What Is Rigid Plastic? Field Tests, Types, And Smart Recycling

What Is Rigid Plastic? Field Tests, Types, And Smart Recycling

Understanding What Is Rigid Plastic in Measurable Terms

When you pick up a plastic part that doesn’t bend easily, you might wonder: what is rigid plastic, and how do professionals actually define it? Is it just about how stiff something feels in your hand, or is there more science behind it?

What Makes a Plastic Rigid?

At its core, rigid plastic refers to a polymer material that resists elastic deformation when subjected to normal service loads. In simple terms, these plastics don’t flex, bend, or stretch easily under everyday use. The degree of plastic rigidity is not just a matter of touch—it’s a measurable property, defined by several key engineering tests.

Defining Rigidity with Test Methods

To move beyond guesswork, engineers rely on standardized testing to quantify how stiff or “rigid” a plastic is. Here are the main indicators you’ll find on a technical datasheet:

- Flexural modulus (ASTM D790): Measures resistance to bending. Higher values mean greater rigidity. For example, rigid plastics like PMMA (acrylic) or PC (polycarbonate) often have flexural modulus values above 2 GPa, while flexible plastics like LDPE are much lower.

- Tensile modulus (ASTM D638): Measures resistance to stretching. This is another way to gauge a material’s stiffness under tension.

- Shore hardness (ASTM D2240): Indicates surface hardness, which often correlates with rigidity, especially for comparing different types of plastics.

- Heat deflection temperature (HDT, ASTM D648): Indicates the temperature at which a plastic begins to soften under load. Rigid plastics maintain their form well below this point.

Each of these tests provides a quantifiable benchmark, so you can compare different rigid materials based on real numbers, not just feel.

“Treat ‘rigid’ as a property range measured by standardized tests, not just a feel-in-hand.”

Why Rigidity Influences Performance

Why does it matter if a plastic is rigid? In real-world applications, rigidity determines whether a plastic can serve as a structural element, protective cover, or load-bearing component. For example, rigid plastic is commonly used in:

- Electronics housings

- Food and storage containers

- Structural panels and machine guards

- Protective covers and enclosures

However, keep in mind that a rigid material is not always a tough plastic. High stiffness can sometimes mean brittleness—think of how a polystyrene cup can snap rather than bend.

What Determines Plastic Rigidity?

Several factors influence how rigid a plastic feels and performs:

- Crystallinity: More crystalline polymers (like PET) tend to be stiffer.

- Molecular weight: Higher molecular weight can increase rigidity.

- Filler content: Adding glass fibers or minerals can boost both stiffness and rigidity.

- Wall thickness: Thicker parts feel stiffer, even if made from the same resin.

Temperature also plays a role. As a plastic approaches its glass transition temperature (Tg) or melting temperature (Tm), it can temporarily lose rigidity—becoming softer or even flexible under heat.

“Rigid” does not mean “tough”—some rigid plastics are brittle, while others combine stiffness with impact resistance.

Quick Reference: What to Check on a Datasheet

- Flexural modulus (look for values above 2 GPa for most rigid plastics)

- Tensile modulus (also in the GPa range for stiff materials)

- Shore hardness (higher numbers = harder/less easily indented)

- Heat deflection temperature (higher HDT = better performance at elevated temperatures)

As you continue through this guide, you’ll learn how to distinguish rigid plastic from flexible types, compare common material families, understand processing methods, and make smart choices for sourcing and recycling. Ready to dive deeper? Let’s explore the spectrum of plastic rigidity in the next section.

Rigid Versus Flexible Plastics in the Real World

Ever wondered why some plastic containers snap when you bend them, while others fold and bounce back? The answer lies in the fundamental differences between rigid and flexible plastics. Let’s break down how you can tell them apart, both in the lab and in your everyday life.

Rigid Versus Flexible Behavior Explained

Rigid plastics are engineered to keep their shape under normal use—they resist bending, stretching, or compressing. Think of a sturdy yogurt cup or a clear plastic box: press on them, and you’ll feel only a slight give, if any. In contrast, flexible plastics are designed for movement and adaptability. Squeeze a sandwich bag or a shrink wrap, and you’ll notice how easily it flexes and reshapes. This plastic flexibility comes from differences in polymer structure, additives, and thickness.

Packaging is a perfect example: rigid packaging refers to molded, self-supporting shapes like bottles, jars, or clamshells, while flexible vs rigid packaging often comes up when comparing these to films, pouches, or wraps that conform to the product inside. Rigid options offer more protection and an upscale look, while flexible plastics save space and cost—each has its place depending on your needs.

Tactile and Visual Cues You Can Trust

When you’re unsure whether a plastic item is rigid or flexible, your senses can offer quick clues:

- Sound: Tap a rigid plastic—it gives a sharp, high-pitched sound. Flexible plastic sounds duller or muffled.

- Gloss and Clarity: Rigid plastics like acrylic (PMMA) and polycarbonate (PC) often look glassy and clear. Flexible plastics tend to be hazier or matte.

- Creak or Snap: Try flexing a polystyrene (PS) cup. Hear that creak? That’s a classic sign of a rigid, brittle plastic.

- Hinge Behavior: Polypropylene (PP) can be semi-rigid—thicker parts feel stiff, but thin sections may act as living hinges, bending repeatedly without breaking.

Remember, rigidity is a spectrum. Some plastics, like certain grades of PP or PVC, can go from flexable plastic to rigid depending on their formulation and thickness. A thin sheet might feel flexible, while a thicker panel of the same material becomes quite stiff (source).

Simple At-Home Checks

If you want to test an unknown plastic, try these quick steps:

- Bend Test: Gently try to flex the item. Rigid plastics will resist and may snap, while flexable plastic bends easily and springs back.

- Thumbnail Indentation: Press your nail into the surface. Rigid plastics hardly dent; flexible ones may leave a mark.

- Float–Sink Density Check: Place a small piece in water or mild saltwater. Some rigid plastics (like HDPE) float, while others (like PET) sink. Always verify density with datasheets for accuracy.

- Glossy, clear appearance? Likely rigid (PMMA, PC).

- Creaks or snaps when flexed? Likely rigid (PS).

- Acts as a hinge without breaking? Could be semi-rigid PP.

“Rigid” is not a recyclability category—it’s a descriptor of how a plastic behaves under stress. Always check resin codes and datasheets for certainty.

Environmental factors matter too. The same plastic can feel more or less rigid depending on temperature and thickness. For example, a plastic bottle left in the sun may soften, while a thick panel stays stiff. That’s why it’s best to check multiple cues and, when in doubt, consult the manufacturer’s datasheet for definitive answers.

Now that you can spot the difference between rigid and flexible plastics, let’s explore which plastic families are most often used for rigid applications—and how their properties stack up in real-world products.

Common Rigid Plastics and How They Compare

When you’re choosing a material for a sturdy container, a protective panel, or even a thick plastic window, you’ll quickly discover there’s no single answer to what makes a plastic “rigid.” Instead, engineers and designers rely on several types of hard plastic materials, each with its own blend of strength, clarity, and resilience. So, how do you decide which is right for your project?

Core Families Used for Rigid Applications

Let’s break down the most common rigid plastics you’ll encounter in manufacturing, construction, and everyday products. Each of these types of hard plastic materials brings something unique to the table:

- PMMA (Acrylic): Renowned for glass-like clarity and UV resistance. Perfect for display cases, aquariums, and signage where visual appeal and weatherability matter.

- Polycarbonate (PC): Combines high impact strength with transparency. Used for safety glazing, riot shields, and bullet-resistant windows—think of it as the go-to for a demanding thick plastic window.

- HDPE (High-Density Polyethylene): Lightweight, strong, and chemical-resistant. Common in industrial tanks, playground equipment, and marine parts.

- PVC (Polyvinyl Chloride): Offers excellent fire resistance and durability. Rigid PVC is a staple for window frames, pipes, and wall panels.

- ABS (Acrylonitrile Butadiene Styrene): Balances rigidity and impact resistance. Found in tool housings, toys (like LEGO bricks), and automotive trim.

- HIPS (High-Impact Polystyrene): Cost-effective and easy to process. Used in packaging, signage, and disposable utensils.

- PET (Polyethylene Terephthalate): Stiff and clear. Ideal for beverage bottles and food containers.

- PP (Polypropylene): Can be semi-rigid or rigid depending on grade. Used for automotive parts, reusable containers, and living hinges.

- Nylon (Polyamide): Tough and abrasion-resistant. Suits gears, bearings, and structural machine parts.

Where Each Plastic Excels

Not all hard plastics are created equal. Imagine you need a thick plastic window for a machine guard: you might pick polycarbonate for its impact resistance, or acrylic for its unmatched clarity. For chemical tanks, HDPE’s resistance to corrosion stands out. Here’s how these types of plastic sheet material stack up:

| Plastic | Density | Stiffness/Modulus | Clarity | Heat Tolerance | Common Uses |

|---|---|---|---|---|---|

| PMMA (Acrylic) | ~1.18 g/cm³ | High | Excellent | Moderate (up to ~80°C) | Glazing, signs, displays, plastic sheet rigid |

| Polycarbonate (PC) | ~1.20 g/cm³ | High | Very good | High (up to ~140°C) | Machine guards, riot shields, safety glazing, thick plastic window |

| HDPE | ~0.95 g/cm³ | Moderate | Opaque | Moderate (up to ~120°C) | Containers, tanks, playground equipment |

| PVC (Rigid) | ~1.38 g/cm³ | High | Opaque | Moderate (up to ~60°C) | Pipes, window frames, panels |

| ABS | ~1.04 g/cm³ | Moderate-High | Opaque | Moderate (up to ~100°C) | Tool housings, toys, automotive trim |

| HIPS | ~1.05 g/cm³ | Moderate | Opaque | Low-Moderate (up to ~70°C) | Packaging, signage, utensils |

| PET | ~1.38 g/cm³ | High | Good | Moderate (up to ~80°C) | Bottles, food containers |

| PP | ~0.90 g/cm³ | Moderate | Translucent | Moderate (up to ~100°C) | Automotive, reusable containers, hinges |

| Nylon | ~1.14 g/cm³ | High | Opaque | High (up to ~120°C) | Gears, wear parts, bearings |

Limitations to Consider Before Choosing

Every material has trade-offs. Here are some quick flags to keep in mind as you compare the stiffest plastic options for your job:

- Stress Cracking: Some plastics, such as PMMA and HIPS, can crack under certain chemicals or stress.

- UV Sensitivity: Polycarbonate is tough but can yellow outdoors unless UV-stabilized. Acrylic fares better in sunlight.

- Brittleness at Low Temperatures: Polystyrene and acrylic can become brittle in the cold.

- Surface Wear: PC is prone to scratching unless coated; ABS can scuff under heavy use.

- Cost vs. Performance: The stiffest plastic may not always be the most cost-effective. Sometimes a moderate option with added fillers or coatings is best.

It’s also important to note that formulation and processing can shift these properties dramatically. For example, adding fillers can make a plastic stiffer or more heat-resistant, while changing processing conditions can affect clarity or toughness.

Always check datasheets and relevant standards for food contact, flammability, and outdoor durability before finalizing your selection. The right choice depends on your application’s unique needs.

Now that you know how the leading types of hard plastic materials compare, you’re ready to see how these materials are shaped into the products you use every day. Next, we’ll explore the manufacturing processes that bring rigid plastics to life.

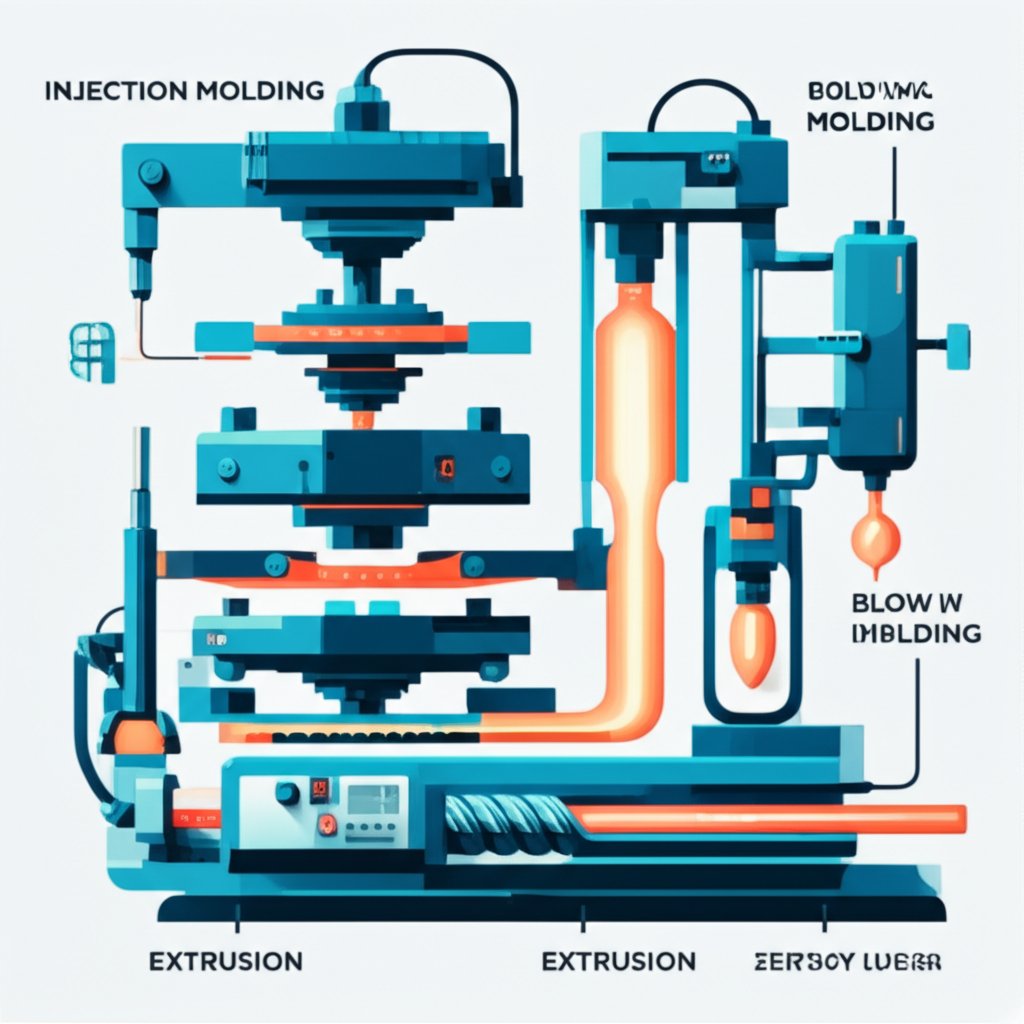

Manufacturing Processes for Rigid Plastics Made Practical

Ever wondered how a rigid plastic container gets its shape, or what makes a machine guard so flawlessly sturdy? The answer lies in the manufacturing process. Let’s break down the most common ways rigid plastics are transformed from raw resin into everyday products, and what you need to watch for when designing or specifying rigid packaging material.

Injection Molding for Complex Rigid Parts

Injection molding is the go-to process for producing intricate, high-precision rigid plastic components—think electronics housings, automotive trim, and durable rigid plastic containers. Here’s how it works: melted plastic is injected under pressure into a steel or aluminum mold, then rapidly cooled to form the finished part. This method excels at producing complex shapes with tight tolerances and smooth finishes, especially for high-volume runs.

- Compatible resins: ABS, PC, PMMA, PP, PS, HDPE, PVC

- Strengths: High detail, repeatability, and surface quality

- Surface finish: Can be glossy, matte, or textured depending on mold design

Blow Molding and Thermoforming for Containers and Panels

Need hollow, lightweight, or large-volume parts—like bottles, tanks, or clamshells? Blow molding and thermoforming are your best bets.

- Blow molding: Forms hollow items by inflating hot plastic inside a mold. Perfect for bottles, jugs, and some rigid packaging material.

- Thermoforming: Involves heating plastic sheet rigid until pliable, then pulling it over a mold using vacuum or pressure. This is ideal for trays, lids, and custom packaging inserts.

- Compatible resins: HDPE, PET, PP, PVC, PS for blow molding; ABS, HIPS, PETG, PMMA for thermoforming

- Strengths: Efficient for large parts, lower tooling costs (especially for thermoforming), and great for clear or colored items

Extrusion and Compression Molding Basics

Extrusion is the backbone for making continuous profiles—think pipes, window frames, and flat plastic sheet rigid. Molten plastic is pushed through a die to create long, uniform shapes. Compression molding, on the other hand, is best for dense, flat, or reinforced parts. The resin is placed in a heated mold, compressed, and then cured under pressure.

- Compatible resins: PVC, HDPE, PP, ABS, and more

- Strengths: Extrusion is ideal for high-volume, uniform cross-sections; compression molding is suited for thick, strong, or composite parts

Common Defects and How to Prevent Them

No process is perfect. Here are issues you might encounter—and how to address them (source):

- Warpage: Uneven cooling or wall thickness causes parts to twist. Tip: Keep wall thickness uniform and optimize cooling channels.

- Sink marks: Depressions in thick areas. Tip: Core out thick zones and follow rib-to-wall ratios.

- Brittle weld lines: Weak seams where melt fronts meet. Tip: Improve venting and move weld lines away from stress points.

- Voids: Internal air pockets. Tip: Avoid sudden thickness changes and ensure proper venting.

- Stress whitening: Visible white marks from bending or impact. Tip: Use appropriate resins and avoid sharp corners.

- Set minimum wall thickness (avoid thick-to-thin transitions)

- Use ribbing to support large flat areas

- Incorporate generous fillet radii (rounded corners)

- Design bosses with proper support and avoid sharp edges

- Position gates in thicker sections for better flow

Process Comparison Table

| Process | Best for Part Size | Tooling Complexity | Production Volume | Typical Applications |

|---|---|---|---|---|

| Injection Molding | Small to Large, Complex | High | Medium to High | Housings, containers, precision parts |

| Blow Molding | Medium to Large, Hollow | Medium | High | Bottles, tanks, rigid packaging |

| Thermoforming | Medium to Large, Shallow | Low to Medium | Low to Medium | Trays, lids, display panels |

| Extrusion | Long, Uniform | Medium | High | Pipes, profiles, plastic sheet rigid |

| Compression Molding | Small to Medium, Flat/Thick | Medium | Low to Medium | Panels, reinforced parts |

Design and Material Selection Tips

When specifying rigid plastic containers or rigid plastic packaging, consider the following:

- Clarity: Choose PMMA or PET for see-through packaging; HDPE or PP for opaque, robust options.

- Impact resistance: Polycarbonate for high-impact, ABS for balanced performance.

- Barrier needs: PET and multilayer constructions for food or chemical resistance.

Always consult supplier guides and relevant standards to match the resin and process to your specific requirements. The right combination ensures your product is not only rigid, but also reliable and efficient to produce.

Next, you’ll learn how to source these materials, what drives costs, and how to work with suppliers to get the right rigid plastic sheet or part for your needs.

Sourcing and Procurement Guidance for Rigid Plastic Sheet Materials

Imagine you need rigid plastic sheets for a new product or a construction project. Where do you start, and how do you avoid costly mistakes? Sourcing the right rigid plastic sheet material is about more than just finding a supplier—it’s about understanding your requirements, the market, and what truly drives price, quality, and delivery.

Where to Buy Sheet, Rod, and Resin

There are several channels for acquiring rigid plastic sheets and related forms like rods or resin pellets. Here’s how to navigate your options:

- Distributors: These companies stock a wide range of standard and specialty rigid plastic sheets. They offer cut-to-size services and quick shipping for common sizes, including hard plastic sheets 4x8 and custom thicknesses. Distributors are ideal for small-to-medium orders and fast turnaround.

- Compounding Houses: If you need custom colors, fillers, or performance additives, compounding houses can blend resin to your spec. This route is best for large runs or when your project requires unique properties.

- Converters and Fabricators: These suppliers purchase bulk sheet and transform it into finished or semi-finished parts—think machined panels, CNC-cut guards, or printed signage.

- Direct from Manufacturer: For very large projects or export, buying direct may offer cost advantages and the broadest selection, but often comes with higher minimum order quantities (MOQs) and longer lead times.

Before you buy, always request datasheets that specify mechanical, thermal, and chemical properties, verified by ASTM or ISO test methods. If your application involves food contact, outdoor use, or electrical insulation, ask for the relevant certifications up front.

Cost Drivers That Matter

What makes one rigid plastic sheet more expensive or harder to get than another? Here are the main cost and lead time drivers:

| Cost/Lead Time Driver | Impact on Sourcing |

|---|---|

| Tooling Complexity | Custom molds or dies for unique shapes increase upfront costs and extend lead times. |

| Run Length | Longer production runs reduce per-unit cost. Small orders may incur setup fees or higher prices. |

| Part Size/Thickness | Very thick or large sheets (e.g., hard plastic sheets 4x8) may require special handling and longer production cycles. |

| Surface Finish | Glossy, matte, or textured finishes can require extra processing steps, impacting cost and delivery. |

| Secondary Operations | Machining, printing, or bonding add time and labor, increasing overall cost. |

| Quality Requirements | Tight tolerances, flatness, or certifications (e.g., UL, FDA) can drive up both cost and lead time. |

Don’t forget that resin density (specific gravity) also affects cost per part, especially when comparing materials by weight versus by volume (Teknor Apex).

Procurement Checklist: What to Confirm with Suppliers

- Minimum Order Quantity (MOQ): Can you order a single sheet, or is there a minimum lot size?

- Color and Additive Availability: Are custom colors, UV stabilizers, or flame retardants available?

- Tolerances: What are the standard and achievable tolerances on thickness, width, and length?

- Flatness and Thickness Specs: Especially critical for stiff plastic sheet material used in glazing or machine guards.

- Post-Processing Needs: Will you need machining, printing, or bonding? Can the supplier handle these, or do you need a fabricator?

- Packing and Shipping: How will sheets be protected in transit? Is there an option for export crating or custom labeling?

Before placing an order, double-check all specifications, quantities, and delivery details. This step is crucial for avoiding surprises and ensuring a smooth transaction.

Lead Times and Special Considerations

Lead times for rigid plastic sheets can vary widely. Stock sizes and standard grades are often available for immediate shipment. However, custom compounds, special thicknesses, or large volumes may require several weeks of production. Geometric complexity—such as cutouts or intricate shapes—adds setup and processing time.

If your application requires special additives, flame retardants, or food contact grades, engage your supplier early. Custom formulations may need additional testing or regulatory review, which can delay delivery if not planned for in advance.

"A proactive, detail-driven approach to sourcing rigid plastic sheet material saves time, reduces cost, and ensures your project stays on track."

With your procurement strategy in place, you’re ready to move to the next step: identifying rigid plastics in the field and ensuring their responsible end-of-life management.

Field Identification and Responsible Recycling of Hard Plastics

When you’re sorting through household waste or managing materials at work, how do you know which items are rigid plastics—and what’s the right way to recycle them? With so many kinds of plastic and different forms of plastic packaging, it’s easy to get confused. Here’s how you can confidently identify rigid plastics and handle them responsibly at the end of their life.

Reading Resin Identification Codes

Ever noticed a triangle with a number on the bottom of a bottle or container? That’s the Resin Identification Code (RIC), a key tool for recognizing hard plastic types. The most common codes for rigid plastics include:

- #1 PET (Polyethylene Terephthalate): Clear drink bottles, food containers

- #2 HDPE (High-Density Polyethylene): Milk jugs, detergent bottles

- #5 PP (Polypropylene): Yogurt cups, caps, some food tubs

- #6 PS (Polystyrene): Disposable cutlery, rigid cups

- #7 Other: Multilayer or specialty plastics

Keep in mind: the presence of a code does not guarantee recyclability in your area. Many states require RICs on rigid plastic containers, but acceptance varies by community.

DIY Checks for Rigidity and Density

Not sure if an item is a rigid plastic? Try these quick steps to identify and compare:

- Locate the Code: Look for the triangle with a number—usually on the bottom or side.

- Bend/Thumbnail Test: Gently flex the item or press your nail into it. Rigid plastics resist bending and denting; flexible types will yield or crease.

- Float–Sink Test: Place a small piece in water or a mild salt solution. Some rigid plastics (like HDPE) float, while others (like PET) sink. Compare with known items if you’re unsure.

- Compare to Known Items: Match the look and feel to common rigid products—like a milk jug or a clear food container.

These methods help distinguish hard plastic from other different forms of plastic, such as films and foams.

Recycling Preparation Best Practices

Proper preparation is essential for hard plastic recycling. Here’s a quick checklist to make your recycling efforts count:

- Empty and rinse all containers to remove residue

- Keep caps on bottles if your local program requests it

- Do not mix different materials (e.g., plastic with metal or glass)

- Check for food-contact marks and temperature ratings if you plan to reuse containers

- Remove labels or inserts only if instructed by your recycler

Note: Not all rigid plastics are accepted curbside. Some items—like multi-material packaging or products with metal inserts—may not be suitable for standard hard plastic recycling streams (EPA).

Local recycling rules can differ widely. Always check with your municipal program, the EPA, or industry resources before placing plastics in your recycling bin. When in doubt, ask—responsible recycling starts with good information.

For added safety and sustainability, always defer to reputable standards and local authorities. By following these simple steps, you’ll reduce contamination, improve recycling rates, and help ensure that rigid plastics are handled in a way that benefits both your community and the environment.

With a handle on field identification and recycling, you’re ready to make smarter choices about material selection—balancing performance, cost, and environmental impact in your next project.

How to Choose the Right Rigid Plastic for Your Job

When you’re faced with hundreds of resin options, how do you narrow down the best hard plastic material for your application? Sounds complex? It doesn’t have to be. The secret lies in matching your performance priorities to the resin families and manufacturing processes that deliver the results you need. Let’s walk through a practical framework that will help you select the right stiff plastic—without overengineering or overspending.

Selecting for Clarity and Impact

Imagine you’re designing a protective cover that must be both clear and tough. Your first step is to list what matters most: do you need high transparency, impact resistance, or both? For applications like machine guards, lighting covers, or display cases, clarity and toughness are key. Polycarbonate (PC) and acrylic (PMMA) are top contenders:

- Polycarbonate (PC): Excellent impact strength, good clarity, but more prone to scratching. Ideal for safety glazing and shields.

- Acrylic (PMMA): Superior optical clarity and weatherability, but less impact-resistant than PC. Great for signage and display panels.

Both are available as light plastic material in sheet form, making them easy to fabricate for all types of plastic materials that require transparency.

Choosing for Heat and Chemicals

What if your part needs to handle hot environments or resist aggressive chemicals? This is where you’ll want to look at specialty engineering resins and tough plastic materials:

- Nylon (PA): High mechanical strength and wear resistance—well-suited for gears, bushings, and automotive brackets. Be mindful of moisture absorption in humid settings.

- PBT, PET, PPS: These engineering plastics retain stiffness and dimensional stability at elevated temperatures. PPS, in particular, stands out for heat and chemical resistance, making it a strong plastic material for automotive and industrial uses.

- Polypropylene (PP): Lightweight, excellent chemical resistance, and good fatigue durability. Used in containers exposed to acids or bases, and in living hinges.

When working in environments with oils, fuels, or solvents, always check datasheets for compatibility. Not all types of hard plastic materials will stand up to every chemical or temperature extreme.

Balancing Cost with Performance

Budget matters too. Sometimes the stiff plastic with the highest performance isn’t necessary—and a more economical option will do the job. Here’s a quick comparison to help you map common needs to resin/process choices:

| Performance Priority | Likely Resins | Processing Route | Typical Use |

|---|---|---|---|

| High Impact + Clarity | PC, PMMA | Injection Molding, Extrusion, Sheet Fabrication | Guards, covers, windows |

| Heat Resistance | PPS, PBT, PET | Injection Molding | Automotive, electronics |

| Chemical Resistance | PP, Nylon | Injection Molding, Extrusion | Containers, bushings |

| Low Weight | PP, HDPE | Blow Molding, Extrusion | Packaging, tanks |

| Surface Finish/Color | ABS, PP | Injection Molding | Consumer products, housings |

Remember, all types of plastic materials have unique trade-offs. Sometimes a blend or a filled grade is the answer. For example, glass-filled nylon boosts stiffness and heat resistance, but may reduce toughness or complicate processing.

Key Trade-Offs to Consider

- Clarity vs. Scratch Resistance: Clear plastics may scratch more easily (PC vs. PMMA).

- Stiffness vs. Impact: The stiffest plastics can be brittle; tougher grades may sacrifice some rigidity.

- Heat Resistance vs. Cost: High-heat materials (PPS, PBT) cost more than commodity resins (PP, ABS).

- Bonding/Printing: Some plastics are easier to print or glue than others—always test before committing to a process.

“A strategic approach to plastic material selection balances performance, processability, and cost. Match each property to your functional needs for best results.”

Before making a final choice, validate your assumptions with supplier datasheets, regulatory requirements, and—if the application is safety-critical—real-world testing. This is especially important with all types of plastic materials, as subtle formulation differences can lead to big performance shifts. If you’re unsure, consult a materials expert or request samples for prototyping. That way, you’ll know your chosen hard plastic material will deliver the strength, durability, and value your project demands.

Ready to turn your resin choice into a finished part? In the next section, we’ll explore when machining rigid plastics makes sense and how to get precision results for your toughest jobs.

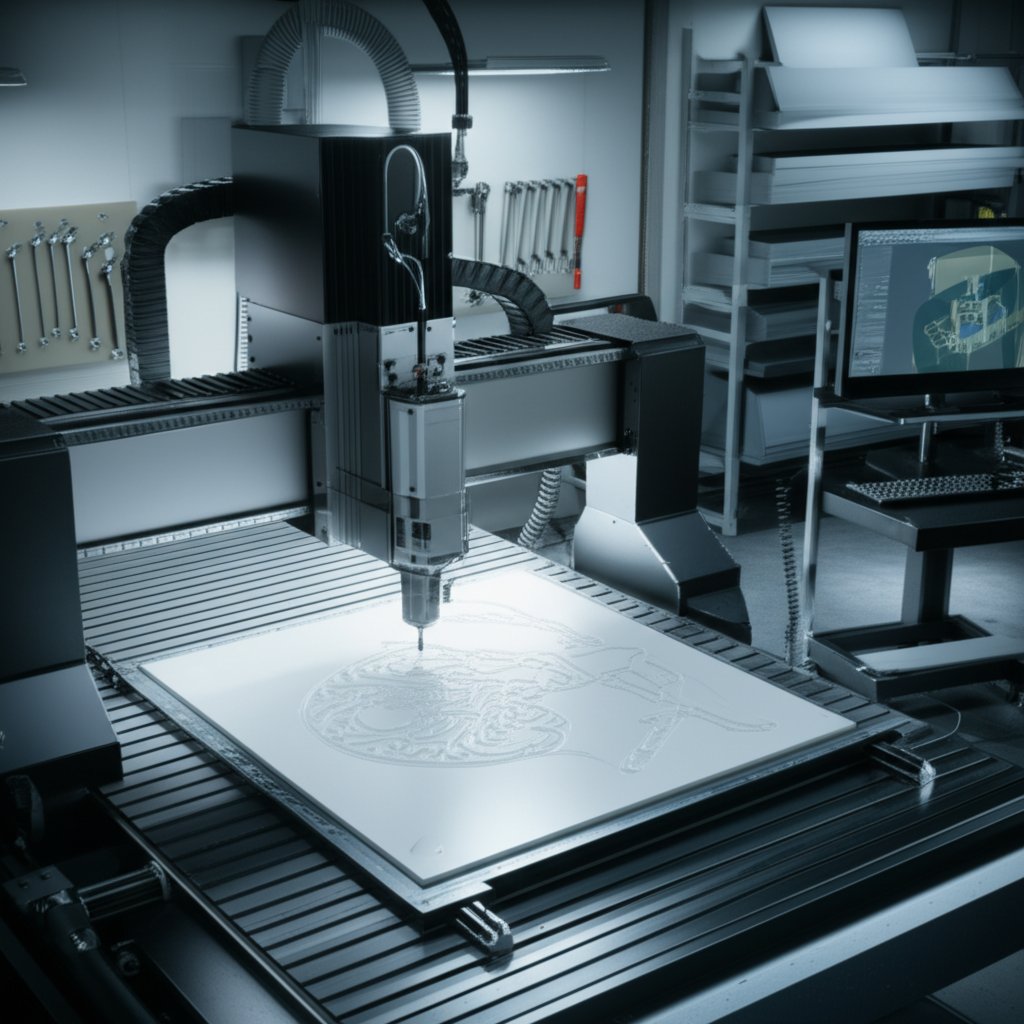

When and How to Get Tight Tolerances

Ever wondered when it makes sense to machine hard plastic sheets or thick plastic blocks instead of molding them? Or how to ensure your stiff plastics turn into high-precision parts without warping, melting, or surface flaws? Let’s break down when CNC machining is the smart choice for rigid plastics, and how to get the best results for demanding jobs.

When CNC Machining Beats Molding

Imagine you need a handful of custom components, a prototype for testing, or a part with complex internal features. Setting up an injection mold would be overkill—expensive, slow, and inflexible. That’s where CNC machining shines. Here’s when this approach is your best bet:

- Low-volume runs: Ideal for quantities from one-off samples up to a few hundred parts, where tooling costs for molding can’t be justified.

- Iterative prototypes: Quickly refine designs and test fit, function, or aesthetics before moving to mass production.

- Tight tolerances: Need features within +/- 0.005mm, or precise fits for assemblies? CNC machining delivers unmatched accuracy.

- Thick section parts: Molding thick plastic often leads to sink marks or voids; machining from solid stock avoids these issues.

- Specialty materials or hard plastic covers: Some engineering plastics are easier to source as sheet or rod, then machine to size, rather than mold.

Providers like XTJ offer advanced 4 and 5-axis CNC machining for rigid plastics, with ultra-tight tolerances and fast lead times—making them a go-to resource for precision jobs across industries.

Design Tips for Machined Plastics

Designing for machined thick plastic or rigid sheets is different from metals or molded parts. Here are key considerations to ensure your parts come out right:

- Toolpath strategy: Use gradual curves and avoid abrupt corners to minimize stress and tool chatter.

- Chip evacuation: Plastics tend to form long, stringy chips—design open pockets and through-holes to aid chip removal and prevent tool jamming.

- Stress relief: Consider annealing after machining to reduce internal stresses, especially for load-bearing or thick plastic parts.

- Heat buildup: Plastics are more prone to melting or warping from friction. Use sharp tools, light passes, and cooling air or fluids when appropriate. Not all coolants are suitable—check compatibility with your chosen plastic.

For hard plastic sheets used in covers, guards, or enclosures, specify tolerances and flatness requirements up front, as plastics can move more than metals during machining and after release from clamps.

Finishing and Tolerances for Stiff Plastics

After machining, rigid plastic parts may need additional finishing to meet their final requirements. Here’s what you can expect:

- Sanding and deburring: Removes tool marks and sharp edges for a smooth finish.

- Polishing or vapor polishing: Essential for clear plastics like acrylic or polycarbonate, restoring optical clarity for windows or display panels.

- Bead blasting: Creates a uniform matte texture for grip or aesthetics, but use caution with softer plastics.

- Painting, coating, or marking: Apply colors, improve wear/UV resistance, or add logos and serial numbers.

- Dimensional inspection: Use CMM or vision systems to verify tight tolerances and part quality.

| Attribute | CNC Machining | Injection Molding | 3D Printing |

|---|---|---|---|

| Setup Time | Low (hours) | High (tooling, weeks) | Very Low (minutes) |

| Unit Cost (Low Volume) | Moderate | High | Highest |

| Surface Finish | Excellent to Good | Excellent | Fair to Good |

| Geometry Freedom | High (but limited by tool access) | High (complex molds possible) | Very High (organic shapes, internal features) |

| Tolerance Potential | Very Tight (+/- 0.005mm possible) | Good (typically +/- 0.05mm or more) | Moderate (+/- 0.1mm typical) |

“CNC machining of rigid plastics is unbeatable for fast, accurate, and complex parts in low to medium volumes—especially when tight tolerances or thick sections are required.”

With the right design, material, and machining partner, you can turn stiff plastics into robust, reliable components—whether you need a handful of prototypes or a batch of custom hard plastic covers. Next, we’ll show you how to put all these insights into action for your next project, from validation to sourcing and beyond.

Putting Rigid Plastic Knowledge into Action

Key Takeaways You Can Act On

Rigidity is not just a "feel"—it must be verified through standardized tests and validated in your actual application. Always combine datasheet values with real-world trials for the best results.

When you’re ready to put your understanding of what is rigid plastic into practice, the difference between success and costly mistakes often comes down to a few critical steps. Whether you’re specifying a plastic cover for equipment, sourcing a hardened plastic material for safety panels, or trying to determine what is hard plastic called in industry terms, these actions ensure your project delivers on quality, performance, and sustainability.

What to Request from Suppliers

Imagine you’ve selected your preferred material rigid enough for your needs. Before you commit, here’s what you should always request:

- Resin identification and datasheets: Ask for documentation that includes ASTM or ISO test methods for key properties (flexural modulus, tensile modulus, Shore hardness, heat deflection temperature).

- Processing recommendations: Get guidance on molding, machining, or forming the chosen plastic—especially if your design has tight tolerances or unique shapes.

- Certifications and compliance: Confirm food contact, flammability, UV resistance, or other regulatory requirements as needed.

- Material samples or test coupons: If possible, request small samples to perform your own checks or prototype before full-scale production.

When to Prototype Before Tooling

Before investing in expensive tooling or committing to a large production run, prototyping is your best insurance policy. It lets you:

- Validate that your chosen hardened plastic material meets strength, fit, and finish requirements in real-world use.

- Check that assembly, bonding, and finishing processes work as expected.

- Test for recyclability, labeling, and any regulatory marks required for your market.

For tight-tolerance prototypes or bridge production, CNC machining is a practical path—especially for rigid plastic sheets and blocks. Providers like XTJ offer advanced 4 and 5-axis machining, tolerances down to +/- 0.005mm, and fast lead times across 30+ materials (including most rigid plastics). Their ISO 9001:2015 and IATF16949 certifications add assurance for demanding applications. If you’re considering CNC, request design-for-manufacturing (DFM) feedback early to ensure your part geometry, tolerances, and finishes are achievable without costly rework.

Final Checklist for Rigid Plastic Success

| Step | Action |

|---|---|

| 1. Confirm resin and datasheets | Ensure ASTM/ISO tests are cited for all critical properties |

| 2. Align process with geometry | Match manufacturing method to part shape, size, and tolerance needs |

| 3. Plan for finishing/assembly | Specify post-processing (machining, printing, bonding) and check compatibility |

| 4. Review recyclability/regulatory | Verify end-of-life handling and compliance marks are addressed early |

By following these steps, you’ll minimize surprises, reduce rework, and ensure your material rigid selection delivers the performance and sustainability your project demands.

Ready to move from concept to reality? Whether you’re prototyping a new plastic cover or scaling up for production, remember: the path to reliable, high-performing hard plastics starts with validation, smart sourcing, and a commitment to quality at every stage.

Frequently Asked Questions about Rigid Plastic

1. What is the difference between rigid and flexible plastic?

Rigid plastics maintain their shape and resist bending or stretching under normal use, making them ideal for structural roles like containers and covers. Flexible plastics, on the other hand, are designed to bend, stretch, or wrap easily, such as bags or films. The choice depends on the need for protection, durability, and the specific application.

2. What are examples of rigid plastic containers?

Common examples include milk jugs, yogurt cups, food storage boxes, buckets, and clear display cases. These items are typically made from materials like PET, HDPE, PP, and PS, offering durability and maintaining their shape during use.

3. How can I identify if a plastic is rigid or flexible at home?

You can use simple tests: try to bend the item (rigid plastics resist and may snap, while flexible ones bend), press your thumbnail into the surface (rigid plastics don’t dent easily), and check for a sharp tap sound. Also, look for resin identification codes and compare with known rigid items like hard containers.

4. Is rigid plastic recyclable, and how should I prepare it for recycling?

Many rigid plastics are recyclable, but acceptance depends on local programs. Always check local guidelines, rinse containers, and keep caps on if requested. Avoid mixing plastics with other materials, and check for resin codes to ensure proper sorting.

5. Where can I buy rigid plastic sheets or parts for my project?

Rigid plastic sheets and parts can be sourced from distributors, compounding houses, converters, or directly from manufacturers. For custom or precision parts, CNC machining services like XTJ offer tight tolerances and fast lead times. Always request datasheets and confirm specifications before purchasing.