How to Read a CNC Inspection Report: A Practical Method

TL;DR

To read a CNC inspection report, typically a CMM report, first perform a sanity check on the header to ensure the part number and revision level match your purchase order. Next, scan the document for any overall "FAIL" status or line items marked "OOT" (Out of Tolerance). For any flagged dimensions, focus on the 'Deviation' column; if this value (the difference between the 'Actual' measurement and the 'Nominal' target) exceeds the allowed 'Tolerance,' the feature fails. This methodical approach allows you to quickly assess part quality and make an informed decision.

CNC vs. CMM Reports: Clarifying the Connection

When you request an inspection report for a CNC-machined part, you'll almost always receive a document from a Coordinate Measuring Machine (CMM). This often causes confusion, but the distinction is critical for understanding quality control. While a CNC machine can perform some in-process checks with on-machine probing, the CMM is the gold standard for final verification. Think of the CNC machine as the talented writer creating the work, and the CMM as the meticulous proofreader who generates the final, authoritative report.

The CMM is a separate, highly precise piece of equipment that measures a part's geometry with far greater accuracy than the machine that made it. This step is a key part of a robust quality system, often formalized in processes like the Production Part Approval Process (PPAP) and First Article Inspection (FAI). As explained in quality control guides from sources like Stecker Machine, the FAI verifies that the production process can produce a part that meets all specifications before mass production begins. The CMM report is the primary evidence for this verification.

Understanding this relationship is the first step in properly interpreting the report. You are not just checking the CNC machine's work; you are reviewing a high-precision audit of that work. This ensures that the part conforms to every specification on the engineering drawing, from simple dimensions to complex geometric relationships.

On-Machine Inspection vs. CMM Inspection

To clarify the roles of these two processes, consider their primary purposes and limitations in the table below.

| Method | Best For | Limitations | Typical Use Case |

|---|---|---|---|

| On-Machine Inspection | Quick, in-process checks | Lower accuracy; subject to machine's own potential errors | Verifying a feature was cut before the next operation |

| CMM Inspection | High-accuracy final QA | Slower cycle time; requires programming and setup | First Article Inspection (FAI) and final lot acceptance |

The Anatomy of an Inspection Report: Decoding Key Sections

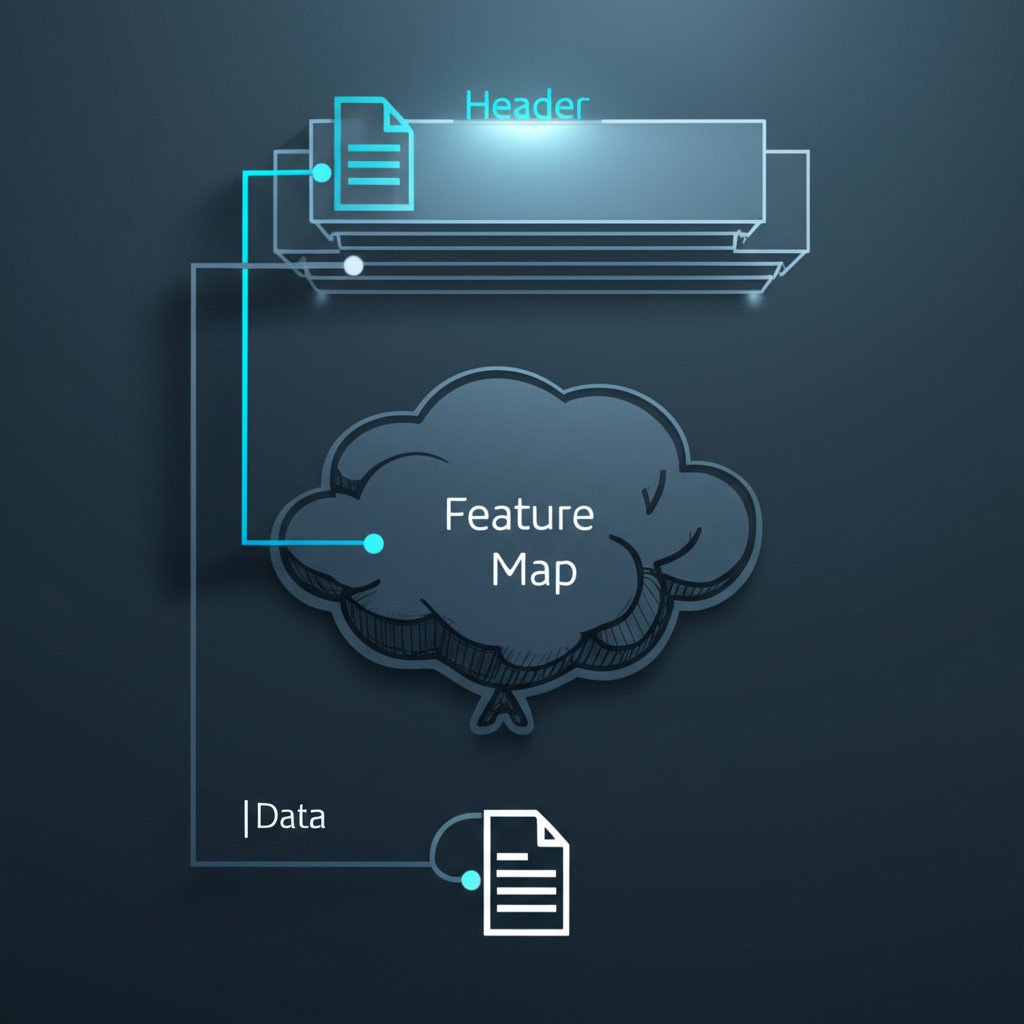

A CMM report can seem intimidating with its dense tables of data. However, most reports follow a logical structure that can be broken down into three main parts: the header, the feature map, and the measurement data. Learning to navigate these sections will turn a confusing document into a clear quality dashboard.

The first and most critical step is what Zenithin Manufacturing calls the "Sanity Check." Before you look at a single measurement, you must verify the administrative data in the header. A perfect report for the wrong part revision is a total failure. This initial check prevents costly mistakes, like approving a batch of parts built to an outdated drawing. After verifying the header, you can move on to understanding how the report connects back to the physical design.

This connection is typically made through a "ballooned drawing." As detailed by TheSupplier.in, a ballooned drawing is an engineering print where each specified dimension is circled and assigned a unique number. This creates a direct, one-to-one link: balloon #1 on the drawing corresponds to line item #1 in the CMM report's data table. This system is the backbone of traceability, ensuring every single requirement is checked and accounted for.

Your 5-Minute Triage Checklist

Before diving deep into the data, use this quick checklist to perform a high-level triage and spot major issues immediately.

- Verify Header Info: Check the Part Number, Revision Level, and Purchase Order Number against your own records. If they don't match, stop. The report is invalid.

- Find Overall PASS/FAIL Status: Look for a summary on the first page. This gives you an immediate top-level result.

- Check Quantity Inspected: Did they inspect one "golden sample" or a statistically significant number from the batch? A small sample size on a large order increases your risk.

- Scan for Red Flags: Quickly scroll through the report and look for lines highlighted in red or marked "OOT" (Out of Tolerance). This gives you a sense of the scale of any quality issues.

How to Read the Core Data: A Practical 4-Column Method

The heart of the CMM report is the data table. While it may contain a dozen columns, you only need to focus on four to make a sound judgment. Understanding the relationship between these columns is the key to decoding the report's findings. The process is a simple comparison of the design's intent versus the part's physical reality.

The four core columns are:

- Nominal: This is the "perfect" target dimension specified on the engineering drawing.

- Actual: This is the real measurement taken from the physical part by the CMM.

- Tolerance: This is the acceptable margin of error (e.g., ±0.05 mm) that the engineer has defined for that feature.

- Deviation: This is the most important column. It is the simple mathematical difference between the Actual and Nominal values (`Actual - Nominal = Deviation`).

The rule for passing or failing is straightforward: if the absolute value of the Deviation is less than or equal to the allowed Tolerance, the feature PASSES. If the Deviation exceeds the Tolerance, it FAILS. For parts requiring high precision and reliability, partnering with a service that provides Design for Manufacturability (DFM) feedback, like the formative manufacturing services offered by XTJ, can help ensure these tolerances are achievable from the start, preventing failures before they happen.

A Special Case: Geometric Dimensioning & Tolerancing (GD&T)

Beyond simple sizes, you'll see symbols for GD&T, which control the relationships between features (e.g., Position, Flatness, Perpendicularity). As Zenith MFG notes, a failure here is often more critical than a simple size error. A hole can be the correct diameter (size), but if its position (relationship) is wrong, the part won't assemble. Pay extra attention to any failures related to GD&T features, as they often indicate a higher risk of functional failure.

The Decision Framework: How to Act on a PASS or FAIL Result

Reading the report is only half the battle; the real value comes from taking the right action. Your response should be guided by the type and severity of the findings. This transforms you from a passive report reader into a strategic risk manager. Based on the framework outlined by industry experts, there are three primary scenarios you will encounter.

Scenario A: 100% PASS

This is the ideal outcome. Your immediate action is to approve the shipment and archive the report for traceability. The advanced move is to ask about the supplier's process capability (Cpk). A passing report proves they made a good part this time; a high Cpk (≥1.33) proves they can do it consistently.

Scenario B: FAIL on Non-Critical Features

This is the most common situation and a chance to add significant value. Do not immediately reject the parts. A minor failure on a non-functional feature, like a chamfer, may not impact the part's use. Your action is to take the report to your engineering team and ask if a waiver or deviation can be granted. This pragmatic approach can prevent unnecessary production delays and costs.

Scenario C: FAIL on Critical Features or GD&T

This requires a firm and immediate response. If a critical functional dimension or a key GD&T relationship is out of tolerance, the part is likely unusable. Your action is to stop the shipment, place the batch on a quality hold, and issue a formal Non-Conformance Report (NCR) to the supplier. The CMM report is now your objective, data-driven evidence for negotiating a rework, replacement, or credit.

Frequently Asked Questions

1. How do I interpret an inspection report?

To interpret an inspection report, start by verifying the administrative data in the header (part number, revision). Then, look for an overall pass/fail summary. Finally, analyze the data table by comparing the 'Deviation' of each feature to its allowed 'Tolerance' to understand any specific out-of-tolerance conditions.

2. What should I look for in an inspection report?

The most important things to look for are a correct part number and revision level, the overall pass/fail status, the quantity of parts inspected, and any specific features flagged as 'OOT' (Out of Tolerance). Pay special attention to failures on critical dimensions and GD&T features.

3. What are the major components of an inspection report?

A typical CMM inspection report has three major components: the Header, containing administrative information; the Feature Map, which links the report to a 'ballooned' engineering drawing; and the Data Table, which lists the nominal, actual, tolerance, and deviation values for each measured feature.

-

Posted in

CMM report, CNC inspection, GD&T, manufacturing, Quality Control