3 vs. 4-Axis CNC Milling: Choosing the Right Technology

TL;DR

The core difference between 3 and 4 axis CNC milling is the addition of a rotational axis. A 3-axis machine moves a cutting tool along three linear axes (X, Y, and Z), while a 4-axis machine adds a rotational A-axis, allowing the workpiece to be turned. This extra movement enables the machining of more complex geometries, reduces the need for multiple setups, and improves overall efficiency and precision.

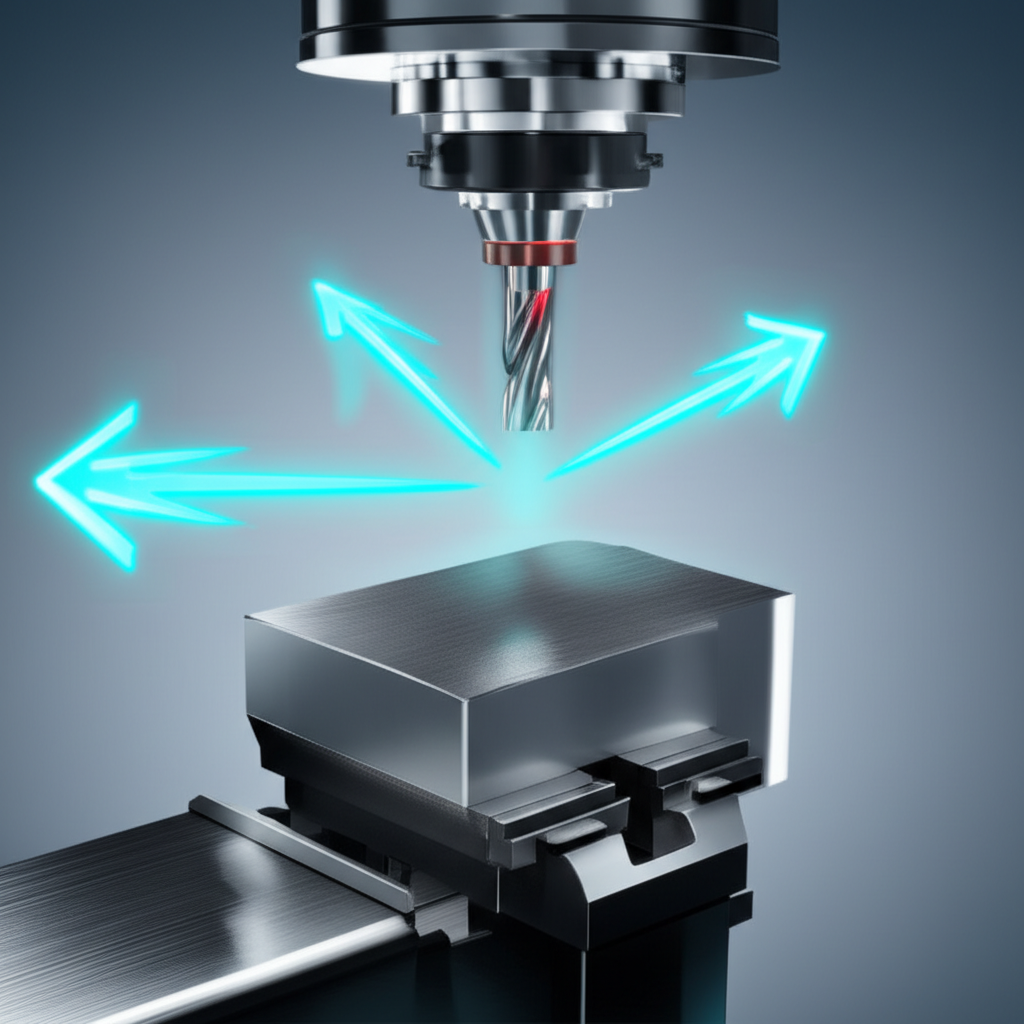

Understanding the Basics: What is 3-Axis CNC Milling?

Three-axis CNC milling is one of the most common and fundamental forms of machining. In this process, the workpiece is held stationary while the cutting tool moves along three linear axes: left-to-right (X-axis), front-to-back (Y-axis), and up-and-down (Z-axis). This setup allows the machine to perform operations like drilling holes, cutting slots, and creating parts with relatively simple, flat-surfaced geometry. It operates much like a sophisticated drill press, where the tool can approach the workpiece from a single direction at a time.

Because of its straightforward mechanics, 3-axis machining is ideal for producing 2D and 2.5D parts. These include components like machine brackets, enclosures, and panels. While it is possible to machine all six sides of a block, each side requires a separate setup where the operator must manually unclamp, rotate, and re-clamp the part. According to manufacturing experts at CloudNC, these additional setups can increase both time and cost, and also introduce a higher risk of positioning errors.

The primary advantages of 3-axis milling are its simplicity and cost-effectiveness. The machines are less complex to program and operate, making them a widely accessible solution for a vast range of manufacturing needs. However, their main limitation is the inability to machine undercuts or angled features without specialized tooling or multiple setups. For parts with complex curves or features on multiple faces, a more advanced solution is often required.

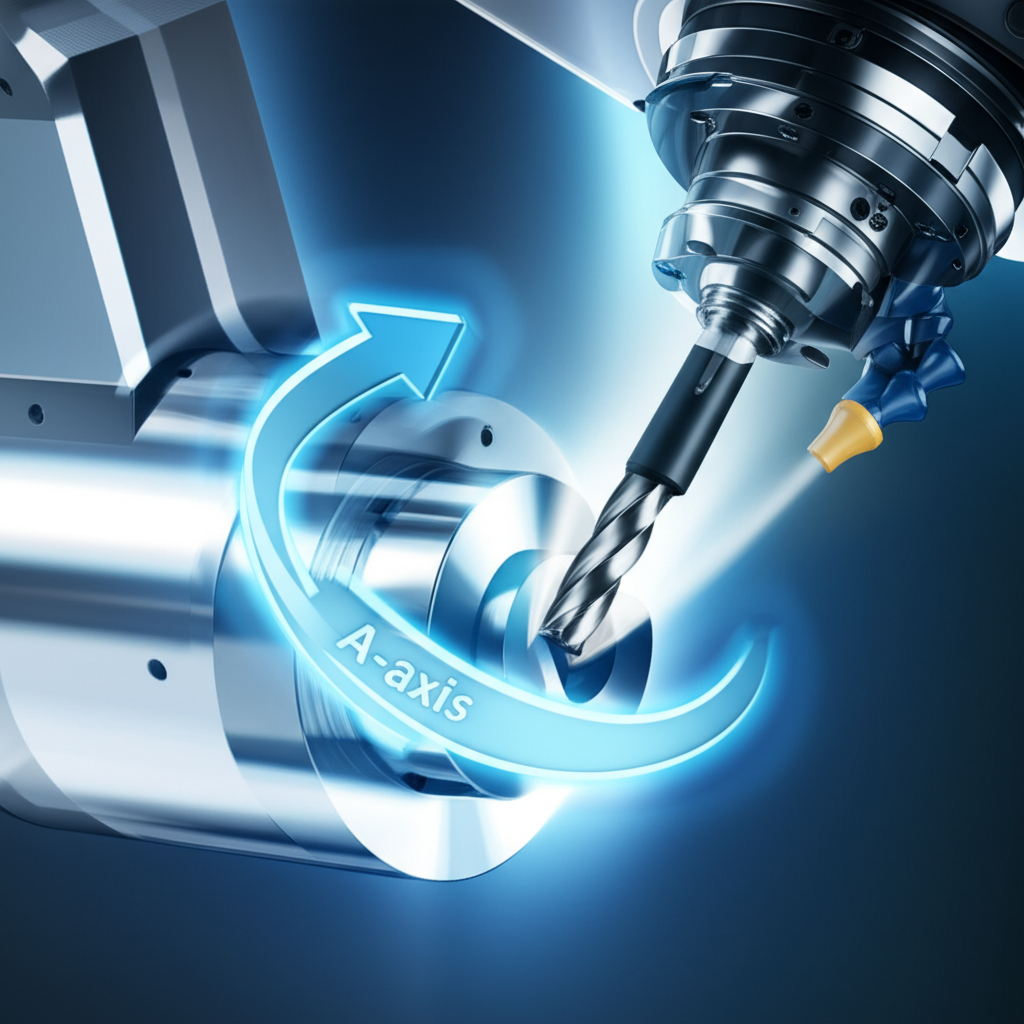

The Next Level: Introducing 4-Axis CNC Milling

Four-axis CNC milling builds upon the foundation of 3-axis machining by introducing a crucial element: rotation. It incorporates the same three linear axes (X, Y, Z) but adds a fourth rotational axis, known as the A-axis. This A-axis allows the workpiece, which is mounted on a rotary table, to turn around the X-axis. This capability fundamentally changes how a part can be machined, enabling access to multiple sides of the workpiece in a single setup.

The addition of the A-axis unlocks the ability to create more intricate and complex parts. As explained in a detailed article by AMFG, this rotation allows for machining angled features, engraving on cylindrical surfaces, and creating features like cams or helixes. Instead of stopping the machine to manually reposition the part, the 4-axis machine can simply rotate it to the precise angle needed for the next operation. This automation significantly reduces the total production time and minimizes the potential for human error associated with manual setups.

There are two primary modes of 4-axis milling: indexed and continuous. In indexed 4-axis milling (also called 3+1), the A-axis rotates the workpiece to a specific position, and then a brake is applied while the machine performs 3-axis cutting operations. In continuous 4-axis milling, the cutting tool and the rotating workpiece can move simultaneously. This is essential for creating smooth, complex curves and helical profiles that would be impossible with indexed machining alone.

Key Differences: 3-Axis vs. 4-Axis Head-to-Head

The choice between 3-axis and 4-axis CNC milling hinges on a trade-off between simplicity, cost, and the complexity of the part being manufactured. While 3-axis machines are the workhorses for simpler components, 4-axis machines offer enhanced capabilities that streamline production for more intricate designs. The primary distinction lies in the added rotational movement, which translates into significant differences in efficiency, accuracy, and the types of geometries that can be produced.

The table below provides a clear, side-by-side comparison of these two technologies across several critical factors.

| Feature | 3-Axis Milling | 4-Axis Milling |

|---|---|---|

| Axes of Motion | Three linear axes: X, Y, and Z. The cutting tool moves, the workpiece is stationary. | Three linear axes (X, Y, Z) plus one rotational axis (A-axis). The workpiece rotates. |

| Part Complexity | Best for simple, planar parts, drilling, and slotting. Limited on angled features and undercuts. | Can produce more complex geometries, including angled holes, cylindrical features, and continuous curves. |

| Setup Efficiency | Requires multiple manual setups to machine different sides, increasing time and potential for error. | Allows machining on multiple sides in a single setup, drastically reducing setup time and improving workflow. |

| Machining Accuracy | Good for features on a single plane. Tolerances between features on different faces can be compromised by re-fixturing. | Higher accuracy and tighter tolerances between features on different faces since the part is not re-clamped. |

| Typical Cost | Lower initial machine cost and simpler programming make it more affordable for basic jobs. | Higher initial investment and more complex programming, but can be more cost-effective for complex parts due to efficiency gains. |

The most significant operational advantage of 4-axis milling is the reduction in setups. As noted by industry experts at DATRON, eliminating the need for additional fixtures not only saves time but also makes it easier to hold tight tolerances across the entire part. Each time a part is manually moved, there is a risk of slight misalignment. By keeping the workpiece in a single fixture, 4-axis machining ensures that all features are machined in precise relation to one another.

Practical Applications: When to Choose Each Technology

Selecting the right machining process is crucial for achieving the desired quality, cost, and lead time for a project. The decision between 3-axis and 4-axis milling should be driven by the specific geometry of the part and the overall production goals.

When to Use a 3-Axis Mill

A 3-axis mill is the most economical and efficient choice for parts with features confined to a single plane. Its simplicity makes it perfect for high-volume production of straightforward components. Ideal applications include:

- Facing and Pocketing: Creating flat surfaces or shallow cavities on a part.

- Drilling and Tapping: Making holes that are perpendicular to the surface.

- Simple Profiles: Cutting the outline of a 2D shape or creating basic contours.

- Prototyping: Quickly creating simple models and functional prototypes where complex geometry is not required.

When to Use a 4-Axis Mill

A 4-axis mill becomes necessary when a part requires machining on multiple faces or includes angled or cylindrical features. While the initial cost is higher, the efficiency gains can make it more cost-effective for complex jobs. Consider a 4-axis machine for:

- Cylindrical Parts: Engraving text or cutting features around a shaft or tube.

- Angled Features: Drilling holes or milling slots on an angle relative to the primary axes.

- Multi-Sided Machining: Creating parts with features on four or more sides, such as engine blocks or complex housings.

- Complex Contours: Machining smooth, curved surfaces like cam lobes or impellers.

For projects with demanding specifications, tight tolerances, or complex geometries, partnering with a specialized service provider can be a strategic advantage. For instance, services that offer rapid prototyping and production with advanced multi-axis machines, such as XTJ's 4 and 5-axis CNC machining services, can handle a wide range of materials and deliver high-precision components for industries from aerospace to medical.

A Glimpse Beyond: Understanding the Role of 5-Axis Milling

While 4-axis milling significantly expands machining capabilities, 5-axis milling represents the next frontier of complexity and precision. As the name suggests, a 5-axis machine adds a second rotational axis (typically the B or C-axis) to the existing four. This allows the cutting tool to approach the workpiece from virtually any direction in a single setup.

The primary advantage of 5-axis machining is its ability to produce extremely complex parts, such as turbine blades, medical implants, or intricate molds, without ever needing to re-fixture the workpiece. This capability, detailed by sources like Owens Industries, enables the creation of parts with compound angles and complex 3D surfaces that would be impossible or prohibitively expensive to make otherwise. While not necessary for all jobs, understanding 5-axis technology provides important context for the progression of CNC capabilities.

Frequently Asked Questions

1. What is the difference between 3 axis and 4 axis mill?

The primary difference is that a 4-axis mill adds a rotational axis (the A-axis) to the three linear axes (X, Y, Z) of a 3-axis machine. This allows the workpiece to be rotated during the machining process, enabling the creation of more complex parts with features on multiple sides in a single setup, which is not possible on a standard 3-axis mill without manual repositioning.

2. What is a 4 axis CNC mill?

A 4-axis CNC mill is a machine that can move a cutting tool along three linear axes (X, Y, Z) and simultaneously rotate the workpiece around one of those axes (typically the X-axis, referred to as the A-axis). This additional rotational movement allows for more complex operations like machining on the side of a part or on a cylindrical surface without needing to change the setup.

3. What is a 3 axis CNC milling machine?

A 3-axis CNC milling machine is a manufacturing tool where the workpiece remains stationary while the cutting tool moves along three linear axes: X (left-right), Y (forward-backward), and Z (up-down). It is best suited for producing parts with simple geometries, such as drilling holes, cutting slots, and milling flat surfaces on one side of a workpiece at a time.