Essential Factors That Determine CNC Machining Cost

TL;DR

The primary factors affecting CNC machining cost are material selection, part design complexity, and total machining time. Softer, common materials are cheaper, while complex designs with tight tolerances increase machine run-time. Secondary costs like tooling, labor, finishing treatments, and economic factors such as order quantity also play a crucial role in determining the final price per part.

The Primary Cost Drivers: Material, Design, and Machining Time

Understanding the cost of CNC machining begins with three foundational pillars: the material you choose, the complexity of your part's design, and the time a machine spends cutting it. These elements are deeply interconnected, and a change in one often has a cascading effect on the others. For instance, selecting a hard, exotic material will not only increase raw material costs but also dramatically extend machining time, as the cutting tools must move slower and will wear out faster. This interplay is the core of any CNC machining cost calculation.

Material selection is a critical first step. The cost of the raw material is just the beginning; its machinability—how easily it can be cut—is equally important. Softer materials like Aluminum 6061 are relatively inexpensive and can be machined quickly, making them a popular choice for prototypes and many production parts. In contrast, harder materials like stainless steel or titanium are more expensive per kilogram and require slower cutting speeds and more robust tooling, which increases both machining time and tooling costs. According to data from Komacut, the choice of material can significantly influence the final price, even when all other factors are equal.

Part design complexity is another major cost driver. Features like intricate geometries, deep pockets, thin walls, and tight tolerances all add to the time and effort required to produce a part. A simple block with a few holes can be machined quickly on a basic 3-axis machine. However, a part with curved surfaces, undercuts, and features on multiple faces may require a more advanced and expensive 5-axis machine to avoid multiple manual setups. As noted by FirstMold, design elements that are difficult to machine, such as sharp internal corners that standard round tools cannot create, necessitate smaller tools and slower, more meticulous machining paths, directly increasing the time and cost.

Ultimately, these factors culminate in machining time, which is often the single most significant cost component. The longer a part occupies a CNC machine, the higher the cost, as it includes labor, electricity, machine depreciation, and tool wear. A design that requires removing a large volume of material or has features that demand slow, precise cuts will have a much longer cycle time than a simpler part. Therefore, optimizing a design for manufacturability is not just about making it possible to create, but about making it efficient and economical to produce.

| Material | Relative Cost per Kg | Machinability | Common Applications |

|---|---|---|---|

| Aluminum 6061 | Low | Excellent | Prototypes, structural components, consumer electronics |

| Stainless Steel 304 | Medium | Fair | Food processing equipment, medical devices, corrosion-resistant parts |

| Carbon Steel Q235 | Very Low | Good | General fabrication, structural parts, machinery components |

| Titanium | Very High | Poor | Aerospace components, high-performance parts, medical implants |

Strategic Design for Cost Reduction (DFM)

One of the most effective ways to control CNC machining costs is by optimizing your part design before it ever reaches a machine. This practice, known as Design for Manufacturability (DFM), involves making conscious design choices that reduce complexity, machining time, and material waste. By simplifying a part's geometry and adhering to standard machining practices, you can achieve significant savings without compromising functionality. Many service providers can help with this; for instance, you can accelerate your product development with XTJ's comprehensive formative manufacturing services, as they provide expert engineering teams offering Design for Manufacturability (DFM) feedback to optimize your designs for quality and cost-efficiency.

Applying DFM principles can have a dramatic impact on the final price. These are not just abstract concepts but actionable rules that directly address the realities of the machining process. A few key adjustments can transform an expensive, difficult-to-machine part into an economical one. By considering how a tool will physically move to create your part, you can eliminate costly features and streamline production.

Here are several practical DFM tips to reduce your CNC machining costs:

- Fillet Internal Corners: CNC cutting tools are round, so they cannot create perfectly sharp 90-degree internal corners. Attempting to do so requires very small tools or secondary processes like EDM, both of which are expensive. A simple solution is to add a radius (fillet) to all internal corners. A good rule of thumb is to design a corner radius that is at least 1/3 of the cavity's depth, which allows for a larger, more rigid tool to be used, reducing chatter and machining time.

- Avoid Thin Walls: Walls that are too thin are prone to vibration, distortion, and breakage during machining. This forces the machinist to use slower cutting speeds and take multiple light passes, increasing time and risk. For metal parts, a minimum wall thickness of 0.8mm is recommended, while for plastics, 1.5mm is a safer guideline. Thicker walls provide stability and are much more cost-effective to machine accurately.

- Standardize Holes and Threads: Using standard drill bit sizes for holes is much cheaper than requiring a non-standard size that must be created with an end mill. Furthermore, limit the depth of threads. A thread depth greater than three times the hole's diameter does not add significant holding strength but does increase the risk of tap breakage and requires more machining time.

- Loosen Tolerances Where Possible: Not every feature on a part requires high precision. Applying tight tolerances across the board dramatically increases cost, as it necessitates more careful machining, specialized measurement tools, and higher rejection rates. Specify tight tolerances only for critical features and surfaces, and use standard tolerances (e.g., ±0.2mm) for non-critical dimensions.

Secondary and Overhead Costs: Tooling, Labor, and Finishing

Beyond the primary drivers of material and machine time, a range of secondary and overhead costs contribute significantly to the final price of a CNC machined part. These factors, including tooling, labor for setup, and post-processing finishes, are often less visible but can have a substantial impact on your budget. Understanding these hidden costs is essential for accurate quoting and avoiding unexpected expenses.

Tooling is a key consideration. While shops have a wide array of standard tools, any part with unique features may require custom tooling or fixtures. According to Stecker Machine, while custom tools carry an upfront cost, they can sometimes reduce cycle times on high-volume runs by combining operations. For prototypes or small batches, however, designing parts that can be made with standard tools is a far more cost-effective strategy. Similarly, labor costs for setup—the process of preparing the machine, fixtures, and program for a specific job—are a fixed expense for each production run. This setup cost is amortized across the number of parts produced, which is why the per-part price drops significantly with larger quantities.

Post-processing and finishing are additional steps required to meet a part's final aesthetic or functional requirements. These operations, such as anodizing, powder coating, or plating, are performed after the primary machining is complete and add both time and cost. The complexity and type of finish can vary widely, from a simple deburring to a multi-step chemical treatment. It is crucial to specify only necessary finishes, as each additional process adds to the overall expense and lead time.

| Finishing Process | Description | Relative Cost Impact |

|---|---|---|

| As-Machined | The part's natural finish after cutting, with minor tool marks visible. | Baseline (Lowest) |

| Bead Blasting | Creates a uniform matte or satin surface finish. | Low |

| Anodizing (Type II & III) | Adds a corrosion-resistant, colored ceramic layer to aluminum parts. | Medium |

| Powder Coating | Applies a durable, protective, and decorative polymer finish. | Medium to High |

| Plating (Zinc, Nickel) | Deposits a thin metallic layer for corrosion resistance or cosmetic appearance. | High |

Economic Levers: Quantity, Machine Type, and Turnaround Time

The business and logistical decisions surrounding a CNC machining project are just as important as the technical ones. Factors like production volume, the type of machine used, and the required delivery speed act as powerful economic levers that can scale the base cost of a part up or down. Strategically managing these elements is key to achieving the best possible price for your project.

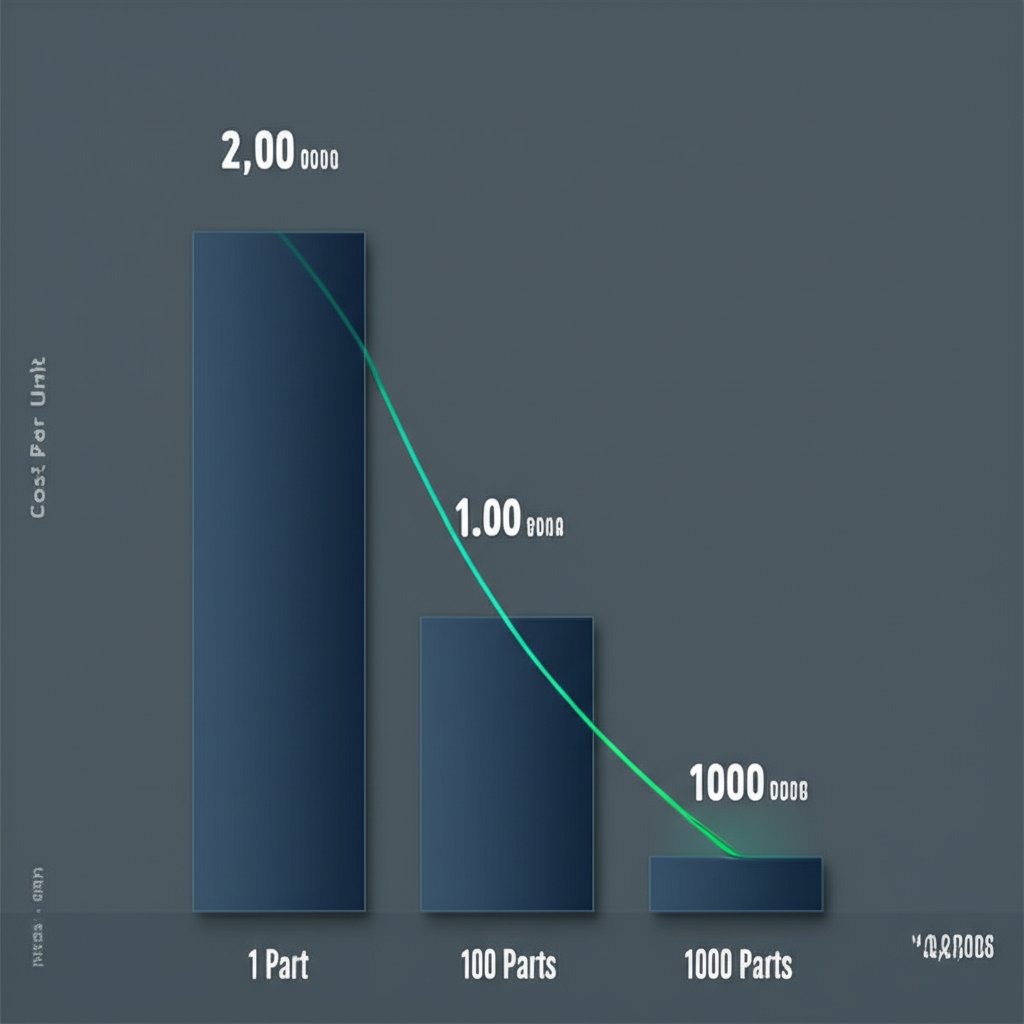

Production volume, or batch size, is arguably the most significant economic factor due to the principle of economies of scale. As detailed in a cost analysis by Komacut, the cost per part decreases dramatically as the quantity increases. This is because the initial setup costs—programming, fixturing, and machine preparation—are spread across a larger number of units. Ordering 100 parts in a single run will result in a much lower per-unit cost than placing five separate orders of 20 parts each. Therefore, consolidating orders and planning for larger production runs is a primary strategy for cost reduction.

The choice of machine also has direct cost implications. CNC machines are categorized by their number of axes, with 3-axis, 4-axis, and 5-axis machines being the most common. While a 5-axis machine has a higher hourly rate, it can machine complex parts with features on multiple faces in a single setup. A less expensive 3-axis machine might require multiple manual setups and custom fixtures to achieve the same result, which could lead to a higher total cost due to increased labor and potential for error. The most cost-effective choice depends on the part's geometry; simple parts are best for 3-axis machines, while complex parts can be produced more efficiently on a 5-axis machine despite the higher hourly rate.

Finally, turnaround time is a crucial variable. Standard lead times allow a machine shop to schedule jobs efficiently, optimizing machine use and labor. Requesting an expedited or rushed delivery forces the shop to interrupt its schedule, potentially requiring overtime labor and express shipping for materials. These rush fees can significantly inflate the final cost. Unless a deadline is absolutely critical, planning projects with standard lead times is a simple yet effective way to keep costs under control.

| Machine Type | Estimated Cost per Hour (USD) | Best Suited For |

|---|---|---|

| 3-Axis CNC Machining | $50 – $100 | Simple parts with features on a single plane. |

| 4-Axis CNC Machining | $75 – $125 | Parts requiring machining around a cylindrical axis. |

| 5-Axis CNC Machining | $100 – $150+ | Highly complex parts with features on multiple faces. |

Frequently Asked Questions

1. What are the key factors that affect manufacturing costs in general?

Beyond CNC machining, general manufacturing costs are driven by several core factors. These include the cost of raw materials, labor wages, overhead expenses like factory rent and utilities, the initial investment in machinery and equipment, and the specific manufacturing processes required to create the product. Supply chain logistics and production volume also play a crucial role in determining the final cost per unit.

2. How is the final cost of a CNC machined part calculated?

The final cost is typically calculated by summing several components. It starts with the raw material cost. To this, the machining cost is added, which is often based on an hourly rate for the specific CNC machine multiplied by the total machining time. Then, setup costs for programming and fixturing are included. Finally, costs for any required post-processing (like finishing or deburring) and a margin for overhead and profit are factored in to arrive at the total price.

-

Posted in

cnc machining, cnc pricing, cost reduction, design for manufacturability, manufacturing cost