Rigid Plastic Materials Matrix: Compare ABS, PC, PVC, More

Understanding the Fundamentals of Rigid Plastic

When you hear the term rigid plastic, what comes to mind? Maybe it’s a sturdy bottle, a protective panel, or a durable tool handle. But what is rigid plastic, really, and how does it differ from flexible plastics that you might find in bags or wraps?

What is rigid plastic?

Rigid plastic refers to a broad category of polymer materials that keep their shape under normal use and resist bending or deformation. Unlike flexible plastics, which are easily twisted or compressed, rigid plastics offer structural integrity and a firm feel. You’ll notice them in applications where protection, stability, or a premium appearance is required—think containers, trays, machine guards, or automotive parts. Importantly, rigid plastic is not a single material, but a behavior observed across many types of polymers. ABS, polycarbonate, PVC, and acrylic are just a few examples that fall under this umbrella, each with their own unique blend of properties.

How plastic rigidity is measured

Sounds complex? Fortunately, engineers have clear ways to quantify plastic rigidity. The two most common metrics are flexural modulus (measured by ASTM D790 or ISO 178) and tensile modulus (measured by ASTM D638 or ISO 527). These tests evaluate how much a plastic resists bending and stretching under load. The higher the modulus, the stiffer the plastic. For example, a rigid plastic will have a much higher flexural modulus than a material designed for plastic flexibility, such as a film or sheet used in packaging. These test standards ensure consistency and comparability across materials, making them essential references for material selection.

Rigid versus flexible plastics

So, how do rigid plastics stack up against flexible plastics? The main differences come down to:

- Stiffness: Rigid plastics maintain their shape under load, while flexible plastics bend or stretch easily.

- Impact resistance: Some rigid plastics are tough and resist cracking, while others may be brittle. Flexible plastics often absorb impacts by deforming.

- Heat deflection: Rigid plastics generally perform better at higher temperatures before softening or warping.

- Chemical resistance: Both categories can offer good chemical resistance, but it varies widely by polymer type.

- Machinability: Rigid plastics can be cut, drilled, or milled with precision, making them suitable for structural or load-bearing parts.

When deciding if a rigid plastic is right for your application, consider the working environment. For outdoor or high-impact uses, prioritize materials with proven impact toughness and UV stability. In chemical processing or food contact, chemical resistance may be your top concern. Always consult manufacturer technical data sheets or trusted resources like MatWeb to compare properties and ensure suitability for your needs.

Key takeaway: The best rigid plastic for your project depends on the specific environment and requirements—not just a single property. Evaluate all relevant factors before making your selection.

(How Do Rigid Plastics Stack Up?

Imagine standing in front of a wall of plastic materials, each labeled with a different name: ABS, polycarbonate, acrylic, HDPE, PVC, and more. How do you compare these kinds of plastic and choose the right one for your project? The answer lies in understanding the core properties that define types of hard plastic materials—and seeing them side by side.

Material families for rigid plastic applications

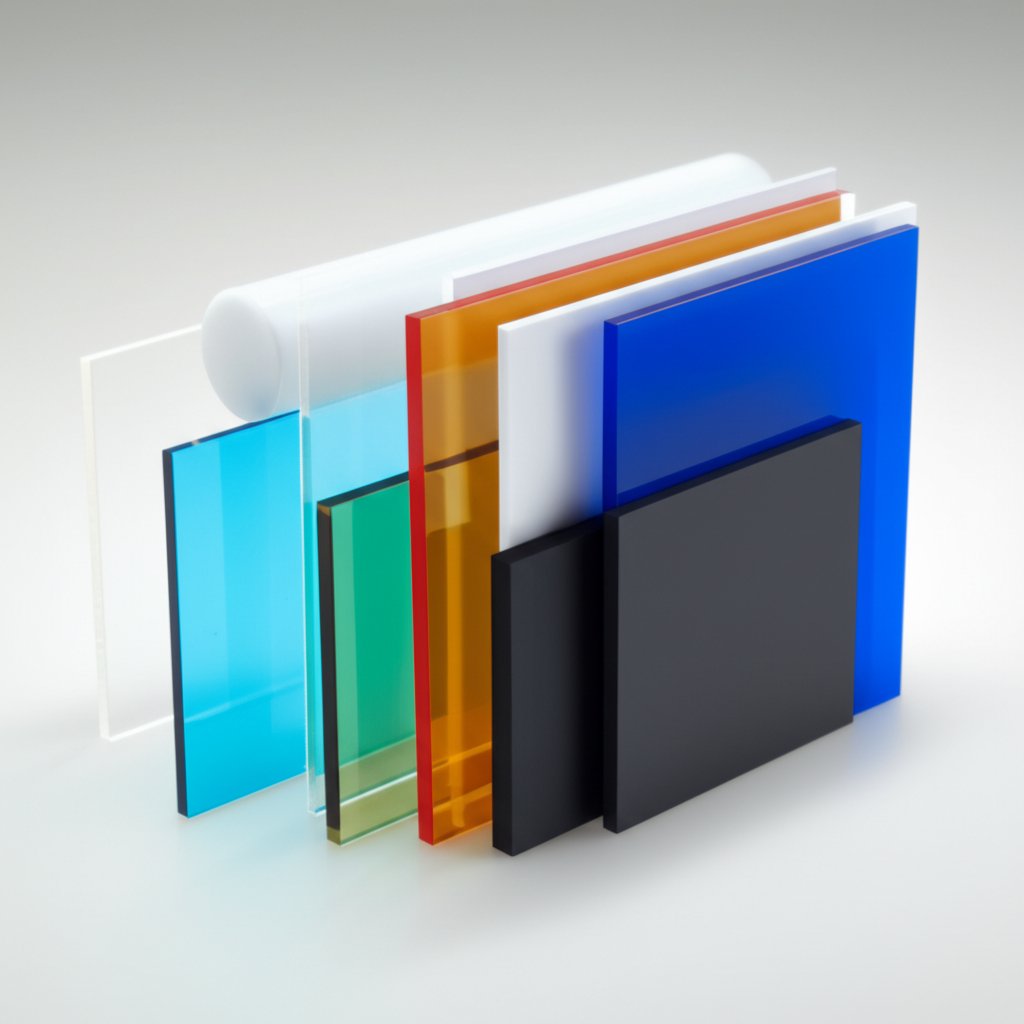

Rigid plastics are not a single material, but a menu of options spanning several major polymer families. Each brings a unique blend of strength, toughness, chemical resistance, and workability. Whether you need tough plastic for impact resistance, optically clear panels, or cost-effective sheet stock, there’s a match among these types of plastic sheet material:

| Material | Tensile Strength (psi) ASTM D638 |

Flexural Modulus (psi) ASTM D790 |

Izod Impact (ft-lb/in) ASTM D256 |

Heat Deflection Temp (°F) ASTM D648 |

Density (g/cm³) | UV Resistance | Chemical Resistance | Machinability | Clarity | Common Applications |

|---|---|---|---|---|---|---|---|---|---|---|

| ABS | 4,100 | 304,000 | 7.7 | 200/177 | ~1.04 | Moderate | Good | Good | Opaque | Housings, panels, toys |

| Acrylic (PMMA) | 10,000 | 480,000 | 0.4 | 195 | ~1.19 | Excellent | Fair | Fair | High | Glazing, signage, displays |

| Polycarbonate (PC) | 9,500 | 345,000 | 12–16(Some grades can reach 18 ft-lb/in or higher) | 280/270 | ~1.20 | Good | Fair | Good | High | Machine guards, safety glazing |

| HDPE | 4,000 | 200,000 | – | 172 | ~0.96 | Excellent | Excellent | Fair | Opaque | Cutting boards, tanks, outdoor parts |

| PETG | 7,700 | 310,000 | 1.7 | 164/157 | ~1.27 | Good | Good | Good | High | Machine guards, display fixtures |

| POM (Acetal/Delrin) | 10,000 | 420,000 | 1.5 | 336/257 | ~1.41 | Poor | Excellent | Excellent | Opaque | Bearings, gears, precision parts |

| PVC (Rigid) | 7,500 | 481,000 | 1.0 | 158 | ~1.38 | Excellent | Excellent | Good | Opaque | Piping, window frames, panels |

| Polypropylene (PP) | 5,400 | 225,000 | 1.2 | 210 | ~0.91 | Good | Excellent | Fair | Translucent | Chemical tanks, labware |

| HIPS | 3,500 | 310,000 | 2.8 | 196 | ~1.05 | Poor | Fair | Excellent | Opaque | Signs, trays, packaging |

Actual values may vary by grade and supplier.

Comparing performance across common resins

Let’s break down what you’ll see in this table:

- Tensile strength and flexural modulus show how much force a material can withstand before breaking or permanently bending. Polycarbonate and acrylic offer high strength, while HDPE is valued for its toughness despite lower stiffness.

- Izod impact measures resistance to sudden shocks—polycarbonate excels here, making it a go-to for safety shields and guards.

- Heat deflection temperature tells you how hot a material can get before it starts to lose rigidity. Acetal and polycarbonate hold up well under heat, while PETG and HDPE are better suited to moderate temperatures.

- UV and chemical resistance are key for outdoor and industrial use. Acrylic and HDPE are outstanding for UV, while POM and PVC resist many chemicals.

- Machinability and clarity affect how easily you can fabricate the material and whether it can be used for transparent applications.

Trade-offs between clarity, toughness, and cost

Choosing between these types of plastic sheets means weighing priorities. For example:

- Need optical clarity? Acrylic and polycarbonate are leaders, but acrylic is more brittle while polycarbonate is tougher and more expensive.

- Looking for chemical resistance? Acetal, PVC, and polypropylene excel, but clarity and UV resistance may be limited.

- On a budget? HIPS and HDPE are cost-effective for large panels or disposable items but may lack high-end performance.

Each of these types of hard plastic materials brings unique strengths to the table. The best choice depends on your application’s demands—mechanical, thermal, optical, and environmental.

Remember: Actual grades, fillers, and manufacturing processes can significantly alter performance. Always confirm with the supplier’s most recent technical data sheet before finalizing your design or procurement.

A Step-by-Step Workflow for Selecting the Right Rigid Plastic

Choosing the best material rigid for your project can feel overwhelming—especially with so many rigid type plastics, each offering a different balance of strength, weight, and resistance. How do you narrow it down to the ideal durable plastic material or lightweight plastic for your needs? Here’s a proven, risk-reducing workflow that engineers and buyers rely on to make confident, data-driven decisions.

Step by step workflow for choosing a rigid plastic

-

Define your requirements and constraints. Start by listing what your part must do and where it will operate. Consider:

- Mechanical loads (static, impact, fatigue)

- Temperature range (operating and peak)

- Chemical exposure (cleaners, fuels, process fluids)

- UV/weather exposure (indoor vs. outdoor)

- Transparency or color needs

- Flammability and regulatory standards (FDA, UL, etc.)

- Fabrication or molding method (machining, thermoforming, injection molding)

- Shortlist 3–5 candidate materials. Use manufacturer technical data sheets or trusted databases like MatWeb to compare potential strong plastic material options. Focus on those that meet your top priorities—whether it’s a tough plastic material for impact, or a light plastic material to reduce weight.

- Build a decision matrix and weight your criteria. List your candidate resins as rows, and your most important properties as columns (see template below). Assign weights to each property based on your priorities. Populate the table with sourced data or qualitative ratings (e.g., High/Medium/Low), always referencing your sources.

- Prototype and test as needed. Fabricate samples and test them using relevant ASTM or ISO methods. For example, use ASTM D638 for tensile strength or ASTM D790 for flexural modulus. Testing in real-world conditions helps validate your assumptions and avoid surprises.

- Finalize your resin and form factor. Review your test results and supplier feedback. Confirm your choice with a final review of cost, availability, and manufacturability. Only then move to full-scale procurement or production.

Decision matrix to balance trade offs

| Material Candidate | Stiffness (Flexural Modulus) | Impact Toughness | Chemical Resistance | UV Stability | Cost | Machinability | Weight | Other (e.g., Color, Regulatory) |

|---|---|---|---|---|---|---|---|---|

| ABS | Medium | High | Good | Moderate | Low | Good | Medium | UL 94 HB |

| Polycarbonate | High | Very High | Fair | Good | High | Good | Medium | UL 94 V-2 |

| HDPE | Low | Medium | Excellent | Excellent | Low | Fair | Low | FDA grades available |

Weight columns according to your project’s priorities.

From prototype to validated material

Once you’ve built your matrix, it’s time to move from theory to practice. Prototype your part in two or more top-ranked materials. Test for mechanical strength, chemical compatibility, and environmental durability based on your real-world use case. If your application needs a durable plastic material for repeated impact, but also needs to be a lightweight plastic for portability, compare both properties side by side and run targeted tests.

Joining and finishing: Do’s and don’ts

- Do use mechanical fasteners (screws, bolts, rivets) with proper washers to distribute load and avoid stress concentrations.

- Do use adhesives or solvent welding only with resins compatible with the bonding agent—check the resin supplier’s recommendations.

- Don’t overtighten fasteners or use countersunk heads that can introduce tensile stress and cause cracking.

- Don’t mix dissimilar materials without allowing for different thermal expansion rates—use slotted holes for flexibility.

- Don’t skip prototyping and stress testing before committing to a material or joining method.

Key takeaway: A structured, data-driven selection process—anchored by technical data, prototyping, and application-specific testing—will help you find the right balance of performance, cost, and manufacturability for any rigid plastic application.

Ready to move from material selection to form factor? Next, we’ll explore how to choose the right sheet thickness and handle fabrication for your chosen plastic.

Forms, Thickness, and Span

When you’re designing a guard, a cover, or a structural panel, the form and thickness of your rigid plastic sheet can make or break your project’s success. But with so many options—sheets, boards, rods, panels, and a wide range of thicknesses—how do you pick the right one? Let’s break it down with practical insights and real-world examples.

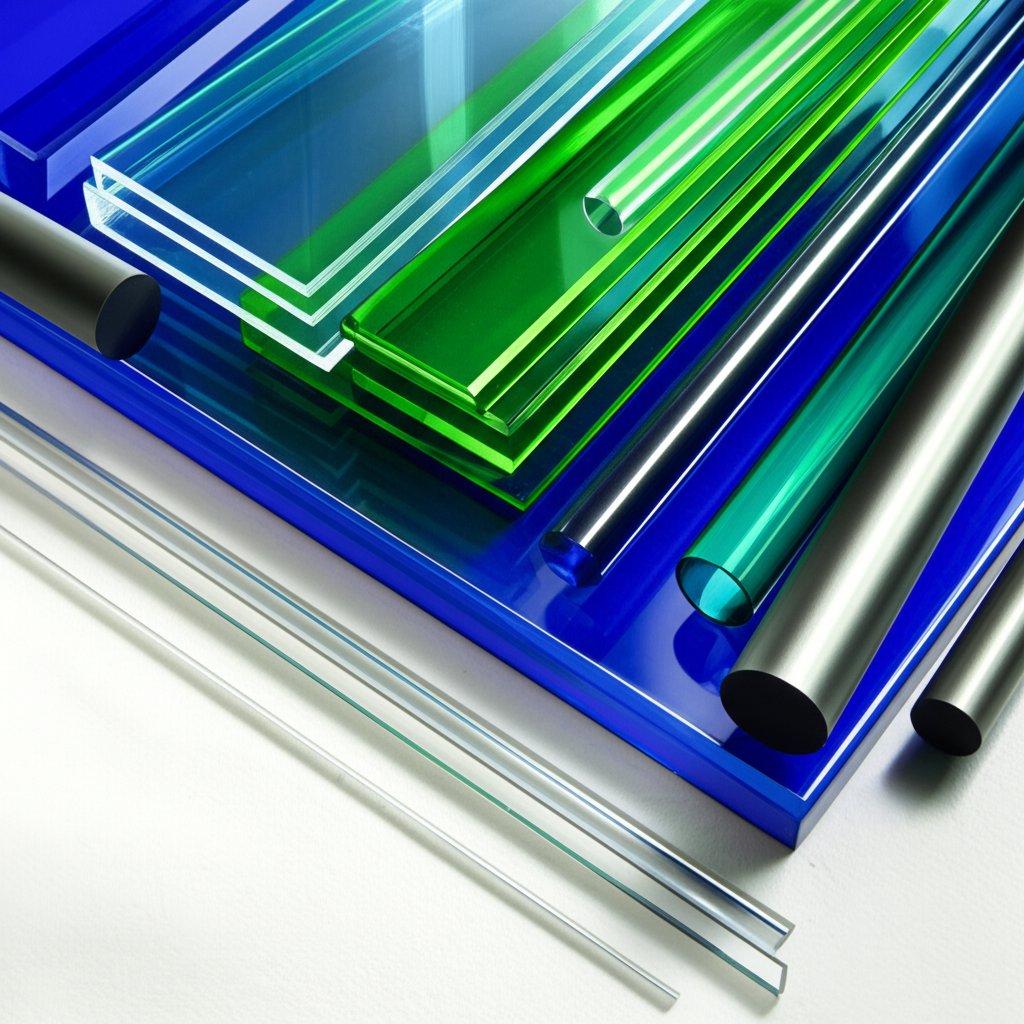

Choosing Between Sheets, Boards, and Panels

Imagine you’re outfitting a machine with a protective cover. Should you use a thin, clear sheet or a thick, heavy-duty panel? Here’s what you need to know:

- Sheets: Typically flat and available in standard sizes (like hard plastic sheets 4x8), sheets are the go-to for guards, window glazing, and signage. They’re easy to cut, drill, and fabricate.

- Boards: Thicker than sheets, boards offer more rigidity for structural supports, mounting plates, or equipment bases.

- Panels: This term is often used interchangeably with sheets and boards, but usually refers to larger, pre-cut sections for walls, partitions, or architectural uses.

- Rods and Tubes: Ideal for bushings, spacers, and load-bearing shafts, but less common for flat coverage.

Most rigid plastic sheets are available in a variety of grades, colors, and surface finishes, allowing you to tailor the look and performance to your needs.

Thickness Selection and Span Considerations

How thick should your sheet of hard plastic be? It depends on a few key factors:

- Span: The wider the unsupported distance, the thicker your sheet should be to avoid sagging or excessive deflection.

- Expected Load: Heavier loads require thicker, stiffer sheets to maintain integrity.

- Deflection Tolerance: For safety guards or covers, minimal flexing is often desired. For light diffusers or display panels, some flexibility might be acceptable.

- Safety Factor: Always consider a margin for unexpected impacts or loads.

Common thicknesses range from thin rigid plastic sheet (as little as 0.06 inch) up to 6 inches for heavy-duty applications. Popular sizes include 1/4 plastic sheet and 1/2 inch plastic sheet, which balance strength and workability for many industrial and architectural uses.

| Thickness Range | Typical Use Cases | Span/Deflection Notes | Machining/Fabrication Tips |

|---|---|---|---|

| 0.06 – 0.125 inch (Thin sheet) |

Light covers, retrofit lighting, signage, display windows | Best for short spans; may flex under load | Easy to cut and thermoform; handle with care to avoid cracking |

| 0.25 inch (1/4 plastic sheet) |

Machine guards, medium-duty panels, protective screens | Good for moderate spans and light impacts | Can be drilled, routed, or edge-finished; deburr edges for safety |

| 0.5 inch (1/2 inch plastic sheet) |

Structural supports, heavy-duty guards, equipment bases | Suitable for longer spans and higher loads | Requires sharp tools; may need pre-drilling to avoid stress cracking |

| 1 inch and above | Load-bearing walls, dock fenders, architectural panels | Minimal deflection, even over wide spans | Best cut with industrial saws; consider weight for handling |

If your application has strict deflection or safety requirements, consult engineering tables or supplier calculators to select the right thickness for your hard plastic sheets.

Handling and Cutting Rigid Plastic Sheet

Working with rigid plastic sheets is straightforward with the right approach:

- Use sharp, carbide-tipped tools for clean cuts and drilled holes.

- Deburr edges after cutting to prevent injury and reduce crack initiation points.

- For thicker sheets, consider pre-drilling and gradual feed rates to avoid heat buildup and stress.

- Thermoforming is possible with some plastics (like PETG or polycarbonate); always follow material-specific guidelines.

- Apply protective masking during fabrication to preserve surface finish.

- For load-bearing or safety-critical parts, allow for stress-relief or annealing as recommended by the material supplier.

These practices help maintain the strength and appearance of your sheet of hard plastic throughout its service life.

- Checklist for Ordering Rigid Plastic Sheets:

- Dimensions (length x width)

- Thickness and tolerance

- Protective masking (one or both sides)

- Surface finish (matte, gloss, textured, etc.)

- Color or transparency

- Quantity and cut-to-size needs

Key takeaway: The right form and thickness of rigid plastic sheet depends on your application’s span, load, and durability needs. Always match your selection to engineering requirements, and consult supplier resources for detailed recommendations.

Next, we’ll explore best practices for machining and finishing rigid plastics—so you can turn your chosen sheet into a high-performance, finished part.

CNC Machining Best Practices for Rigid Plastics

Ever tried to machine a solid plastic sheet and ended up with melted edges, warping, or cracks? If so, you’re not alone. Machining hard plastic materials like ABS, polycarbonate, PMMA (acrylic), HDPE, POM (Delrin), PVC, and PETG requires a different approach than working with metals or softer polymers. The right techniques can transform a stiff plastic sheet into a precision part—without costly mistakes or rework.

Machining Rigid Plastic Without Stress Cracking

Imagine you’re milling a panel from laminated plastic sheet material for a machine guard. Unlike metals, these plastics are more sensitive to heat and cutting forces. Excessive speed, dull tools, or poor chip evacuation can lead to stress cracking, crazing, or even catastrophic part failure. Here’s how to avoid those headaches:

- Use sharp, dedicated tooling: Carbide or diamond-coated cutters with polished flutes minimize friction and heat. Sharp tools are especially important for brittle plastics like PMMA and stiff plastics such as POM or polycarbonate.

- Favor climb milling over conventional milling: This reduces chip load and helps achieve smoother cuts, especially on flat plastic sheet stock.

- Control feeds and speeds: Softer plastics (like HDPE or ABS) can handle higher cutting speeds, but lower speeds are safer for harder, glassy plastics. Always check the resin’s technical data sheet or use a feeds and speeds calculator tailored for plastics.

- Apply coolant or air blast as recommended: Many plastics have low thermal conductivity and will melt or deform if heat builds up. Use compressed air or a resin-compatible coolant to keep the cut zone cool—but always verify compatibility first to prevent crazing or chemical attack (CNCCookbook).

- Employ peck drilling for chip evacuation: When drilling, retract the bit periodically to clear chips and reduce heat. This is especially important for durable plastic materials like POM, which can bind or crack if chips aren’t removed efficiently.

- Design stable workholding and fixturing: Plastics are more elastic than metals and can deform under clamping force. Use soft jaws, vacuum tables, or custom fixtures to secure the part without introducing internal stress.

- Minimize residual stress: For thick or hard plastic material sections, consider annealing before and after machining to relieve internal stress and prevent future cracking.

Tolerance, Surface Finish, and Inspection

How precise can you get with CNC-milled rigid plastics? While tolerances of ±0.05 mm are achievable for many plastics, tighter tolerances (down to ±0.01 mm) require careful material selection, stable fixturing, and sometimes temperature-controlled environments. POM and PEEK are known for excellent dimensional stability, making them ideal for high-precision parts. However, softer plastics may deform or expand with heat, so specify tight tolerances only when truly needed.

Surface finish also matters—especially for display covers, lenses, or sealing surfaces. As-machined finishes are typically Ra 3.2–1.6 µm, but polishing, flame polishing (for PMMA), or UV coatings can achieve near-mirror gloss. Some plastics, like UHMW or PTFE, remain matte due to their structure and cannot be polished to a high shine. For plastic tough components, prioritize function over appearance unless clarity or gloss is critical.

Key takeaway: Achieving ultra-tight tolerances and fine finishes in rigid plastics demands stable fixturing, careful process control, and sometimes multi-axis CNC capability. For quality-critical parts, consider experienced suppliers with advanced equipment and certifications such as ISO 9001:2015 and IATF16949. Services like XTJ CNC Machining offer 4- and 5-axis machining centers, rapid turnaround, and engineering support for complex plastic parts. Always compare multiple suppliers to ensure the right fit for your application.

When to Prototype Before Scaling

Imagine launching a new product only to discover your solid plastic sheet part warps or cracks during assembly. Prototyping in the actual resin and geometry is essential—especially for stiff plastics or parts requiring tight tolerances. Use prototypes to validate your machining strategy, check for warping or stress cracking, and refine fixturing or finishing steps. For multi-material or laminated plastic sheet material assemblies, prototyping helps identify potential bonding or compatibility issues before full production.

By mastering these machining best practices, you’ll unlock the performance and reliability of any hard plastic material—from a simple flat plastic sheet to intricate, high-precision components. Next, we’ll cover how to keep those finished parts looking and performing their best with proper maintenance and cleaning.

Maintenance, Cleaning, and Chemical Resistance

Ever wondered why some 4x8 sheets of clear plastic stay crystal-clear for years, while others turn cloudy or crack? The difference often comes down to how you clean, maintain, and protect your rigid plastic components. Whether you’re working with a durable acrylic sheet, polycarbonate guard, or a hard black plastic sheet outdoors, following the right care routine is essential for longevity and performance.

Cleaning and Care for Rigid Plastic

Sounds simple, but not all cleaners are created equal. Using the wrong product can cause irreversible damage—especially to ultra clear plastic sheeting or heavy clear plastic sheet used in display windows and machine guards. Here’s how to do it right:

- DO use a solution of mild soap or detergent with lukewarm water. Apply with a clean, soft cloth and rinse thoroughly.

- DO dry by blotting with a damp cloth or chamois—never rub aggressively.

- DO remove protective films just before installation to avoid scratches or dust attraction from static.

- DO use anti-static cleaners or a soft, damp microfiber to reduce dust buildup on plastic sheet outdoor installations.

- DON’T use window sprays, kitchen scouring powders, or solvents like acetone, gasoline, benzene, or alcohol—these can cause surface crazing or cracks, especially on acrylic and polycarbonate.

- DON’T dry rub with gritty or dirty cloths, which can scratch the surface.

- DON’T use abrasive pads or cleaners on any heavy duty sheets of plastic—they’ll dull the finish and reduce clarity.

Chemical Compatibility and Stress Cracking

Imagine using a disinfectant on your durable acrylic sheet only to find cracks forming days later. This is often due to a phenomenon called environmental stress cracking (ESC), where certain chemicals—combined with residual stress from machining or forming—cause plastics to fail prematurely.

To avoid surprises, always check the resin manufacturer’s technical data sheet for chemical resistance, or refer to standards like ASTM D543 when evaluating exposure to oils, fuels, acids, or cleaning agents. Below is a general guide—always confirm with your supplier for your specific grade:

| Chemical Category | Example Chemicals | Typical Compatibility (Acrylic/PC/HDPE/PVC) | Notes |

|---|---|---|---|

| Alcohols | Ethanol, Isopropanol | Varies (Acrylic: Poor, PC: Fair, HDPE/PVC: Good) | Can cause crazing in acrylic; check data sheet for PC |

| Hydrocarbons | Hexane, Kerosene | HDPE/PVC: Good; Acrylic/PC: Fair | May remove grease; avoid prolonged contact |

| Acids | Sulfuric, Hydrochloric | HDPE/PVC: Good; Acrylic/PC: Poor | Use caution; always rinse thoroughly |

| Bases | Ammonia, Sodium Hydroxide | HDPE/PVC: Good; Acrylic/PC: Poor | Strong bases can attack acrylic and polycarbonate |

Ratings are qualitative; always verify with the resin supplier or ASTM D543 testing for your application.

Protecting Optical Clarity and Surface Finish

Want your ultra clear plastic sheeting to stay flawless? Prevention is key:

- Store 4x8 sheets of clear plastic flat, in a clean, dry area, with masking in place until fabrication or installation.

- Use only recommended polishes or scratch removers for minor blemishes—never sand unless directed by the manufacturer.

- For plastic sheet outdoor use, choose UV-stabilized grades and clean regularly to minimize buildup of grime or pollutants.

Key takeaway: Environmental stress cracking is often a result of both chemical exposure and residual processing stress. For critical applications, consider annealing or stress-relief—especially after machining or forming—to extend the service life of your rigid plastic parts.

By following these care and compatibility guidelines, you’ll maximize the clarity, strength, and durability of your rigid plastics in any environment. Next, we’ll explore recycling and end-of-life handling to ensure your materials have a sustainable future.

Recycling Processing and End Markets for Rigid Plastics

Ever wondered what happens to a rigid plastic container after you toss it in the recycling bin? The journey is more complex than you might think, with each step designed to maximize material recovery and minimize contamination. Understanding this process is key to making better choices—whether you’re designing rigid plastic packaging, managing waste, or simply trying to recycle that old plastic rigid sheet from your last project.

How Rigid Plastics Are Recycled

Imagine a mountain of mixed recyclables arriving at a Material Recovery Facility (MRF). Here’s how rigid plastic sheeting, containers, and bulky items are processed for a new life:

- Intake & Initial Sorting: Trucks deliver post-consumer materials to the MRF, where everything is tipped onto the floor and loaded onto conveyors (Plastics Recycling).

- Visual Inspection & Pre-Sorting: Workers remove obvious contaminants—think electrical cords, food, and plastic bags—that could jam equipment or degrade the recycled material.

- Removal of Contaminants: Non-recyclable items and problematic plastics (like film or black plastics) are separated out. This is critical because contaminants increase costs and can lead to rejected bales.

- Size Reduction: Rigid items are ground or shredded into smaller pieces, making downstream sorting and washing more efficient.

- Washing: The shredded plastic is washed in hot water and detergent to remove dirt, adhesives, and labels. This step is vital for high-quality recycled output.

- Float-Sink or Optical Sorting: Different plastics are separated by density (float-sink tanks) or by optical sorters that identify resin types and direct them with puffs of air. For example, a plastic rigid sheet made of HDPE will float, while PET will sink.

- Final Quality Control: Robotic arms or human sorters conduct final checks to remove lingering contaminants, ensuring only the correct polymers move forward.

- Pelletizing: Clean, sorted plastic is melted, filtered, and extruded into pellets. These pellets serve as feedstock for new products.

- Shipment to End Markets: The recycled plastic pellets are shipped to manufacturers who use them to create new products—completing the recycling loop.

Sorting Contaminants and Acceptance Criteria

Not everything you toss in the bin is destined for recycling. Facilities follow strict guidelines—like those from ISRI and the Association of Plastic Recyclers—to decide what stays and what goes. Here are common contaminants that can downgrade or even reject a load of rigid plastics:

- Food residue or leftover liquids

- Labels, adhesives, or paper/cardboard stuck to items

- Metal fasteners, screws, or handles (unless specifically allowed)

- Mixed materials (plastic bonded to metal, glass, or electronics)

- Plastic bags or film mixed with rigid items

- Black plastics, which can defeat optical sorters

- Prohibited resins (e.g., PVC, polycarbonate, ABS in certain bales)

- Hazardous material containers, foam, or biomedical waste

For example, the ISRI Mixed Bulky Rigid Plastic spec allows large PP, HDPE, and LDPE items but prohibits PVC, polycarbonate, and ABS rigid plastics in these bales. Contamination above 15% by weight can result in rejection. Always check with your local MRF or buyer, as acceptance criteria can vary by region and over time.

End Markets for Recycled Rigid Polymers

After all that sorting and cleaning, where does recycled rigid plastic sheeting go? While it depends on the resin type and purity, here are some typical end markets:

- Lumber substitutes: Recycled HDPE and PP are often used for composite decking, park benches, and landscaping timbers.

- Containers: Where regulations permit, recycled plastics can be made into new bottles, pails, or storage bins.

- Industrial components: Recycled resin finds new life in pipe, conduit, pallets, and even new plastic rigid sheet products.

- Other applications: Automotive parts, crates, and infrastructure products may also incorporate recycled content.

These markets help close the loop, creating demand for recycled content and supporting the economics of collection and processing.

Recycling tip: To improve recycling outcomes, always rinse containers, remove non-plastic parts, and check the resin code before placing items in the bin. Proper preparation increases the odds that your plastic rigid sheet or container will be successfully recycled into new products.

By understanding how rigid plastics are collected, sorted, and processed, you’re better equipped to design, use, and dispose of these materials responsibly. Next, we’ll provide tools and checklists to help you specify and source rigid plastic materials with confidence.

Procurement Tools and Supplier Comparison Checklist for Rigid Plastic Materials

When you’re ready to turn your design into a finished part, how do you ensure you get the right plastic sheet material—with no surprises in quality, finish, or performance? A clear, well-structured procurement process is your best defense against delays, rework, and unexpected costs. Let’s walk through a toolkit you can use to specify, compare, and inspect rigid plastic materials with confidence.

Copy-Ready Procurement Spec: What to Include

Sounds complex? It doesn’t have to be. Imagine you’re ordering a plastic sheet board for a machine guard or a pvc sheet rigid for a chemical tank. Here’s a sample spec paragraph you can adapt for your own needs (Usetorg: Material Purchase Specification):

Resin: [Specify polymer, e.g., ABS, polycarbonate, PVC]

Grade/Property Targets: [List required grade, impact strength, UV resistance, etc.]

Form: [Sheet, rod, tube, etc.]

Thickness and Tolerance: [e.g., 0.25 inch ±0.01 inch]

Finish: [Matte, gloss, textured]

Protective Masking: [One side, both sides, or none]

Color: [Specify color or transparency]

Flammability/Smoke Rating: [UL 94, ASTM E84, as needed]

Inspection Standards: [ASTM, ISO, or company-specific requirements]

Acceptance Criteria: [No visual defects, within dimensional tolerances, certificate of analysis included]

Collaborate with your engineering and quality teams to ensure all functional and regulatory requirements are captured. Reference relevant standards (ASTM, ISO) where possible to speak a common language with suppliers and minimize miscommunication.

Supplier Comparison Checklist

When you’re sourcing plastic sheet materials—especially for critical or regulated applications—a structured checklist helps you compare apples to apples. Here’s what to look for:

- Lead time (standard and expedited)

- Available forms and sizes (sheet, rod, tube, flat plastic sheets, long plastic sheet options)

- Finishing options (edge finishing, surface treatments, pre-cut sizes)

- Secondary operations (CNC machining, drilling, assembly, custom fabrication)

- Minimum order quantities (MOQ)

- Certifications (ISO 9001, IATF16949, RoHS, REACH, etc.)

- Traceability (batch/lot tracking, certificates of analysis)

- Documentation (material data sheets, compliance certificates, inspection reports)

For complex parts in rigid materials—especially those requiring tight tolerances or multi-axis machining—consider suppliers with proven expertise and relevant certifications. For instance, XTJ CNC Machining offers advanced 4- and 5-axis centers, rapid turnaround, and ISO/IATF certifications, making them a strong candidate for high-precision plastic components. Always request multiple quotes to benchmark pricing and service, and verify supplier capability before committing to production.

Incoming Inspection Template: Verifying Quality on Arrival

Once your shipment arrives, a systematic incoming inspection ensures your pvc sheet plastic sheet or custom part meets spec before it enters production. Use the template below to standardize your quality checks:

| Check Item | Specification/Reference | Measured Value | Pass/Fail | Notes/Comments |

|---|---|---|---|---|

| Dimensions (L x W x Thickness) | As per drawing/spec | [Enter value] | [✔/✘] | |

| Thickness Tolerance | e.g., ±0.01 inch (ASTM D1597) | [Enter value] | [✔/✘] | |

| Visual Defects (scratches, bubbles, warping) | No defects allowed | [OK/Defect] | [✔/✘] | |

| Protective Masking Intact | Yes/No | [Yes/No] | [✔/✘] | |

| Surface Finish | As specified | [Enter value] | [✔/✘] | |

| Flatness | As per spec | [Enter value] | [✔/✘] | |

| Certificate of Analysis/Compliance | Included/Not included | [Yes/No] | [✔/✘] |

Populate numeric tolerances and reference standards from your drawings or supplier documentation. A digital checklist can help streamline recordkeeping and ensure no step is missed.

Key takeaway: Clear specifications, a structured supplier comparison, and diligent incoming inspection are your best tools for managing the cost of plastic sheet procurement and ensuring consistent quality. For complex or high-precision parts in rigid materials, partner with an experienced CNC provider—like XTJ CNC Machining—but always benchmark multiple suppliers to get the best fit for your project.

By following these steps, you’ll reduce procurement risks and set your next rigid plastic project up for success—whether you need a single prototype or a full run of custom flat plastic sheets or long plastic sheet components.

Frequently Asked Questions about Rigid Plastic

1. What is an example of a rigid plastic?

Common examples of rigid plastics include polypropylene, polycarbonate, acrylic (PMMA), ABS, PVC, and nylon. These materials are used for products like containers, machine guards, panels, and tool housings due to their high stiffness and ability to maintain their shape under load.

2. Can rigid plastic be recycled?

Yes, many rigid plastics can be recycled, but acceptance depends on local recycling facilities and the specific resin type. Items like bottles, crates, and rigid plastic sheets are often accepted if clean and free of contaminants. Always check local guidelines and remove non-plastic parts to improve recycling outcomes.

3. How is the rigidity of plastic measured?

Plastic rigidity is typically measured using flexural modulus and tensile modulus tests, such as ASTM D790 and ASTM D638. These tests determine how much a plastic resists bending or stretching, helping engineers compare materials for structural or load-bearing applications.

4. What are the main differences between rigid and flexible plastics?

Rigid plastics are stiff, maintain their shape under stress, and are used for structural or protective parts. Flexible plastics bend or stretch easily, making them suitable for bags, wraps, or cushioning. The choice depends on required stiffness, impact resistance, and application environment.

5. How do I choose the right rigid plastic sheet for my project?

Start by defining your mechanical, thermal, chemical, and environmental requirements. Compare material properties using technical data sheets or trusted databases, then prototype and test top candidates. Consider factors like thickness, span, and fabrication method to ensure the sheet meets your needs.

-

Posted in

hard plastic, material selection, plastic machining, plastic sheet material, rigid plastic