Essential Practices for Machining Carbon Steel

TL;DR

Mastering the art of machining carbon steel hinges on a strategic blend of material science, precise tooling, and operational discipline. Best practices involve a deep understanding of the steel's chemical makeup and thermal history to gauge its machinability. Success requires selecting the right carbide tooling, optimizing cutting speeds and feeds to balance production speed with tool longevity, and using proper coolants to effectively manage heat and ensure a superior surface finish.

Understanding Machinability: The Core Principles

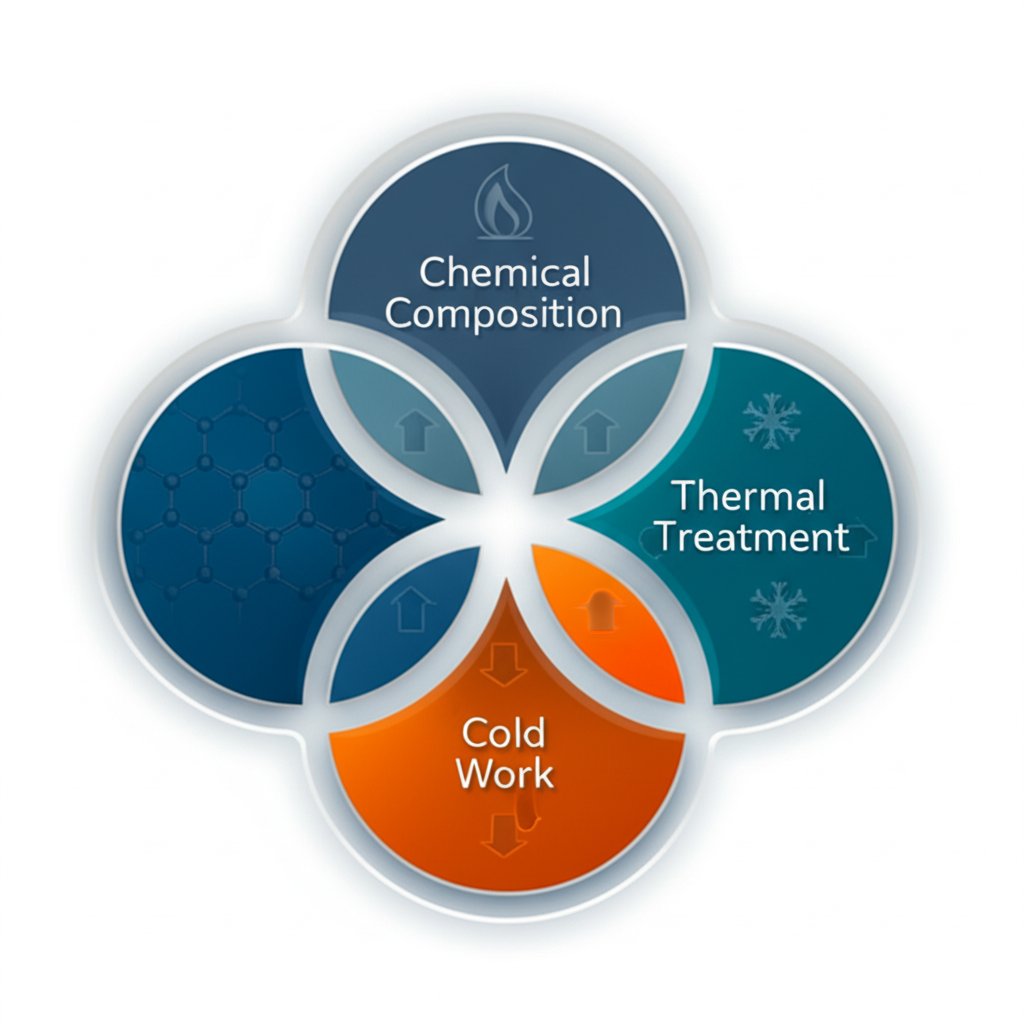

Before a single chip is cut, understanding the inherent machinability of carbon steel is the most critical step toward achieving precision and efficiency. Machinability isn't a single property but a complex interplay of the material's characteristics and the conditions under which it's cut. According to insights from the Precision Machined Products Association, three primary factors dictate how well a steel will perform in the workshop: its chemical composition, any cold work it has undergone, and its thermal treatment history. Mastering these principles allows a machinist to look at a spec sheet and predict how the material will behave, turning potential guesswork into a calculated science.

Chemical composition is the foundational element of machinability. The carbon content itself is a balancing act; steels with 0.15-0.30 wt% carbon tend to offer the best performance. Below this range, the steel can be too soft and ductile, leading to gummy chips and a poor finish. Above it, hardness increases, making the material more difficult to cut. Beyond carbon, certain additives can either help or hinder the process. Beneficial elements are added to create what are known as free-machining steels.

- Sulfur: Combines with manganese to form manganese sulfides, which act as internal chipbreakers, leading to smaller, more manageable chips and a better surface finish.

- Lead: Acts as an internal lubricant, reducing friction between the tool and the workpiece.

- Phosphorus: Strengthens the ferrite in the steel, which helps produce more brittle chips that break away cleanly.

Conversely, some elements, often used as deoxidizers or grain refiners, can make machining more challenging. Silicon and aluminum, for example, can form abrasive oxides that accelerate tool wear. It's important to recognize that these additives create trade-offs. For instance, the high sulfur content in a grade like 1215 steel, which makes it exceptionally easy to machine, also makes it difficult to weld.

Beyond chemistry, mechanical and thermal histories play a huge role. Cold work, such as die drawing, reduces the steel's natural ductility. This makes the chips harder and more brittle, preventing the formation of a built-up edge on the cutting tool. Thermal treatments like annealing are also used to optimize the steel's microstructure for machining. Processes like a stress relief anneal or a spheroidize anneal can reduce internal stresses and lower hardness, making the material easier to cut and extending tool life, especially in higher-carbon steels. By understanding how these three pillars—chemistry, cold work, and heat treatment—interact, a machinist can select the right material and anticipate its behavior, setting the stage for a successful operation.

Tool Selection and Heat Management

Once the material is understood, the focus shifts to the practicalities of cutting. The right tool selection and effective heat management are non-negotiable for achieving a high-quality surface finish and preserving tool life. The intense friction and pressure generated during cutting can quickly lead to tool failure and dimensional inaccuracies if not properly controlled. Therefore, choosing the correct cutting tool material, geometry, and coolant strategy is a cornerstone of best practices in machining carbon steel.

For most carbon steel applications, carbide tools are the preferred choice over High-Speed Steel (HSS). Carbide's superior hardness and heat resistance allow for significantly higher cutting speeds, which translates to faster cycle times and greater efficiency. Modern carbide inserts often feature advanced coatings, such as Titanium Nitride (TiN) or Titanium Carbonitride (TiCN), which further reduce friction, prevent material from sticking to the tool (edge buildup), and extend its operational life. Tool geometry is also critical; positive rake angles are generally recommended as they help curl and break chips more effectively, reducing cutting forces and improving the surface finish.

Effective heat management is arguably as important as tool selection. The heat generated at the cutting interface can cause thermal damage to both the workpiece and the tool. This is where coolants and lubricants become essential. A steady flow of coolant, typically a water-soluble oil, serves multiple purposes: it dissipates heat, flushes away chips from the cutting zone, and provides lubrication to reduce friction. For high-volume production or more demanding operations, high-pressure coolant systems can be particularly effective at chip evacuation and cooling. The goal is to maintain a stable thermal environment to prevent tool wear and ensure the dimensional stability of the part.

To provide a clearer picture, here is a comparison between the two primary tool materials used for machining steel:

| Feature | Carbide Tools | High-Speed Steel (HSS) Tools |

|---|---|---|

| Speed Capability | Very High (e.g., 400-650 SFM) | Low to Medium (e.g., 130-230 SFM) |

| Wear Resistance | Excellent, especially at high temperatures | Good, but softens at high temperatures |

| Cost | Higher initial cost | Lower initial cost |

| Best Use Cases | High-volume production, hard materials, high-speed operations | Short runs, custom jobs, older or less rigid machines |

Optimal Cutting Parameters: Speeds, Feeds, and Depth of Cut

Dialing in the correct cutting parameters—specifically cutting speed, feed rate, and depth of cut—is where theoretical knowledge meets practical application. This is a delicate balancing act. Pushing the parameters too high can lead to rapid tool wear, poor surface finish, or even catastrophic tool failure. Setting them too low sacrifices productivity and can lead to other issues like rubbing instead of cutting. The goal is to find the sweet spot that maximizes the material removal rate (MRR) while maintaining part quality and achieving predictable tool life. For highly machinable steels like 1215, these parameters can be pushed higher, showcasing why material selection is so impactful.

Cutting speed, often measured in Surface Feet per Minute (SFM), refers to the relative speed between the cutting tool and the workpiece. Feed rate, measured in Inches Per Revolution (IPR) for turning or Inches Per Tooth for milling, is the distance the tool advances with each revolution or each cutting edge engagement. Depth of cut is simply how deep the tool penetrates the material in a single pass. These three variables are interconnected and must be adjusted in concert. For instance, a deeper cut might require a lower feed rate or cutting speed to manage the increased forces and heat.

Observing the process provides critical feedback for optimization. The color of the chips, for example, is an excellent indicator of cutting temperature. Straw-colored or brown chips are generally good, while blue chips are a sign of excessive heat, indicating that the cutting speed should be reduced or coolant flow increased. Similarly, a poor surface finish or excessive vibration can signal that the feed rate is too high or the tool is dull. A methodical approach is best: start with recommended parameters from a reliable source, run a test cut, observe the results, and make small, incremental adjustments until the process is stable and efficient.

For a practical starting point, the following table, adapted from guidelines for machining 1215 carbon steel, provides recommended parameters for turning and milling operations. Note that these are starting points and may need adjustment based on machine rigidity, specific tooling, and part geometry.

| Operation | Tool Type | Speed (SFM) | Feed (IPR) |

|---|---|---|---|

| Turning | Carbide | 400-650 | 0.004-0.016 |

| Turning | HSS | 130-230 | 0.004-0.016 |

| Milling | Carbide | 350-600 | 0.002-0.012 (per tooth) |

Finishing, Heat Treatment, and Safe Handling

The machining process doesn't end when the final cut is made. Post-machining steps are crucial for ensuring a part meets its functional requirements for durability, corrosion resistance, and performance over its lifespan. These practices include surface treatments, heat treatments, and proper handling and inspection. Overlooking this final stage can undermine even the most precise machining work, leading to premature failure in the field. A holistic approach that considers the entire lifecycle of the component is a hallmark of expert practice.

Surface treatments are often applied to enhance the properties of the finished part. For carbon steel, which is prone to rust, this is especially important. Common treatments include Zinc Plating, which provides excellent corrosion resistance, or applying a Black Oxide coating to improve wear resistance while maintaining tight dimensional tolerances. The choice of finish depends entirely on the part's intended application and operating environment. For complex projects where material selection and finishing are critical, partnering with a service that provides comprehensive support can be invaluable. For instance, services that offer rapid prototyping with Design for Manufacturability (DFM) feedback, such as XTJ's formative manufacturing services, can help accelerate product development by ensuring these considerations are addressed early on.

Heat treatment is another critical post-machining process used to alter the mechanical properties of steel. As discussed in CNCCookbook's guide to machining steel, processes like annealing soften the steel, quenching hardens it, and tempering is used after hardening to reduce brittleness and improve toughness. For example, a knifemaker might temper a high-carbon steel blade to achieve the perfect balance between a hard, sharp edge and the flexibility needed to prevent it from chipping. These treatments are a science in themselves and must be precisely controlled to achieve the desired outcome.

Finally, safe handling and meticulous inspection are the last steps in guaranteeing quality. Finished parts should be stored in a dry, climate-controlled environment, often with a light oil coating to prevent corrosion. Regular inspection, both during and after production, is essential to catch any potential defects like micro-cracks or excessive wear. A simple checklist can ensure consistency and prevent costly mistakes.

Post-Machining Checklist:

- Deburring: Remove all sharp edges and burrs left from the machining process.

- Cleaning: Thoroughly clean the part to remove all coolant, chips, and contaminants.

- Surface Treatment: Apply any required coatings (e.g., zinc plating, black oxide) for corrosion or wear resistance.

- Heat Treatment: Perform any necessary annealing, quenching, or tempering as specified by the design.

- Final Inspection: Conduct a final check for dimensional accuracy, surface finish, and any signs of defects like cracks.

- Proper Storage: Store parts in a way that protects them from moisture and physical damage, often elevated and with a protective coating.

Frequently Asked Questions

1. Is carbon steel hard to machine?

The difficulty of machining carbon steel varies greatly depending on its carbon content and additives. Low-carbon steels (like 1018) are generally soft and easy to machine, though they can produce gummy chips. Medium-carbon steels (like 1045) offer a good balance of strength and machinability. High-carbon steels (like 1095) are much harder and more abrasive, requiring slower speeds, rigid setups, and advanced tooling like carbide or ceramic. Free-machining steels (like 1215 or 12L14) have additives like sulfur or lead that make them exceptionally easy to machine at high speeds.

2. What are the rules of thumb for machining?

General rules of thumb for machining focus on stability, heat management, and efficiency. Always use the shortest, most rigid tool possible to minimize deflection and vibration. Maintain sharp cutting edges, as dull tools increase cutting forces and generate excess heat. Ensure a consistent and ample flow of coolant to control temperature and evacuate chips. Start with conservative speeds and feeds recommended by the tool manufacturer and gradually optimize them based on chip formation, surface finish, and sound. Finally, a common guideline for milling cavities is to keep the depth no more than four times the tool's diameter to maintain rigidity.

3. What is the best carbon steel for machining?

For pure machinability, free-cutting steels like 1215 and 12L14 are considered the best. They are specifically designed for high-speed, high-volume production on automatic screw machines. The added sulfur in 1215 and the lead in 12L14 act as internal lubricants and chip breakers, resulting in excellent tool life and surface finish with minimal effort. However, these grades are not suitable for applications requiring welding or significant forming. For a more general-purpose, weldable, and still highly machinable option, 1018 cold-rolled steel is a very popular choice in many machine shops.