Essential Finishes for CNC Aluminum Parts Explained

TL;DR

Post-processing for CNC aluminum parts refers to a range of finishing treatments applied after machining. These processes are essential for enhancing a part's functional properties, such as corrosion resistance, wear resistance, and surface hardness. They also significantly improve aesthetics by adding color or creating specific textures. Key techniques include anodizing for durability, bead blasting for a uniform matte finish, and powder coating for a resilient color layer, each chosen to meet specific application requirements.

What Is Post-Processing for CNC Aluminum and Why Is It Crucial?

Post-processing encompasses any secondary operation performed on a CNC machined aluminum part to alter its surface and enhance its properties. While CNC machining creates a precise geometry, the resulting part often has visible tool marks and a surface that is vulnerable to environmental factors. Bare aluminum naturally forms a thin, passive oxide layer, but this is often insufficient to protect against corrosion, wear, and scratching, especially in demanding applications. Post-processing addresses these limitations by adding a protective and often decorative final layer.

The primary purpose of these treatments is twofold: functional enhancement and aesthetic improvement. Functionally, finishes like hardcoat anodizing can dramatically increase the surface hardness and wear resistance of aluminum, making it suitable for high-friction applications. Treatments such as chromate conversion coatings provide excellent corrosion resistance, which is critical for parts used in marine or industrial environments. These processes augment aluminum's inherent strength, ensuring the final component performs reliably throughout its lifecycle.

Aesthetically, post-processing offers a wide spectrum of possibilities. Anodizing, for example, can impart a variety of colors to a part, while bead blasting creates a clean, uniform matte finish that hides imperfections. Polishing can produce a mirror-like surface for decorative components. This ability to control the final look and feel is crucial in consumer electronics, automotive interiors, and architectural elements where appearance is as important as performance. Ultimately, post-processing transforms a raw machined part into a finished, application-ready component.

Key Post-Processing Techniques: A Detailed Comparison

Selecting the appropriate post-processing method is critical to achieving the desired performance and appearance for a CNC machined aluminum part. The most common techniques each offer a unique combination of benefits tailored to specific needs. Understanding the differences between these processes is key to making an informed decision for any project. The primary methods include anodizing, bead blasting, and powder coating, each with distinct advantages.

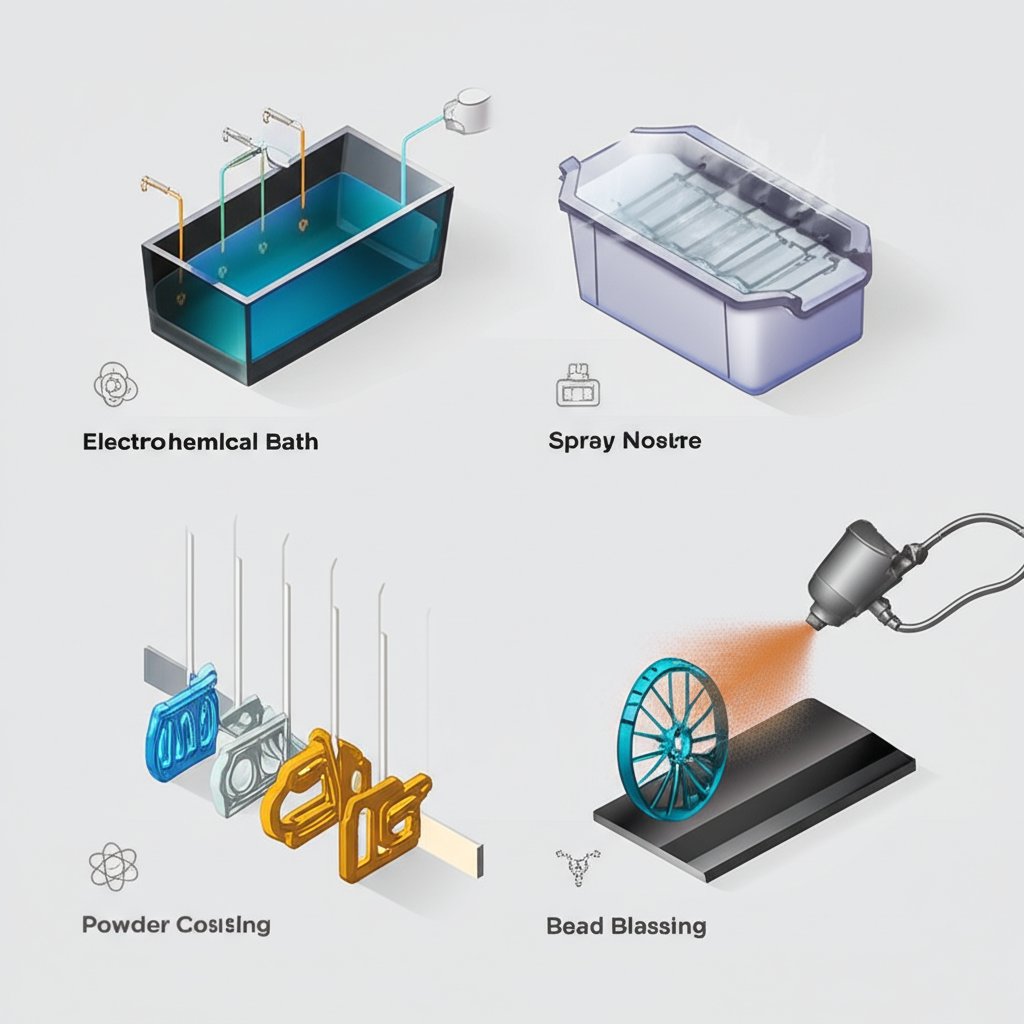

Anodizing is an electrochemical process that thickens the natural oxide layer on the aluminum's surface, creating a hard, durable, and corrosion-resistant coating. It is not an additive layer like paint; instead, it integrates with the underlying aluminum. There are two main types: Type II, often called decorative anodizing, which provides good corrosion resistance and can be dyed in various colors; and Type III, or hardcoat anodizing, which creates a much thicker, denser layer for superior wear and abrasion resistance, though it is typically limited to darker colors like gray or black. This makes anodizing highly versatile for everything from colorful electronics casings to rugged industrial components.

Bead blasting is a mechanical surface treatment where fine glass beads are propelled at high pressure against the part. Unlike more aggressive abrasive blasting, bead blasting is non-destructive and is used to remove tool marks, clean the surface, and create a uniform, non-directional matte or satin finish. This process is excellent for preparing a surface for another finish, such as anodizing, or as a final finish itself when a clean, textured look is desired. It does not significantly improve corrosion or wear resistance but is highly effective for achieving a consistent aesthetic.

Powder coating involves electrostatically applying a dry polymer powder to the part, which is then cured with heat to form a hard, protective layer. This method produces a finish that is typically thicker and more durable than conventional liquid paint. Powder coating offers excellent impact resistance and corrosion protection and is available in a virtually unlimited range of colors, textures, and gloss levels. Because it adds a layer of material to the surface, it can slightly alter part dimensions, which must be considered for components with tight tolerances.

| Technique | Primary Benefit | Best For | Considerations |

|---|---|---|---|

| Anodizing (Type II & III) | Corrosion & Wear Resistance, Color Options | Aerospace parts, electronics enclosures, high-wear industrial components | Integral to the part; Type III has limited color options. Can be brittle. |

| Bead Blasting | Uniform Matte Finish, Hides Imperfections | Aesthetic parts, pre-treatment for other finishes | Minimal dimensional change; does not add corrosion protection. |

| Powder Coating | Durability, Wide Color Range, Impact Resistance | Automotive parts, architectural components, outdoor equipment | Adds thickness to the part; requires high-temperature curing. |

| Chem Film (Chromate) | Excellent Corrosion Resistance, Electrical Conductivity | Internal components, primer for paint, military/aerospace parts | Minimal dimensional change; offers a distinct greenish-yellow color. |

How to Select the Right Post-Processing Finish

Choosing the correct post-processing finish for a CNC aluminum part is a critical decision that directly impacts its performance, longevity, and cost. The selection process should be guided by the part's intended application and operational environment. By systematically evaluating key factors, you can ensure the chosen finish meets all functional and aesthetic requirements without unnecessary expense.

Consider the following criteria when making your selection:

- Functional Requirements: This is the most important factor. Will the part be exposed to moisture, chemicals, or saltwater? If so, corrosion resistance is paramount, making options like anodizing or chem film ideal. For parts subjected to friction or abrasion, a hard finish like Type III hardcoat anodizing is necessary to prevent wear.

- Aesthetic Needs: The visual appearance of the part can be a primary driver. If a specific color is required to match branding or other components, powder coating or Type II anodizing offer a wide palette. For a clean, non-reflective surface, bead blasting provides a uniform matte texture. If a brilliant, mirror-like appearance is desired, mechanical polishing is the best choice.

- Mechanical Properties: Beyond surface hardness, consider if the finish needs to maintain electrical conductivity. Standard anodizing creates an electrically insulating layer, whereas a chromate conversion coating maintains conductivity. The finish should not compromise the structural integrity or dimensional tolerances of the part, especially for precision assemblies.

- Cost and Budget: Finishing processes vary significantly in price. Simple treatments like bead blasting are generally less expensive, while multi-step processes like hardcoat anodizing or achieving a mirror polish are more costly. It is important to balance the performance requirements with the project budget to find a cost-effective solution.

For example, a structural bracket inside an industrial machine may only require a simple chem film for corrosion protection, as aesthetics are not a concern. In contrast, the outer casing for a high-end consumer electronic device would likely need Type II anodizing for its combination of durability and premium, colorful appearance. For complex projects where the interplay between material, design, and finish is critical, consulting with a manufacturing partner can provide invaluable guidance. Services like XTJ's comprehensive formative manufacturing offer expert Design for Manufacturability (DFM) feedback, helping to optimize not only the machining process but also the selection of the most effective post-processing treatments to ensure quality and performance.

Exploring Advanced and Specialized Finishing Options

While anodizing, blasting, and powder coating cover the majority of applications, some projects demand more specialized surface treatments to meet unique requirements. These advanced options can provide specific properties, such as extreme smoothness, enhanced conductivity, or a unique decorative appearance that standard finishes cannot achieve. Understanding these niche processes allows for greater design freedom and performance optimization in specialized fields.

Electropolishing is an electrochemical process that is essentially the reverse of plating. Instead of depositing material, it removes a microscopic outer layer of the aluminum surface, leveling out peaks and valleys. The result is an exceptionally smooth, bright, and often reflective finish. This process is highly valued in the medical and food-grade industries, where a clean, non-porous surface is critical to prevent bacterial growth and ensure easy sterilization. While it enhances appearance, it can slightly reduce the part's overall corrosion resistance compared to an anodized finish.

Electroplating involves coating the aluminum part with a thin layer of another metal, such as nickel, chrome, zinc, or even gold. This is done to impart the properties of the plated metal onto the aluminum substrate. For instance, nickel plating adds significant wear and corrosion resistance, while chrome plating is often used for its brilliant, mirror-like aesthetic and hardness, popular in automotive and decorative applications. Electroplating is an excellent choice when a specific metallic property not inherent to aluminum is required.

Mechanical Grinding and Polishing are multi-step, labor-intensive processes used to achieve a true mirror finish. This involves progressively sanding the surface with finer grits of abrasive material to remove all imperfections, followed by buffing with polishing compounds. While chemical processes like electropolishing can create a bright finish, only mechanical polishing can achieve the highest level of reflectivity. This finish is purely aesthetic and is reserved for high-end decorative parts, custom automotive components, and architectural trim where a flawless, mirror-like appearance is the primary goal.

Frequently Asked Questions

1. What is post-processing in CNC?

In the context of manufacturing, post-processing refers to any secondary operation performed on a part after the primary CNC machining is complete. These processes are not about creating the part's shape but rather about refining its surface to improve functional properties like durability and corrosion resistance, or to enhance its aesthetic qualities with specific colors, textures, or finishes.

2. How do you clean aluminum after machining?

Cleaning aluminum after machining is a crucial first step before any post-processing can occur. The process typically involves removing cutting fluids, oils, and metal chips using aqueous degreasers or solvents. A thorough cleaning ensures that finishing treatments like anodizing or powder coating will adhere properly and perform effectively. Post-processing itself is the final protective step that seals the cleaned surface against future contamination and corrosion. According to a guide from Protolabs, proper surface preparation is key to a successful finish.

3. What type of end mill is best for aluminum?

While the focus of this article is on finishing, the initial machining quality is also important. For machining aluminum, end mills with two or three flutes are generally recommended. These allow for efficient chip evacuation, which is crucial as aluminum produces large, soft chips that can otherwise clog the tool. The choice of tool directly impacts the surface finish before any post-processing begins.

4. How much does post-processing add to the cost of CNC aluminum parts?

The cost of post-processing varies widely depending on the chosen method, the size and complexity of the part, and the volume of the order. Simple finishes like bead blasting might add a small percentage to the total cost. More complex, multi-step processes like Type III hardcoat anodizing or mechanical polishing can be significantly more expensive, sometimes constituting a substantial portion of the final part cost. It is essential to factor in finishing costs early in the design and budgeting process.

-

Posted in

aluminum finishing, Anodizing, cnc machining, post-processing, surface treatment