Precision Perfected: CNC Machining for Consumer Electronics

TL;DR

CNC (Computer Numerical Control) machining is an indispensable manufacturing process for the consumer electronics industry, prized for its exceptional precision, speed, and material versatility. It enables the creation of complex and reliable components, from intricate smartphone enclosures to custom heatsinks. This technology is fundamental to achieving the tight tolerances and innovative designs that define modern electronics, facilitating rapid prototyping and high-volume production while ensuring superior quality.

The Critical Role of Precision: Why CNC Machining Dominates in Electronics

In the fast-paced world of consumer electronics, success is measured in micrometers. The relentless drive toward smaller, more powerful, and aesthetically refined devices creates immense manufacturing challenges. Miniaturization and complex geometries demand a production method that can deliver flawless accuracy on a massive scale. This is where CNC machining establishes its dominance. By using computer-guided tools to cut, drill, and shape materials, CNC technology replaces manual processes with automated precision, making it a cornerstone of modern electronics manufacturing.

The foremost advantage of CNC machining is its ability to achieve incredibly tight tolerances, often down to ±0.005mm. This level of precision is not a luxury but a necessity for electronic components that must fit together perfectly within compact assemblies. Whether creating the subtle grooves in a Printed Circuit Board (PCB) or fabricating a custom connector, even a minor deviation can compromise the functionality of the entire device. CNC systems follow programmed instructions with absolute fidelity, ensuring every part meets exact specifications, a critical factor in an industry with no room for error.

Furthermore, CNC machining is a key enabler of innovation. As designers push the boundaries with sleeker, more complex product forms—like the unibody chassis of a laptop created from a single block of aluminum—they rely on advanced manufacturing to bring their visions to life. Multi-axis CNC machines can produce intricate shapes and features that would be impossible or cost-prohibitive with other methods like molding or casting. This capability allows for greater design freedom, helping brands differentiate their products in a crowded market.

Speed and consistency are also vital. The electronics industry operates on compressed product development cycles, requiring rapid iteration from prototype to production. CNC machining excels here, allowing engineers to produce and test physical prototypes quickly, often on the same day a design is finalized. Once a design is approved, the same programmed process can be repeated thousands or millions of times with perfect consistency, ensuring that every unit off the production line maintains the same high standard of quality. This repeatability minimizes defects and streamlines the assembly process, reducing both costs and time to market.

Key Applications: From Prototypes to Production Components

The impact of CNC machining is evident across the entire spectrum of consumer electronics, from the devices in our pockets to the complex systems that power our digital world. Its versatility allows for the fabrication of a wide array of components, each with unique requirements for precision, durability, and performance. This adaptability makes it an essential tool for both initial prototyping and full-scale manufacturing.

Common applications include:

- Housings and Enclosures: The sleek metal body of a smartphone, the durable case of a tablet, or the intricate chassis of a high-end laptop are often produced using CNC machining. This process allows for the creation of lightweight yet strong enclosures from materials like aluminum, providing both structural integrity and a premium aesthetic finish.

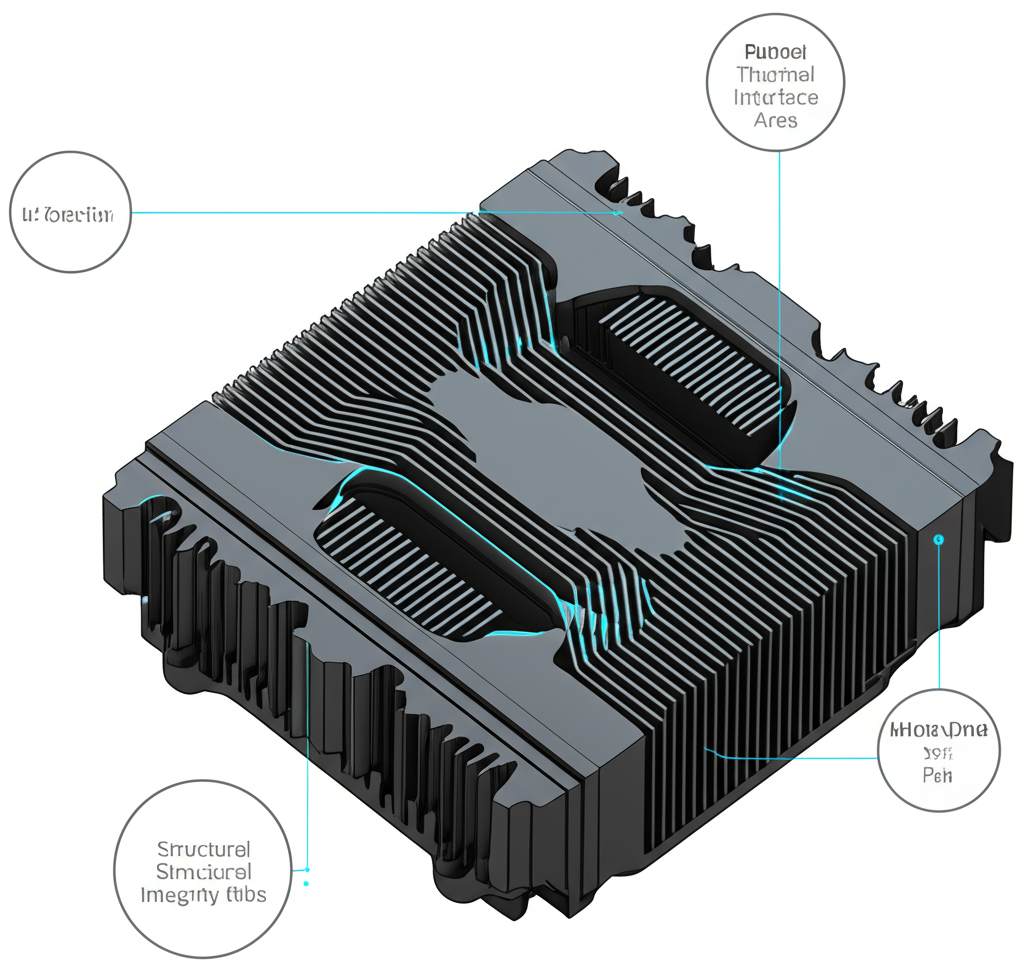

- Heatsinks and Thermal Management: Electronic components generate significant heat, and effective thermal management is crucial for performance and longevity. CNC machining is used to create custom heatsinks from highly conductive materials like aluminum and copper. The process can produce complex fin geometries designed to maximize surface area for efficient heat dissipation.

- Connectors and Sockets: The small, precise connectors for charging ports, data transfer, and internal connections require exacting tolerances to function reliably. CNC machining ensures these parts are made to precise dimensions for a perfect fit and dependable electrical contact.

- Test Jigs and Fixtures: During the manufacturing and quality control phases, specialized jigs and fixtures are needed to hold PCBs and other components for testing. CNC machining is used to create these custom tools, ensuring that testing is accurate and repeatable.

The journey from a single prototype to a million units requires a manufacturing partner capable of scaling without compromising quality. For companies needing to transition quickly, services that specialize in both rapid prototyping and high-volume production are invaluable. For instance, providers like XTJ offer advanced 4 and 5-axis CNC machining with the flexibility to handle over 30 different materials, meeting demanding specifications for industries from aerospace to medical. Their ability to deliver custom parts with tight tolerances and quick lead times helps streamline the entire production workflow, from initial concept to final assembly.

Material and Machine Selection for Electronic Components

Choosing the right material is a critical decision in the manufacturing of electronic components, as it directly influences the part's conductivity, thermal properties, durability, weight, and cost. CNC machining's compatibility with a diverse range of materials is one of its greatest strengths, allowing engineers to select the optimal substrate for each specific application. From conductive metals to insulating polymers, the choice of material is guided by the functional requirements of the component.

Common materials used in CNC machining for electronics include:

| Material | Key Properties | Typical Applications in Electronics |

|---|---|---|

| Aluminum (e.g., 6061) | Lightweight, high thermal conductivity, excellent machinability, corrosion-resistant. | Housings, enclosures, heatsinks, chassis, brackets. |

| Copper | Excellent electrical and thermal conductivity. | Heatsinks, busbars, electrical connectors, thermal management components. |

| Stainless Steel | High strength, durability, corrosion resistance. | Durable enclosures, mounting hardware, structural components. |

| Plastics (PEEK, PTFE, Acetal) | Electrical insulation, lightweight, chemical resistance, wear resistance. | Insulators, sockets, connectors, covers, wear parts. |

While CNC machining is incredibly versatile, not all materials are suitable for this subtractive process. Materials that are too soft, brittle, or abrasive can be difficult or impossible to machine effectively. For example, soft rubbers and flexible polymers can deform under the cutting tool, carbon fiber composites can delaminate, and hard ceramics can cause excessive tool wear. Understanding these limitations is crucial for successful product design and manufacturing.

Future Trends: How CNC Machining is Evolving with Consumer Electronics

The symbiotic relationship between consumer electronics and CNC machining continues to drive innovation in both fields. As electronic devices become more powerful, compact, and complex, CNC technology is evolving to meet these escalating demands. The future of manufacturing in this sector will be defined by greater speed, intelligence, and integration, ensuring that production capabilities keep pace with imagination.

One of the most significant trends is the increasing adoption of 5-axis and multi-axis CNC machining. While traditional 3-axis machines move along the X, Y, and Z axes, 5-axis machines add two rotational axes. This allows for the creation of exceptionally complex geometries in a single setup, reducing production time and improving accuracy. For electronics, this means the ability to machine intricate internal features, curved surfaces, and thin-walled enclosures that were previously unachievable.

Automation and smart technology integration are also transforming the factory floor. The principles of Industry 4.0 are being applied to CNC operations, with AI-driven systems optimizing tool paths for greater efficiency and predictive maintenance algorithms minimizing machine downtime. Robotic arms are increasingly used to load and unload parts, enabling continuous, 24/7 production with minimal human intervention. This level of automation not only lowers labor costs but also enhances consistency and output, which is critical for meeting the massive demand for consumer electronics.

Finally, the push for greater speed continues to shape the technology. High-speed machining techniques, which involve spindles running at tens of thousands of RPM, allow for faster material removal rates and finer surface finishes. This acceleration of the production process reduces cycle times and enables manufacturers to bring products to market more quickly—a decisive competitive advantage in the fast-moving electronics industry.

Frequently Asked Questions

1. What are the primary benefits of CNC for electronics prototyping?

CNC machining offers significant advantages for prototyping in the electronics industry. Its primary benefit is speed; engineers can create and test a physical part, such as a custom enclosure or heatsink, often on the same day it is designed. This rapid iteration cycle accelerates product development. Furthermore, CNC prototypes can be made from the exact same materials intended for final production, providing accurate performance testing for factors like thermal management and durability.

2. How does CNC machining contribute to the aesthetic quality of electronics?

CNC machining is crucial for achieving the premium look and feel of modern consumer electronics. It produces components with clean lines, sharp edges, and exceptionally fine surface finishes. Processes like milling a unibody chassis from a single block of aluminum eliminate seams and gaps, creating a sleek and robust final product. The precision of CNC also allows for intricate designs, logos, and patterns to be machined directly into surfaces with high fidelity.

3. Can CNC machining be used for both metal and plastic electronic components?

Yes, one of the key strengths of CNC machining is its versatility across a wide range of materials. It is routinely used to process metals like aluminum, copper, and stainless steel for parts requiring conductivity or strength. Simultaneously, it is highly effective for engineering plastics like PEEK, PTFE, and Acetal (Delrin) for components that require electrical insulation, light weight, or chemical resistance. This flexibility allows designers to choose the best material for each specific function within an electronic device.

-

Posted in

cnc machining, consumer electronics, electronic components, precision manufacturing, rapid prototyping