Custom Heatsink CNC Machining: A Guide to Precision Cooling

TL;DR

Custom heatsink CNC machining is a manufacturing process that carves heat sinks from a solid block of metal, typically aluminum or copper. This method offers exceptional design freedom for complex geometries and is highly cost-effective for prototypes and low-volume production because it requires no expensive tooling or dies, eliminating Non-Recurring Engineering (NRE) charges.

What Is a CNC Machined Heat Sink?

A CNC (Computer Numerical Control) machined heat sink is a thermal management component created through a subtractive manufacturing process. Unlike methods that cast or extrude metal into a shape, CNC machining starts with a solid block of a thermally conductive material, like aluminum or copper, and precisely removes material using high-speed cutting tools to achieve the final design. This process is guided by a digital 3D model, ensuring exceptional accuracy and repeatability.

This method is essential for producing high-precision thermal components, including not just heat sinks but also integrated solutions like cold plates and vapor chambers. The ability to machine from a solid billet results in a monolithic component with continuous thermal pathways, which can offer superior performance compared to heat sinks assembled from multiple pieces. Because the process is digitally controlled and does not require the creation of expensive molds or dies, it is an ideal choice for rapid prototyping and small-to-medium production runs.

CNC machining provides the flexibility to create complex features that are impossible with other methods. This includes intricate fin patterns, thin walls, undercuts, and integrated mounting points like threaded holes or counterbores. As a result, this technique is widely used for critical applications in high-performance computing, LED lighting, power electronics, and telecommunications equipment where customized, high-efficiency cooling is non-negotiable.

Key Advantages of CNC Machining for Heat Sinks

Choosing CNC machining for heat sink manufacturing provides several distinct advantages, particularly for projects that demand high performance, customization, and speed. The process offers a unique combination of precision, flexibility, and cost-effectiveness for specific production scales, making it a preferred method for many engineers.

Unmatched Design Freedom and Precision

The primary benefit of CNC machining is the ability to produce highly complex geometries with tight tolerances. Unlike extrusion, which is limited to linear profiles, machining can create multi-directional fin arrays, curved surfaces, and intricate cutouts to maximize surface area and optimize airflow in constrained spaces. This precision is critical for ensuring flat, smooth contact surfaces, which minimizes thermal resistance between the heat sink and the electronic component it cools.

Cost-Effectiveness for Prototypes and Low Volumes

For prototyping and smaller production runs, CNC machining is often more economical than methods like die-casting or extrusion. This is because it eliminates the need for expensive tooling, dies, or molds. As noted by industry experts, this means there are no Non-Recurring Engineering (NRE) charges, which can save thousands of dollars in initial setup costs. This allows for rapid design iteration and testing without a significant financial commitment for each new version.

Superior Material Performance and Versatility

CNC machines can work with a wide range of materials, including high-conductivity copper alloys that are difficult to process with other methods like extrusion. Machining a heat sink from a single, solid block of metal creates a monolithic structure. This single-piece design provides a continuous, uninterrupted path for heat to travel from the base to the fins, offering better thermal performance than bonded or assembled heat sinks, which can have thermal resistance at the joints.

Material Selection for Custom Machined Heat Sinks

The choice of material is one of the most critical decisions in designing a custom heat sink, as it directly impacts thermal performance, weight, and cost. While various metals can be used, aluminum and copper are the predominant choices for their excellent thermal properties and machinability.

Aluminum, particularly alloys like 6061 and 6063, is the most common material due to its excellent balance of thermal conductivity, low weight, and cost-effectiveness. It is easily machined and can be finished with treatments like anodizing to improve corrosion resistance and emissivity. Copper, on the other hand, offers nearly double the thermal conductivity of aluminum, making it the superior choice for high-power or high-heat-flux applications where thermal performance is paramount. However, copper is significantly heavier and more expensive, and it can be more challenging to machine.

Choosing between these materials involves a trade-off. For most standard applications, aluminum provides sufficient cooling performance at a reasonable cost and weight. For demanding environments, such as high-performance CPUs or power electronics, the superior heat dissipation of copper may be necessary to maintain optimal operating temperatures, despite its higher cost and density.

| Material | Thermal Conductivity (W/m·K) | Relative Cost | Weight | Best For |

|---|---|---|---|---|

| Aluminum (6061/6063) | ~180–200 | Low | Light | General-purpose applications, lightweight designs, cost-sensitive projects |

| Copper (C110) | ~390–400 | High | Heavy | High-power density electronics, compact designs requiring maximum heat dissipation |

Critical Design Tips for CNC Machined Heat Sinks

Effective heat sink design goes beyond simply choosing the right material; it requires optimizing the physical geometry for both thermal performance and manufacturability. A well-designed machined heat sink efficiently transfers heat while remaining cost-effective to produce. Following key design principles is crucial for achieving this balance.

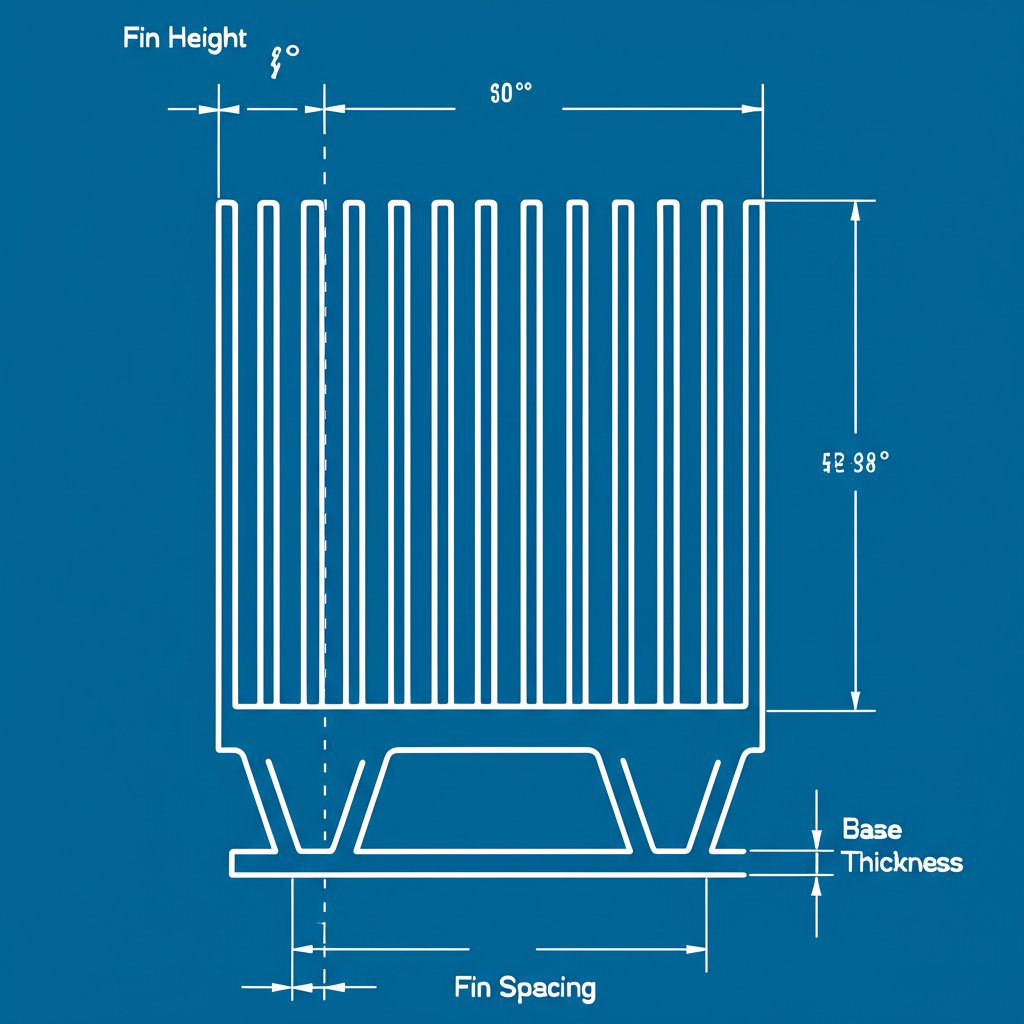

One of the most important aspects is fin design. The height, thickness, and spacing of the fins determine the total surface area available for heat dissipation. However, there are practical limits. According to an in-depth guide on the topic, fins that are too tall and thin can be prone to vibration or breakage during machining, while fins spaced too closely can restrict airflow, trapping heat instead of allowing it to escape. A general rule of thumb for aluminum is to maintain a fin height-to-thickness aspect ratio of 6:1 or less to ensure structural integrity as detailed in design guidelines from JLCCNC.

The following best practices can help optimize your design for both performance and production:

- Optimize Fin Geometry: Balance fin height, thickness, and spacing to maximize surface area without impeding airflow or compromising manufacturability. For forced air cooling, consider angled or staggered fins to increase turbulence and improve heat transfer.

- Ensure Adequate Base Thickness: The base of the heat sink must be thick enough to spread heat evenly from the source to the fins. An overly thin base can lead to hot spots and inefficient performance.

- Specify Surface Flatness and Finish: The contact surface mating with the heat source must be extremely flat (typically within ±0.05 mm) to minimize thermal resistance. A smooth finish further reduces microscopic air gaps. Post-processing treatments like black anodizing can also improve radiative cooling.

- Design for Manufacturability (DFM): Avoid overly deep pockets or features that require very long, thin cutting tools, as this increases machining time and risk. Partnering with a manufacturing expert can provide crucial DFM feedback. For instance, services like XTJ's formative manufacturing offer expert engineering reviews to optimize your design for efficiency and performance before production begins, helping you avoid costly revisions.

Finalizing Your Custom Heat Sink Strategy

Successfully implementing a custom CNC machined heat sink requires a holistic approach that balances thermal requirements, mechanical constraints, and budget. The process begins with a clear understanding of the heat load and the target operating temperature of your component. From there, the key decisions revolve around material selection—choosing between the cost-effective performance of aluminum and the superior conductivity of copper—and geometric optimization.

By leveraging the design freedom offered by CNC machining, engineers can create highly specialized solutions that are not possible with other manufacturing methods. Whether it involves integrating mounting features directly into the heat sink, creating complex fin patterns for turbulent airflow, or prototyping designs rapidly without tooling costs, this technology offers a powerful tool for solving today's toughest thermal challenges. Ultimately, a well-executed strategy results in a reliable, high-performance product that keeps critical electronics cool under pressure.

Frequently Asked Questions

1. How does the cost of CNC machining compare to extrusion for heat sinks?

For low volumes and prototypes, CNC machining is generally more cost-effective because it has no tooling costs (NRE). Extrusion requires a custom die to be made, which can cost thousands of dollars, making it economical only for high-volume production where the cost of the die can be amortized over many units.

2. What is the best material for a custom heat sink?

The best material depends on the application's specific needs. Aluminum (like 6061 or 6063 alloys) offers an excellent balance of thermal performance, low weight, and affordability, making it suitable for most applications. Copper has superior thermal conductivity and is best for high-power density components where maximum heat dissipation is critical, despite being heavier and more expensive.

3. What is a typical lead time for a CNC machined prototype heat sink?

Lead times can vary depending on complexity and shop capacity, but one of the key advantages of CNC machining is speed for prototyping. Simple designs can often be produced in as little as a few days to two weeks, as there is no need to wait for tooling to be manufactured. This allows for rapid testing and design iteration.