Plastic Prototyping Services: From Design to Part in Days

TL;DR

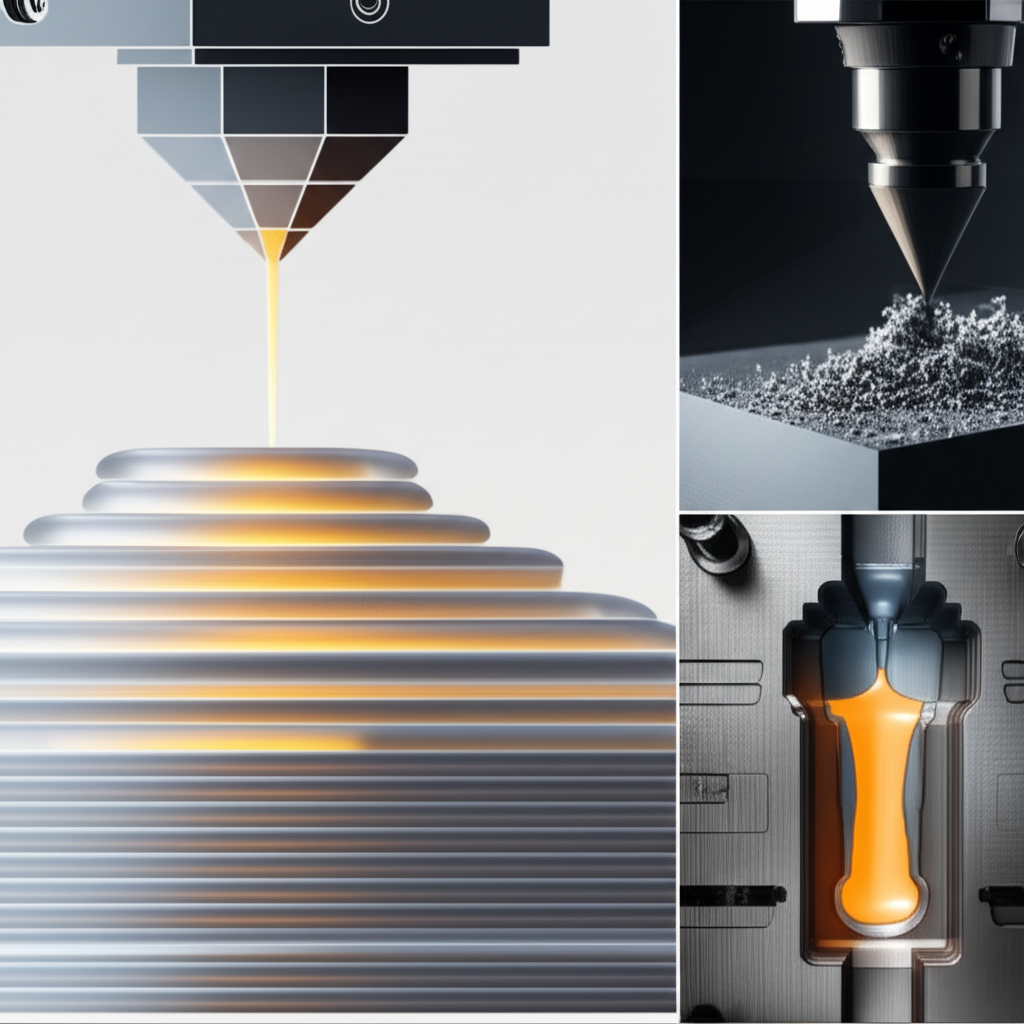

Plastic prototyping services use advanced manufacturing to create functional product samples quickly. Core technologies like 3D printing, CNC machining, and injection molding allow businesses to test a product's design, form, and function cost-effectively before committing to full-scale production. This process is crucial for refining designs, validating materials, and accelerating time to market.

Understanding Plastic Prototyping: From Concept to Reality

Plastic prototyping is the process of creating a tangible sample or model of a product design. It serves as a critical bridge between a digital concept, often a 3D CAD file, and a mass-produced final product. Before investing in expensive tooling and large production runs, companies use prototypes to physically evaluate, test, and refine their ideas. This step is indispensable in the modern product development lifecycle, as it provides invaluable real-world feedback that digital simulations alone cannot offer.

The primary importance of prototyping lies in risk mitigation and design optimization. By holding a physical part, engineers and designers can validate its form, fit, and function. This hands-on evaluation helps identify design flaws, ergonomic issues, or assembly problems early in the process when changes are least expensive to make. As noted by leading service providers, this iterative process allows for rapid design adjustments, ensuring the final product is fully optimized before it reaches consumers.

The benefits of utilizing professional plastic prototyping services are significant. Speed is a primary advantage; companies like Protolabs offer turnaround times as fast as one day, drastically shortening development cycles. This allows for multiple design iterations in a short period. Cost-effectiveness is another key benefit. Creating prototypes with affordable methods like 3D printing or low-cost aluminum tooling for injection molding avoids the massive financial commitment of steel production molds until the design is proven. This approach makes innovation more accessible and financially viable for businesses of all sizes.

Key Technologies in Plastic Prototyping

Choosing the right manufacturing technology is essential for creating a prototype that meets your specific testing needs. The three dominant technologies in plastic prototyping are 3D printing, CNC machining, and injection molding, each offering distinct advantages in speed, cost, material properties, and precision.

3D Printing (Additive Manufacturing)

3D printing builds parts layer-by-layer directly from a digital file. It is often the fastest and most cost-effective method for early-stage prototypes. Its key advantage is the ability to create highly complex geometries without the need for tooling. Several types of 3D printing are commonly used:

- Stereolithography (SLA): Uses an ultraviolet laser to cure liquid resin into hardened plastic. SLA is known for producing parts with very high resolution and a smooth surface finish, making it ideal for visual models and prototypes requiring fine details.

- Selective Laser Sintering (SLS): Employs a laser to fuse powdered plastic material, typically nylon, into a solid structure. SLS parts are strong and functional, making them suitable for testing mechanical properties.

- Fused Deposition Modeling (FDM): Extrudes a thermoplastic filament through a heated nozzle, building the object layer by layer. FDM is a versatile and widely accessible technology that offers a range of engineering-grade plastics like ABS and polycarbonate.

- Multi Jet Fusion (MJF): A powder-based technology similar to SLS, MJF uses a fusing agent to create strong, detailed parts with consistent mechanical properties, making it another excellent choice for functional prototypes.

CNC Machining (Subtractive Manufacturing)

Unlike 3D printing, CNC (Computer Numerical Control) machining is a subtractive process. It starts with a solid block of plastic and uses computer-controlled cutting tools to remove material until the final shape is achieved. This method is prized for its high precision and ability to produce prototypes from production-grade materials. CNC machining can achieve very tight tolerances, which is critical for parts that require a precise fit. It is an excellent option when the prototype needs to be evaluated in its final, intended material to test its mechanical strength and durability accurately.

Injection Molding

For later-stage prototyping or low-volume production runs, injection molding is a highly effective technology. The process involves injecting molten plastic into a custom-made mold (or tool). While the initial tooling cost is higher than for 3D printing, it becomes very cost-effective per part when producing dozens or hundreds of units. Rapid injection molding uses aluminum molds, which are cheaper and faster to produce than traditional steel molds, to create high-quality, repeatable parts that closely resemble the final production goods. This makes it ideal for pilot runs and market testing before committing to expensive production tooling.

How to Choose the Right Prototyping Service Provider

Selecting the right partner for your plastic prototyping needs is a critical decision that can impact your project's timeline, budget, and ultimate success. A systematic approach to evaluating providers will help you find one that aligns with your specific requirements. Consider the following key criteria when making your choice.

First, evaluate the provider's technological capabilities and material selection. Ensure they offer the specific manufacturing process—be it 3D printing, CNC machining, or injection molding—that best suits your prototype's purpose. For components requiring extreme precision, look for providers with advanced equipment. For example, services like XTJ CNC Machining utilize 4 and 5-axis machines to achieve tight tolerances suitable for demanding applications. A broad inventory of materials is also crucial, as it allows you to test your design with plastics that closely match your final production material's properties.

Turnaround time is another vital factor. In product development, speed is often a competitive advantage. Look for providers that offer rapid or expedited services, with clear lead times stated upfront. Many leading services now feature online quoting platforms that provide instant pricing and estimated delivery dates, streamlining the entire process from design submission to part delivery. This transparency helps in planning your development schedule effectively.

Finally, consider the provider's level of support and expertise. A good partner does more than just manufacture parts; they offer design for manufacturability (DFM) feedback to help you optimize your design for cost and efficiency. They should have experienced engineers available to discuss your project's challenges and guide you toward the best solutions. Reading case studies and testimonials can provide insight into their track record and ability to handle projects similar to yours.

The Prototyping Process: A Step-by-Step Overview

Engaging a plastic prototyping service is typically a straightforward and highly digitized process. Understanding the workflow helps set clear expectations and ensures a smooth transition from your design to a physical part. While specifics may vary slightly between providers, the customer journey generally follows these key steps.

- Submit Your 3D CAD Design: The process begins when you upload your 3D computer-aided design (CAD) file to the service provider's online platform. Common file formats include .STL, .STEP, or .IGES. This digital blueprint contains all the geometric information needed to manufacture your part.

- Receive an Instant Quote: Sophisticated quoting engines analyze your design's geometry and allow you to configure your order. You can select the manufacturing technology, material, quantity, and desired finish. The platform will then generate an instant quote with a detailed cost breakdown and an estimated lead time. Many systems also provide automated design for manufacturability (DFM) feedback at this stage, highlighting potential issues that could be optimized.

- Material and Technology Confirmation: After reviewing the quote, you finalize your choices. If you have questions about which material or process is best for your application, this is the ideal time to consult with the provider's application engineers for expert guidance.

- Manufacturing and Quality Control: Once you place the order, the provider begins manufacturing your prototype. Whether it's being 3D printed, CNC machined, or injection molded, the part is created according to your exact specifications. Throughout the process, quality control checks are performed to ensure the part meets the required tolerances and standards.

- Part Delivery: After production and final inspection, your finished prototype is securely packaged and shipped directly to you. With rapid services, you can have a physical part in your hands in just a matter of days, allowing you to proceed with testing and design validation promptly.

Frequently Asked Questions About Plastic Prototyping

1. How do I get a plastic prototype made?

The typical process starts with a 3D CAD (Computer-Aided Design) model of your part. You then upload this file to a plastic prototyping service provider's website. From there, you can select your desired manufacturing process (like 3D printing or CNC machining), choose a material, and receive an instant quote. Once you approve the order, the company will manufacture and ship the part to you.

2. What is plastic prototyping?

Plastic prototyping is the creation of a sample version or a functional model of a plastic product before it goes into mass production. It is a critical step in product development used to test and validate a design's form, fit, and function. This process helps identify potential flaws and allows for improvements to be made early, saving time and money.

3. What are the main types of prototyping?

While there are many methodologies, prototyping often falls into several key categories based on function and fidelity. These include visual prototypes, which demonstrate a product's appearance; proof-of-concept prototypes, which validate a core idea or technology; functional prototypes, which are used for performance and engineering tests; and pre-production prototypes, which are made using production-intent methods like injection molding to finalize the design before a full launch.