Strategic Material Selection for CNC Turning Success

TL;DR

Effective material selection for CNC turning requires choosing from common metals like aluminum, steel, and brass, or versatile plastics such as ABS, Nylon, and PEEK. The optimal choice hinges on a careful balance between the material's mechanical properties, such as strength and hardness, its machinability, overall cost, and the specific performance requirements of the final component and its application environment.

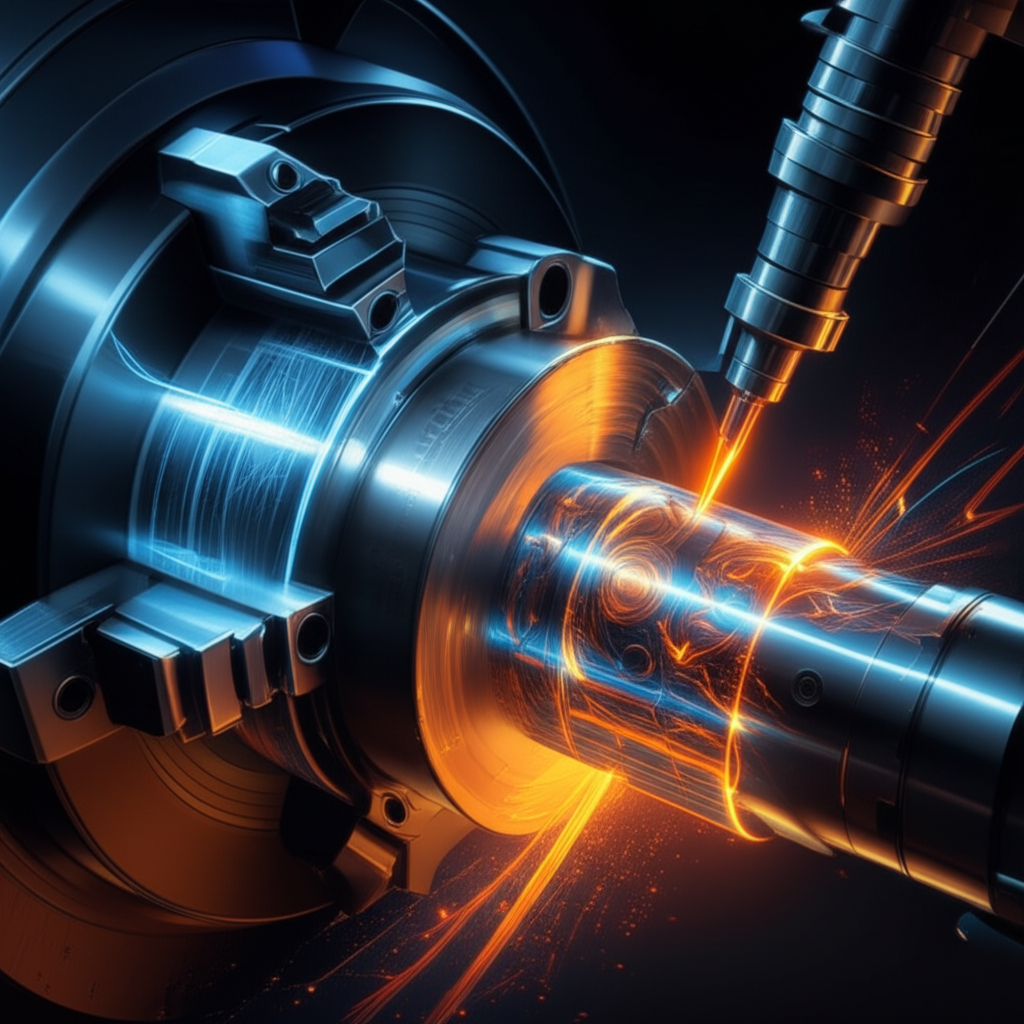

The Critical Role of Material Selection in CNC Turning

Choosing the right material is a foundational decision in any CNC turning project, with far-reaching implications for the final part's performance, cost, and manufacturing timeline. This choice is not merely about the raw substance but about aligning a material's inherent properties with the functional demands of the component. An informed decision can prevent common pitfalls like premature part failure, budget overruns, and production delays, ensuring the final product meets all technical specifications and performance criteria.

The material directly influences several key project factors. Machinability—the ease with which a material can be cut—affects both the speed of production and the wear on cutting tools, directly impacting cost. For instance, materials like Aluminum 6061 are known for their excellent machinability, allowing for faster and more economical production runs. In contrast, harder materials like titanium or certain stainless steels require slower machining speeds and more robust tooling, increasing both time and expense.

Furthermore, the selected material dictates the final part's functional characteristics. Properties such as tensile strength, corrosion resistance, thermal stability, and weight are critical to its performance in its intended environment. A component for an aerospace application might prioritize a high strength-to-weight ratio, making an alloy like Aluminum 7075 or Titanium Grade 5 an ideal candidate. Conversely, a part for a medical device would require biocompatibility and the ability to withstand sterilization, pointing towards specific grades of stainless steel or PEEK. Ultimately, strategic material selection is a balancing act that underpins the entire success of a CNC turning project.

Deep Dive: Common Metals for CNC Turning

Metals are the cornerstone of many CNC turning applications due to their strength, durability, and versatility. Understanding the unique profile of each common metal is essential for matching the right material to the job.

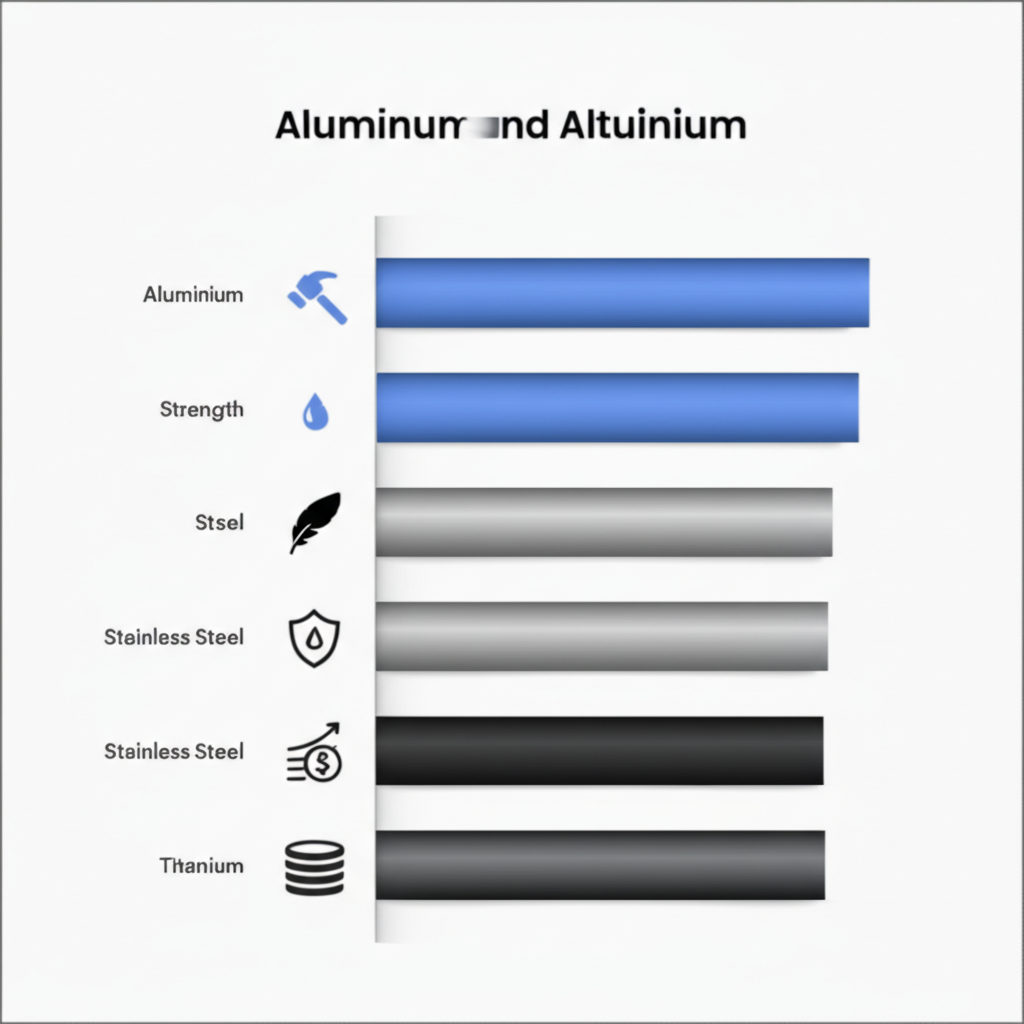

Aluminum

Aluminum alloys are highly favored for their excellent strength-to-weight ratio, thermal conductivity, and natural corrosion resistance. Their superb machinability often makes them one of the most cost-effective options, especially for prototypes and high-volume production. Aluminum 6061 is a popular general-purpose alloy offering a great balance of strength, machinability, and corrosion resistance. For more demanding applications, Aluminum 7075 provides significantly higher strength and hardness, comparable to some steels, making it a top choice for aerospace and high-stress components.

Steel

Steel is chosen for applications demanding high strength, hardness, and wear resistance. Mild Steels (Low-Carbon) like 1018 are valued for their good machinability, weldability, and cost-effectiveness, making them suitable for general-purpose parts, jigs, and fixtures. Alloy Steels, such as 4140, contain additional elements that enhance properties like toughness and fatigue resistance, suiting them for gears, shafts, and other high-stress industrial components. While incredibly durable, steels are generally more challenging and costly to machine than aluminum.

Stainless Steel

Stainless steel alloys offer the strength of steel with superior corrosion resistance. Stainless Steel 304 is the most common grade, providing a robust, corrosion-resistant option for everything from kitchen equipment to automotive parts. For applications in harsh or saline environments, such as marine or chemical processing, Stainless Steel 316 offers enhanced resistance due to its molybdenum content. While highly effective, stainless steels are typically less machinable and more expensive than standard steels.

Brass

Brass, an alloy of copper and zinc, is prized for its excellent machinability—among the best of all metals—and low-friction properties. It also features good corrosion resistance and electrical conductivity. Its attractive gold-like appearance makes it a popular choice for cosmetic parts, plumbing fittings, electrical connectors, and components where low friction is critical, such as bearings and gears.

Titanium

Titanium boasts an exceptional strength-to-weight ratio, outstanding corrosion resistance, and biocompatibility. Titanium Grade 5 (Ti-6Al-4V) is the most common alloy and is frequently used in high-performance applications where weight is a critical factor, such as in the aerospace, medical implant, and high-performance automotive industries. However, its benefits come at a cost; titanium is difficult to machine and is one of the more expensive material options available.

| Material | Key Properties | Best For | Relative Cost |

|---|---|---|---|

| Aluminum (6061) | Excellent machinability, good strength-to-weight, corrosion resistant | General purpose parts, prototypes, automotive, aerospace | Low |

| Mild Steel (1018) | High strength, good machinability and weldability | Jigs, fixtures, machinery parts, high-strength applications | Low-Medium |

| Stainless Steel (304) | Excellent corrosion resistance, high strength, durable | Food processing, medical devices, kitchen equipment | Medium-High |

| Brass (C36000) | Highest machinability, low friction, corrosion resistant | Fittings, valves, bearings, decorative parts | Medium |

| Titanium (Grade 5) | Highest strength-to-weight ratio, excellent corrosion resistance, biocompatible | Aerospace, medical implants, high-performance parts | Very High |

Exploring Versatile Plastics in CNC Turning

While metals are known for their strength, engineering plastics offer a unique combination of properties, including light weight, chemical resistance, electrical insulation, and often lower cost. They are increasingly used in CNC turning for a wide range of applications, from prototypes to functional end-use parts.

ABS

Acrylonitrile Butadiene Styrene (ABS) is a common thermoplastic known for its excellent impact strength, toughness, and rigidity. It is relatively easy to machine and has a low density, making it ideal for lightweight applications. Due to its affordability and good mechanical properties, CNC-machined ABS parts are frequently used as functional prototypes before transitioning to high-volume injection molding. Common applications include electronic enclosures, automotive components, and consumer products.

Polycarbonate (PC)

Polycarbonate stands out for its superior impact strength, high toughness, and good temperature resistance. It is also naturally transparent, which is a significant advantage for applications requiring optical clarity, such as automotive lighting, protective guards, and fluidic devices. While tougher to machine than ABS, its durability and strength make it a reliable choice for demanding applications where other plastics might fail.

Nylon (PA)

Nylon is an engineering thermoplastic valued for its excellent mechanical strength, abrasion resistance, and chemical resistance. It's a durable material often used for parts that experience friction and wear, such as gears, bearings, and fasteners. However, it is important to note that nylon is susceptible to moisture absorption, which can affect its dimensional stability and mechanical properties if not accounted for in the design process.

POM (Delrin/Acetal)

Polyoxymethylene (POM), widely known by its trade name Delrin, is one of the most machinable plastics. It offers high stiffness, excellent dimensional stability, low friction, and very low moisture absorption. These properties make it the preferred material for high-precision mechanical parts, such as gears, bushings, electrical insulators, and components that require tight tolerances and stability in moist environments.

A Practical Framework for Material Selection

Selecting the ideal material for CNC turning moves beyond simply knowing the options; it requires a systematic approach to balance competing project requirements. By asking a series of targeted questions, you can navigate the trade-offs and arrive at an optimal choice that ensures both performance and cost-effectiveness.

First, define the Mechanical Requirements of the part. This is the most critical step, as it dictates the part's ability to function safely and reliably. Consider the following:

- What level of tensile strength and hardness does the part need to withstand operational loads?

- Will it be subjected to repeated cycles of stress that could cause fatigue?

- Does it need to be rigid and stiff, or is some flexibility required?

- Will the part experience high impact or abrasive wear?

Answering these questions will help you shortlist materials like alloy steel for high strength or POM (Delrin) for excellent wear resistance.

Next, evaluate the Application Environment. A material that performs well in a controlled setting may fail in a harsh environment. Key considerations include:

- Will the part be exposed to extreme temperatures, either high or low?

- Is there exposure to moisture, saltwater, or specific chemicals? Materials like Stainless Steel 316 or Titanium are ideal for corrosive settings.

- Does the application require electrical conductivity (like copper) or insulation (like PEEK or PTFE)?

- Is weight a critical factor? For aerospace or automotive parts, lightweight options like aluminum or PEEK are often necessary.

Finally, balance these technical needs with Budget and Manufacturing Constraints. The cost of the raw material is only one part of the equation; machinability plays a huge role in the final price. A material like brass is highly machinable, leading to faster production and lower costs, while titanium is challenging to machine, increasing both time and expense. If you require high-precision custom parts and need to navigate these material trade-offs, services like XTJ CNC machining services can deliver rapid prototyping and volume production across dozens of materials, ensuring your components meet demanding specifications with certified quality.