Rigid Plastic Packaging Explained: Formats, Uses, Recycling

Rigid Plastic Packaging Explained: Formats, Uses, Recycling

What Is Rigid Plastic Packaging?

Ever wondered why some packages keep their shape no matter what, while others crumple or fold easily? The answer lies in the type of packaging material—and understanding these differences is the first step to choosing the right solution for your product, brand, or sustainability goals.

What is rigid packaging?

Rigid packaging refers to containers or enclosures made from sturdy, inflexible materials that maintain their shape—empty or filled—offering robust protection and a premium look across industries.

Unlike flexible packaging (like pouches or bags), rigid packaging is designed to resist bending, crushing, or deformation under normal handling and shelf conditions. This form stability is what makes it a go-to for products that require protection, consistent appearance, or a high-end shelf presence.

Materials commonly used include glass, metal, and, most notably for this article, rigid plastics such as PET (polyethylene terephthalate), HDPE (high-density polyethylene), and sometimes PP (polypropylene).

What is rigid plastic?

Rigid plastic is a subset of rigid packaging materials, specifically focusing on plastics engineered for strength and inflexibility. These plastics are molded or formed to create containers that retain their shape, provide structural support, and shield contents from external stresses. Think of the difference between a sturdy yogurt cup and a flexible pouch of baby food—the former is rigid plastic, the latter is flexible packaging.

Common rigid plastic packaging formats

- Bottles – Used for beverages, personal care, and household cleaners; offer excellent barrier properties and are easy to decorate.

- Jars – Common for sauces, condiments, and cosmetics; provide reclosability and product visibility.

- Tubs – Ideal for dairy, spreads, or ready meals; stackable and protective.

- Trays – Used in food, electronics, and industrial parts; allow for organized presentation and protection.

- Closures and Caps – Essential for sealing bottles and jars, often made from PP or HDPE for durability and compatibility.

These formats are found across food and beverage, beauty, personal care, household, electronics, and pharmaceutical sectors. Their popularity is driven by the need for protection, shelf life, and consumer appeal (reference).

How does rigid plastic packaging differ from semi-rigid and flexible options?

It’s easy to confuse the three, but each has distinct characteristics:

- Rigid packaging – Maintains its shape, offers the highest protection, often used for fragile or premium products.

- Semi-rigid packaging – Holds its form but can flex under pressure (think yogurt cups or clamshell trays).

- Flexible packaging – Easily bends or folds; best for snacks, pouches, or products where space and weight are priorities.

Rigidity is all about shape retention and the ability to protect contents from crushing, impact, and environmental factors. This is why rigid plastic packaging is so often chosen for products where presentation, protection, and shelf life matter most.

Why does format choice matter?

Choosing the right format isn’t just about aesthetics. It affects:

- Recyclability – Single-material rigid plastics (like PET or HDPE) are widely recycled, while mixed materials can complicate sortation.

- Logistics – Rigid containers take up more space but offer superior stacking and protection.

- Consumer experience – Rigid packaging signals quality and can enhance ease of use and reclosability.

Whether you’re a buyer prioritizing performance, an engineer balancing design constraints, or a sustainability lead focused on compliance, understanding these fundamentals ensures your packaging decisions are informed and future-ready.

How Design Choices Shape Rigid Packaging

When you pick up a sturdy plastic bottle or a tough food tray, what gives it that unmistakable strength? The answer lies in the science of plastic rigidity—and the design decisions that engineers make every step of the way.

Understanding Plastic Rigidity

At its core, rigidity is a material’s resistance to bending or deformation when force is applied. In the world of rigid plastic packaging, this means your container won’t easily flex, buckle, or warp—protecting its contents and preserving its shape on the shelf. But what actually determines the rigidity of a material?

- Material Selection: Different plastics have different inherent stiffness. For instance, PET and HDPE are common choices for rigid containers because of their high flexural modulus—a measure of how much a material resists bending.

- Geometry: The shape and thickness of the packaging walls, the use of ribs, and the addition of corners all influence how much a container will flex under stress.

- Processing: How the plastic is molded or formed (injection, blow, or thermoforming) can affect alignment of polymer chains and, ultimately, stiffness.

- Additives & Fillers: Reinforcements like glass fibers or mineral fillers can be blended into the plastic to boost stiffness, but may also affect weight and impact resistance.

Material Rigidity and Stiffness Fundamentals

Sounds complex? Here’s a simple way to think about it: the flexural modulus tells you how much a material will bend under a given load. The higher the modulus, the stiffer the plastic. For example, unfilled polypropylene is more flexible, while glass fiber-reinforced polypropylene is much stiffer—but also more brittle and heavier.

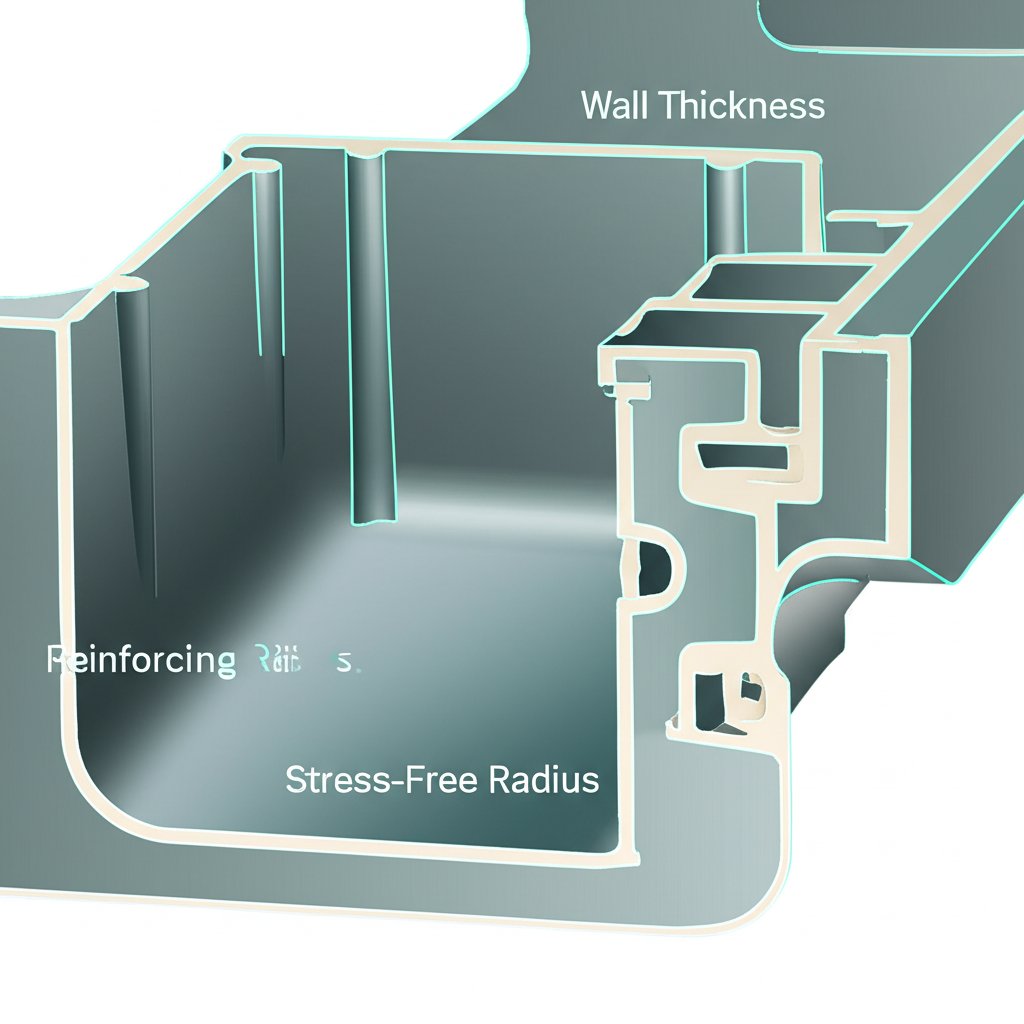

But rigidity isn’t just about material choice. The design of the part itself—wall thickness, ribbing, and even corner shapes—can dramatically boost the perceived and actual stiffness. For instance, adding ribs or gussets to a thin-walled container can make it much harder to flex, without adding a lot of extra material or weight (source).

- Wall Thickness: Thicker walls generally mean greater stiffness, but too much thickness can lead to manufacturing issues like sink marks or voids.

- Ribs and Gussets: Strategically placed support structures reinforce thin sections and prevent flexing.

- Fillets and Radii: Rounded internal corners distribute stress more evenly, reducing the risk of cracking.

- Draft Angles: Slight tapers help with part removal from molds, but also affect local wall strength.

There’s always a tradeoff: maximizing stiffness often adds weight and can reduce impact resistance—so the best designs balance rigidity with overall performance.

Designing Walls, Ribs, and Corners for Strength

Imagine a yogurt tub that feels solid in your hand. Its strength comes not just from the plastic used, but from thoughtful design—thin walls supported by vertical ribs, rounded corners to prevent stress cracks, and just enough thickness to resist crushing without wasting material. Designers often follow guidelines like keeping ribs at 40–60% of the wall thickness and using generous radii on internal corners to avoid stress concentrations.

Temperature and long-term use also matter. Plastics can creep (slowly deform) under constant load, especially at higher temperatures. That’s why material rigidity must be considered alongside the packaging’s real-world environment—like hot warehouses or repeated squeezing by consumers.

- Choose resins with the right balance of rigidity and toughness for the application.

- Validate designs using standard tests, such as ASTM D790 for flexural modulus, to ensure performance meets expectations.

- Factor in the effects of temperature, load duration, and potential impacts during shipping and use.

Balancing Rigidity with Drop Resistance

It’s tempting to make packaging as stiff as possible, but too much rigidity can make it brittle—prone to cracking on impact. That’s why successful designs balance stiffness with just enough flexibility to absorb shocks, especially in products likely to be dropped or squeezed.

Gate Locations and Flow Effects on Part Stiffness

If you’re involved in molding, you’ll notice that the location where plastic enters the mold (“gate location”) and how it flows can create areas of different stiffness and strength. Fiber orientation, weld lines, and even minor geometric tweaks can all influence the final performance of your rigid material.

By understanding these principles, you’ll be better equipped to choose or design packaging that not only looks and feels strong—but truly delivers the performance your application demands. Next, let’s see how these formats and material choices map to real-world applications and industry standards.

Formats and Applications for Rigid Containers

Ever wondered why a yogurt tub feels different from a shampoo bottle, or why electronics are packed in sturdy trays instead of bags? The answer often comes down to the type of rigid container used—and how its features are tailored to the demands of each product and industry.

Rigid Container Formats by Industry

Rigid plastic containers come in a variety of shapes and sizes, each designed for specific roles. Let’s break down the most common formats and where you’ll find them in action:

| Format | Typical Applications | Surface Finish | Decoration Methods |

|---|---|---|---|

| Bottles | Beverages, personal care, household cleaners, pharmaceuticals | Clear, tinted, or opaque; smooth or textured | Labeling, direct printing, shrink sleeves |

| Jars | Food (sauces, spreads), cosmetics, health supplements | Clear or colored; often glossy | Pressure-sensitive labels, screen printing |

| Tubs | Dairy (yogurt, butter), ready meals, spreads | Matte or glossy; sometimes textured | In-mold labeling, adhesive labels |

| Trays | Food portions, electronics, industrial parts | Smooth or ribbed for stacking | Embossing, adhesive labels |

| Pails/Buckets | Bulk food, industrial chemicals, paints | Matte or semi-gloss; heavy-duty | Screen printing, adhesive labels |

| Caps & Closures | Bottles, jars, tubes (across all industries) | Textured or smooth; sometimes colored | Embossing, hot stamping |

| Dispensers | Personal care, cleaning products, food condiments | Smooth, ergonomic shapes | Direct printing, labeling |

Hard Plastic Packaging Use Cases

Why do brands choose hard plastic packaging for certain products? It’s usually about meeting a set of requirements that flexible options can’t match. Here are the key drivers:

- Barrier performance: Protects contents from moisture, oxygen, and light—crucial for food and pharmaceuticals.

- Clarity and product visibility: Transparent PET or acrylic lets consumers see the product, building trust and shelf appeal (source).

- Impact resistance: Rigid containers shield fragile or valuable items (like electronics or cosmetics) from knocks and drops.

- Heat tolerance: Some rigid plastics withstand hot-fill processes or microwave reheating.

- Decoration options: Smooth, stable surfaces enable advanced printing, labeling, and branding techniques.

When to Choose Rigid Plastic Containers

Imagine you’re launching a new product. When would you opt for a rigid plastic container? Here are scenarios where it’s the right call:

- You need maximum protection for fragile or high-value goods.

- Product presentation and shelf impact are priorities (think clear jars for gourmet foods or premium cosmetics).

- Regulatory or industry standards demand tamper evidence or child resistance (as with pharmaceuticals).

- Automated filling lines require precise shapes and stacking strength.

- Reusable or refillable packaging is part of your sustainability strategy.

Operational Considerations for Rigid Containers

- Line speeds: Can the container withstand fast, automated filling and capping?

- Cap compatibility: Are closures secure, leak-proof, and easy to apply?

- Stacking strength: Will the containers maintain shape during shipping and warehousing?

- End-of-life pathways: Is the material recyclable or reusable in your target markets?

Compatibility with Automated Handling and Transport Loads

Rigid containers are often designed with logistics in mind. Their uniform shapes and robust structure enable efficient handling by robots and conveyors, while also protecting products from compression or impact during transport. For brands, this means fewer damaged goods and smoother operations across the supply chain.

Choosing the right rigid container format is not just about looks—it’s about balancing protection, efficiency, and consumer experience from the filling line to the end user.

Next, we’ll explore how rigid packaging stacks up against flexible options, so you can make the most informed decision for your products and business goals.

Rigid vs Flexible Packaging

When you’re weighing the best way to package your product, the choice often comes down to rigid vs flexible packaging. Sounds simple, right? But as you dig deeper, you’ll notice there’s a lot more to consider than just the look or feel. Let’s break down the key differences so you can make an informed decision that fits your product, your brand, and your sustainability goals.

Rigid vs Flexible Packaging Tradeoffs

Imagine you’re launching a new snack line. Should you go with a sturdy plastic tub or a sleek pouch? Here’s how the two stack up in the real world:

| Attribute | Rigid Packaging | Flexible Packaging |

|---|---|---|

| Product Protection | Excellent—protects against crushing, impact, heat, and light. Ideal for fragile or premium products. | Moderate—suitable for less fragile items. Less robust against punctures or drops. |

| Branding & Shelf Impact | High—offers premium look and feel, stands out on shelves, supports complex shapes and finishes. | Good—customizable surfaces, but may not convey luxury. Flexible forms support creative designs. |

| Shipping & Storage Efficiency | Lower—bulky and heavier, leading to higher shipping costs and more shelf space required. | High—lightweight, compact, and space-saving. Reduces logistics costs and environmental footprint. |

| Consumer Convenience | Often resealable and reusable. Rigid shape makes pouring and portioning easy. | Easy to open, lightweight, and portable. Often single-use; reclosure options may be limited. |

| Line Changeover & Automation | Supports high-speed, automated filling and capping. Consistent shapes aid handling. | May require specialized machinery for filling and sealing. Flexible shapes can challenge automation. |

| Recyclability Pathway | Widely recycled (PET, HDPE, glass, metal). Single-material formats are best for sortation. | Less widely recycled; multi-layer films are challenging for current recycling systems. |

| Cost | Higher raw material and shipping costs. Perceived as more premium. | Generally lower material and transport costs. Efficient for high-volume goods. |

Speed, Cost, and Supply Chain Factors

Flexible packaging has surged in popularity for good reason—it’s space-saving, lightweight, and cost-effective. Think of chip bags, coffee pouches, or shrink-wrapped produce. These formats help brands cut shipping costs and reduce their carbon footprint by fitting more units per pallet and truckload.

On the other hand, rigid packaging is the go-to when product integrity and presentation matter most. Glass jars, hard plastic tubs, and metal cans offer robust protection, making them ideal for delicate foods, premium cosmetics, or anything that needs to look pristine on the shelf. The tradeoff? Higher shipping and storage costs, and sometimes more complex supply chain logistics.

Sustainability and Recycling Implications

Curious about which is greener? It depends on your priorities. Flexible plastic packaging uses less material and energy to produce, and takes up less landfill space. However, it’s often made from multi-layer films that are hard to recycle in most municipal systems. Rigid packaging, especially when made from single-material plastics like PET or HDPE, is widely accepted in recycling streams and supports circularity. Glass and metal rigid formats are also highly recyclable, but their heavier weight increases emissions during transport.

Some brands are now exploring hybrid approaches—using flexible pouches inside rigid cartons, or refillable rigid containers paired with flexible refill packs—to balance protection, branding, and sustainability.

Prioritize product protection first, then optimize for cost and sustainability—never compromise safety for savings or green credentials.

Choosing between flexible and rigid packaging isn’t about picking a winner; it’s about matching the right solution to your product, market, and values. Up next, we’ll dive into how your packaging choices can be optimized for recyclability, helping you close the loop and meet evolving consumer and regulatory expectations.

Design for Recycling

When you’re designing rigid packaging material, recyclability isn’t just a buzzword—it’s a practical design challenge that can make or break your package’s journey through the recycling stream. Sounds complex? It can be, but with the right framework, you’ll see how small design choices in rigid plastics have a big impact on sortation, yield, and the quality of recycled resin. Let’s break down the essentials and build a decision matrix you can use right away.

Label, Color, and Closure Choices That Sort Better

Imagine your packaging containers plastic rolling down a recycling conveyor. Will it be sorted efficiently, or will labels, inks, or closures get in the way? According to the APR Design® Guide, every design feature—from resin type to adhesive choice—affects recyclability. Here’s what to watch for:

- Base Resin: Stick to a single polymer (like PET, HDPE, or PP) for the body and closure whenever possible.

- Color: Avoid dark or carbon black pigments. Clear or light-colored plastics are preferred for higher-value recycling streams.

- Closures: Use closures made from the same polymer family as the container, and avoid metal or multi-material inserts.

- Labels: Choose labels that are easily removable in standard recycling processes. Pressure-sensitive or washable labels are best.

- Inks and Adhesives: Use water-soluble or recycling-compatible options to prevent contamination.

Rigid Packaging Examples with Clear Recycling Pathways

Want to see what works? Here are a few rigid packaging examples that set the standard for recyclability:

- PET water bottles with clear, floatable labels and HDPE closures—widely accepted and processed into high-quality PCR.

- HDPE milk jugs with minimal or no labeling—easy to sort, clean, and reprocess.

- Polypropylene yogurt tubs with in-mold labels that separate cleanly during washing.

These designs follow the principle of minimizing non-compatible components and using features classified as "APR Design Preferred"—meaning they’re readily accepted by most recycling facilities and don’t reduce the quality of recycled resin (APR reference).

Decision Matrix by Format and Resin

Not sure where your design stands? Use this matrix to quickly assess best practices for common rigid formats and resins:

| Format | Recommended Resin | Label/Ink/Closure Notes | Sorting Flag |

|---|---|---|---|

| Bottle | PET, HDPE | Use floatable, removable labels; same-polymer closures; avoid dark colors | Preferred (if all features are compatible) |

| Jar | PET, PP | Pressure-sensitive or in-mold labels; avoid metal lids; clear or light colors | Preferred or Needs Improvement (if mixed materials used) |

| Tray | PET, PP | Minimal labeling; avoid multi-layer structures; light colors best | Preferred (single polymer); Non-Recyclable if multilayer |

| Tub | PP, HDPE | In-mold or easily removed labels; matched polymer lids | Preferred |

| Closure/Cap | HDPE, PP | Same polymer as container; no metal inserts | Preferred |

For a deeper dive, always consult the latest APR Design® Guide or local recycling guidelines. If your design includes any "Detrimental" or "Non-Recyclable" features, consider alternatives or request testing to confirm recyclability.

- Use compatible closures and labels to maximize yield.

- Design for easy separation of labels and caps during washing.

- Minimize use of additives, coatings, or multilayer structures.

- Regularly check regional guidelines for accepted materials and features.

Minimize cross-resin combinations—keeping all components in the same polymer family is the single most effective way to protect recycling streams and ensure your packaging is truly circular.

By following these best practices, you’ll not only simplify recycling for your consumers but also help ensure a steady supply of high-quality recycled material for the next generation of packaging. Up next, we’ll look at how these design choices intersect with compliance and regulatory reporting, so your packaging can meet both market and legal expectations.

Meeting RPPC and Packaging Regulations with Confidence

When you hear about packaging regulations, do you picture a maze of forms and shifting requirements? You’re not alone. But with a clear roadmap, compliance for rigid plastic packaging becomes a manageable, step-by-step process—whether you’re targeting the California RPPC program, navigating the broader rigid plastic packaging market, or planning for future EPR laws across the US and beyond.

Determine Whether Your Packaging Is Covered

First things first: does your product actually fall under state or national packaging regulations? For example, California’s Rigid Plastic Packaging Container (RPPC) law applies to most plastic converters and brands selling products in rigid plastic containers within the state, with some exemptions for food, drugs, and medical devices (CalRecycle). Other states and regions may have different thresholds or definitions, so always review local guidelines before proceeding.

- Map where your products are sold and in what volumes.

- Check if your packaging meets the state’s definition of a rigid plastic container (e.g., shape, capacity, intended use).

- Identify any exemptions or special categories (such as refillable, reusable, or single-resin containers).

Registration and Reporting Steps

Once you know your packaging is covered, it’s time to get organized. Here’s a high-level overview of the RPPC compliance process, which mirrors many EPR and packaging laws worldwide:

- Registration: If notified, register your company with the relevant agency—such as CalRecycle in California—within the required window (often 90 days from notice) (see RPPC process).

- Pre-Certification: Use the advance notice period (usually one year) to review requirements and ensure your packaging design aligns with the law.

-

Data Gathering: Collect detailed data on each covered packaging format:

- Container weights (empty and filled)

- Material composition (resin type, recycled content percentage)

- Component breakdown (closures, labels, additives)

- Production and sales volumes by jurisdiction

- Documentation: Prepare and maintain records such as bills of materials, compliance statements from plastic converters, and recycled content certifications.

- Compliance Certification: Submit compliance certifications for the specified measurement period by the stated deadline (e.g., by April 1 for California, covering the prior calendar year).

- Ongoing Review: Monitor changes in laws and update your compliance documents and internal controls regularly.

Avoid Common Compliance Pitfalls

Staying compliant is about more than just filling out forms. Imagine discovering a missing supplier attestation after a regulatory audit—stressful, right? Here’s how to keep your compliance program strong and future-proof:

- Maintain versioned specifications for all packaging formats.

- Request and archive supplier attestations for recycled content and material safety (especially for the rigid packaging market).

- Set up audit trails for all compliance-related documents and submissions.

- Stay current on evolving requirements in each region where you sell—regulations for flexible containers, labeling, or chemical content (like PFAS or PVC) can change quickly.

- Consult official program pages for up-to-date forms, calculation formulas, and reporting templates.

-

Required Documentation Checklist:

- Compliance certifications and registration confirmations

- Supplier and converter attestations

- Packaging weights and material breakdowns

- Recycled content and resin source documentation

- Audit logs and submission records

Building compliance into your packaging design from the start is far easier—and less costly—than retrofitting after regulations change. Proactive documentation and supplier coordination are your best defense against future surprises.

By following these steps, you’ll not only meet today’s regulatory demands but also position your brand to adapt as the rigid packaging market evolves. Next, let’s explore how rapid prototyping and pilot tooling can help you validate new designs before full-scale rollout.

Prototyping and Pilot Tooling Options Compared

When developing new rigid plastic packaging, how do you know your design will work before committing to expensive production molds? If you’ve ever asked, “How can I validate fit, sealing, and assembly for hard plastics without burning through my budget or timeline?”—you’re not alone. Let’s walk through the leading prototyping and pilot tooling options so you can make confident, informed decisions.

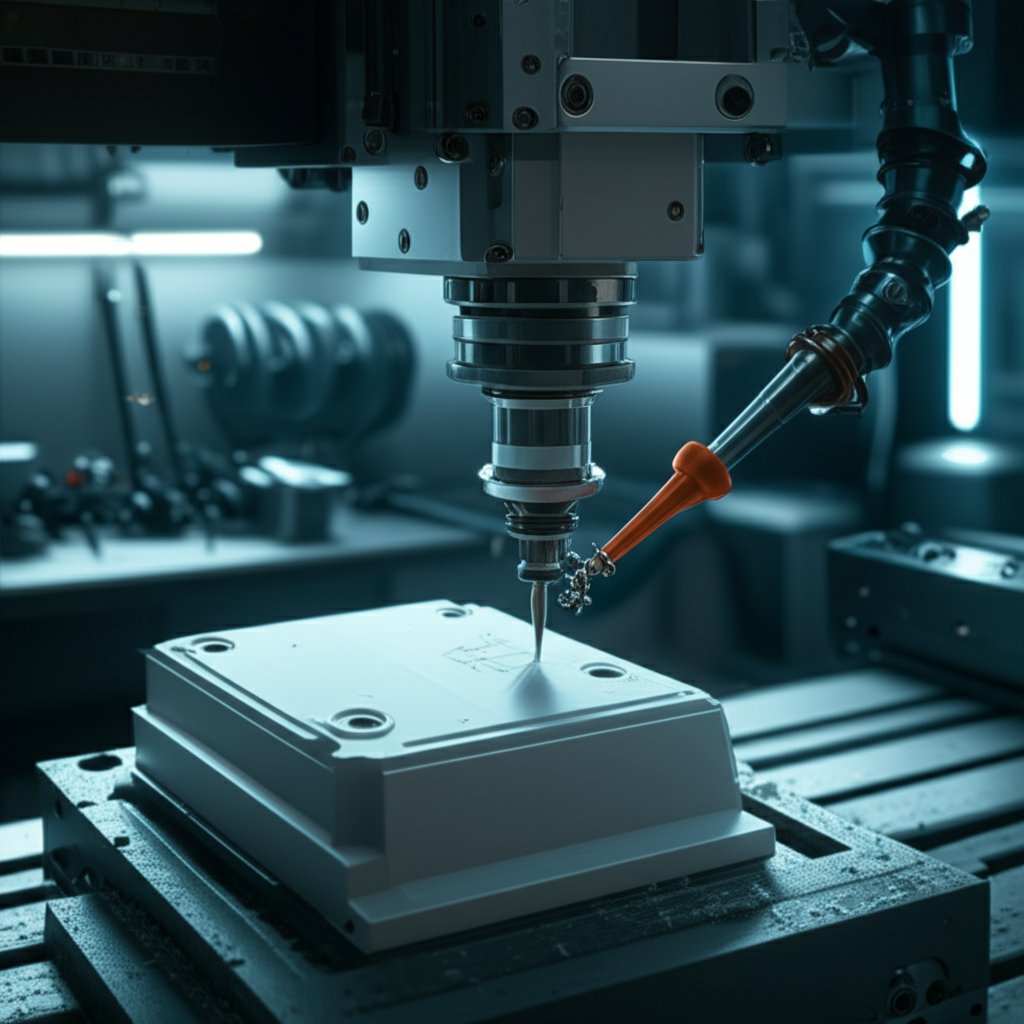

Why CNC for Rigid Packaging Development?

Imagine you’re launching a new closure or cap design. You need to check torque, fit, and sealing—often with tolerances measured in hundredths of a millimeter. This is where CNC machining shines. Unlike additive or soft tooling methods, CNC delivers prototypes and fixtures directly from production-grade materials, offering unmatched dimensional accuracy and repeatability. For rigid packaging solutions like snap-fit lids, threaded caps, and custom trays, CNC helps you catch issues early—before investing in full-scale injection molds.

CNC vs 3D Printing vs Soft Tooling: Which Fits Your Project?

Choosing the right prototyping method depends on what you need to test. Do you need high-fidelity material properties? Is speed the top priority? Or is cost the deciding factor? Here’s a side-by-side look at the most common approaches for rigid plastic packaging development:

| Service/Method | Dimensional Accuracy | Material Compatibility | Lead Time | Scalability | Best Use Cases |

|---|---|---|---|---|---|

| XTJ CNC Machining Services | Ultra-high (to +/- 0.005mm) | 30+ plastics & metals (production-grade) | As fast as 3 days | From single parts to pilot runs | Caps, closures, test fixtures, pilot components; functional validation for sealing and torque |

| CNC Machining (General) | High (to +/- 0.01mm) | Wide range (ABS, PC, PP, metals) | Days to 1 week | Small to medium batches | Functional prototypes, fit and assembly checks |

| 3D Printing (Multi Jet Fusion, SLS, FDM) | Moderate (0.1–0.3mm typical) | Limited (mostly PA12, ABS, PC, PLA) | 1–3 days | Prototypes, small series (up to a few thousand) | Complex shapes, design verification, fast iteration |

| Soft Tooling (Vacuum Casting) | Good (0.1–0.2mm) | Polyurethanes, epoxies, acrylics | 1–2 weeks (includes master model) | 15–50 parts per mold | Pre-series parts, surface finish simulation, low-volume runs |

As you can see, CNC machining—especially with advanced providers like XTJ—offers the tightest tolerances and broadest material options, making it ideal for functional validation of rigid packaging components. 3D printing excels at rapid, low-cost iteration for complex geometries, while soft tooling bridges the gap for small pre-series runs with good surface quality.

How to Brief a Machining Partner for Rigid Packaging Solutions

Ready to move from CAD to a physical prototype? Here’s a quick checklist for briefing your machining partner to ensure you get the most accurate and useful results:

- Provide detailed 3D CAD files, including all critical dimensions and tolerances (especially for sealing and fit areas).

- Specify the exact material or closest production-grade equivalent for your rigid plastic part.

- Indicate any features that must be tested, such as snap-fits, threads, or hinge points.

- Clarify the intended use of the prototype—fit check, functional test, assembly validation, or pilot production.

- Discuss surface finish requirements, especially if aesthetics or label adhesion will be evaluated.

- Request documentation or certificates when needed (e.g., material traceability, ISO certifications), especially for regulated industries.

“The advantage of using rigid containers in prototyping is simple: what you see is what you get. By validating your design in production-equivalent materials and dimensions, you minimize surprises, speed up approvals, and reduce costly mold changes down the line.”

By selecting the right prototyping method for your rigid packaging project, you’ll ensure your designs are robust, manufacturable, and ready for market. Next, let’s explore how to source recycled content and work with converters to bring your sustainable packaging vision to life.

Sourcing PCR and Working with Converters

When you set ambitious sustainability goals for your rigid plastic packaging, how do you actually move from good intentions to boxes of finished containers made with recycled content? The answer lies in sourcing the right post-consumer recycled (PCR) materials and partnering with reliable plastic converters who can deliver on quality, performance, and compliance. Sounds daunting? Let’s break it down into practical steps that anyone—from procurement teams to packaging engineers—can follow.

Finding and Vetting PCR Suppliers

Imagine you’re ready to specify recycled content for your next packaging run. Where do you start? First, you’ll need to identify PCR suppliers and plastic converters who have proven experience with recycled resins—especially for food or sensitive applications where quality and safety are non-negotiable.

- Look for suppliers with a track record in your target application (e.g., food-grade PET or HDPE for containers).

- Ask about their sourcing network and whether they rely on mechanical or chemical recycling (each has unique implications for quality and consistency reference).

- Request documentation: material safety data sheets (MSDS), technical data sheets, and compliance statements for food contact or regulatory standards.

- Check for certifications by recognized bodies (e.g., FDA, EFSA for food safety) that confirm the PCR has been processed to remove contaminants and is suitable for your application.

- Inquire about supply stability—can the supplier meet your volume and timing needs, especially as demand for recycled content rises globally?

Specifying Recycled Content in Contracts

Once you’ve found potential partners, it’s time to lock in your requirements. But how do you balance sustainability with the realities of material performance? Here’s where clear, detailed specifications are essential:

- Define the minimum and maximum PCR content acceptable for your application, considering both performance and visual appearance (higher PCR levels may introduce color tints or reduce clarity).

- Allow for tolerance bands—specifying a range (e.g., 25–35% PCR) rather than a fixed percentage can help manage supply fluctuations without sacrificing quality.

- Include clauses requiring batch-level documentation: test results for mechanical properties, color, and contamination; recycled content certifications; and traceability records for each lot.

- Establish performance benchmarks—clarity, impact resistance, and sealing must meet your functional needs, even if the resin source varies from batch to batch.

- For food applications, require ongoing compliance with food safety regulations and regular re-testing as part of your contract.

Managing Supply Variability and Quality

You’ll notice that recycled content isn’t always as consistent as virgin plastic. That’s why robust quality management is crucial. Here are proven strategies to keep your operations running smoothly:

- Dual source your PCR—work with more than one supplier to reduce the risk of shortages or sudden quality shifts.

- Qualify new lots or suppliers through pilot runs and lab testing before full-scale rollout. Test for key parameters like mechanical strength, color, and contamination.

- Set up clear communication protocols with suppliers to flag any changes in resin source, processing method, or regulatory status.

- Request regular sample submissions and retain samples for traceability in case of downstream issues.

- Collaborate with converters who can adjust compounding or processing parameters to compensate for PCR variability, protecting both product performance and aesthetics (see compounding insights).

Supplier Screening and Contract Checklist

- Application-specific experience (food, pharma, household, etc.)

- Certifications for recycled content and food safety

- Material spec sheets and compliance documentation

- Defined PCR content range and tolerance clauses

- Batch-level traceability and regular quality test results

- Clear communication and change notification procedures

- Dual sourcing and lot qualification protocols

Traceability and batch testing aren’t just checkboxes—they’re your best insurance for consistent quality, regulatory compliance, and brand protection when scaling up recycled content in rigid plastic packaging.

By following these steps, you’ll be able to confidently transition from intent to procurement, ensuring your packaging meets sustainability goals without sacrificing performance or risking compliance. Next, we’ll close with a roadmap to implementation—so you can measure, validate, and scale your progress with clarity.

Implementation Roadmap

Ever launched a new packaging design only to wonder—did it really deliver the results you promised? For teams working with rigid plastic packaging, a clear, actionable roadmap is the key to turning good intentions into measurable outcomes. Let’s walk through a practical, step-by-step approach that will help you move from concept to scale, track what matters, and keep improving over time.

From Audit to Pilot to Scale: The Phased Approach

Imagine you’re tasked with rolling out a new rigid container—where do you start? Here’s a proven path:

- Baseline Audit: Assess current packaging formats, materials, and performance. Identify pain points (e.g., high defect rates, poor recyclability, or consumer complaints).

- Concept Iteration: Develop initial redesign concepts. Screen for process compatibility, sustainability potential, and cost implications.

- Lab Testing: Validate key properties—barrier performance, impact resistance, seal integrity, and dimensional stability—using standardized tests for rigid packaging.

- Pilot Run: Produce limited batches on actual equipment. Monitor filling line efficiency, defect rates, and consumer feedback.

- Post-Market Review: Collect real-world data on recyclability, user experience, and supply chain performance. Use these insights to refine future iterations.

Metrics That Matter for Rigid Packaging

Wondering which numbers will actually move the needle? Here are the KPIs that leading teams track to measure the impact of new packaging—whether it’s rigid or even types of flexible packaging for comparison:

- Line Efficiency: How does the new packaging affect throughput, downtime, and changeover speed? Track overall equipment effectiveness and unscheduled downtime.

- Seal Integrity Pass Rate: What percentage of units pass leak, torque, and drop tests? Higher pass rates mean fewer recalls and returns.

- Consumer Usability: Are consumers reporting easier opening, better reseal, or improved product dispensing? Gather feedback through surveys, hotlines, or social media.

- Recyclability Pathway Compatibility: Are the new formats being accepted and processed by local recycling systems? Monitor sortation rates and feedback from recyclers.

- Recycled Content Rate: How much post-consumer recycled (PCR) material is actually present in your packaging, verified by batch testing and supplier documentation?

- Quality and Defect Rates: Track the percentage of products meeting quality standards and the number of reworks required.

Testing and Validation Before Launch

Before any full-scale rollout, thorough testing is essential. Imagine skipping a drop test, only to see a spike in damaged products during shipping—costly and avoidable. Here are the core tests to request from accredited labs for rigid plastic packaging:

- Dimensional Testing: Ensures containers fit filling and labeling equipment, and stack properly for transport.

- Drop and Impact Testing: Simulates real-world handling and transport stresses.

- Seal and Leakage Testing: Confirms closures and seals perform under vacuum, slant, and pressure scenarios.

- Barrier Performance: Measures resistance to moisture, oxygen, and other environmental factors.

- Label Adhesion: Verifies that branding and regulatory labels stay put throughout the product lifecycle.

- Sortation Trials: Validates recyclability and compatibility with automated sorting systems.

For each test, compare results against industry benchmarks and your own historical data. Use findings to fine-tune design and manufacturing processes before committing to large-scale production.

Align performance, cost, and circularity: The most successful rigid packaging projects balance robust protection, operational efficiency, and sustainability from the start.

By following this roadmap and tracking meaningful metrics, you’ll not only ensure your new packaging meets expectations—but also create a culture of continuous improvement. Keep the feedback loop open with suppliers, converters, and end users, and your packaging will keep evolving to meet tomorrow’s demands, whether you’re working with rigid or exploring the future of packaging flexible solutions.

Frequently Asked Questions About Rigid Plastic Packaging

1. What is a rigid plastic packaging container?

A rigid plastic packaging container is a plastic enclosure designed to maintain its shape and provide strong protection for its contents. These containers are made entirely from plastics like PET, HDPE, or PP, and are commonly used for food, beverages, personal care, and household products. Their inflexible structure helps prevent crushing or deformation during handling and storage, making them ideal for products requiring robust protection and a premium appearance.

2. What are the advantages of rigid plastic packaging?

Rigid plastic packaging offers several advantages, including superior durability, which safeguards products from impact and extends shelf life. Many rigid containers are clear, allowing for enhanced product visibility and branding. They are often resealable or reusable, supporting sustainability initiatives. Additionally, rigid packaging is compatible with high-speed automated filling lines and is widely recyclable when made from single-material plastics.

3. How does rigid plastic packaging differ from flexible packaging?

Rigid plastic packaging is designed to retain its shape and provide maximum protection against crushing, impact, and environmental factors. In contrast, flexible packaging, such as pouches or bags, bends and folds easily, making it lighter and more space-efficient but less protective. Rigid formats are preferred for products needing a premium look, strong protection, or precise handling, while flexible options are often chosen for shipping efficiency and cost savings.

4. What factors should be considered when designing rigid plastic packaging for recycling?

To maximize recyclability, use a single polymer type for both the container and its closure, avoid dark or carbon black colors, and select labels and adhesives that are easily removable during recycling. Compatibility between all packaging components is crucial to ensure efficient sortation and high-quality recycled material. Regularly consult regional recycling guidelines and design-for-recycling resources to stay compliant and support circularity.

5. When is CNC machining preferred for prototyping rigid plastic packaging?

CNC machining is preferred when high dimensional accuracy, rapid turnaround, and production-grade material properties are required for prototypes or pilot runs. For rigid plastic packaging, CNC machining allows you to test fit, sealing, torque, and assembly with tolerances down to +/- 0.005mm, as offered by providers like XTJ. This approach is ideal for validating caps, closures, and custom components before investing in full-scale molds.

-

Posted in

packaging compliance, packaging design, plastic prototyping, recyclable packaging, rigid plastic packaging