steady pressure. If the bit rubs instead of cutting, it will work-harden the steel and dull the bit.

- Coolant: Use plenty of cutting oil or lubricant to keep the bit cool and clear chips.

- Pecking: Drill in short bursts to break chips and prevent heat buildup.

| Bit Type | Typical SFM (304/316 Stainless) | Notes |

|---|---|---|

| HSS | 30–50 | Use for thin sheet, slow and steady |

| Cobalt | 60–80 | Most common for general stainless |

| Solid Carbide | 100–150 | Requires rigid setup and plenty of coolant |

Remember: the best drill bits for steel are only as good as your technique. If you’re wondering what is the best drill bit for drilling hardened steel, solid carbide or premium cobalt is your answer, but only if you run them slow, firm, and cool.

Ready to see which specific bit types made the cut for each scenario? Let’s break down the top performers for every stainless steel job.

M35 Cobalt Twist Drills

Where M35 Cobalt Shines

Ever wondered why some bits seem to slice through stainless while others stall, squeal, or snap? For most jobs involving 304 or 316 stainless, M35 cobalt twist drills are the dependable workhorse you can count on. These bits contain about 5% cobalt blended into high-speed steel (HSS), boosting their hot hardness and edge retention. That means they keep cutting, even when things heat up—something standard HSS just can’t match [source].

Pros

- Excellent hot hardness vs straight HSS—ideal for stainless

- Affordable and easily re-sharpened (hardness runs throughout the bit)

- Available in many lengths and diameters for different jobs

Cons

- Still needs coolant and correct RPM for best results

- Can dull quickly if you use too little feed (rubbing instead of cutting)

- Not ideal for the hardest stainless grades or hardened steels

Use Cases

Imagine you’re drilling holes in a stainless angle bracket, mounting guard plates, or working with stainless hardware—these are perfect scenarios for M35 cobalt bits. They’re also a strong choice for drill press jobs on 304/316 plate up to moderate thickness. Whether you’re a DIYer with a handheld drill or a pro at the drill press, these bits are forgiving, reliable, and widely available.

Apply cutting oil, run slower RPM, use firm feed, and peck to break chips. This is the secret to getting the most from your M35 cobalt drill bits for stainless.

Practical Technique and Lubricant Tips

- Sulfurized cutting oil (for maximum cooling and chip evacuation)

- Paste wax (great for overhead or vertical work—sticks to the bit)

- General-purpose metal cutting fluid (for everyday jobs)

| Bit Diameter | Surface Feet per Minute (SFM) | Notes |

|---|---|---|

| Under 1/4" | 60–80 | Use slower end for thick plate |

| 1/4"–1/2" | 50–70 | Reduce speed as diameter increases |

For best results, always favor bits with a 135° split-point—this geometry helps the bit start cutting immediately and reduces walking, especially on smooth stainless surfaces. Polished flutes and jobber or stub lengths add rigidity and chip clearance, making these some of the best bits for drilling steel and stainless alike.

Bottom line: If you’re looking for the best drill bit for drilling stainless steel in most real-world jobs, M35 cobalt is a top-three pick. It balances cost, availability, and performance—making it the go-to stainless drill bit for both pros and serious DIYers. In fact, many shops consider these among the best drill bits for drilling metal and the best bits for drilling steel overall, not just stainless. Next, we’ll look at what to reach for when your job calls for even more heat resistance or precision.

Solid Carbide Stub Drills

Where Solid Carbide Stub Drills Shine

Ever found yourself facing stainless steel so tough that even your trusty cobalt bits begin to struggle? That’s when solid carbide stub drills step in as the pro’s choice. These bits are engineered for demanding scenarios—think thick plate, hardened alloys, or jobs where precision and tool life are non-negotiable. Their rigid, short design minimizes deflection and vibration, making them the best drill bits for hardened steel and the clear answer when you need a drill bit that will drill through hardened steel with accuracy.

Pros

- Exceptional wear resistance and edge retention—ideal for abrasive and hard stainless families

- Stub length boosts rigidity, reducing the chance of bit breakage and improving hole accuracy

- Purpose-built for high-temperature, high-hardness environments where lesser bits fail

Cons

- Higher cost compared to HSS or cobalt bits—an investment for critical jobs

- More brittle: sensitive to side loading, chatter, or interrupted cuts

- Prefer rigid setups—best used in drill press or CNC rather than handheld drills

Use Cases

Imagine you’re drilling mounting holes in a stainless fixture, prepping pilot holes for reaming in precision jigs, or tackling fasteners made from hardened stainless. Solid carbide stub drills excel in these situations. They’re also the go-to drill bits for hard metals when you need dimensional accuracy and repeatable performance—think aerospace, medical, or high-end fabrication.

Carbide needs rigidity—clamp the work, reduce overhang, and keep the feed positive.

Technique Tips and Speed/Feed Guidance

To get the most from solid carbide drill bits for stainless steel, combine these best practices:

- Always use mist or flood coolant to control heat and extend tool life

- Secure your workpiece firmly—use a vise or fixture

- Keep the drill overhang as short as possible for maximum stability

- Apply a steady, positive feed—avoid pecking unless chip evacuation is poor

Wondering about the right speed? Carbide bits can run much faster than HSS or cobalt, but they still benefit from controlled feeds and effective chip removal. Here’s a quick reference for optimal surface speeds (SFM) when drilling stainless:

| Stainless Type | Typical SFM | Feed per Revolution (IPR) | Notes |

|---|---|---|---|

| 304/316 (Moderate) | 100 | 0.001–0.002 | Use lower end for thick or tough sections |

| 17-4PH, 316L (Hard) | 75 | 0.0008–0.0015 | Reduce speed for harder alloys |

For most jobs, carbide drill bits for stainless steel deliver the longest tool life and best accuracy, especially when other bits stall or dull quickly. If you’re looking for a drill bit to drill steel that’s both tough and precise, this is your upgrade path.

Next, we’ll look at how advanced coatings and premium cobalt blends push production speed and heat resistance even further—ideal for high-volume or automated stainless steel drilling.

TiAlN Coated M42 Cobalt

Where TiAlN-Coated M42 Cobalt Shines

When you’re running a series of holes in tough stainless—think 304 or 316 plate—and need speed, consistency, and fewer tool changes, TiAlN-coated M42 cobalt drill bits stand out. Imagine a job where HSS bits burn up and even standard cobalt slows down: this is where the extra cobalt content and advanced coating make a real difference. The M42 alloy (with roughly 8% cobalt) boosts hot hardness, while the Titanium Aluminum Nitride (TiAlN) coating gives you the thermal stability and reduced friction that production environments demand. Combined, these features let you push through stainless at higher feed rates and with longer tool life, making these bits a favorite for anyone seeking the best drill bit material for steel in high-volume settings.

Pros

- Outstanding heat resistance for production drilling—less tip softening and longer bit life

- TiAlN coating reduces friction, helps chip flow, and minimizes built-up edge

- Re-sharpenable core—M42 cobalt runs through the bit, not just on the surface

- Widely available in jobber and screw-machine lengths for both handheld and press setups

Cons

- Coating benefits decline after regrinding—TiAlN is a surface layer

- Still needs proper coolant and controlled feed to avoid overheating

- More expensive than M35 cobalt or uncoated bits

Use Cases

Picture a fabrication shop drilling hundreds of holes in stainless brackets, or a maintenance crew running repetitive holes in 316 plate. TiAlN-coated M42 cobalt bits are the go-to for small-run production, especially when drilling speed in stainless steel matters. They’re ideal for drill presses and CNCs but also work well in handheld drills when you need extra durability and are willing to pay for it. If you’re working with hard-to-machine alloys, these bits can handle the heat and pressure where others fail.

Coatings manage heat, but geometry and coolant still do the heavy lifting.

Technique and Buying Tips

- Prioritize 135° split points and polished flutes for reduced walking and improved chip evacuation

- Use cutting oil, mist, or flood coolant—especially at higher drilling speeds in stainless steel

- For handheld work, jobber length offers a good balance of reach and rigidity; for precision, opt for screw-machine (stub) length

| Bit Diameter | Surface Feet per Minute (SFM) | Notes |

|---|---|---|

| Under 1/4" | 70–90 | Use lower end for thick plate or tough alloys |

| 1/4"–1/2" | 60–80 | Reduce speed as diameter increases |

When choosing the best drill bit material for stainless steel or any hard metal, consider the demands of your operation. TiAlN-coated M42 cobalt bits are a smart investment for anyone who values throughput and tool longevity over upfront cost—especially when every minute and every bit counts.

Next, we’ll look at how high-speed steel bits can still play a role for budget-conscious jobs and lighter-duty stainless drilling, rounding out your options for every scenario.

HSS Split Point Twist Drills

Where HSS Split Point Drills Shine

When you need to drill stainless steel on a budget, or only have a few holes to make in thin sheet or light brackets, high-speed steel (HSS) split point twist drills are still a smart, practical option. Sounds risky? Not if you understand the quirks of stainless and respect the right speeds, feeds, and cooling. Imagine you’re installing an HVAC panel, mounting an appliance skin, or making a quick repair—these are the jobs where HSS shines, especially if you’re using a handheld drill and want to keep costs down.

Pros

- Lowest cost and widely available—ideal for occasional or one-off jobs

- Easy to re-sharpen, extending tool life for repeated use

- Short (stub) lengths improve stability and reduce bit wandering for handheld drilling

- Great for pilot holes and thin stainless sheet—perfect for starting holes before stepping up in size

Cons

- Much shorter life than cobalt or carbide on thick or hard stainless

- Risk of work-hardening if RPM is too high or feed is too light—can stall or dull quickly

- Requires disciplined technique: strict control of speed, plenty of coolant, and pecking to clear chips

Use Cases

Picture yourself drilling in stainless steel for HVAC sheet, appliance skins, or mounting light brackets. HSS split point twist drills are also a good fit for pilot holes—start small, then step up to your final size with a larger bit. If you’re assembling a stainless steel drill bit set for general use, including a few high quality drill bits for stainless steel in stub length is a smart move for tight spots or handheld work. These bits are also a go-to for DIYers who want the best drill bit to drill stainless steel without overspending for a full cobalt or carbide set.

Technique Tips: How to Get the Most from HSS Bits

- Mark your hole with a center punch—this helps prevent the bit from skating on the hard surface

- Start with a small pilot hole (1/8 inch or less) to improve accuracy and reduce side load

- Use a pecking motion—drill a little, back out to clear chips, then continue

- Apply cutting oil or lubricant each time you peck to keep the bit cool and reduce friction

- Step up to your final size gradually, repeating the pecking and oiling process

Backing thin stainless with a piece of wood or aluminum helps prevent blowout and distortion. Always clamp your work securely to avoid movement and ensure safety.

Speed and Feed: What Works Best?

There’s no one-size-fits-all RPM, but here’s a simple rule: slower is better when drilling stainless steel. Too fast, and you’ll overheat the bit; too slow, and you risk rubbing instead of cutting, which can also cause work-hardening. For HSS bits, aim for the lowest speed setting on your drill—typically 500–800 RPM for bits under 1/4 inch, and even slower for larger diameters. Always use steady, firm pressure (don’t let the bit just spin on the surface), and watch your chips: they should be silver and curly, not blue or powdery.

| Bit Diameter | Recommended RPM | Notes |

|---|---|---|

| 1/8" (3mm) | 800–1000 | Use lower end for thick plate |

| 1/4" (6mm) | 500–700 | Slow down for larger holes |

| 3/8" (10mm) | 300–500 | Always use coolant |

Remember, the real secret to success with bits for drilling stainless steel is patience and attention to detail. If you hear squealing or see smoke, stop and let things cool—then add more cutting oil and reduce your speed. With the right approach, even basic HSS drill bits for stainless steel can deliver clean, accurate holes for your next project.

Up next, we’ll explore how step drill bits can make quick, clean work of holes in thin stainless sheet—especially when you need multiple sizes or want to avoid burrs and distortion.

Step Drill Bits for Stainless Steel

Where Step Drill Bits Shine

Ever struggled with ragged holes, burrs, or distorted sheet when drilling holes in stainless steel? Imagine needing several hole sizes in a control panel or enclosure—do you really want to swap bits for every step? That’s where a step drill bit for stainless steel becomes your go-to solution. These specialized bits, often made from cobalt or coated with high-temp finishes like TiAlN, are uniquely designed for thin metals. They combine multiple diameters into a single tool, so you can quickly enlarge holes or create new ones without the hassle of changing bits or risking bit grab on breakthrough.

Pros

- Multiple diameters per tool for quick, efficient sizing—one bit covers many needs

- Produces less burr and distortion in thin stainless sheet, reducing cleanup time

- Self-centering design minimizes walking, even on slick or curved surfaces

Cons

- Not suitable for thick plate—most effective up to 6 mm (about 1/4 inch) material thickness

- Requires sharp cutting edges and consistent coolant use to avoid galling and heat damage

- Coatings (like titanium) can wear out if the bit is overheated or used aggressively

Use Cases

Step bits are trusted for:

- Electrical panels, enclosures, and switch cabinets

- Cable gland installations (DIN EN 60423 sizes)

- Knockout replacements and clean, burr-free holes in sheet metal

- Expanding or reaming existing holes in stainless sheet

Technique Tips: Get the Most from Your Step Bit

- Start with a small pilot hole for best accuracy, especially on hard or polished stainless

- Always clamp your workpiece securely—step bits cut fast and can grab loose sheet

- Use a center punch and painter’s tape to prevent walking and protect finished surfaces

- Run at lower RPMs (typically under 1,000 RPM for stainless) to avoid overheating

- Apply cutting oil or coolant at every step—this keeps chips clear and extends bit life

- Peck lightly and back out to clear chips, especially for larger holes

Stop as soon as you reach size; lingering polishes instead of cuts and can harden the edge.

Step Drill Bit Performance Table

| Bit Material/Coating | Max Stainless Thickness | Recommended Applications |

|---|---|---|

| HSS (uncoated) | Up to 4 mm | General sheet, light brackets, plastics |

| HSS-TiAlN or Cobalt | Up to 6 mm | Stainless panels, cable glands, profiles |

Pro Tips for Flawless Results

- Use step bits from reputable metal drill bit sets—quality matters for edge sharpness and coating durability

- For best results, always keep the bit moving; don’t dwell on a single step

- Step bits are self-centering, but for critical jobs, a center punch still helps

In summary, a step bit for stainless steel is your fastest route to clean, burr-free holes in sheet metal. They’re not for thick plate, but for panels, enclosures, and cable gland installations, they outperform twist bits in speed and finish. Next, we’ll see when it makes sense to outsource your holemaking—especially for prototypes or complex patterns that push even the best drills for stainless steel to their limits.

XTJ Rapid Prototyping Holemaking

When to Outsource Your Stainless Steel Drilling

Ever hit a wall trying to drill a perfect hole in stainless, only to snap bits, burn up time, and still fall short on precision? If you’re working on a prototype with tight tolerances, small diameters in thick plate, or complex hole patterns, sometimes the best move isn’t buying another drill bit—it’s outsourcing the job to a specialist. But how do you know when it’s time to make that call?

- Ultra-tight GD&T or critical tolerances (think aerospace, medical, or high-end electronics)

- Small-diameter holes in thick or duplex/hardened stainless—jobs that push standard bits to their limits

- Complex or repeating hole patterns where manual layout and drilling risk compounding errors

- Prototype deadlines where in-house trial and error would delay your project

In these situations, asking “can you drill stainless steel in-house?” is really a question about time, risk, and cost. If the answer is “not with 100% certainty,” outsourcing can save you from wasted effort and inconsistent results.

How Outsourcing Complements Your Shop Tooling

Imagine you need to validate a design with a functional prototype—fast. Instead of wrestling with what drill bit for stainless steel will survive the job, outsourcing to a rapid prototyping partner like XTJ lets you:

- Access advanced CNC machining, injection molding, and die casting for both metal and plastic components

- Choose from over 50 material options—including stainless steel, aluminum 6061, and 7075—to match your application

- Leverage complimentary DFM (Design for Manufacturability) feedback to optimize hole sizes, edge breaks, and countersinks

- Rely on ISO 9001:2015 certified quality control for consistent, production-grade results

- Benefit from rapid turnaround times—keep your development cycle moving without shop bottlenecks

Instead of asking “can you drill through stainless steel with off-the-shelf bits?” for every new prototype, you can focus on design and function, knowing your parts will arrive ready for assembly and testing.

Shop-Level Benefits: Certainty, Speed, and Quality

Why do so many teams turn to outsourcing for stainless steel drilling? Here’s what you’ll notice right away:

- Reduced risk of tool breakage, work-hardening, or dimensional errors

- Access to specialized processes (deep hole drilling, wire EDM, chemical etching) for features standard drills can’t handle

- Faster iteration—get feedback on your design in days, not weeks

- Lower total cost when factoring in time, failed bits, and rework

“When tolerances are tight and time is short, a rapid prototyping partner is your best tool for stainless steel drilling success.”

For many, the question isn’t just “can you drill into stainless steel?” but “how do I do it with zero risk to my timeline and budget?” Outsourcing—especially to a service like XTJ—gives you that certainty, letting you move from concept to production without the headaches of manual trial and error.

Thinking about whether to make or buy your next prototype? If your shop is facing tight deadlines, unforgiving specs, or simply wants to focus on what you do best, consider rapid prototyping as a practical, value-driven alternative to in-house drilling. Next up, we’ll compare all your options side-by-side, so you can make the right call for your project’s needs.

Side by Side Comparison Matrix

Quick Decision Guide

When you’re staring at a tough stainless steel job, the sheer number of drill bit options can feel overwhelming. Do you need ultimate precision, maximum speed, or just a reliable bit that won’t break the bank? Or maybe your project calls for production-grade accuracy that’s tough to achieve in-house. To help you cut through the confusion, here’s a clear, side-by-side comparison of the best drill bits for metal, including a top outsourcing option for complex or high-tolerance work.

| Tool/Service | Best For | Setup Needed | Heat Resistance | Regrindability | Typical Use | Notes |

|---|---|---|---|---|---|---|

| XTJ Rapid Prototyping Service | Precision prototypes, tight tolerances, complex hole patterns | CNC, professional shop | Highest (industrial-grade) | Not applicable | Outsourced parts, functional prototypes, production validation | Certainty for critical jobs; eliminates bit selection and setup guesswork |

| M35 Cobalt Twist Drill | General 304/316 stainless, DIY & shop use | Handheld, drill press | Medium-High | Yes | Brackets, plates, hardware, everyday holes | Balanced value/performance; widely available; easy to sharpen |

| TiAlN-Coated M42 Cobalt | Production runs, high heat, harder alloys | Drill press, CNC | Very High | Yes (coating fades after regrind) | Repetitive holes, small-run manufacturing | Best for speed; coating manages heat; higher upfront cost |

| Solid Carbide Stub Drill | Hardened stainless, thick plate, precision jobs | Drill press, CNC (rigid) | Top tier | Limited (brittle) | Fixtures, jigs, hard fasteners, pilot holes | Highest accuracy & wear resistance; expensive; needs rigid setup |

| HSS Split Point Twist Drill | Thin sheet, budget jobs, pilot holes | Handheld, drill press | Low-Medium | Yes | Appliance skins, HVAC sheet, light brackets | Low cost; strict speed/coolant discipline needed |

| Step Drill Bit (Cobalt/Coated) | Thin stainless sheet, multiple hole sizes | Handheld, drill press | Medium-High | No | Panels, enclosures, cable glands, knockout holes | Clean holes in sheet; not for thick plate |

Speeds and Feeds at a Glance

Choosing what type of drill bit is best for stainless steel is only half the battle—using the right speed and feed is just as important. Here’s a practical overview, so you can match your bit to your job and setup:

| Bit Type | Recommended SFM | Typical RPM (1/4" bit) | Feed Rate | Coolant Needed |

|---|---|---|---|---|

| HSS | 30–50 | 500–700 | Firm, steady | Yes |

| M35/M42 Cobalt | 60–80 | 700–900 | Firm, steady | Yes |

| Solid Carbide | 100–150 | 1000–1500 | Positive, rigid | Yes (flood/mist) |

| Step Drill | 40–60 | 500–800 | Peck, steady | Yes |

- M35 Cobalt Twist Drills: Balanced value and performance for most jobs

- TiAlN-Coated M42 Cobalt: Best for production heat control and speed

- Solid Carbide Stub: Precision and longevity for hard grades or thick plate

Wondering what is the best drill bit for stainless steel for your scenario? Use this matrix as your fast-start guide. If you need certainty—especially on tight tolerances or complex patterns—XTJ’s rapid prototyping service is the go-to. For shop drilling, match your bit to the job, setup, and budget. The best drill bits for metal aren’t always the most expensive—they’re the ones that fit your needs and technique.

Next, we’ll wrap up with a shop-ready checklist and pro tips to ensure every hole you drill in stainless steel is clean, accurate, and frustration-free.

Final Picks and Shop-Ready Checklist

Your Shop-Ready Checklist

When you’re ready to put drill bits for stainless steel to work, a clear, step-by-step plan is your best insurance against frustration, snapped bits, or ruined holes. Whether you’re a DIYer or running a production shop, this checklist keeps you on track for every job:

- Identify your stainless alloy and thickness. (Know if it’s 304, 316, or something tougher—this guides your bit choice.)

- Clamp and back your workpiece securely. Use non-marring clamps and a backing block (wood or aluminum) for thin sheet to prevent distortion or blowout.

- Mark your hole location and center-punch. This prevents the bit from skating and ensures an accurate start.

-

Select your drill bit:

- HSS split-point for thin sheet, light-duty jobs

- M35 cobalt for general 304/316 stainless

- TiAlN-coated M42 cobalt for production or repetitive holes

- Solid carbide stub for hard grades or precision work

- Set your drill to a slow RPM. Always use a lower speed than you would for mild steel—this is the best way to drill through stainless steel without burning up your bit.

- Use firm, steady feed pressure. Don’t let the bit rub—keep it cutting to avoid work-hardening.

- Apply cutting oil or lubricant generously. Reapply often to keep the bit cool and chips moving.

- Peck drill in short bursts. Drill a little, back out to clear chips, then continue. This prevents heat buildup and chip packing.

- Deburr both sides of the hole. Use a countersink or deburring tool for a clean finish.

“If it squeals, you’re rubbing—slow down, feed more, and add coolant.”

Final Picks by Scenario

Not sure what drill bit is best for stainless steel in your situation? Here’s a quick scenario guide to help you match your bit to the job:

- Thin stainless sheet: Step drill bit (cobalt or coated)

- Everyday 304/316 jobs: M35 cobalt twist drill

- Production holes or high heat: TiAlN-coated M42 cobalt

- Hardened or precision work: Solid carbide stub drill

For most users, the best drill bits for stainless are the ones that fit your alloy, thickness, and setup—not just the most expensive option on the shelf. If you need a best drill bit set for stainless steel, consider assembling a mix: a few M35 cobalts for general use, a step bit for sheet, and a carbide for those stubborn, hard jobs.

Pro Tips to Avoid Work-Hardening

You’ll notice that drilling into stainless steel is all about heat control and chip management. Here’s how to avoid the most common pitfall—work-hardening:

- Always use the slowest speed practical for your bit size and material.

- Keep a firm, steady feed—never let the bit just spin without cutting.

- Generously apply cutting oil and clear chips often (peck drilling is your friend).

- Back thin sheet with a block and clamp tightly to prevent vibration and distortion.

- If you hear squealing or see blue chips, stop, cool down, and reset your technique.

When to Consider Outsourcing

Still struggling with complex patterns, tight tolerances, or production-grade prototypes? Sometimes, the best way to drill through stainless steel isn’t to do it yourself. If in-house drilling becomes a bottleneck, XTJ’s rapid prototyping services offer CNC-drilled parts, complimentary DFM feedback, and ISO 9001:2015 quality—so you can focus on what matters most: your design and deadlines. This is especially valuable when drilling into stainless steel with ultra-tight specs or when you need production-grade results, fast.

Before you start your next project, double-check your bit choice, setup, and speeds/feeds against manufacturer data. With the right bit, careful technique, and a little patience, you’ll get clean, accurate holes every time—no more snapped bits, burned edges, or wasted effort. That’s how you win with stainless, whatever the job.

Frequently Asked Questions About Drill Bits for Stainless Steel

1. What type of drill bit is used for stainless steel?

For stainless steel, the most effective drill bits are made from cobalt steel (M35 or M42), solid carbide, or high-speed steel (HSS) with advanced coatings like TiAlN. Cobalt bits offer a balance of durability and cost for most jobs, while carbide bits excel in hardened or thick stainless. Always choose bits designed specifically for metal, with a 135° split point for best results.

2. Are cobalt or titanium drill bits better for stainless steel?

Cobalt drill bits are generally better for stainless steel because they have higher heat resistance and maintain hardness at elevated temperatures, which is essential for tough metals. Titanium-coated bits reduce friction but are less effective when the coating wears off, making cobalt the preferred choice for repeated or demanding stainless steel drilling tasks.

3. Can you drill through stainless steel with a regular drill?

Yes, you can drill through stainless steel with a regular handheld drill if you use the right bit type—preferably cobalt or carbide—and follow proper technique. Use slow RPM, firm feed, and plenty of cutting oil. Clamping your workpiece and peck drilling to clear chips are also crucial for clean, accurate holes.

4. How do you prevent work-hardening when drilling stainless steel?

To avoid work-hardening, use a slow drill speed, maintain steady pressure so the bit cuts rather than rubs, and apply cutting oil generously. Peck drilling—lifting the bit periodically to clear chips—helps keep the material cool and prevents heat buildup that leads to work-hardening.

5. When should I consider outsourcing stainless steel drilling?

Outsourcing is ideal for prototypes with tight tolerances, small holes in thick or hardened stainless, or complex patterns that are difficult to achieve manually. Professional services like XTJ offer CNC precision, rapid turnaround, and quality assurance, saving time and reducing the risk of errors for demanding projects.

-

Posted in

best drill bits for metal, cobalt drill bits, drill bits for stainless steel, how to drill stainless steel, metalworking tips