Rigid Plastic Sheet Selection For Industrial Clarity And Strength

Understanding Rigid Plastic Sheet Basics

What is a Rigid Plastic Sheet?

When you picture a window guard, a machine cover, or a glossy sign face, you’re likely looking at a rigid plastic sheet. But what exactly sets this material apart? In simple terms, a rigid plastic sheet is a flat panel made from a stiff plastic resin that holds its shape under stress and resists bending or warping. Unlike flexible plastics, which can be rolled or folded, rigid plastic sheets maintain their structure even when subjected to pressure or weight. This makes them a go-to solution wherever clarity, strength, and dimensional stability are must-haves.

Common Types and Where They Shine

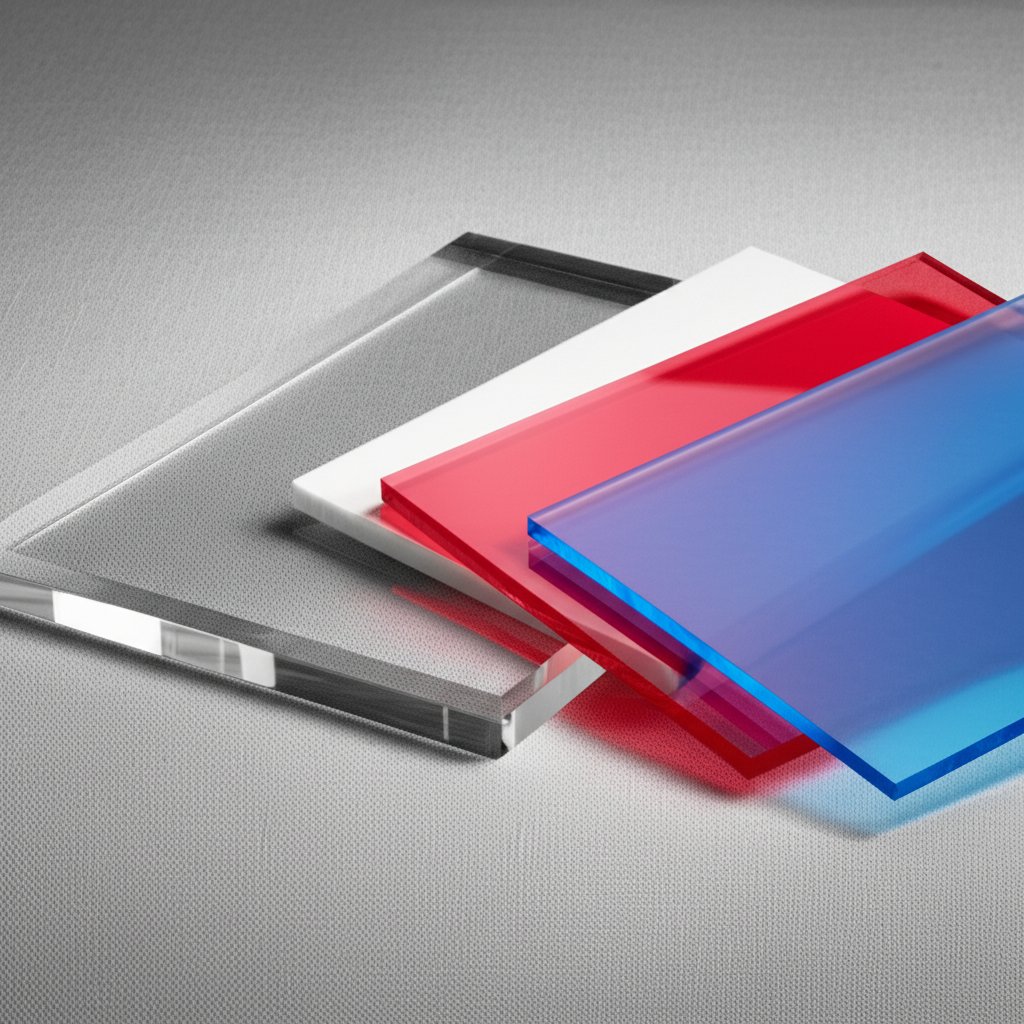

Rigid plastic sheet material comes in many varieties, each with distinct strengths. For example, acrylic (PMMA) is prized for its glass-like clarity and is often used in displays and signage. Polycarbonate is valued in safety glazing for its impact resistance and transparency. HDPE and UHMW are chosen for their durability and chemical resistance in industrial wear applications. PVC and ABS offer toughness and machinability for housings, guards, and panels. PETG, meanwhile, stands out for its easy formability and clarity.

- Clarity: Excellent in acrylic, polycarbonate, and PETG clear plastic sheets for glazing and displays

- Stiffness: Maintains shape in structural and protective panels

- Durability: Resists impact, weather, and chemicals in demanding environments

- Machinability: Can be cut, drilled, routed, and formed for custom applications

- Consistency: Available in a wide range of thicknesses and sizes, from thin covers to hard plastic sheets for heavy-duty use

Typical applications for rigid plastic sheets include:

- Architectural and security glazing

- Signage and point-of-purchase displays

- Machine guards and safety shields

- Equipment housings and enclosures

- Chemical-resistant panels and liners

Key takeaway: The best rigid plastic sheeting balances optical clarity, impact strength, and weatherability—understanding your environment and application needs is crucial to making the right choice.

Rigid vs Flexible Plastic Sheet

Sounds complex? Let’s break it down. Rigid plastic sheeting is engineered for strength and shape retention, making it ideal for structural and protective uses. In contrast, flexible plastic sheet bends and adapts—think of soft covers or films—making it better for wrapping, insulation, or lining where movement or flexibility is required. Choosing the wrong type can lead to cracking, warping, or product failure, so it’s essential to match the material to your project’s demands.

Throughout this guide, you’ll see terms like acrylic, polycarbonate, PETG, PVC, HDPE, UHMW, and ABS. These are the core families of rigid plastic sheet material—each with unique properties and ideal uses. We’ll explore how to select, machine, and maintain these materials so you can make informed decisions for your next project.

Compare Popular Rigid Plastic Sheet Materials

Material Comparison at a Glance

When you’re choosing between different plastic sheets for your project, it’s easy to get lost in a sea of options. Should you reach for acrylic, polycarbonate, or maybe a white plastic sheet for maximum contrast? Let’s break down the most common rigid plastic sheeting materials, so you can make a fast, confident shortlist for your needs.

| Material | Clarity | Impact Resistance | Stiffness | Temp Tolerance | UV Stability | Chemical Resistance | Machinability | Cost | Notes |

|---|---|---|---|---|---|---|---|---|---|

| Acrylic | Very High (92% light transmission) | Moderate | High | Moderate (70–90°C) | Good | Poor | Excellent (cuts, polishes well) | $–$$ | Best for transparent plastic sheet needs; easy to fabricate |

| Polycarbonate | High (90% light transmission) | Very High (200x glass) | High | High (up to 121°C) | Good | Poor | Good (tough to polish edges) | $$$$ | Ideal for safety glazing; strongest among clear plastic sheets |

| PETG | High (90% light transmission) | Good | Moderate | Low (63°C) | Fair | Poor | Excellent (easy to thermoform) | $$ | Good for formed displays; less brittle than acrylic |

| PVC (Rigid) | Opaque or Translucent | Moderate | High | Low–Moderate (50–80°C) | Fair | Good | Good | $$$ | Common as white plastic sheet or clear pvc sheet |

| HDPE | Opaque | High | Moderate | Moderate (up to 80°C) | Good | Excellent | Good (can be tough to cut cleanly) | $$ | Go-to for chemical tanks, polyethylene sheet |

| UHMW | Opaque | Very High | Low–Moderate | Moderate (up to 80°C) | Good | Excellent | Fair (difficult to machine fine details) | $$$ | Low friction, wear sheets; not for clear applications |

| ABS | Opaque | High | Moderate | Moderate (up to 80°C) | Fair | Good | Excellent | $$ | Great for prototyping, tough thermoplastic sheets |

Optical vs Impact vs Cost Tradeoffs

Imagine you need a transparent plastic sheet for a machine guard. You’ll notice acrylic offers unmatched clarity and a glossy finish, but polycarbonate—while slightly less clear—delivers far superior impact resistance. PETG sits in between, offering good clarity and easier forming, but with lower temperature tolerance. Opaque options like HDPE and ABS are better suited for structural or chemical-resistant needs where transparency isn’t required, such as a heavy-duty polyethylene sheet or a delrin sheet for wear surfaces.

Key insight: When selecting a rigid plastic sheet, the higher the optical clarity (like acrylic), the lower the impact resistance compared to polycarbonate. Balance these priorities based on your real-world risks.

Cost is another critical factor. Acrylic and PETG are relatively inexpensive, making them popular for displays and signage. Polycarbonate commands a premium for its toughness. Specialty materials like UHMW and ABS cost more but offer unique performance in wear or structural roles. White plastic sheet and colored PVC are often chosen for visual contrast or branding.

Glossary of Sheet Plastics

- Cast vs Extruded: Cast acrylic is more chemically resistant and has better optical properties than extruded, which is easier to machine and less expensive.

- Tg (Glass Transition): The temperature at which a plastic shifts from rigid to rubbery. Important for thermoforming [source].

- UV-Stabilized: Treated to resist yellowing or degradation from sunlight—critical for outdoor thermoplastic sheets.

- Protective Masking: Temporary film applied to surfaces to prevent scratches during handling and fabrication.

With this comparison, you can quickly match your application—whether you need clear pvc sheet for displays, a tough delrin sheet for wear, or versatile ABS for prototyping—to the right rigid plastic sheet material. Next, we’ll show you a step-by-step flow for choosing the best fit based on your actual environment and performance needs.

Choose The Right Sheet With A Practical Flow

Selection Decision Flow

Wondering how to confidently pick the right rigid plastic sheet for your project? It’s easier when you break it down step by step. Instead of guessing, follow this practical selection flow to quickly narrow your options based on real-world needs like environment, optical clarity, strength, and fabrication method. Here’s how to approach it:

- Indoors or outdoors? Will the sheet face UV rays, moisture, or temperature swings? Outdoor use demands UV-resistant and weatherable materials.

- Is optical clarity required? Do you need a transparent or translucent panel, or is an opaque sheet fine?

- What’s the impact risk? Will the sheet take hits, or is it mainly for display?

- Chemical exposure? Will the surface come in contact with cleaners, solvents, or process chemicals?

- Temperature range? Will it see heat, cold, or thermal cycling?

- Food or medical contact? Does it need to meet FDA or similar standards?

- Machining or forming needs? Will you cut, drill, thermoform, or bond the sheet?

Outdoor and UV Exposure Considerations

When your application calls for outdoor use—think signage, barriers, or architectural glazing—UV resistance and weatherability matter most. Polycarbonate and acrylic excel here, with polycarbonate standing out for demanding environments that need both impact toughness and clarity. If you’re looking for a heavy duty plastic sheet that won’t yellow or crack, UV-stabilized polycarbonate or thick acrylic are top contenders [reference].

Impact and Optical Needs

For high-impact zones, such as machine guards or protective panels, the strongest plastic sheet is often polycarbonate, which can handle repeated blows without shattering. Acrylic offers outstanding clarity for displays and indoor glazing, but is more brittle. If you need a thick plastic sheet for structural support, consider HDPE or ABS, which provide durability and chemical resistance but are typically opaque. UHMW is ideal for wear surfaces where low friction is vital, even if optical clarity isn’t needed.

- Outdoor, high clarity, high impact: Polycarbonate

- Indoor, high clarity, low impact: Acrylic

- Chemical splash shields: PVC or HDPE

- Wear/low friction: UHMW

- General structural panels: ABS, thick HDPE, or PVC

Plastic thickness matters, too. For heavy duty or load-bearing applications, opt for thick plastic sheets—these resist flexing and provide better protection. Flexible plastic sheet may be suitable for liners or covers, but for rigid, long-lasting panels, choose a hard plastic with the correct thickness for your needs.

Tip: The best rigid plastic sheet isn’t the one with the highest single property—it’s the one that best manages your highest-risk failure mode, whether that’s impact, UV, chemical attack, or heat. Always check manufacturer datasheets for compliance with food, medical, or other standards if required.

By following this stepwise flow, you’ll avoid common pitfalls and quickly create a shortlist for your application—whether you need the strongest plastic sheet for safety, a thick plastic sheet for structure, or a material that balances clarity and durability. Next, we’ll dive into chemical resistance, so you can protect your investment during cleaning and exposure.

Chemical Resistance Overview For Rigid Sheets

Chemical Resistance Essentials

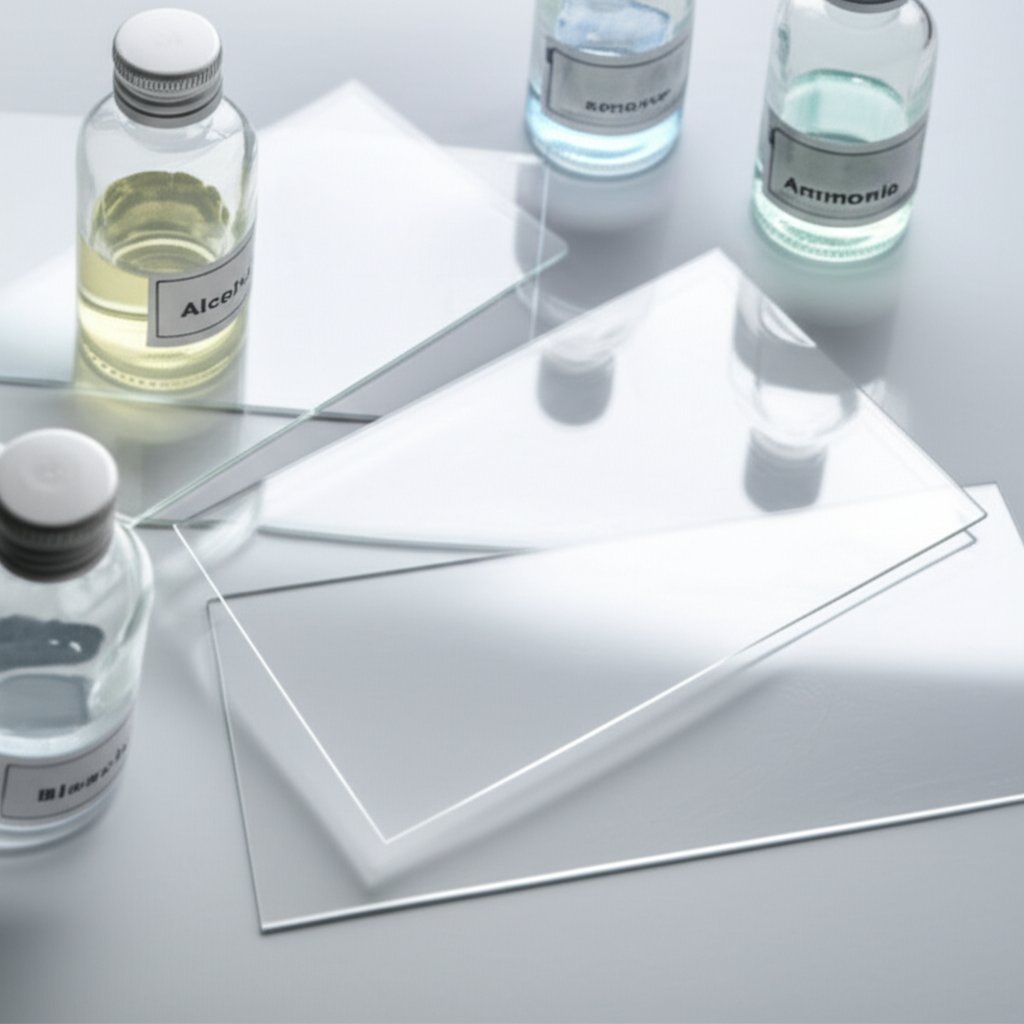

Ever wondered why some rigid plastic sheets hold up to harsh cleaners while others cloud, crack, or even dissolve? When you’re specifying opaque plastic sheeting for a chemical splash guard, or a transparent pvc sheet for a cleanroom, understanding chemical compatibility is crucial. The wrong cleaner can ruin a plastic sheet waterproof barrier, while the right choice ensures long-term clarity and performance.

| Chemical Type | Acrylic | Polycarbonate | PETG | PVC | HDPE | UHMW | ABS |

|---|---|---|---|---|---|---|---|

| Alcohols (Isopropyl, Ethyl) |

Limited (diluted only) |

Compatible (diluted only) |

Compatible | Compatible | Compatible | Compatible | Limited |

| Hydrocarbons (Gasoline, Oil) |

Avoid | Avoid | Avoid | Compatible | Compatible | Compatible | Limited |

| Acids (Dilute, e.g. Vinegar) |

Compatible (dilute) | Limited | Limited | Compatible | Compatible | Compatible | Limited |

| Bases (Mild Alkalis) |

Limited | Limited | Limited | Compatible | Compatible | Compatible | Limited |

| Disinfectants (Hydrogen Peroxide, Bleach) |

Compatible (see notes) |

Compatible (see notes) |

Compatible | Compatible | Compatible | Compatible | Limited |

| Ammonia-based Glass Cleaners | Avoid | Avoid | Avoid | Compatible | Compatible | Compatible | Limited |

Always confirm with your supplier for critical applications.

Cleaner Compatibility and Stress Cracking Risks

Imagine you need to clean a clear pvc sheet after removing a stubborn label. You might ask, “How do you get a sticker off plastic without damaging it?” The answer: avoid aggressive solvents and opt for gentle methods—like using warm, soapy water or diluted alcohol on compatible materials. For acrylic, polycarbonate, and PETG, diluted isopropyl alcohol (up to 30% for acrylic, up to 70% for polycarbonate and PETG) and hydrogen peroxide (3-5%) are generally safe, but always avoid ammonia-based glass cleaners, which can cause clouding or crazing.

Stress cracking is a hidden risk when cleaning or bonding rigid plastic sheeting, especially for amorphous plastics like acrylic, polycarbonate, and ABS. Chemicals—even mild ones—can exploit surface stress from cutting, drilling, or forming, leading to cracks or hazing over time.

Caution: Never use aggressive solvents (acetone, MEK, strong alcohols) on stressed or freshly machined edges—this can trigger environmental stress cracking and premature failure of your pvc hard plastic sheet or other panels.

How to Verify With Datasheets

Sounds complicated? Here’s how to get it right every time, whether you’re working with weatherproof sheeting for outdoor use or clear pvc sheets for indoor barriers:

- Check manufacturer chemical resistance charts for your exact material and chemical type.

- Test the cleaner on a small, inconspicuous area before wide use.

- Rinse thoroughly with clean water after cleaning or chemical exposure.

Remember, chemical resistance is influenced by concentration, temperature, contact time, and the stress level of the plastic. For critical environments—like labs, food processing, or exterior weatherproof sheeting—routine inspection is key. If you spot clouding, cracking, or color change, it’s time to review cleaning protocols or replace the affected panel.

By following these guidelines, you’ll extend the life and clarity of your rigid plastic sheet installation, whether it’s transparent pvc sheet in a hospital, opaque plastic sheeting in a factory, or a pvc hard plastic sheet outdoors. Up next, we’ll explore fabrication tips to help you cut, drill, and finish your sheets with professional results.

Fabrication Tips For Clean Accurate Results

Cutting and Drilling Essentials

Ever wondered, "How do you cut plastic without chipping, melting, or cracking?" Whether you’re working with an 1/8 plastic sheet for signage or a thick panel for machine guards, the right approach makes all the difference. Cutting and drilling rigid plastic sheets—like acrylic, polycarbonate, PVC, or HDPE—requires a few specific techniques and tools to get professional-looking results and reduce wasted material.

- Tool selection: Use fine-tooth blades ("No Melt" blades for saws), sharp high-speed steel or carbide bits for drilling, and jigsaw blades designed for plastics for curved cuts.

- Feed management: Cut or drill at moderate speeds. Too fast, and you risk melting the edge; too slow, and you could chip or crack the sheet.

- Protective masking: Keep the protective film on your rigid plastic sheet during fabrication to prevent scratches and scuffs.

- Chip evacuation: Clear chips frequently to avoid heat buildup and ensure a smoother cut edge.

- Heat control: Pause between cuts or use air cooling to prevent melting, especially with thermoplastics like acrylic and polycarbonate.

- Secure the plastic sheet firmly to prevent shifting.

- Mark your cut or drill line with a non-scratching marker.

- For thin sheets (up to 1/8 inch), score with a utility knife and snap along the line. For thicker sheets, use a table saw or circular saw with a fine-tooth blade.

- When drilling, start with a small pilot hole and gradually increase bit size (step-drilling) for thicker stock.

- Use scrap backing under the sheet to reduce breakout and chipping, especially when drilling through perforated plastic sheet or thin panels.

Safety reminder: Always avoid overheating the plastic—melted edges are hard to repair. Work in a well-ventilated area and wear eye protection when you cut plastic or drill to prevent inhaling dust or fumes.

Routing and Edge Finishing

After cutting, edges may need smoothing or finishing—especially for visible panels or when joining parts. Use a router with a carbide-tipped bit for straight, clean edges. Sandpaper or fine files can remove minor burrs, but always work gently to avoid stress whitening. For clear acrylic, flame polishing can restore gloss, but practice on offcuts first to avoid distortion.

Bonding and Fastening Tips

Joining rigid plastic sheets? The right adhesive and fastening method depend on the plastic type. For polyethylene or HDPE, use a polyethylene adhesive formulated for low-surface-energy plastics. For PVC or acrylic, solvent cements or two-part epoxies work well. When fastening mechanically, use oversized holes and soft washers to allow for thermal expansion and reduce stress cracking. This is especially important for large panels or exterior installations.

Before you start your next project, ask yourself: "How do I cut plastic for the cleanest edge?" or "How can I drill holes in rigid plastic sheet material without cracks?" By following these best practices and testing on scrap pieces, you’ll achieve clean, accurate results—no matter the material thickness or complexity. Up next, let’s look at how to keep your finished panels looking their best with smart maintenance and repair strategies.

Maintenance And Repair For Clarity And Longevity

Safe Cleaning For Clear Sheets

When you invest in clear plastic sheeting or transparent plastic panels, keeping them pristine isn’t just about aesthetics—it’s about protecting their function and value. Sounds simple? The truth is, using the wrong cleaner or tool can leave scratches, haze, or even cause cracks. So, what’s the safest way to clean clear plastic sheets for crafts, glazing, or machine covers?

- Use mild soap and warm water: Mix a small amount of dish soap with water and gently wipe with a soft microfiber cloth. Rinse the cloth often to avoid dragging dirt across the surface.

- Anti-static cleaner: For static-prone panels, an anti-static cleaner designed for plastics helps repel dust and minimize future cleaning needs.

- Avoid harsh chemicals: Never use ammonia-based glass cleaners, acetone, or alcohol in high concentrations, as these can cloud or crack acrylic and polycarbonate sheets.

- Skip abrasive pads: Even a seemingly gentle scrubber can leave permanent marks on a thin clear plastic sheet or clear plastic panels.

For plastics like PVC, HDPE, and polythene, stick to microfiber cloths and anti-static cleaners. Greasy prints? Isopropyl alcohol (diluted) is safe for many rigid plastics, but always test on a small area first and never rub too hard [Plasticsheetsshop].

Scratch Removal And Polishing Basics

Notice a scratch on your plastic cover or display? Don’t panic. Minor surface scratches on acrylic or polycarbonate can often be polished out, restoring the clarity of your transparent plastic. Here’s a practical repair process:

- Clean the area: Remove all dust and debris with mild soap and water; dry with a microfiber cloth.

- Apply a plastic polish: Use a polish formulated for acrylic or polycarbonate (such as Novus or Meguiar’s PlastX). Apply a small amount to a soft, lint-free cloth and buff the scratch in a gentle, circular motion.

- Repeat as needed: For deeper marks, repeat the process or step up to a slightly more abrasive compound, always finishing with a fine polish for maximum clarity.

- For deep scratches: Wet sanding with ultra-fine grit sandpaper (1000–1500+) may be required, followed by polishing. Always keep the area wet and work lightly to avoid heat buildup.

These techniques work well for clear plastic sheets for crafts, signage, and glazing. However, if the scratch is very deep or the panel is badly damaged, professional refinishing or replacement may be the best choice.

Inspection And Replacement Intervals

Imagine you’ve installed a plastic cover on a machine or a window using thin clear plastic sheet. Over time, exposure to sunlight, chemicals, or abrasion can cause yellowing, haze, or surface cracks. Regular inspection helps you spot these issues early:

- Check for yellowing or haze—especially on exterior clear plastic panels exposed to UV.

- Look for fine cracks or crazing, which can indicate chemical damage or stress.

- Inspect mounting points and edges for chips or delamination.

- Replace any panel that has lost clarity or structural integrity.

Tip: Always keep protective films on your rigid plastic sheet until final installation. Schedule periodic inspections for signs of UV yellowing, haze, or cracks to ensure long-term performance.

By following these maintenance and repair practices, you’ll extend the life and clarity of your clear plastic sheeting, whether it’s used in crafts, industrial covers, or architectural glazing. Next, let’s explore how safe handling and installation can further protect your investment and ensure reliable performance for years to come.

Safety Handling And Installation Best Practices

PPE And Ventilation During Machining

When you’re cutting, drilling, or heat-forming stiff plastic sheeting for industrial projects, safety should be your first step—not an afterthought. Imagine trimming hard plastic panels for a large enclosure: airborne dust and fumes can quickly become a hazard. Always suit up with the right personal protective equipment (PPE):

- Eye protection: Safety goggles or a face shield to block chips and dust.

- Hearing protection: Earplugs or earmuffs when using power tools on plastic board or plastic insulation sheets.

- Respiratory protection: A dust mask or respirator—especially when machining plastics that generate fine particles or when heat-forming could release fumes [Acme Plastics].

- Ventilation: Work outdoors or use a fume extraction system indoors to minimize inhalation risks.

Don’t forget to keep the work area clean—frequent cleanup of plastic dust prevents slipping hazards and keeps your project on track.

Safe Mounting And Fastening

Ever installed large plastic panels only to see cracks around the screw holes months later? It’s a common pitfall. The trick is to account for both the material’s rigidity and its need to move with temperature changes. Here’s how you can boost the reliability of your installation:

- Pre-drill oversized holes: Make holes 1.5–2mm larger than the screw diameter to allow for thermal expansion and contraction.

- Use soft washers/gaskets: Neoprene or EPDM washers distribute load and help seal out moisture, especially for exterior plastic sheets.

- Avoid over-tightening: Tighten screws just enough to hold the panel; excessive torque can cause stress cracks around fasteners.

- Choose corrosion-resistant fasteners: Stainless steel screws are best for outdoor or high-humidity environments.

For removable plastic panels, consider fastening systems like Z-clips or quick-release fasteners to minimize wear and enable easy maintenance.

Thermal Movement And Weather Sealing

When installing panels outdoors, thermal movement and moisture management become critical for long-term performance. Polycarbonate and other rigid sheeting expand and contract with temperature swings—if you skip expansion gaps or edge seals, you risk buckling, leaks, or premature panel failure. Here’s a practical checklist for outdoor and weatherproof installations:

- Leave expansion gaps: Allow space at panel edges and joints for thermal movement, especially on plastic board used in sun-exposed areas.

- Seal edges: Use compatible end caps and non-acidic, plastic-safe sealants to block moisture and debris.

- Install vent tape: On multi-wall panels, apply vent tape at the bottom and foil tape at the top to keep internal channels dry and breathable.

- Plan for drainage: Overlap panels correctly and ensure water can run off freely to prevent pooling or leaks.

Key insight: Most failures in rigid plastic sheet installations aren’t due to bad material—they’re caused by installation-induced stresses like over-tightening, skipped expansion gaps, or poor sealing. Careful planning and execution make all the difference.

By following these best practices, you’ll protect both people and property—whether you’re installing plastic insulation sheets in a warehouse, exterior plastic sheets on a facade, or stiff plastic sheeting for a machine guard. Next, let’s look at how to specify and order your panels for precision and long-term performance.

Ordering Checklist And Precision CNC Option

Order And Spec Template

Ever find yourself second-guessing an order for custom plastic panels or a plastic board sheet—wondering if you’ve covered every detail? When it comes to rigid plastic sheet material, accuracy up front saves time, money, and headaches later. Here’s a practical checklist to ensure your order is fabrication-ready, whether you’re sourcing a single sheet of plastic or a full run of plastic sheet board parts.

| Specification Item | Details to Provide | Why It Matters |

|---|---|---|

| Material Family & Grade | Acrylic, polycarbonate, HDPE, PVC, ABS, etc., plus grade if needed | Ensures correct performance and compatibility |

| Thickness & Tolerance | Exact thickness (e.g., 0.236") and acceptable variance (e.g., +/- 5%) | Critical for fit, strength, and compliance |

| Sheet Size or Cut-to-Size | Full sheet or custom plastic cut dimensions (+ tolerances) | Minimizes waste and reduces secondary machining |

| Quantity | Number of parts, sheets, or sets | Accurate quoting and inventory planning |

| Edge Finish | Saw cut, deburred, polished, or CNC-milled | Impacts safety and appearance |

| Hole Patterns | Location, size, and tolerance (provide a drawing if possible) | Ensures precise fit for fasteners and assemblies |

| Protective Masking | One or both sides, removable film | Prevents scratches during shipping and fabrication |

| Surface Finish/Texture | Glossy, matte, textured, anti-glare, etc. | Functional and aesthetic requirements |

| Color or Tint | Clear, white, black, or custom color | Branding, visibility, or light transmission |

| UV Stabilization | Specify if outdoor use is expected | Prevents yellowing and brittleness |

| Certifications | ISO, FDA, UL, RoHS, etc., if needed | Regulatory or industry compliance |

| Delivery Needs | Lead time, packaging, export, or special handling | Ensures safe arrival and meets project schedules |

Tolerances And Edge Finish Notes

Imagine you’ve specified a plastic sheet stock for a machine guard, only to discover the thickness varies more than expected. Tolerances for plastic board sheets are generally wider than for metals, and can differ by material and manufacturing process. For example, cast acrylic may vary by +/- 20%, while extruded polycarbonate or HDPE often holds to +/- 5–10% depending on sheet thickness. When requesting a quote, always:

- Ask for factory thickness and cut tolerances for your chosen material

- Specify if edge finish should be deburred, flame-polished, or CNC-milled

- Request a sample or small run if your project is highly tolerance-sensitive

For saw-cut parts, expect a cutting tolerance of +/- 0.125 inch. CNC machining can achieve much tighter tolerances, but may increase cost—balance your needs for fit and finish with budget and lead time.

When To Use Professional CNC Machining

Not every project needs ultra-precise holes or intricate contours—but when you do, professional CNC machining is the answer. For custom plastic parts with tight tolerances, complex hole patterns, or unique shapes (think: multi-part assemblies, enclosures, or specialty panels), partnering with a dedicated CNC provider can simplify the process. Here’s a step-by-step path to get it right:

- Prepare your drawing: Use CAD software or provide a clear sketch with all dimensions, tolerances, and notes.

- Attach datasheets: Include material specs and any relevant certifications.

- Describe the environment: Note exposure to UV, chemicals, temperature swings, or mechanical loads.

- Submit for review: Send your files to the machining provider and request DFM (Design for Manufacturability) feedback.

- Confirm details: Review the quote, production timeline, and any suggested design tweaks before approving the job.

If you need engineered outcomes beyond basic cutting, consider using XTJ CNC Machining Services. Their advanced 4 and 5-axis machining centers handle tight-tolerance fits (down to +/- 0.005mm) and complex features, with support for over 30 materials—including all major plastic sheet board types. Lead times can be as fast as three days, and ISO certifications ensure quality for demanding industries. This is especially valuable when your project requires precision that standard cutting can’t provide—think medical, aerospace, or high-end industrial applications.

Reminder: Always attach relevant datasheets and clearly describe your environment (UV, chemicals, temperature) when ordering custom plastic parts. This ensures your sheet of plastic performs as intended and reduces costly back-and-forth.

By following this structured approach, you’ll reduce surprises, get exactly the plastic sheet material or custom plastic part you need, and set your project up for success. Whether you’re ordering a simple plastic board sheet or a complex, CNC-machined assembly, clarity and communication at the start make all the difference.

Frequently Asked Questions About Rigid Plastic Sheets

1. What are rigid PVC sheets used for?

Rigid PVC sheets are commonly applied in wall cladding, electrical insulation panels, chemical storage tanks, and hygienic partitions. Their durability, chemical resistance, and ease of fabrication make them suitable for construction, industrial, and food processing environments. These sheets are often chosen for their stability and performance in demanding settings.

2. What is the most rigid plastic sheet?

Polycarbonate is widely recognized as one of the most rigid and impact-resistant plastic sheets available. It combines high stiffness with excellent clarity and can withstand significant force without cracking, making it ideal for safety glazing, protective guards, and heavy-duty industrial applications.

3. How do I choose the right rigid plastic sheet for my project?

Start by assessing your environment (indoor or outdoor), clarity needs, impact risks, chemical exposure, temperature range, and fabrication method. Materials like polycarbonate are best for high-impact and outdoor clarity, while acrylic is ideal for displays. For chemical resistance or structural needs, consider HDPE, UHMW, or PVC. Always check manufacturer datasheets for compliance and suitability.

4. How do you safely clean and maintain clear rigid plastic sheets?

Use mild soap and water with a microfiber cloth for regular cleaning. Avoid harsh chemicals, ammonia-based cleaners, or abrasive pads, as these can scratch or damage the surface. For minor scratches, use a plastic polish designed for acrylic or polycarbonate. Keep protective films on until installation and inspect periodically for yellowing, haze, or cracks.

5. When should I use CNC machining for rigid plastic sheets?

CNC machining is recommended for projects requiring tight tolerances, complex contours, or precise hole patterns that go beyond basic cutting. Services like XTJ CNC Machining offer advanced capabilities for custom parts, ensuring accuracy for demanding industries such as aerospace, medical, or high-end manufacturing.

-

Posted in

industrial plastic panels, plastic fabrication, plastic sheet material, rigid plastic sheet