How On-Demand Manufacturing Works: A Practical Guide

TL;DR

On-demand manufacturing is a production model where goods are produced only after a customer places an order. This approach contrasts sharply with traditional manufacturing, which relies on forecasting to produce items in bulk. By leveraging digital technologies like 3D printing and CNC machining, on-demand manufacturing significantly reduces inventory costs, minimizes waste, and allows for greater product customization and faster speed to market.

What Is On-Demand Manufacturing?

On-demand manufacturing, also known as custom or cloud manufacturing, represents a fundamental shift in production philosophy. At its core, it is a system where products are only created when there is a confirmed customer order and in the exact quantity required. This just-in-time approach eliminates the guesswork of forecasting consumer demand, a practice that often leads to overproduction and costly unsold inventory in traditional models.

The traditional manufacturing process is built on economies of scale; it's a push system where large volumes of standardized products are made and stored in warehouses, waiting for buyers. Think of it like a fast-food chain that pre-cooks dozens of burgers in anticipation of the lunch rush. In contrast, on-demand manufacturing is a pull system, much like a gourmet restaurant where the chef only begins cooking your meal after you've placed your order. This ensures every product is wanted, reducing the financial risk tied up in stock and storage.

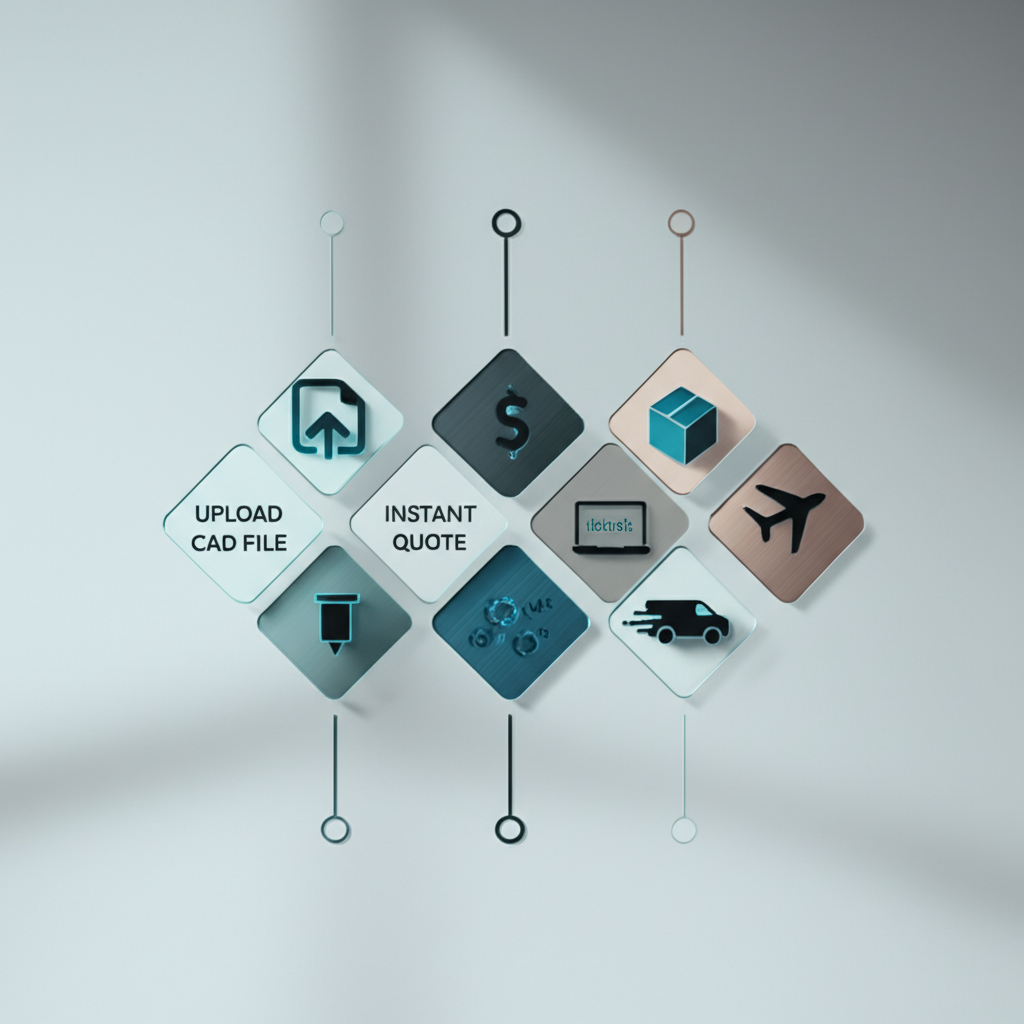

This modern approach is powered by advancements in digital technology and cloud-based platforms. According to an article by NetSuite, these digital tools are essential for shortening production cycles and enabling the agile creation of small product runs. Customers can upload digital design files (like CAD models), receive automated quotes, and track their orders through a streamlined, transparent process, making it an incredibly responsive and customer-centric model.

The On-Demand Manufacturing Process: A Step-by-Step Breakdown

The efficiency of on-demand manufacturing hinges on a highly digitized and automated workflow that transforms a customer's concept into a physical product with speed and precision. While specifics can vary by provider and technology, the process generally follows these key stages:

- Digital Design and Order Placement: The process begins when a customer uploads a digital design file, typically a 3D CAD (Computer-Aided Design) model, to an online platform. At this stage, they specify materials, quantities, finishes, and other critical requirements for their part or product. This digital submission is the foundation for the entire production cycle.

- Automated Quoting and Design Analysis: Once the file is uploaded, sophisticated software analyzes the design for manufacturability. This automated Design for Manufacturing (DFM) analysis checks for potential issues, such as wall thickness or material compatibility, providing instant feedback to the customer. Simultaneously, the platform generates an accurate price quote based on the design's complexity, materials, and production time, eliminating lengthy manual quotation processes.

- Production Scheduling and Manufacturing: After the customer approves the quote and confirms the order, the project is automatically routed to the appropriate manufacturing technology. Depending on the part's requirements, this could involve CNC machining, 3D printing, sheet metal fabrication, or injection molding. For complex parts requiring tight tolerances, providers like XTJ utilize advanced CNC machining services to produce high-precision components from a wide range of materials, ensuring the final product meets exact specifications.

- Quality Control and Fulfillment: Throughout the manufacturing process, quality checks are performed to ensure the product adheres to the customer's specifications. Once production is complete, the parts undergo a final inspection before being packaged and shipped directly to the customer. This streamlined process, from a digital file to a delivered product, can often be completed in a matter of days.

Key Advantages Over Traditional Manufacturing

The on-demand model offers significant strategic benefits that address many of the inefficiencies of traditional, forecast-based production. These advantages empower businesses to be more agile, cost-efficient, and responsive to market demands.

- Reduced Inventory Costs: This is perhaps the most significant financial benefit. Traditional manufacturing requires massive investment in inventory and warehousing. By producing items only when ordered, on-demand manufacturing eliminates the need for large stockpiles, freeing up capital and drastically reducing storage, insurance, and management costs associated with unsold goods.

- Greater Flexibility and Customization: On-demand systems excel at producing highly customized products and small batches. Since production is digitally driven, modifying a design or switching between different products doesn't require expensive retooling of a physical assembly line. This flexibility allows companies to cater to niche markets and offer personalized products, a key competitive advantage.

- Faster Speed to Market: The ability to move from a digital design to a physical prototype or final product in days, rather than weeks or months, is a game-changer. Rapid prototyping allows engineers and designers to test and iterate on new ideas quickly and cost-effectively, accelerating innovation and shortening the product development lifecycle.

- Minimized Waste and Enhanced Sustainability: By producing only what is needed, on-demand manufacturing inherently reduces material waste and energy consumption associated with overproduction. This makes it a more sustainable approach, aligning with growing consumer and regulatory demands for environmentally responsible business practices.

Common Industries and Applications

On-demand manufacturing is not a one-size-fits-all solution, but its flexibility and precision have made it indispensable across several key industries. Its ability to produce custom, low-volume, and complex parts quickly has driven innovation and solved critical production challenges.

Aerospace and Automotive

Both industries require components with extremely high precision and tight tolerances, often in small batches for prototypes, custom jigs, or replacement parts. On-demand technologies like CNC machining and additive manufacturing are ideal for creating lightweight yet strong components for vehicles and aircraft. This allows for rapid testing of new designs and the production of specialized parts without the high cost of traditional tooling.

Healthcare and Medical Devices

The medical field has been revolutionized by on-demand manufacturing. It enables the creation of patient-specific implants, surgical guides, and custom prosthetics that are perfectly tailored to an individual's anatomy. As noted by WayKen, technologies like 3D printing with biocompatible materials allow for the rapid production of these life-changing devices.

Consumer Products and Electronics

For businesses creating consumer goods, on-demand production allows for market testing with small product runs before committing to large-scale manufacturing. It also facilitates a high degree of personalization, from custom phone cases to bespoke footwear from brands like Nike, which uses made-to-order processes for its customized shoe lines.

Fashion and Apparel

The fashion industry is increasingly turning to on-demand models to combat the waste of fast fashion. By producing clothing only after it's ordered, brands can reduce unsold inventory and offer a wider range of sizes and custom designs. This approach is particularly effective for e-commerce businesses looking to operate with more sustainable and cost-effective inventory management.

Potential Challenges and Considerations

While on-demand manufacturing offers compelling advantages, it's essential to have a balanced perspective. This model is not without its challenges, and it may not be the optimal choice for every production scenario. Businesses should carefully consider these factors before adopting an on-demand strategy.

- Higher Per-Unit Costs for High Volumes: The primary strength of on-demand manufacturing is its cost-effectiveness for low to medium volumes. However, for mass-produced, standardized goods, the economies of scale achieved through traditional manufacturing often result in a lower cost per unit. When demand is consistently high and predictable, bulk production remains more financially viable.

- Supply Chain Dependency: The just-in-time nature of on-demand production makes it highly dependent on a responsive and reliable supply chain. Any disruption, such as a material shortage or shipping delay, can halt production and lead to missed customer deadlines, as there is no buffer of finished inventory to fall back on.

- Intellectual Property Risks: The process requires sharing digital design files and detailed specifications with manufacturing partners. While reputable providers have strong security protocols, there is an inherent risk of intellectual property theft if dealing with unreliable vendors. Thorough vetting of partners is crucial to protect sensitive designs.

- Scalability for Sudden Demand Spikes: An on-demand facility is optimized for a certain level of production capacity. A sudden, large surge in orders can create bottlenecks and overwhelm the system, leading to longer lead times. Traditional manufacturers with large inventories are often better equipped to handle unexpected spikes in demand instantly.

Frequently Asked Questions About On-Demand Manufacturing

1. What is on demand manufacturing?

On-demand manufacturing is a production method where goods are made only after a specific customer order is received. This approach avoids mass production and large inventories, focusing instead on producing items in the exact quantities needed, when they are needed. It relies heavily on digital technologies to streamline the process from design submission to final delivery.

2. What does manufactured on demand mean?

Manufactured on demand means that the production process for an item does not begin until a customer has placed a firm order. It is the opposite of the traditional make-to-stock model. This allows for high levels of customization and flexibility, as each production run can be tailored to specific client requirements.

3. What is on demand and how does it work?

In the context of manufacturing, 'on demand' refers to a pull-based production system. It works by integrating digital platforms where customers can upload designs and receive instant quotes. Once an order is confirmed, automated systems schedule the job on agile equipment like 3D printers or CNC machines to produce the part, which is then shipped directly to the customer, minimizing lead time and waste.

4. What is the most in demand manufacturing?

While 'most in-demand' can vary by economic conditions, sectors showing high growth and demand for advanced manufacturing include electronics (especially semiconductors), medical supplies and devices, sustainable energy components (like solar panels and EV parts), and aerospace components. These fields often leverage on-demand principles for prototyping and creating highly specialized, custom parts.

-

Posted in

digital manufacturing, lean manufacturing, on-demand manufacturing, rapid prototyping, supply chain