Swiss Machining vs Conventional Turning: A Precision Breakdown

TL;DR

Swiss machining and conventional turning are both CNC lathe processes, but they differ fundamentally in how they support the workpiece. Swiss machines feed material through a guide bushing, providing rigid support extremely close to the cutting tool. This makes Swiss machining ideal for producing long, slender, and complex parts with tight tolerances. In contrast, conventional turning secures the workpiece in a fixed chuck, making it better suited for shorter, larger-diameter components with simpler geometries.

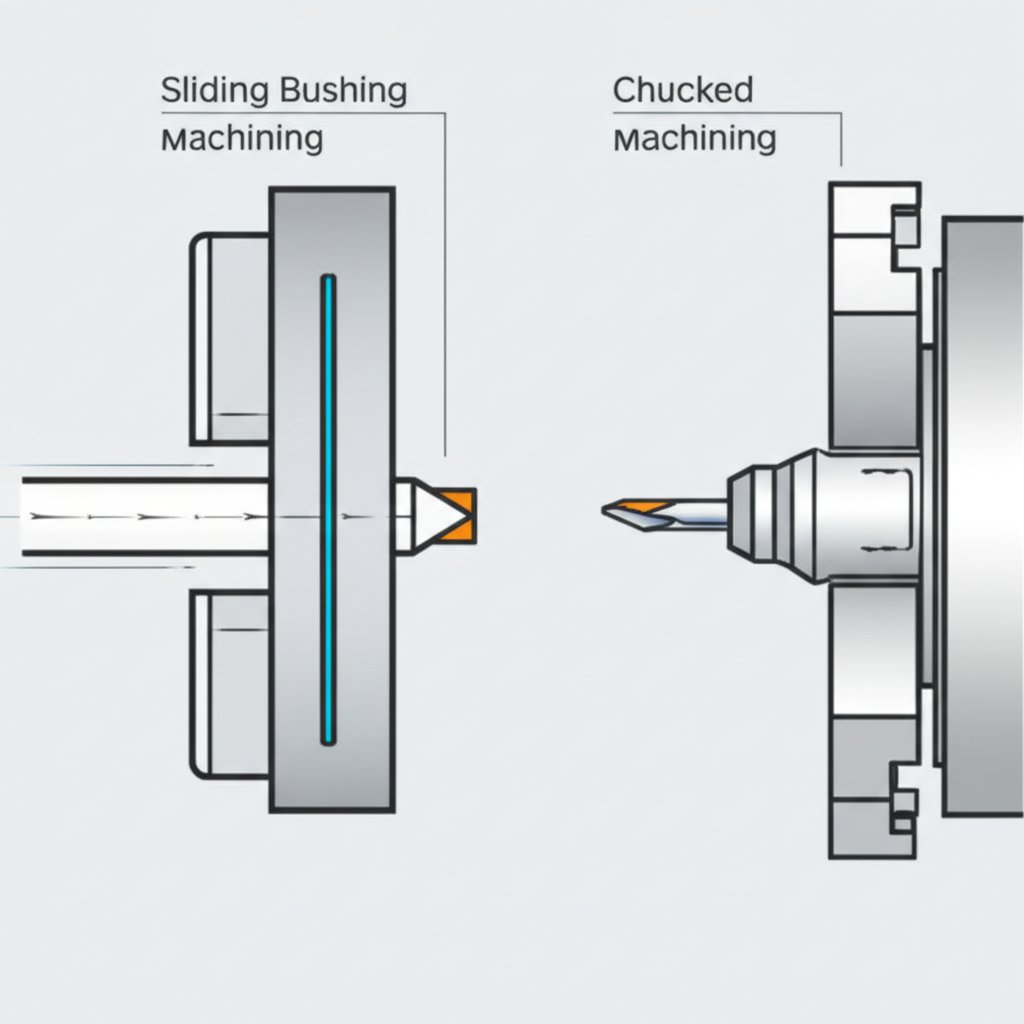

The Fundamental Difference: Workpiece Support and Movement

The core distinction in the Swiss machining vs. conventional turning debate lies in the mechanical setup for holding and cutting the workpiece. Understanding this difference is key to selecting the right process for a specific application. A conventional CNC lathe operates by clamping a workpiece in a chuck or collet, which then rotates at high speed. The cutting tools, mounted on a turret, move along the stationary (but spinning) workpiece to remove material. This method is robust and effective, but for parts that are long and thin, the distance between the chuck and the cutting tool can lead to material deflection, vibration, and chatter, compromising accuracy.

Swiss-type turning, also known as Swiss screw machining, completely inverts this dynamic. In a Swiss machine, the workpiece is held in a sliding headstock and fed through a guide bushing. The cutting tools remain relatively stationary, positioned right at the exit of the guide bushing. This means the material is always supported mere millimeters from the point of the cut, regardless of the part's overall length. This constant, rigid support virtually eliminates deflection and vibration, which is the primary reason Swiss machines excel at producing parts with a high length-to-diameter ratio—often as high as 20:1.

This mechanical difference dictates the entire machining strategy. On a conventional lathe, a machinist might perform a roughing pass followed by a finishing pass along the entire length of the exposed part. On a Swiss machine, the part is machined in segments as it progressively emerges from the guide bushing. This ensures that every feature is cut with maximum support, maintaining tight tolerances from one end of the part to the other.

| Feature | Swiss Machining | Conventional Turning |

|---|---|---|

| Workpiece Support | Sliding headstock feeds stock through a guide bushing | Workpiece held in a fixed chuck or collet |

| Primary Movement | Workpiece moves along the Z-axis; tools are mostly stationary | Tool turret moves along the X and Z axes; workpiece is stationary |

| Rigidity | Extremely high at the point of cut, minimizing deflection | Decreases as the distance from the chuck increases |

| Material Handling | Requires ground bar stock for smooth feeding through the bushing | Can handle a wider variety of raw material forms |

Precision, Complexity, and Ideal Part Geometries

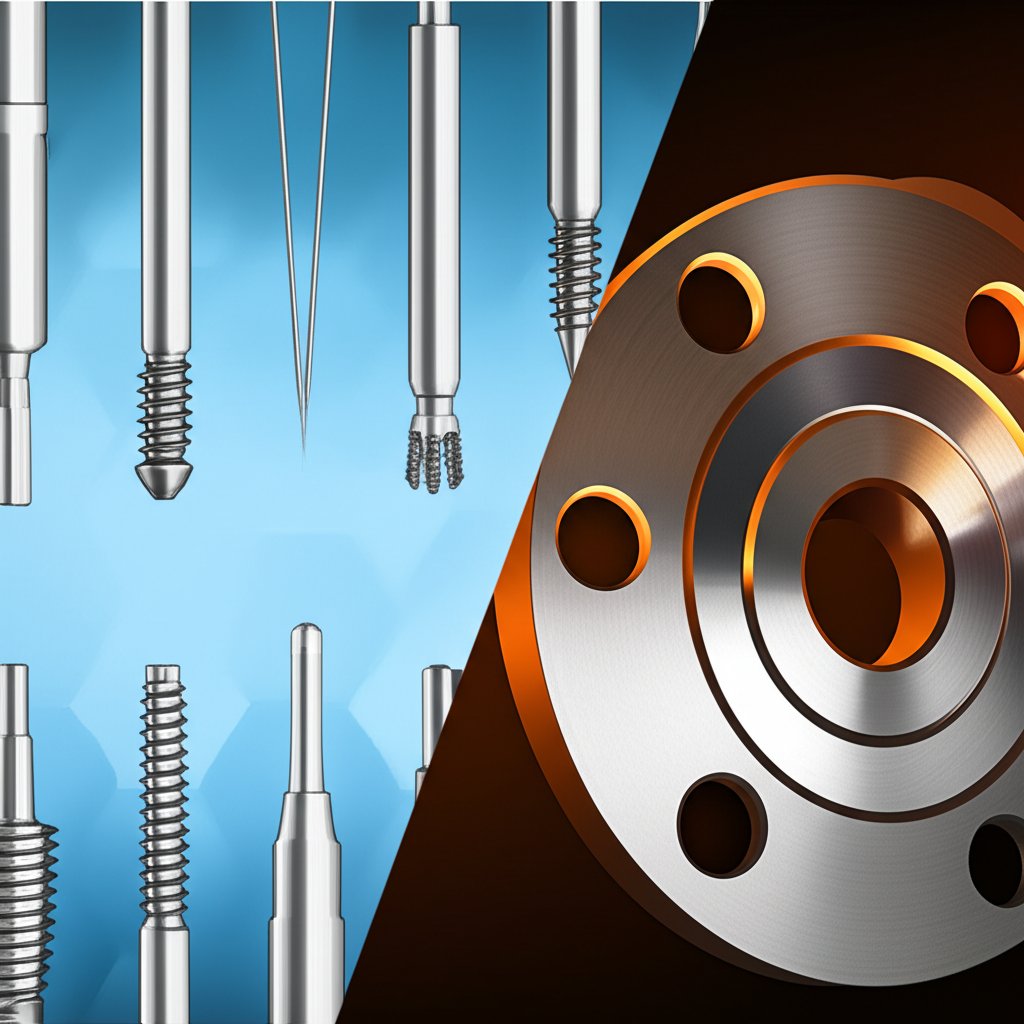

The superior support provided by the guide bushing directly translates to higher precision and the ability to machine more complex parts. Because material deflection is negligible, Swiss machines can consistently hold extremely tight tolerances, often down to ±0.0002 inches. This level of accuracy is critical in industries like medical, aerospace, and electronics, where components must meet exacting specifications. For example, the intricate threads and delicate features of a medical bone screw are nearly impossible to produce without the stability of a Swiss-type lathe.

This capability defines the ideal part geometries for each process. Swiss machining is the go-to solution for long, slender parts where the length-to-diameter ratio is high (typically 3:1 or greater). Conventional turning, conversely, is better suited for parts that are shorter and have a larger diameter, where the risk of deflection is naturally lower. The choice between the two often comes down to the physical characteristics of the final component.

To help engineers and designers decide, here are the typical characteristics of parts best suited for each machine type:

-

Ideal for Swiss Machining:

- Parts with a high length-to-diameter ratio (e.g., shafts, pins, probes).

- Components requiring micrometer-sized features and very tight tolerances.

- Complex parts with intricate features like off-center holes, slots, or threads.

- Examples include: medical implants, watch components, electrical connectors, and complex fasteners.

-

Ideal for Conventional Turning:

- Parts with a low length-to-diameter ratio (e.g., flanges, rings, knobs).

- Larger-diameter components that require significant material removal.

- Simpler parts where extreme precision over a long length is not the primary concern.

- Examples include: hydraulic fittings, simple shafts, automotive pistons, and industrial flanges.

Machine Capabilities: Axes, Tooling, and 'Done-in-One' Manufacturing

Modern Swiss machines are marvels of multitasking, far surpassing the capabilities of standard lathes. While a conventional CNC lathe typically operates on 2 or 3 axes (X and Z, sometimes with a C-axis for rotating the spindle), Swiss machines often feature 7, 9, or even 13 axes. These additional axes, combined with live tooling and sub-spindles, enable a concept known as "done-in-one" manufacturing.

Live tooling allows the machine to perform secondary operations like drilling, tapping, and milling perpendicular to the part's centerline without removing it from the machine. A sub-spindle acts as a second chuck that can grab the part after it's cut off from the main stock. This allows for complete machining of the back side of the part simultaneously while the main spindle begins work on the next component. This capability to perform turning, milling, drilling, and back-working in a single setup drastically reduces cycle times and eliminates inaccuracies that can arise from re-fixturing a part on multiple machines.

The trade-off for this immense capability is increased programming complexity and setup time. However, for complex parts, the ability to produce a finished component in a single cycle is a powerful advantage that conventional lathes cannot match. The table below outlines these key capability differences.

| Capability | Multi-Axis Swiss Machine | Standard CNC Lathe |

|---|---|---|

| Typical Axes | 5 to 13 axes (X, Y, Z, C, etc.) | 2 to 4 axes (X, Z, sometimes C and Y) |

| Live Tooling | Standard feature for milling, drilling, tapping | Available on higher-end models, but not standard |

| Sub-Spindle | Common, enables back-working operations | Less common, typically found on more advanced lathes |

| Automation | Designed for use with automatic bar feeders for unattended operation | Bar feeders are optional add-ons |

Economic Factors: Cost, Cycle Times, and Production Volume

The decision between Swiss and conventional turning often comes down to economics. Swiss-type lathes are a significant investment, costing considerably more than their conventional counterparts due to their complexity, precision components, and advanced controls. However, this higher upfront cost can be justified by a lower per-part cost in the right scenarios. The key factors to consider are setup time, cycle time, and production volume.

Swiss machines typically have longer and more complex setup procedures. However, once running, their cycle times for complex parts are remarkably fast due to simultaneous machining capabilities. Combined with automatic bar feeders, they can run unattended for hours or even days, a practice often referred to as "lights-out manufacturing." This makes them exceptionally cost-effective for high-volume production runs, often in the tens of thousands of pieces or more. For these large quantities, the savings in cycle time and labor quickly offset the initial machine cost.

Conventional lathes, being simpler to set up and program, are more economical for prototyping, small-to-medium production runs, and larger, less complex parts. For these applications, the speed and complexity of a Swiss machine would be overkill and not cost-effective. When developing new products, many companies rely on partners for rapid prototyping and formative manufacturing. For instance, services like those offered by XTJ's comprehensive formative manufacturing can be invaluable for creating initial prototypes and providing Design for Manufacturability (DFM) feedback before scaling to mass production.

-

Swiss Machining Economic Profile:

- Initial Cost: High

- Setup Time: Longer and more complex

- Cycle Time: Very fast for complex parts

- Ideal Volume: High-volume production (10,000+ pieces)

- Labor Cost: Lower per part due to unattended operation

-

Conventional Turning Economic Profile:

- Initial Cost: Lower

- Setup Time: Shorter and simpler

- Cycle Time: Slower, especially for complex parts requiring multiple operations

- Ideal Volume: Prototyping and low-to-mid volume production

- Labor Cost: Higher per part due to more operator involvement

Choosing the Right Turning Process

Ultimately, Swiss machining and conventional turning are not competing technologies but complementary ones, each with a distinct set of strengths. The choice is not about which is "better" but which is the most appropriate and cost-effective for the specific part being manufactured. A thorough analysis of the part's geometry, required precision, complexity, and expected production volume will always point to the optimal solution.

To summarize, if your project involves long, thin, and intricate components needed in high quantities, the precision and efficiency of Swiss machining are likely the right answer. If you are producing shorter, larger-diameter parts, prototyping, or working with lower volumes, the flexibility and lower setup cost of conventional turning make it the more practical and economical choice. By understanding these core differences, manufacturers and designers can make informed decisions that optimize quality, speed, and cost.

Frequently Asked Questions

1. What is the difference between Swiss machining and lathe?

The key difference is how the material is supported. A conventional lathe holds the workpiece in a fixed chuck and moves the cutting tool along it. Swiss machining feeds the workpiece through a guide bushing, which provides support extremely close to the cutting tool. This makes Swiss machines ideal for long, slender parts that would otherwise deflect or vibrate during cutting.

2. What is the difference between a Swiss machinist and a CNC machinist?

While both are skilled professionals, their specializations differ. A general CNC machinist typically operates conventional lathes and mills, focusing on a wide variety of part geometries. A Swiss machinist specializes in operating Swiss-type lathes, which requires a deep understanding of their unique multi-axis programming, sliding headstock mechanics, and the nuances of machining very small, high-precision parts.

3. What are the disadvantages of conventional machining?

The main disadvantages of conventional turning appear when machining long, thin parts, where it is prone to material deflection, leading to lower precision and poor surface finishes. For complex components, it often requires multiple setups on different machines, which increases cycle time, labor costs, and the potential for error when re-fixturing the part.

4. Why is it called Swiss machining?

The technology is called "Swiss" machining because it was invented in Switzerland in the late 1870s. It was originally developed to efficiently produce the small, precise screws and components required by the Swiss watchmaking industry, a problem that conventional lathes of the time could not solve effectively. You can learn more about its origins from resources like this article on the history of Swiss machining.

-

Posted in

cnc machining, conventional turning, lathe operations, precision manufacturing, swiss machining