Is Aluminium Magnetic Material? Quick Tests, Real Answers

Why magnets don’t stick

Ever tried sticking a fridge magnet to a soda can or an aluminum ladder? You’ll notice nothing happens—the magnet simply slides off. This common experience leads many to wonder: is aluminium magnetic material at all? The answer is clear and consistent: aluminum is not magnetic in the way most people expect. While aluminum is technically classified as a paramagnetic material, its magnetic response is so weak that it’s undetectable in everyday scenarios, and ordinary magnets will not cling to it.

What makes a metal magnetic?

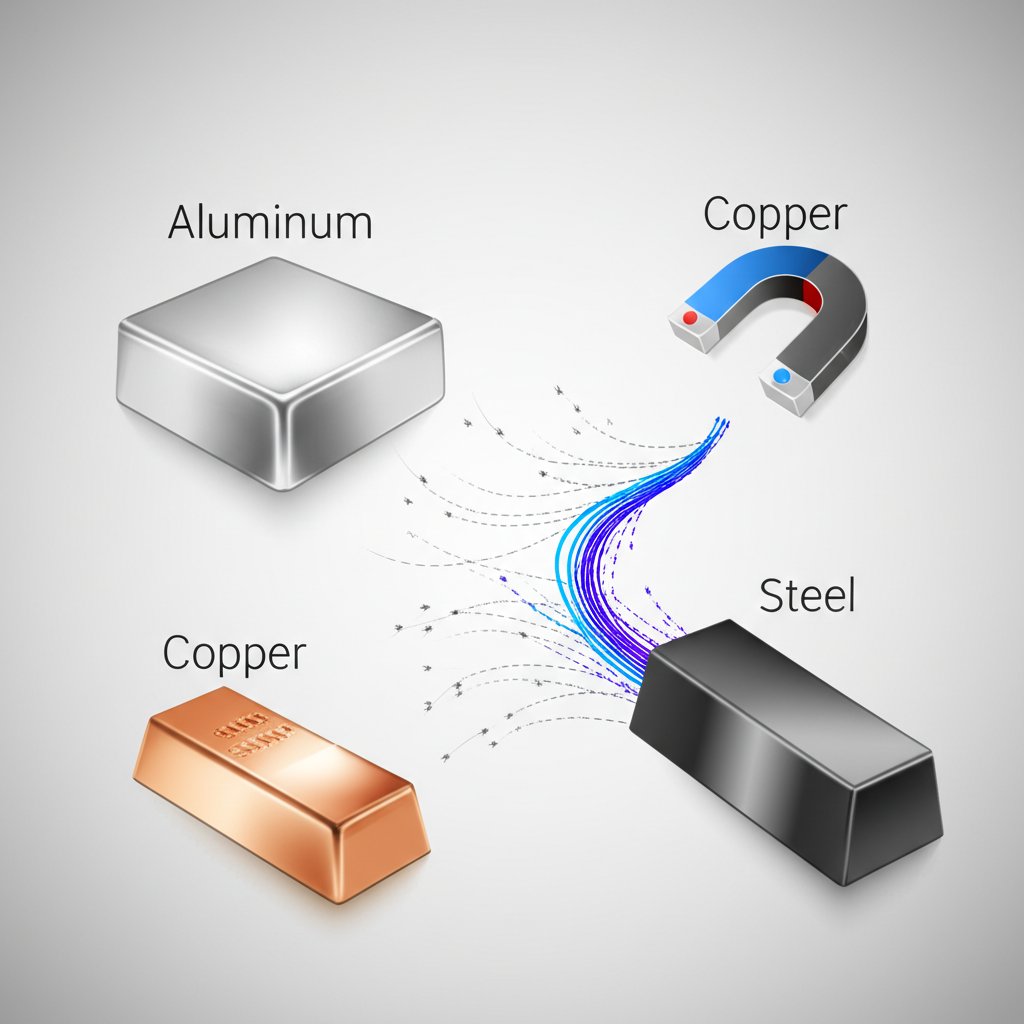

Magnetism in metals comes down to how their electrons are arranged and how their atoms respond to magnetic fields. Some metals, like iron and steel, easily attract magnets, while others, such as aluminum, do not. Here’s a quick guide to the main types of magnetic behavior:

- Ferromagnetic: Materials that are strongly attracted to magnets—examples include iron, nickel, and cobalt. They can become magnets themselves.

- Paramagnetic: Materials like aluminum that are only very weakly attracted to magnets. Their response is so faint that you need special instruments to detect it.

- Diamagnetic: Materials that are slightly repelled by magnets, such as copper and lead. The effect is generally even weaker than paramagnetism.

Is aluminum magnetic in everyday tests?

Let’s make it practical: If you grab a kitchen magnet and touch it to a piece of aluminum foil, a soda can, or a window frame, nothing happens. Do magnets stick to aluminum? No—they don’t. In fact, will a magnet stick to aluminium in any normal home or shop setting? The answer is still no. The reason is that aluminium magnetic behavior is so slight that it’s invisible to the naked eye and irrelevant for most daily uses (Amazing Magnets).

Some people are surprised to find that moving a strong magnet quickly past a piece of aluminum can create a brief resistance or force. This is not traditional magnetism, but rather a different phenomenon called eddy currents—a topic we’ll explore in detail later. For now, remember: why is aluminum non magnetic? It’s due to its atomic structure and the way its electrons behave, not because of any flaw or impurity.

Paramagnetism versus ferromagnetism explained

To understand is aluminum magnetic, it helps to compare these two types of magnetism:

- Ferromagnetic materials have regions called domains that align with a magnetic field, making them strongly magnetic and able to retain magnetization.

- Paramagnetic materials like aluminum have unpaired electrons that weakly align with a magnetic field, but the effect vanishes as soon as the field is gone.

So, while aluminum is not magnetic in the way iron or nickel is, it does have a tiny, temporary response to strong fields—a fact that matters only in specialized scientific or industrial settings.

Key takeaway: Magnets do not normally stick to aluminum—its magnetic response is so weak that, for all practical purposes, aluminum is non-magnetic.

In the next sections, we’ll cover how to test for magnetism, what happens with alloys and contamination, why moving magnets create odd effects, and how to ensure you’re getting the right material for your needs.

Quantitative properties without the math overload

Key magnetic parameters for aluminum

When engineers or materials scientists discuss aluminum magnetic properties, they typically focus on two main measurements: magnetic susceptibility and relative permeability. These technical terms might sound intimidating, but they are simply ways to describe how a material responds to a magnetic field. Let’s break them down:

- Magnetic susceptibility tells you whether a material is attracted or repelled by a magnetic field, and how strong that response is. Positive values mean weak attraction (paramagnetic), while negative values mean weak repulsion (diamagnetic).

- Relative permeability compares how easily a magnetic field passes through a material versus through empty space. For most engineering purposes, a value close to 1 means the material is nearly invisible to magnetic fields.

How permeability and susceptibility relate to real behavior

So, is aluminum paramagnetic? Yes—aluminum’s magnetic susceptibility is small and positive, making it very weakly paramagnetic. In practical terms, this means the permeability of aluminum is almost the same as the permeability of free space (the baseline for all magnetic measurements). According to Fitzpatrick, University of Texas, “the permeabilities of common diamagnetic and paramagnetic materials do not differ substantially from the permeability of free space. In fact, to all intents and purposes, the magnetic properties of such materials can be safely neglected.” In other words, the magnetic permeability of aluminum is so close to one that it barely alters a magnetic field at all.

To make this more tangible, here’s a quick comparison table for common metals and alloys:

| Material/Alloy Family | Relative Permeability | Magnetic Susceptibility Sign | Practical Magnet Test Outcome | Notes |

|---|---|---|---|---|

| Pure Aluminum (1xxx series) | Near unity (≈1) | Positive (paramagnetic) | No visible attraction | Magnetism only detectable with sensitive instruments |

| Common Aluminum Alloys (2xxx–7xxx) | Near unity (≈1) | Positive (paramagnetic) | No visible attraction | Behavior unchanged unless alloyed with strong magnetic elements |

| Iron | Much greater than 1 | Strongly positive (ferromagnetic) | Strong attraction | Classic magnetic metal |

| Copper | Near unity (≈1) | Negative (diamagnetic) | No visible attraction | Slight repulsion in strong fields |

Alloy family notes for 1xxx to 7xxx series

Across the main families of aluminum alloys (1xxx for pure aluminum, 2xxx to 7xxx for alloys with elements like copper, magnesium, or zinc), the aluminium magnetic properties remain weak. Only when significant amounts of ferromagnetic elements like iron or cobalt are added does the magnetic response become detectable in everyday tests. For the vast majority of commercial and household aluminum products, the magnetic permeability of aluminium is so close to that of air that magnets still won’t stick.

Because the permeability of aluminum is so close to that of empty space, ordinary magnets won’t stick—even though sensitive instruments can detect a tiny, temporary response.

Next, we’ll walk through simple and advanced tests so you can see these subtle effects (or their absence) for yourself.

How to test aluminum for magnetism step by step

When you want to know if a piece of metal is truly aluminum or just want to see do magnets stick on aluminum, there are several practical tests you can perform—no special lab required. Let’s walk through simple, reliable methods so you can confidently answer, will magnets stick to aluminum, and avoid common mistakes that can lead to false results.

Bench tests with household and rare earth magnets

Sounds complex? Actually, the basic magnet test for metals is one of the easiest ways to check if you have aluminum or a magnetic metal. Here’s how to do it right:

- Choose your magnet: Use a standard fridge magnet for a quick check, or a strong neodymium magnet for more sensitivity. If you’re curious about magnets that stick to aluminum, you’ll find that even the strongest household magnets won’t cling to pure aluminum.

- Prepare the surface: Clean the metal to remove dust, grease, or any attached hardware. Contaminants or hidden steel clips can give misleading results.

- Test the contact: Hold the magnet against the metal’s flat surface. Does it stick firmly, slide off, or do nothing at all? For aluminum, the answer is almost always no attraction—magnet that sticks to aluminum is a myth in normal conditions.

- Compare with known samples: For best results, compare your unknown sample with a piece of steel and a piece of copper. This way, you’ll see the clear difference in magnetic response.

- Try both static and moving tests: Hold the magnet still (static test), then slide it quickly across the surface (dynamic test). Any resistance felt during movement is likely due to eddy currents, not true attraction—a topic we’ll cover in detail soon.

Using a gaussmeter for practical verification

If you want to go beyond the basic magnet for aluminum check, a gaussmeter is the next step. This instrument measures the strength of magnetic fields in units of Gauss or Tesla (Magnetstek). Here’s how to use one for aluminum:

- Calibrate the gaussmeter: Always follow the manufacturer’s instructions to ensure accurate readings. Calibration is critical before each use.

- Position the probe: Place the gaussmeter’s sensor directly above or against the aluminum surface, keeping a consistent distance for each measurement.

- Take your reading: Note the field strength. For pure aluminum, the reading should be nearly identical to the background level—no significant spike means no magnetic field is present.

- Compare materials: Repeat the measurement with a piece of steel and a nonmagnetic metal (like copper) to observe the difference. Steel will show a strong response, aluminum will not.

- Document your results: Record your findings for future reference, especially if you’re testing multiple parts or materials.

Remember, do magnets work on aluminum in these tests? Only sensitive equipment like a gaussmeter can pick up the faintest response, and even then, it’s negligible compared to truly magnetic metals.

When to consider laboratory magnetometry

For most practical purposes, the above tests are enough. But if you need to detect extremely weak magnetism or verify purity at the highest level, specialized lab methods like Vibrating Sample Magnetometry (VSM) or SQUID magnetometry are used. These tools can detect magnetic fields in the nano-Tesla range. However, for everyday users, these are not necessary—household and shop tests will tell you what you need to know.

- Check for attached or embedded steel fasteners—these can cause a magnet to stick, even if the base metal is aluminum.

- Look for machining residue or filings stuck to the surface, which could be magnetic.

- Clean the metal thoroughly before testing for accurate results.

- If in doubt, compare with a known piece of steel and a known piece of aluminum.

Safety note: Strong neodymium magnets can pinch fingers or snap together unexpectedly. Always handle with care, especially near electronics or delicate surfaces.

By following these steps, you can confidently answer whether magnets stick to aluminum—and avoid being fooled by hidden steel or contamination. Next, we’ll explore why moving magnets create surprising effects with aluminum, even when static magnets don’t stick at all.

Why moving magnets interact with aluminum

Why moving magnets affect aluminum

When you first see a magnet glide slowly down an aluminum tube or feel resistance sliding a magnet across an aluminum plate, it’s tempting to ask: does a magnet stick to aluminum after all? Or can magnets stick to aluminum if you move them fast enough? The answer is still no—aluminum is not ferromagnetic, so static magnets do not attract or cling to it. But there’s a fascinating effect at play when magnets move near aluminum: eddy currents.

The root cause is aluminum’s excellent electrical conductivity. When a changing magnetic field (from a moving magnet) passes through or near aluminum, it induces swirling electric currents—called eddy currents—within the metal. These currents create their own magnetic fields, which always oppose the change that caused them. This is why you feel a braking force or see a magnet fall slowly through an aluminum tube. But crucially, this is not the same as true magnetic attraction—aluminum is not ferromagnetic, and the effect disappears when the magnet stops moving (ABC Science).

Simple demonstrations of eddy current braking

Want to see the illusion of aluminum magnetism for yourself? Here are three classic, hands-on experiments you can try at home or in the lab:

- Drop a magnet through an aluminum tube: Take a strong neodymium magnet and drop it through a non-magnetic (aluminum) tube. You’ll see the magnet fall much more slowly than it would through air or a plastic tube. The induced eddy currents in the tube create a magnetic field that pushes back against the falling magnet, acting like an invisible brake.

- Slide a magnet across a thick aluminum plate: Place a disc magnet on a flat aluminum surface and give it a push. You’ll feel resistance—almost as if the magnet is gliding through syrup. This drag is the result of eddy currents swirling in the plate beneath the moving magnet (K&J Magnetics).

- Swing a magnet past an aluminum sheet: If you attach a strong magnet to a string and swing it close to an upright aluminum sheet, the motion will quickly slow and stop. The changing magnetic field as the magnet moves by induces eddy currents, which resist the motion.

These experiments make it clear: can magnets attract aluminum? Not in the traditional sense. The resistance you feel is not the result of permanent magnetization, but a fleeting, motion-dependent effect.

The key insight: Eddy currents in aluminum oppose changes in the magnetic field, creating a temporary force that slows or resists motion—but do not make aluminum magnetic or cause magnets to stick.

Design implications for sensors and equipment

The aluminum eddy current effect isn’t just a curiosity—it’s used in real-world technology:

- Damping in machine guards and conveyor systems: Eddy current brakes use moving magnets and aluminum plates to safely slow down heavy machinery or amusement park rides—without physical contact or wear.

- Metal sorting and recycling: Eddy current separators help distinguish and remove non-ferrous metals like aluminum from mixed waste streams.

- Non-destructive testing: Eddy current probes detect cracks or flaws in aluminum parts by analyzing how induced currents behave.

- Motion sensors: The same principles are used in some speedometers and industrial sensors to measure velocity or detect position changes.

So, why is aluminum not magnetic in the classic sense? Its atomic structure simply doesn’t allow for the alignment of magnetic domains like iron or nickel. But its conductivity makes it uniquely responsive to moving magnetic fields, creating the illusion of magnetism that vanishes the moment everything is still.

Next, we’ll look at how alloying and contamination can sometimes trick you into thinking a piece of aluminum is magnetic—and how to test for the real thing.

Why aluminum sometimes seems magnetic

How alloying and processing affect magnetic behavior

Ever wondered why aluminum is an alloy in most real-world products, and why sometimes a magnet seems to stick—or at least cling—for a moment? If you’ve ever asked, does a magnet stick to aluminium or noticed a magnet barely hanging on to a scrap piece, you’re not alone. The answer lies in both what’s inside the alloy and what might be on the surface.

Pure aluminum is classified as paramagnetic and shows virtually no attraction to magnets. But in practice, aluminum is rarely used in its pure form. Instead, it’s combined with elements like copper, magnesium, zinc, or silicon to create alloys with enhanced strength, corrosion resistance, or workability. Still, these additions do not make the metal magnetic in a way you’d notice during routine tests. Only when significant amounts of ferromagnetic elements—mainly iron or nickel—are present do you get a measurable magnetic response, and even then, it is extremely weak compared to iron or steel.

- 1000 Series (Commercially Pure): Non-magnetic. Highly resistant to contamination, but not immune if handled poorly.

- 2000 Series (Al-Cu): Slightly paramagnetic. May contain trace iron impurities but still does not stick to a magnet.

- 3000 Series (Al-Mn): Non-magnetic. Low risk of magnetic response unless contaminated.

- 5000 Series (Al-Mg): Non-magnetic. Magnesium does not introduce magnetism.

- 6000 Series (Al-Mg-Si): Non-magnetic. Most common in construction and automotive; contamination is the main risk.

- 7000 Series (Al-Zn): Slightly paramagnetic, especially if iron content is elevated. Still, does aluminum stick to a magnet in these alloys? No, unless contaminated.

Spotting ferromagnetic contamination in aluminum parts

Here’s where things get tricky. Even if the base alloy is non-magnetic, small amounts of iron filings, steel machining residue, or attached fasteners can fool you into thinking the aluminum itself is magnetic. This is a common issue in manufacturing, fabrication, and even in home workshops (MarineLog). Cross-contamination can happen during cutting, grinding, or handling with tools used on steel. Sometimes, steel screws or clips are left in place, and a magnet will stick to these, not to the aluminum.

So, if you’re wondering, does aluminum stick to magnets or is aluminum attracted to magnets, always consider the possibility of contamination before drawing any conclusions about the material itself.

Shop-floor checks to confirm true material behavior

Want to make sure you’re really dealing with non-magnetic aluminum, not a contaminated or mislabeled part? Here’s a simple workflow you can use in any shop or lab:

- Clean the part: Remove dust, oil, and especially any visible metallic debris using a clean cloth and, if needed, a solvent.

- Retest with a magnet: Touch a strong magnet to the clean surface. If it still sticks, proceed to the next step.

- Scan with a gaussmeter: Measure the magnetic field at various points. If readings spike in certain spots, you may have embedded steel particles or attached hardware.

- Isolate hardware: Remove any screws, clips, or fasteners and retest the bare aluminum.

- Document findings: Record which steps removed the magnetic response. This helps trace contamination sources and prevent future issues.

Observed sticking almost always means contamination or attached ferrous parts—not that the aluminum itself became magnetic. If you find that a magnet clings to your aluminum, check for steel debris or fasteners before assuming the metal is at fault.

In summary, does aluminum attract magnets? Not under ordinary conditions. If you notice a magnetic effect, it’s nearly always due to contamination or hardware, not the alloy’s composition. For engineers and quality inspectors, this is a critical distinction—ensuring that non-magnetic aluminum stays that way is mostly about rigorous cleaning and careful handling, not about the alloy’s chemistry. Next, we’ll compare aluminum’s magnetic behavior with other metals, so you can spot differences at a glance and avoid costly mix-ups.

Compare aluminum with other metals quickly

How aluminum compares to steel and stainless

When you need to tell metals apart in the shop, at the scrapyard, or on the job site, the magnet test is often the first thing people try. But what should you expect if you run a fridge magnet over aluminum, steel, or other common metals? Let’s break it down with real-world examples and clear science, so you’ll know exactly what metals are not magnetic and which ones will surprise you.

| Material | Visible attraction to a fridge magnet | Detectable by a portable gaussmeter | Strong eddy current effect (moving magnet) | Alloy sensitivity to ferromagnetic contamination | Common use-case notes |

|---|---|---|---|---|---|

| Aluminum | No | No (response is negligible) | Strong (motion-dependent) | Low/Moderate (watch for steel debris) | Lightweight, nonmagnetic; used where what metals don't stick to magnets is critical |

| Carbon Steel | Yes | Yes (strong signal) | Weak | High (iron-based, easily magnetized) | Structural, magnetic; classic answer to what metal is magnetic |

| Stainless Steel (Austenitic, e.g., 304) | No | No or very weak | Weak | Low | Nonmagnetic grade; used in medical and food industries |

| Stainless Steel (Ferritic/Martensitic, e.g., 430, 410) | Yes | Yes | Weak | Moderate/High | Appliances, cutlery; magnetic grades |

| Copper | No | No (diamagnetic, weak repulsion) | Strong (motion-dependent) | Low | Used in wiring; is copper a magnetic metal? No, but strong eddy current effects |

| Brass | No | No | Strong | Low | Decorative, plumbing; nonmagnetic |

| Magnesium | No | No (weak paramagnetic) | Strong | Low | Lightweight, nonmagnetic; is magnesium magnetic? Not in practice |

| Titanium | No | No (weak paramagnetic) | Strong | Low | Medical, aerospace; nonmagnetic |

| Tin | No | No (diamagnetic) | Strong | Low | Solder, coatings; is tin magnetic material? No |

Quick-reference outcomes for common shop metals

- Will a magnet stick to steel? Always, unless it’s an austenitic stainless grade.

- What metals are not magnetic? Aluminum, copper, brass, magnesium, titanium, tin, and austenitic stainless steel.

- Is copper a magnetic metal? No, but it shows strong eddy current effects when magnets move nearby.

- Is tin magnetic material? No; it’s diamagnetic and does not attract magnets.

- Is magnesium magnetic? Not in any practical sense—it’s weakly paramagnetic and will not attract or hold a magnet.

Choosing materials when magnetic behavior matters

Imagine you’re designing equipment for an MRI room, or you need to avoid interference with sensitive electronics. In these cases, knowing which metal is not magnetic is essential. For most applications where you want to avoid magnetic attraction, stick with aluminum, copper, brass, titanium, or austenitic stainless steel. If you need magnetic properties for sensors, separation, or holding power, carbon steel or ferritic/martensitic stainless is your best bet.

Key takeaway: Aluminum is nonmagnetic in static tests and does not attract or hold a magnet, but it can show strong eddy-current damping when magnets move nearby. This sets it apart from truly magnetic metals like steel, and from other nonmagnetic metals that may still interact with moving magnets.

Now that you can spot at a glance what metals don't stick to magnets and what metal is magnetic, you’ll be better equipped to choose the right material for your next project or inspection. In the next section, we’ll turn this knowledge into practical steps for procurement and inspection, ensuring your aluminum parts perform as expected every time.

Procurement and inspection that prevent surprises

What to put in your RFQ and drawing notes

When specifying aluminum for critical applications—whether in electronics, medical devices, or sensitive equipment—the expectation is clear: the material should remain aluminum non magnetic throughout its lifecycle. But how do you ensure your supplier delivers exactly that? It starts with precise language in your requests for quotation (RFQs) and technical drawings. Here’s a checklist to help you communicate requirements unambiguously:

- Specify the material family and alloy: Clearly indicate the desired aluminum series (e.g., 6061, 5052) to avoid unintentional inclusion of alloys with higher iron content.

- State magnetic response requirements: Use phrases like "no detectable magnetic attraction with a standard neodymium magnet" or "relative permeability must be near unity (≈1)." This sets an explicit expectation for non magnetic aluminum behavior.

- Include test methods: Specify if a magnet test or gaussmeter check is required for incoming inspection. For highly sensitive applications, request instrumented verification.

- Define acceptance criteria: Outline what constitutes a pass/fail result—e.g., "no sticking or measurable field above background." This prevents ambiguity in quality control.

- Note fabrication and finishing steps: If processes like welding or anodizing will be performed, require that the finished part remains nonmagnetic after all operations. For example, "anodized aluminum magnetic response must remain negligible post-finish."

Inspection steps that catch magnetic surprises

Even with careful specification, surprises can occur—especially if parts are processed in facilities that also handle steel or other ferromagnetic metals. Here’s a practical inspection workflow for incoming aluminum parts:

- Visual and surface cleaning: Remove any visible debris, oil, or attached hardware. This is essential for accurate testing.

- Basic magnet test: Apply a strong neodymium magnet to multiple locations on the part. No attraction should be observed if the part is truly aluminum non magnetic.

- Instrumented check (if needed): Use a gaussmeter to scan the surface for any abnormal magnetic fields, especially around welds, fasteners, or areas with surface discoloration.

- Isolate and retest: If a magnetic response is detected, remove any attached hardware (screws, clips) and retest the bare aluminum.

- Document and trace: Record the results and, if an issue is found, trace it back to fabrication steps or supplier batches for corrective action.

This stepwise approach helps ensure that can aluminium be magnetised or can aluminium be magnetized isn’t just a theoretical concern, but a practical quality checkpoint in your workflow.

Fabrication considerations for aluminum parts

Sounds complex? Imagine you’ve sourced top-grade aluminum, but after welding or finishing, the part suddenly shows weak magnetic behavior. What happened? While pure and alloyed aluminum are inherently nonmagnetic, certain fabrication steps—especially welding—can introduce contamination or alter the microstructure of the metal. According to engineering best practices and published research, here’s what to watch for:

- Welding and joining: While aluminum itself does not become magnetic through welding, contamination from steel tools, wire brushes, or grinding wheels can leave ferromagnetic particles on the surface. Always use dedicated, clean tools for aluminum work (MarineLog).

- Finishing processes: Anodizing, powder coating, and other finishes do not inherently make aluminum magnetic. However, ensure that the finishing facility does not use steel racks or fixtures that could transfer magnetic particles. If you require anodized aluminum magnetic response to remain negligible, specify this in your contract.

- Machining and handling: Cross-contamination is common when shops process steel and aluminum with the same equipment. Request segregation of workspaces or cleaning protocols from your supplier.

For organizations that need repeatable, quality-controlled results, sourcing from a provider with robust process controls and quality certification is essential. For example, when you need custom aluminum parts that must remain nonmagnetic after forming and finishing, it’s prudent to work with a fabrication partner offering ISO 9001 certified quality assurance, fast lead times, and a track record of clean, contamination-free production. XTJ's cnc machining services specializes in aluminum and other nonmagnetic metals, using advanced processes like laser cutting, bending, and welding, and offers custom finishes such as anodizing and powder coating—all with strict process controls to help ensure your parts meet demanding nonmagnetic specifications.

Consistent process control and quality assurance throughout fabrication and finishing are key to minimizing contamination risks and ensuring that aluminum remains nonmagnetic in your finished parts.

By integrating these procurement, inspection, and fabrication best practices, you can confidently answer questions like is aluminum a magnetic material and deliver parts that perform as expected—every time. In the final section, we’ll wrap up with a decision checklist and guidance for sourcing with confidence.

From understanding to confident decisions

Key takeaways you can apply today

After exploring the science, tests, and practical scenarios, you might still wonder, is aluminium a magnetic material in any way that matters for your project or daily life? Here’s the bottom line: aluminum is technically paramagnetic, but its magnetic response is so weak that for nearly all real-world purposes, it behaves as a nonmagnetic metal. If you’re asking, “will magnet stick to aluminum?”—the answer is no, unless there’s contamination or a hidden ferrous part involved. Yet, if you move a magnet rapidly near aluminum, you’ll observe eddy current effects—not true magnetic attraction, but a momentary force caused by induced currents.

Decision checklist for material selection and testing

To help you make confident, mistake-free decisions about aluminum and its magnetic behavior, use this quick checklist:

- Define your need: Do you require a metal that won’t interfere with sensitive electronics or magnetic fields? If so, aluminum is a top choice among what metals do not stick to a magnet.

- Specify the alloy: Choose a standard aluminum alloy (like 6061 or 5052) that is free from significant ferromagnetic elements.

- Test for magnetism: Use a strong neodymium magnet to check for any sticking. For critical applications, supplement with a gaussmeter or magnetic susceptibility meter for added assurance (FIRST4MAGNETS).

- Inspect for contamination: Clean the part thoroughly and remove any attached hardware before testing. Even a small steel screw can make it seem like the aluminum is magnetic.

- Document and trace: Keep records of your test results, especially if parts are destined for sensitive environments or safety-critical applications.

- Review fabrication process: Confirm that machining, welding, or finishing steps haven’t introduced ferrous contamination. Specify requirements for nonmagnetic final parts in your RFQs and contracts.

Static magnets don’t stick to aluminum, but moving magnetic fields can create temporary eddy-current effects—so always test and specify materials carefully when magnetic neutrality is critical.

Where to source aluminum parts with confidence

Choosing the right supplier is just as important as specifying the right material. If your project demands aluminum components that must remain nonmagnetic and contamination-free, it’s wise to work with a provider offering robust process control and traceability. Look for features like ISO 9001 quality assurance, in-house capability for custom alloys and finishes, and proven experience with nonmagnetic metals. This is especially vital for industries where even slight magnetic interference can cause costly problems.

For engineers, buyers, or designers seeking a reliable route to custom aluminum parts, cnc machining services from XTJ is a practical resource. Their advanced processes, rapid lead times, and strict QA protocols make them a strong choice for projects where nonmagnetic behavior, clean finishes, and full traceability are non-negotiable.

- Aluminum is not magnetic for all practical purposes; it’s ideal for applications where you need what type of metal is not attracted to magnets.

- Always test and inspect for contamination—most apparent magnetism in aluminum is due to steel debris or fasteners.

- Specify and verify magnetic requirements in your procurement documents to prevent surprises.

- Choose fabrication partners with proven process control and quality assurance for best results.

By following these steps, you’ll confidently answer “is aluminum magnetic yes or no” for any scenario—and avoid costly mix-ups or performance issues down the line. Whether you’re sourcing, inspecting, or designing, a little extra care ensures aluminum’s unique benefits shine through in your finished parts.

FAQs About Aluminum and Magnetism

1. Will magnets stick to aluminum surfaces?

Magnets will not stick to aluminum surfaces in everyday scenarios because aluminum is not magnetic. Its weak paramagnetic response is only detectable with specialized instruments, not with common magnets.

2. Why don't magnets work on aluminum boats or cars?

Aluminum boats and cars are nonmagnetic, so magnetic signs or objects will not adhere to them. This is due to aluminum's atomic structure, which doesn't support strong magnetic attraction like iron or steel.

3. Can an electromagnet pick up aluminum?

A standard electromagnet cannot pick up aluminum because the metal is not ferromagnetic. However, moving a strong magnet quickly near aluminum can create eddy currents, producing a temporary force but not true attraction.

4. How can I tell if a metal is aluminum or just looks like it?

To identify aluminum, use a strong magnet: if it doesn't stick and there’s no attraction, it's likely aluminum. Always clean the surface first and check for hidden steel parts or contamination that could affect the result.

5. Does aluminum ever become magnetic during fabrication?

Aluminum itself remains nonmagnetic during fabrication, but contamination from steel tools or fasteners can cause a magnetic response. Sourcing from quality-controlled suppliers and specifying nonmagnetic requirements prevents this issue.

-

Posted in

aluminum alloys, aluminum magnetism, is aluminium magnetic, magnet test, magnetic properties of metals