Rigid Plastics: 9 Essential Points Engineers Must Nail

Rigid Plastics Fundamentals That Matter for Engineers

What Is Rigid Plastic?

Ever wondered why some plastics snap instead of bend, or why certain containers keep their shape no matter what you put inside? That’s the world of rigid plastics. These materials are the backbone of countless consumer products and industrial components, prized for their structural integrity and ability to hold form under stress.

Rigid plastics are stiff, shape-retaining materials that resist bending or deformation under normal use, thanks to their molecular structure and high modulus.

Think of the sturdy case of a power tool, a clear water bottle, or a PVC pipe—these are all classic examples of what is rigid plastic. Unlike their flexible plastic counterparts, which are designed to stretch or conform, rigid plastics maintain a set geometry, offering reliable protection and dimensional stability.

Rigid Plastics Versus Flexible Plastics

So, how do you tell the difference between rigid and flexible plastic in the field? It comes down to their molecular arrangement and the presence (or absence) of plasticizers—additives that increase plastic flexibility. Rigid plastics feature tightly packed polymer chains, resulting in high plastic rigidity, while flexible plastics have more loosely arranged chains or added agents that allow them to bend and flex. Here’s how you can spot rigid plastic on the job:

- Sharp, resonant sound when tapped

- Cannot be folded or bent without whitening or cracking

- Maintains a flat or planar shape under moderate force

- High modulus (resists bending)

- Retains shape under load

- Dimensional stability over time

- Resistant to creep and long-term deformation

Why Rigidity Matters in Design and Manufacturing

Rigid plastics are essential when you need a part to keep its shape, support weight, or protect contents from impact. Their predictable behavior under stress makes them a top choice for structural applications, packaging that must resist crushing, and components where tight tolerances are critical. For example, HDPE and PET are staples in bottles and containers, while ABS and PC offer toughness and clarity for housings and lenses. PVC is a workhorse in construction, and PMMA (acrylic) is valued for its optical properties in glazing and displays.

Here’s a quick overview of common rigid plastic families you’ll encounter:

- HDPE (High-Density Polyethylene): Tough, chemical-resistant, used in bottles and piping

- PP (Polypropylene): Lightweight, fatigue-resistant, found in automotive and consumer goods

- PVC (Polyvinyl Chloride): Durable, weather-resistant, used in pipes and window frames

- ABS (Acrylonitrile Butadiene Styrene): Impact-resistant, used in housings and automotive parts

- PC (Polycarbonate): Transparent and strong, ideal for lenses and safety shields

- PET (Polyethylene Terephthalate): Clear, strong, widely used in beverage containers

- PMMA (Polymethyl Methacrylate): Excellent clarity, used in signs and glazing

Each of these kinds of plastic can be tailored further with additives or by blending, allowing engineers to fine-tune plastic flexibility or stiffness for the application at hand. Processing methods—like extrusion, molding, or sheet forming—also influence the final rigidity of the product.

Design insight: Boosting rigidity improves dimensional stability, but can make materials more brittle at low temperatures, so always weigh the trade-offs for your use case.

As you explore the next sections, you’ll discover how to select the right rigid plastic sheet, understand processing and machining tips, and navigate recycling challenges. Mastering these fundamentals will help you make smarter material choices for both performance and sustainability.

- Listen for a solid "click" or "tap" sound

- Try to bend—rigid plastics resist and may show whitening at stress points

- Check if the item springs back or stays flat—rigid plastics maintain their shape

Ready to dive deeper? Next, we’ll map out the most common rigid plastics and how to match their traits to your engineering needs.

Common Rigid Plastics and Where They Excel

Common Types of Hard Plastics

When you’re specifying a part or product, how do you decide which hard plastic material to use? The answer starts with understanding the unique strengths and trade-offs of each type. From the tough shell of a tool housing to the crystal-clear face of a display, rigid plastics like HDPE, PP, PVC, ABS, PC, PET, and PMMA each bring something different to the table. Let’s break down their hallmark traits and typical applications so you can match the right material to your design challenge.

| Plastic Type | Impact Resistance | Stiffness | Transparency | Chemical/Weather Resistance | Machinability | Bonding Options | Recyclability | Typical Uses |

|---|---|---|---|---|---|---|---|---|

| HDPE | Good | High | Opaque | Excellent chemical & UV resistance | Good (cuts, routes cleanly) | Thermal welding, mechanical fasteners | Widely recycled (#2) | Piping, tanks, outdoor equipment, containers |

| PP | Fair | Moderate | Semi-clear to opaque | Excellent chemical resistance, moderate weatherability | Good, but softer than HDPE | Heat welding, snap fits | Recyclable (#5) | Automotive, hinges, labware, food containers |

| PVC (Rigid) | Moderate | High | Opaque, some grades translucent | Excellent chemical & fire resistance | Good | Solvent bonding, fasteners | Recyclable (#3), but less common | Pipes, window frames, conduit, signage |

| ABS | High | Moderate | Opaque | Good chemical resistance | Excellent (machines, sands well) | Solvent welding, adhesives, fasteners | Recyclable (#7, other) | Housings, automotive trim, toys, appliance covers |

| PC (Polycarbonate) | Very high | High | Transparent | Moderate chemical resistance, good weatherability | Good (can stress crack if mishandled) | Solvent/adhesive bonding, fasteners | Recyclable (#7, mixed) | Safety shields, glazing, medical devices, machine guards |

| PET | Good | High | Transparent | Excellent chemical resistance | Fair (sensitive to heat when machining) | Thermal welding, fasteners | Widely recycled (#1) | Bottles, food packaging, trays, films |

| PMMA (Acrylic) | Moderate | High | Excellent clarity | Good UV/weather resistance | Excellent (cuts, polishes well) | Solvent bonding, adhesives | Recyclable (#7, varies) | Displays, glazing, aquariums, lighting diffusers |

How Material Traits Translate to Use Cases

Imagine you’re designing a chemical storage tank, a transparent display, or a rugged industrial guard. The right choice among these types of hard plastic will make or break your project’s performance. For outdoor or chemical-heavy environments, HDPE and PVC stand out due to their resistance to corrosion and weathering. If you need toughness and a smooth finish for consumer products, ABS is a reliable go-to. For impact-resistant, see-through barriers, polycarbonate (PC) offers a unique blend of clarity and strength that’s hard to match. PET is a staple for packaging and food-contact applications thanks to its clarity and chemical inertness.

- Housings, covers, and guards: ABS, PC, HDPE

- Glazing and displays: PMMA, PC

- Containers and packaging: PET, HDPE, PP

- Outdoor/structural: PVC, HDPE

From Data Sheets to Decisions

Choosing the best hard plastic material isn’t just about matching a name to a function. It’s about weighing the performance traits that matter most for your end-use environment, regulatory needs, and processing route. If you need specific numbers—like tensile strength, notched impact, or heat deflection temperature—authoritative sources such as Curbell Plastics’ properties table and ASTM or ISO data sheets are your best bet. These resources allow you to compare grades side by side and spot critical differences.

Keep in mind, every design involves trade-offs. For example, ABS offers excellent machinability and a good balance of toughness, but if your part needs to withstand high impacts at low temperatures, PC may be a better fit. For living hinges or fatigue resistance, PP outperforms HDPE. Early prototyping and testing are key to validating your assumptions.

- Need clarity? → PMMA or PC

- Need chemical resistance and stiffness? → PVC or HDPE

- Need a balance of toughness and aesthetics? → ABS

Up next, we’ll look at how to select and specify rigid plastic sheets for fabrication and real-world builds—ensuring your chosen material performs as expected from the shop floor to the finished product.

Choosing Rigid Plastic Sheets for Real-World Builds

Rigid Plastic Sheet Materials Explained

When you need a part or enclosure that stays flat, resists impact, and delivers a clean finish, rigid plastic sheets are often the go-to solution. But with so many options—each with unique strengths—how do you choose the right one? Imagine you’re designing a machine guard, a sign face, or a weatherproof panel. Your choice of rigid plastic sheet material will shape not only the performance but also the ease of fabrication and long-term durability.

Popular hard plastic sheets include ABS, acrylic (PMMA), polycarbonate (PC), HDPE, and PVC. Each brings its own balance of impact resistance, clarity, machinability, and cost. For example, acrylic offers brilliant clarity and weatherability, while PC excels in impact resistance and can be cold-formed for curved panels. HDPE stands out for chemical resistance and outdoor toughness, and ABS is valued for easy machining and thermoforming. PVC provides a strong, low-cost option for flat panels and signage, especially when flame retardance is a must.

Choosing Sizes, Finishes, and Tolerances

Sounds complex? Let’s break it down. When specifying rigid plastic sheets, details matter. Here’s a practical checklist to guide your order:

- Polymer type (ABS, PC, PMMA, HDPE, PVC, etc.)

- Thickness range (e.g., 0.06 inch to 6 inches)

- Sheet size (standard hard plastic sheets 4x8, or custom cut-to-size)

- Color/opacity (clear, tinted, opaque, colored)

- Surface finish (glossy, matte, textured, patterned)

- Protective film (for scratch-sensitive applications)

- Flatness/tolerance (verify against supplier data sheets)

- Certification/grade (UV-stabilized, flame retardant, FDA-compliant, etc.)

Market terms like “hard plastic sheets 4x8” are common shorthand for procurement, but always confirm the actual thickness, width, and flatness tolerances with your supplier’s technical data—cutting or forming can introduce small deviations, especially with larger panels.

Cutting, Bending, and Thermoforming Considerations

Not all rigid plastic sheets behave the same when you need to cut, bend, or thermoform them. Some, like ABS and polycarbonate, are easy to thermoform thanks to their wide processing windows and good melt strength. Others, like HDPE and PP, can be more challenging due to lower melt strength and narrower processing windows. Acrylic (PMMA) offers excellent optical clarity but is prone to whitening or stress crazing if bent too sharply. Always test bend radii before committing to a design—especially for clear or decorative parts.

| Sheet Material | Thermoforming Ease | Best for CNC Routing | Scratch Resistance | Common Applications |

|---|---|---|---|---|

| ABS | Excellent | Yes | Moderate | Machine guards, housings, automotive trim |

| Polycarbonate (PC) | Excellent | Yes | Fair (can be coated for improvement) | Glazing, safety shields, curved panels |

| Acrylic (PMMA) | Good | Yes | High (especially AR grades) | Displays, signage, windows, lighting |

| HDPE | Fair | Yes | Moderate | Cutting boards, marine panels, outdoor benches |

| PVC (Rigid) | Good | Yes | Moderate | Signage, wall panels, chemical enclosures |

For glazing or display projects, consider the trade-off between clarity and scratch resistance. Acrylic delivers the best optical finish and can be specified in abrasion-resistant grades, while polycarbonate offers more impact strength but scratches more easily unless coated. For outdoor or high-traffic uses, UV-stabilized or textured surfaces can extend service life and maintain appearance.

| Rigid Plastic Sheet | Typical Applications | Processing Notes |

|---|---|---|

| ABS | Machine guards, housings, panels | Easy to machine and thermoform; moderate scratch resistance |

| Polycarbonate (PC) | Safety shields, curved glazing, protective covers | Cold-forms well; can stress crack if mishandled; coat for scratch resistance |

| Acrylic (PMMA) | Signage, windows, displays | Excellent clarity; avoid sharp bends to prevent whitening/crazing |

| HDPE | Outdoor furniture, marine panels, cutting boards | Good chemical/weather resistance; more challenging to thermoform |

| PVC (Rigid) | Panels, signage, chemical enclosures | Easy to cut and bond; flame retardant grades available |

You’ll notice that even within the category of rigid plastic sheets, the right choice depends on your application’s need for clarity, toughness, machinability, and environmental resistance. Always consult supplier data and test your process—especially if you’re working with large, thick, or decorative panels.

Next, we’ll explore how manufacturing processes—from injection molding to extrusion—impact the performance, cost, and recyclability of your chosen rigid plastic sheet material.

How Rigid Plastics Are Made and Why Process Selection Counts

Matching Process to Part Geometry

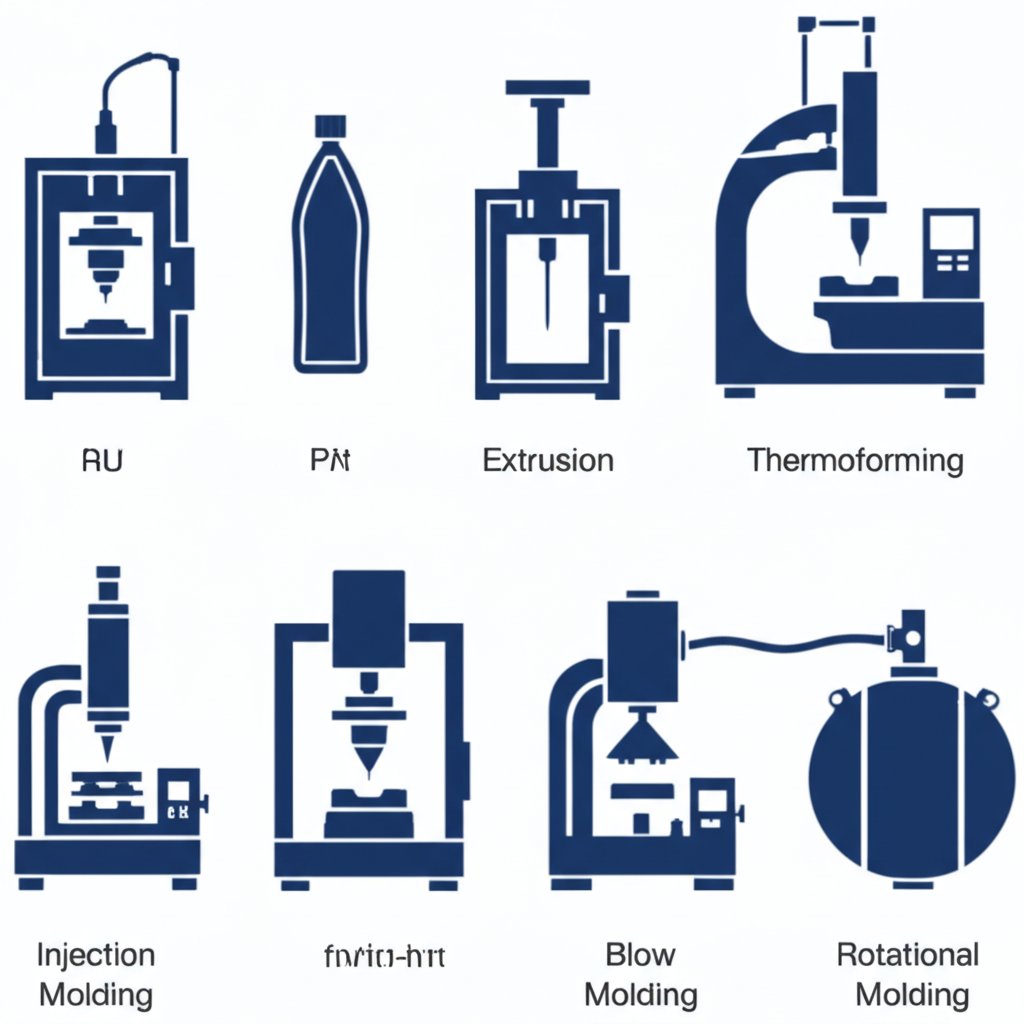

When you’re mapping out a new part—whether it’s a thick plastic sheet rigid guard or a complex enclosure—the way you manufacture it shapes everything from cost to performance. Which process fits best? Let’s break down the five most common methods for shaping stiff plastics and see how each stacks up for wall thickness, volume, and design complexity.

| Process | Best For | Wall Thickness Range | Volume Suitability | Feature Complexity | Post-Processing | Recyclability Impact |

|---|---|---|---|---|---|---|

| Injection Molding | Precision parts, stiff plastic sheet material, enclosures | Thin to moderately thick (varies by polymer) | High | High (fine details, undercuts possible) | Minimal (deburring, trimming gates) | Mono-material streams preferred for easier recycling |

| Extrusion | Continuous profiles, tubes, plastic sheet rigid | Uniform; typically moderate | High | Low to moderate (simple shapes) | Cutting to length, minor machining | Good (single polymer, easy to separate) |

| Blow Molding | Hollow parts (bottles, tanks) | Moderate to thick (varies by design) | Medium to high | Moderate (limited by mold) | Trimming flash, finishing necks | Label/closure compatibility affects recyclability |

| Thermoforming | Large panels, packaging, stiff plastic sheet material | Thin to moderate (sheet-based) | Low to medium | Low to moderate (depends on mold) | Trimming, edge finishing | Mono-material preferred; coatings may complicate |

| Rotational Molding | Large, hollow, seamless parts | Thick, uniform | Low to medium | Low (simple, uniform walls) | Minimal | Usually mono-material, easy to recycle |

Tooling Surface Finish and Gate Considerations

Imagine you need a hardened plastic material for a medical device housing or a batch of stiff plastics for industrial guards. Injection molding shines for high volumes and tight tolerances, but it requires costly, precise tooling—usually steel or aluminum molds. The surface finish of your mold sets the cosmetic standard for every part, so polishing or texturing the tool is a critical step. Gate placement (where material enters the mold) affects flow, part strength, and visible vestiges. Poorly placed gates or insufficient cooling can lead to defects like sink marks, warpage, or visible weld lines (Elastron).

For extrusion, the die shape determines your profile, and surface finish is set by the die and cooling conditions. Thermoforming leverages a mold to shape a heated plastic sheet rigid, so mold texture and temperature control are key for appearance and dimensional accuracy. Rotational molding uses relatively simple molds but excels at making large, uniform-walled parts with minimal finishing.

Failure Modes to Watch

No process is immune to defects. You’ll notice issues like sink marks, warpage, stress whitening, or knit lines most often in parts with uneven wall thickness or sharp corners. Common failure modes include:

- Sink Marks: Depressions from uneven cooling or insufficient packing pressure

- Warp: Twisting or bending due to differential cooling rates

- Stress Whitening: Visible white marks where stiff plastic has been over-stressed

- Knit Lines: Weak spots where two flow fronts meet and don’t fully bond

Mitigating these issues comes down to smart design and process control. Here’s a quick list of strategies:

- Maintain uniform wall thickness throughout your part

- Use generous radii at corners and transitions

- Apply proper draft angles for easy ejection

- Optimize gate placement and cooling channels

- Select the right material rigid type for your process and geometry

Key insight: Tooling costs for injection molding and some other processes are high up front, but the per-part cost drops dramatically at higher volumes. Always weigh the trade-off between initial investment and unit cost based on your production run.

Process Choice and Recyclability

Process selection isn’t just about cost and speed—it shapes your environmental impact too. Using mono-materials in extrusion or injection molding supports easier recycling and cleaner waste streams. In rigid plastic packaging, label and closure compatibility is critical; mixed materials can complicate recycling and reduce the value of recovered stiff plastics.

When should you pick extrusion? If you need long, continuous profiles or plastic sheet rigid for machining or thermoforming, it’s the go-to method. Thermoforming is ideal for large, shallow parts—think machine covers or signage—where you want to minimize tooling but still achieve crisp detail. Rotational molding is your best bet for big, hollow parts like tanks or bins, especially when you need uniform wall thickness and minimal seams.

Understanding the unique strengths and limitations of each process helps you specify the right hardened plastic material and manufacturing route for your next project. Up next, we’ll dive into machining, bonding, and finishing tips to get the most from your chosen rigid type—ensuring your parts perform and look their best on the shop floor and in the field.

Practical Machining, Bonding, and Finishing of Rigid Plastics

Machining Rigid Plastics Without Chatter or Melt

Ever tried to drill or cut a tough plastic material, only to end up with melted edges or rough holes? Machining rigid plastics isn’t just “like metal, but softer”—it brings unique challenges and rewards. Whether you’re shaping stiffest plastic sheet for a machine guard or routing a strong plastic material into a custom enclosure, following the right steps can mean the difference between a clean, precise part and a warped, brittle mess.

- Choose sharp, positive-rake tools. Dull cutters generate excess heat, leading to melting or poor surface finish. Carbide or diamond-tipped tools with polished surfaces work best, especially for glass-filled or reinforced grades.

- Control feed and speed. Plastics lose heat slowly and expand more than metals, so use moderate speeds and higher feed rates to minimize friction and localized heating. For drilling, always use coolant or air to keep the bit and part cool.

- Clear chips often. Plastics are prone to chip buildup, which can clog cutters and cause overheating. Use air blasts or vacuum to keep the work area clean.

- Support thin or bendable plastic strips. Rigid plastics can deflect or vibrate under machining forces, especially in thin sections. Use fixtures or backing plates to prevent chatter and maintain tolerances.

- Trial-fit before bonding or assembly. Plastics can swell, warp, or relax after machining. Check fits before final joining to avoid surprises.

Adhesives and Solvent Bonding Basics

Joining rigid plastics is about more than just picking a glue. Some plastics—like acrylic (PMMA) and polycarbonate—solvent-weld beautifully, forming strong, nearly invisible joints. Others, such as HDPE and PP, resist most adhesives and require surface prep, primers, or specialized welding. Always consult manufacturer technical data and ASTM/ISO standards for compatibility and best practices. For tough plastic assemblies that must withstand load or vibration, mechanical fasteners may be a better choice, but bonding can deliver seamless aesthetics and water-tight performance.

- Solvent welding: Ideal for PMMA, PC, and some PVC. Use the minimum solvent necessary and clamp parts to avoid bubbles or weak joints.

- Adhesives: Two-part epoxies, acrylics, or urethanes work well for many engineering plastics. Surface prep—cleaning, roughening, or priming—can make or break bond strength.

- Heat welding: For compatible polymers, heat or ultrasonic welding can form robust, permanent joints—especially valuable for thick or high-stress parts.

Pros and Cons of Joining Methods

-

Mechanical Fasteners

- Pros: Easy disassembly, reliable for thick or tough plastic material, no chemical compatibility issues

- Cons: Can induce stress, require precise hole sizing, may loosen over time

-

Bonding (Adhesive/Solvent)

- Pros: Seamless finish, water/air-tight, no stress concentrations

- Cons: Permanent, surface prep critical, not all plastics bond easily

Heat Forming and Controlled Curves

Need to form a curved plastic panel or create bendable plastic strips for an enclosure? With rigid plastics, cold bending is rarely an option—most will crack or whiten. Instead, use controlled heat (strip heaters or ovens) to soften the material along the bend line. Even heating, form tooling, and gradual cooling are key to achieving smooth, stress-free curves. For precise results, test the minimum bend radius for your material and thickness, especially if clarity or appearance is critical.

- Evenly heat the area to be bent (avoid overheating, which causes bubbles or discoloration)

- Use a form or jig to set the desired curve; hold in place until the plastic cools

- For tight radii, consider multiple shallow bends or use bendable plastic strips as reinforcement

Edge Finishing and Deburring

Once your part is cut or machined, finishing the edges is essential for safety, aesthetics, and fit. Options include scraping, sanding (progressively finer grits), and flame polishing (for clear plastics like PMMA). Take care to avoid introducing new stresses—annealing after machining can help prevent future cracking, especially in thick or tough plastic components.

-

Troubleshooting Tips:

- Burrs: Use sharp tools and deburr immediately after cutting

- Stress cracking: Slow down feed, reduce clamping force, and anneal after machining

- Hole breakout: Support exit side, use backing material, and drill at moderate speeds

Imagine finishing a curved plastic shield for a machine, or assembling tough plastic parts for a demanding application—by applying these machining and joining fundamentals, you’ll ensure your rigid plastics perform as designed and look their best. Next, we’ll explore recycling strategies to close the loop on your plastic fabrication process.

Getting Rigid Plastics Ready for Recycling the Right Way

Identifying Rigid Plastics in the Field

Ever wondered why some bottles go in your blue bin while others don’t make the cut? The answer starts with knowing what is hard plastic called and how to spot it. Most rigid plastic containers are marked with a Resin Identification Code (RIC)—those small numbers inside the recycling triangle, typically found on the bottom of bottles, tubs, and jars. These codes (1–7) tell you the polymer type, which is essential for proper sorting and hard plastic recycling.

But what if the code is missing or unreadable? Here’s a quick field test to help you distinguish rigid plastics from flexible plastics or plastic flexible packaging:

- Safety first: Wear gloves and goggles if testing unknown items.

- Sample prep: Cut a small, clean piece from the rigid plastic container.

- Sink-float test: Place the sample in water. If it floats, it’s likely HDPE or PP; if it sinks, it could be PET, PVC, or PS.

- Saline step: Add salt to increase water density and repeat. Some plastics that sank may now float, helping you further distinguish types.

- Interpret results: Always confirm with authoritative data or NIR sorting where available, as density ranges can overlap.

Near-infrared (NIR) sorting is increasingly used at material recovery facilities. This technology scans plastics by their unique light signature, quickly separating flexible and rigid packaging streams and boosting the purity of recycled material.

Washing and Contamination Control

Cleanliness is crucial for high-quality hard plastic recycling. Rigid packaging material often comes with labels, closures, or food residues that can disrupt downstream processes. Before recycling, containers should be rinsed and, if possible, labels and caps removed. Why? Because even a small amount of food or oil can contaminate an entire truckload, sending everything to landfill instead of being recycled (Recycle Nation).

- Oils and greases from food residue

- Organic matter (leftover food or drink)

- Paper or plastic labels

- Mixed polymers (e.g., multi-layer containers)

| Rigid Plastic Container Type | Likely Contaminants | Cleaning/Prep Notes |

|---|---|---|

| PET Bottles (RIC #1) | Labels, closures, beverage residue | Rinse thoroughly; remove caps; labels often removed by friction or water in wash plants |

| HDPE Jugs (RIC #2) | Labels, caps, detergent or food residue | Empty and rinse; remove caps; adhesive labels separated during processing |

| PVC Containers (RIC #3) | Labels, closures, chemical residues | Remove hazardous residues; labels may require manual removal |

| PP Tubs (RIC #5) | Food residue, labels, mixed polymer lids | Rinse well; check for incompatible lids; labels separated during processing |

For mixed or multi-layer containers, compatibilizers may help blend different polymers, but always validate with lab testing—there’s no substitute for a clean, single-polymer stream when aiming for high-quality recycled resin.

Reprocessing Constraints and PCR Quality

What happens after cleaning? Rigid plastics are ground into flakes, then washed and separated again—often using sink-float or air classification methods. Advanced NIR or laser sorting can further purify the stream, removing stubborn contaminants and even separating black or colored plastics (PMC: Plastics Recycling).

During reprocessing, keep an eye out for signs of degradation in the recycled plastic—color shifts, off odors, or increased brittleness signal material breakdown. These defects can limit the use of post-consumer recycled (PCR) resin in new products. The quality of PCR depends heavily on the source stream and how well contamination was controlled. Always check the Certificate of Analysis (COA) from your supplier and review relevant standards to ensure your recycled resin meets application needs.

Maintaining traceability and lot segregation throughout collection and processing is essential for protecting the quality and consistency of recycled rigid plastics.

As recycling expands to cover both flexible and rigid packaging, the ability to separate streams—like plastic flexible packaging from rigid plastic containers—will only grow in importance. By following these best practices, you not only support hard plastic recycling but also help ensure that recycled rigid packaging material can be used in new, high-value applications, closing the loop for all types of plastic waste.

Next, we’ll compare flexible vs rigid packaging, so you can make smart choices based on product needs, protection, and sustainability goals.

Rigid Versus Flexible Packaging

What Is Rigid Packaging?

When you pick up a yogurt cup, a clear salad container, or a sturdy bottle, you’re holding an example of rigid packaging. But what is rigid packaging exactly? In plain terms, it’s packaging made from firm materials—like rigid plastic, glass, or metal—that keep their shape even when empty or under pressure. Rigid plastic packaging is especially common for products needing reliable protection, stackability, and a premium shelf presence. Think of containers, trays, bottles, and clamshells that don’t collapse or deform easily.

Rigid Versus Flexible Packaging

Picture a snack pouch that bends in your hand versus a hard plastic tub that stays put. That’s the heart of the flexible vs rigid packaging debate. Flexible packaging plastic includes bags, films, and pouches—lightweight, adaptable, and often more space-efficient. Rigid packaging, by contrast, excels in protecting fragile or high-value goods and offers a robust, high-end feel. Here’s a side-by-side comparison to help you see how these options stack up:

| Attribute | Rigid Plastic Packaging | Flexible Plastic Packaging |

|---|---|---|

| Protection Level | High impact/crush resistance, ideal for fragile items | Good barrier, but less impact/crush protection |

| Barrier Options | Excellent for moisture, oxygen, and physical barriers | Excellent for moisture/oxygen; customizable multilayer films |

| Shelf Impact | Premium look, maintains shape, strong brand presence | Flexible clear plastic can showcase contents, but less structural presence |

| Shipping Efficiency | Bulkier, higher shipping volume and weight | Lightweight, compact, reduces shipping costs |

| Damage Rates | Lower for drops/impacts | Higher if dropped or punctured |

| Recyclability Pathways | Widely recycled (PET, HDPE); clear material streams | Challenging due to multilayer films; recycling infrastructure still developing |

| Typical SKUs | Bottles, jars, tubs, trays, clamshells | Pouches, sachets, wraps, liners |

Decision Factors by Product and Channel

Sounds like a lot to consider? Here’s how to break down your choice for rigid vs flexible packaging:

- Product fragility: Is your product easily crushed or broken?

- Hot-fill or drop resistance: Does it need to withstand heat or accidental drops?

- Brand display requirements: Do you want a premium, structured look or maximum shelf space?

- EPR or recyclability targets: Are you aiming for widely recycled formats or mono-material packaging?

- Line speed and automation: Does your process favor rigid containers or high-speed pouching?

- Cost structure: Are material and shipping costs a top priority?

Hybrid approaches—like combining a rigid tray with a flexible film lid—are gaining traction for balancing protection and efficiency. Whatever you choose, clear labeling and consumer instructions are critical to avoid confusion and support recycling efforts.

Key insight: Packaging choice isn’t just about one feature—it’s a system decision that affects product safety, logistics, branding, and sustainability. Weigh your priorities carefully before choosing between flexible packaging plastic and rigid formats.

Next, we’ll guide you through specifying, sourcing, and qualifying rigid plastics to ensure your packaging meets every requirement from shelf to recycling bin.

Buying, Testing, and Qualifying Rigid Plastics with Confidence

Building a Clear Material Specification

When you’re sourcing rigid plastics for a new project, the first step is to define exactly what you need. Sounds obvious, right? But with so many types of plastic sheet material and different forms of plastic on the market, a clear, detailed specification is your best defense against costly surprises and delays. Imagine trying to build a machine guard or food container—miss a detail like UV resistance or flame retardance, and you could end up with the wrong product or fail a regulatory check.

- Polymer family and grade intent (e.g., PC for clarity, HDPE for chemical resistance)

- Form (sheet, pellet, rod, or custom shape)

- Color and opacity (natural, tinted, opaque, or transparent)

- Surface finish (glossy, matte, textured, or patterned)

- Thickness and dimensional tolerances (specify range and critical dimensions)

- UV- or flame-retardant (FR) needs (for outdoor or electrical uses)

- Regulatory requirements (FDA, NSF, UL, or other certifications)

- Documentation (material certifications, lot traceability, test reports)

Don’t forget to specify if you need recycled content or a particular grade of light plastic material for weight-sensitive applications. The more complete your spec, the easier it will be for suppliers to match you with the right types of hard plastic materials.

Sourcing and Recycled Content Considerations

Once your specification is set, it’s time to source. Lead times and minimum order quantities (MOQs) can vary widely—especially for specialty grades or recycled-content options. If you require all types of plastic materials for prototyping, check if your supplier offers small sample sizes or cut-to-length sheets. For larger runs, clarify MOQs upfront to avoid last-minute surprises.

Recycled-content procurement is increasingly important for sustainability goals. Always request documentation of recycled content and review Certificates of Analysis (COAs) for key properties—especially if your application involves regulatory or food-contact needs. Traceability is critical: you’ll want to know the source stream and processing history to ensure consistency, especially when blending different forms of plastic or recycled resin.

Testing Plans and Acceptance Criteria

How do you know your rigid plastics will perform as needed? Testing is the answer. Application-critical tests ensure your material meets real-world demands, from packaging drop resistance to thermal stability in hot-fill applications. Here’s a table mapping common tests to the standards you’ll encounter when qualifying types of plastic sheets or molded parts:

| Property/Test | Standard/Method | What It Verifies |

|---|---|---|

| Tensile Strength | ASTM D638 / ISO 527 | Ability to resist stretching or breaking |

| Impact Resistance | ASTM D256 (Izod) / ISO 179 | Resistance to sudden shocks or drops |

| Flexural Modulus | ASTM D790 / ISO 178 | Stiffness under bending loads |

| Heat Deflection Temperature (HDT) | ASTM D648 / ISO 75 | Performance at elevated temperatures |

| Environmental Stress Crack Resistance (ESCR) | ASTM D1693 | Resistance to cracking under stress/chemicals |

| Density & Specific Gravity | ASTM D792 / ISO 1183 | Material consistency and polymer identification |

| Color Consistency | ASTM D6290 | Uniformity across batches |

| Thermal Analysis (DSC/TGA) | ASTM D3418 / ASTM E1131 | Melting, crystallization, and thermal stability |

For packaging or structural applications, acceptance criteria should tie directly to your functional needs—such as withstanding a specific drop height or maintaining shape at a certain temperature. Avoid inventing numeric thresholds; instead, reference authoritative data or run application-specific tests (Bizongo: Testing for Rigid Packaging).

Tip: Align your QA sampling plan with both the risk level and production volume. Higher-risk or high-volume jobs demand more rigorous testing—don’t cut corners where performance or safety are on the line.

Final Notes: Labeling, Food-Contact, and Traceability

Don’t overlook the details that can make or break compliance. For food-contact or medical uses, confirm that your chosen rigid plastic meets all relevant standards and that documentation is available for audits. Labeling should clearly state material type, grade, and lot number for traceability—especially important when using recycled content or blending different forms of plastic. If your application involves light plastic material for weight savings, note this in the specification for easier supplier matching.

By following these steps, you’ll streamline the process of qualifying all types of plastic materials—reducing risk and ensuring your final product meets every requirement from the drawing board to the end user. Up next, we’ll show you how to get the most from machining rigid plastics by partnering with the right supplier.

When to Machine Rigid Plastics with a Trusted Partner

When CNC Machining Rigid Plastics Makes Sense

Faced with a complex geometry, ultra-tight tolerances, or a quick-turn prototype for a thick plastic window or a rugged plastic cover? That’s when it pays to team up with a specialist in CNC machining for rigid plastics. Not every project demands the same level of precision or complexity, but certain scenarios make professional collaboration invaluable:

- Ultra-tight tolerances: When your part requires repeatable accuracy down to a few thousandths of an inch.

- Multi-axis features: For parts with undercuts, angled holes, or 3D contours that basic machines can’t reach.

- Small batch or rapid prototyping: When you need a handful of thick black plastic components fast—without the delays or costs of tooling.

- Mixed-material assemblies: If your design combines rigid plastics with metals or other materials, precision CNC machining ensures a perfect fit.

For these demanding applications, CNC machining services like those offered by XTJ are a top choice. Their advanced 4- and 5-axis machining centers handle everything from intricate hard plastic covers to thick plastic parts with challenging features, all while maintaining ISO 9001:2015 and IATF16949 quality standards. With lead times as short as three days and expert DFM (Design for Manufacturability) support, you can accelerate your development cycle and reduce costly rework.

Design Tips for Better Tolerances and Finish

Getting the most from your machined rigid plastic parts isn’t just about the right equipment—it starts with smart design. Here are proven ways to ensure your thick plastic or hard plastic covers meet expectations for fit, function, and finish:

- Use general tolerances where possible: Reserve tight tolerances for truly critical features to control cost and complexity.

- Minimize deep cavities and sharp internal corners: These require specialized tools and extra machining time.

- Standardize hole sizes and edge radii: Design for standard drill bits and milling tools to streamline production.

- Specify minimum wall thickness: For most rigid plastics, keep walls at least 1.5 mm thick to avoid warping or weakness.

- Plan for post-processing: If your part needs a polished edge or glossy finish (like a thick plastic window), note it on your drawing—techniques like sanding, vapor polishing, or flame finishing may be needed.

Partner Checklists and Hand-off Quality

To get the best results from your machining partner, clear communication is key. Before you hand off a design for manufacturing, make sure you’ve covered all the essentials:

- Material callouts: Specify exact polymer and grade (e.g., PC, ABS, HDPE).

- Stock form: Indicate if you require plate, rod, or sheet stock.

- Critical dimensions: Highlight features that must be held to tight tolerances (e.g., fits for mating parts, window openings).

- Surface finish notes: State if you need a glossy, matte, or textured finish—especially important for visible plastic covers or thick black plastic panels.

- Inspection requirements: List any special QA checks, such as CMM inspection or visual standards.

Early DFM reviews—where your supplier checks your design for manufacturability—save time, reduce costly rework, and ensure your thick plastic or hard plastic covers are right the first time.

Why Supplier Collaboration Matters

Imagine launching a new product and discovering late-stage issues—mismatched holes, warped thick plastic windows, or surface flaws on a critical plastic cover. By partnering with a CNC machining specialist early, you gain access to DFM expertise, material selection guidance, and the latest machining technology. Providers like XTJ not only deliver high-precision parts but also help you optimize your design for manufacturability, cost, and speed.

Whether you need a handful of prototypes or a full production run, choosing the right partner for CNC machining of rigid plastics ensures your designs become reality—on time, on budget, and to the highest quality standards.

Frequently Asked Questions About Rigid Plastics

1. What is a rigid plastic?

Rigid plastics are materials that keep their shape under normal use, resisting bending or deformation due to their tightly packed molecular structure. These plastics are commonly found in sturdy containers, housings, pipes, and packaging that require structural integrity and dimensional stability.

2. What plastic is the most rigid?

Among commonly used plastics, polycarbonate (PC), acrylic (PMMA), and certain grades of high-density polyethylene (HDPE) are known for exceptional rigidity and stiffness. These materials are chosen for applications where maintaining shape and withstanding loads are critical, such as safety shields, glazing, and structural components.

3. How can you tell if a plastic is rigid or flexible?

You can identify rigid plastics by their inability to bend without showing whitening or cracking, their sharp sound when tapped, and their ability to maintain a flat or set shape under pressure. Flexible plastics, on the other hand, can be bent or folded easily without damage and often feel softer or more pliable.

4. What are common types of rigid plastics and their uses?

Common rigid plastics include HDPE (for piping and containers), PP (automotive parts, labware), PVC (pipes, window frames), ABS (housings, appliance covers), PC (lenses, machine guards), PET (bottles, packaging), and PMMA (displays, glazing). Each is selected based on its specific balance of toughness, clarity, chemical resistance, and cost.

5. When should you use CNC machining for rigid plastics?

CNC machining is ideal for rigid plastics when you need high precision, complex geometries, or fast prototyping—especially for thick or detailed parts like covers and windows. Services like XTJ offer advanced 4- and 5-axis machining, tight tolerances, and support for various rigid plastics, ensuring accuracy and quality for demanding projects.

-

Posted in

hard plastic materials, plastic packaging, plastic recycling, plastic sheet types, rigid plastics