Unlock Production Success with Engineering Support for Manufacturing

TL;DR

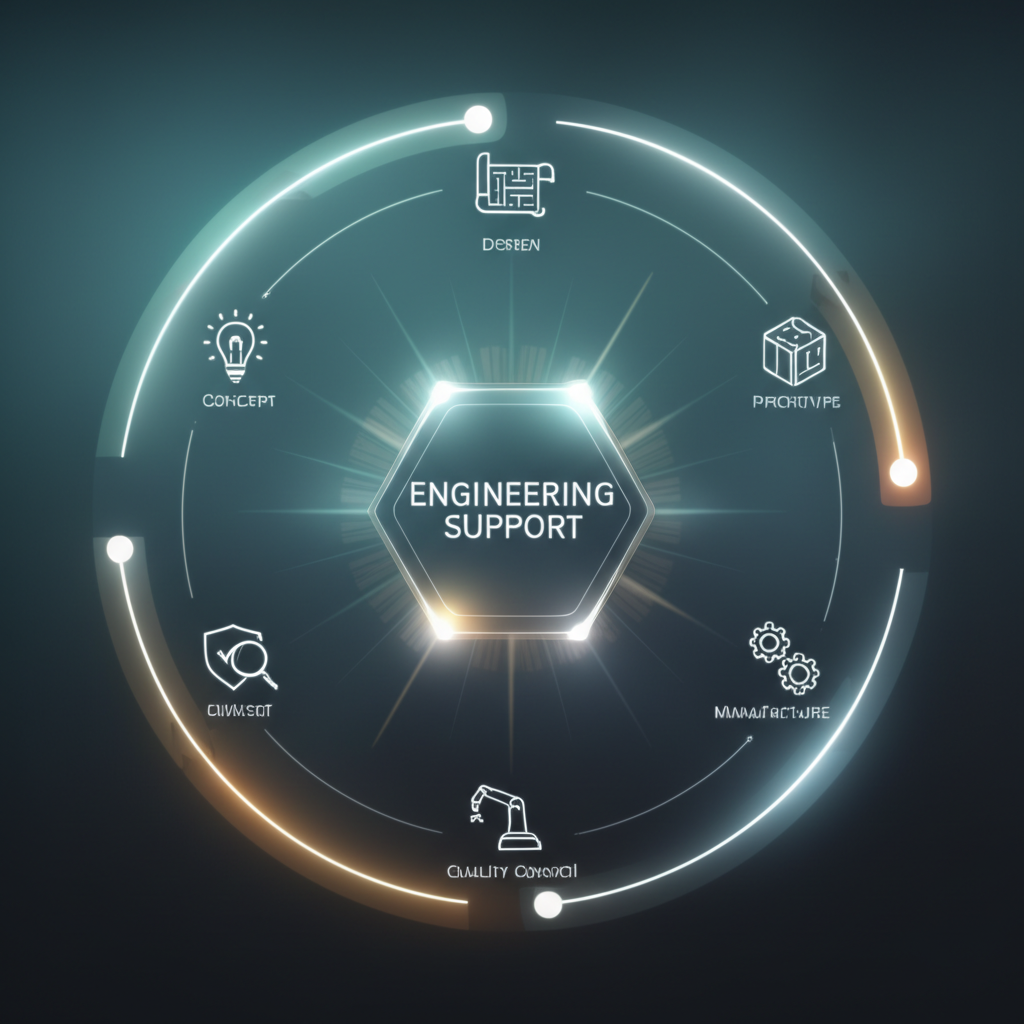

Engineering support for manufacturing is a critical partnership where external experts collaborate with your team across the entire product lifecycle. This service focuses on optimizing product design for manufacturability, refining production processes, and implementing robust quality control. Ultimately, it helps companies reduce costs, accelerate time-to-market, and deliver a higher-quality final product by bridging the gap between design and production.

What is Manufacturing Engineering Support?

Manufacturing engineering support is a comprehensive service that provides technical expertise and guidance throughout a product's journey from concept to full-scale production. It is a collaborative process where a dedicated team of engineers works alongside a client's internal team to ensure a product is not only well-designed but can also be manufactured efficiently, cost-effectively, and to the highest quality standards. This support covers a wide range of activities, including design modifications, prototyping, testing, and process adjustments.

At its core, engineering support acts as a crucial link between the design phase and the factory floor. As explained by the experts at East West Manufacturing, a good engineering team translates customer goals and expectations into clear, executable specifications for the production team. This involves asking critical questions, challenging design assumptions, and ensuring that every decision is made with manufacturability in mind. It's about preventing problems before they start, rather than fixing them after they've caused delays and budget overruns.

This support extends far beyond initial design reviews. It is an ongoing partnership that addresses issues throughout the product lifecycle. Whether it involves troubleshooting production line inefficiencies, implementing quality control measures like error-proofing (Poka-yoke), or training operators on new processes, the engineering support team is there to ensure smooth, consistent, and reliable manufacturing. This holistic approach ensures that the final product not only meets customer expectations but also adheres to all relevant industry standards and regulations.

The Strategic Role of Engineering Support in Production

Integrating engineering support is not just an operational tactic; it's a strategic decision that delivers significant business advantages. By involving manufacturing experts early, companies can position their projects for success and gain a powerful competitive edge. One of the most critical benefits is substantial cost reduction. A staggering 80 percent of a product's cost is determined during the design phase, which means that early engineering involvement can identify and eliminate inefficiencies before they become expensive problems. This focus on Design for Manufacturing (DFM) minimizes material waste, simplifies complex parts, and reduces machining time, leading to lower production costs.

Another key advantage is accelerating the time-to-market. In today's fast-paced environment, speed is essential. Engineering support streamlines the development process by handling the technical complexities, allowing a company’s design team to focus on innovation. By considering manufacturing constraints from the beginning, the number of design revisions is significantly reduced, which means faster and more accurate prototyping. This efficiency shortens the entire development cycle, getting products into the hands of customers much sooner.

Furthermore, robust engineering support directly enhances product quality and reliability. According to Millennium Precision, applying DFM principles leads to improved precision and consistency by standardizing features and maintaining tighter tolerances. This results in a more durable and better-performing product. A skilled engineering team also ensures compliance with all industry standards and regulations, mitigating the risk of costly fines, legal actions, or damage to a brand's reputation. By leveraging this expertise, businesses can build a name for themselves based on quality and innovation.

Core Services within Manufacturing Engineering Support

Engineering support for manufacturing encompasses a suite of specialized services designed to optimize every stage of production. These services are tailored to address specific challenges, from initial design to final assembly, ensuring a seamless and efficient process.

Design and Prototyping

This is the foundational stage where the most impact can be made. Engineers apply Design for Manufacturing (DFM) principles to analyze a product's design, simplifying geometries and selecting cost-effective materials to enhance manufacturability. This phase also includes prototyping to test and validate the design before committing to expensive tooling. For companies that need high-precision custom parts quickly, services like XTJ deliver rapid prototyping and volume production using advanced CNC machining, ensuring components meet the most demanding specifications for industries from aerospace to medical.

Process and Quality Control

Once a design is finalized, the focus shifts to the manufacturing process itself. Quality engineers establish robust process controls, monitoring systems, and error-proofing techniques (Poka-yoke) to ensure consistency and minimize defects. This includes developing operator training programs, creating specifications for product gauging, and managing product certification. The goal is to create a stable, repeatable process that consistently produces high-quality parts.

Continuous Improvement and Production Aids

Engineering support doesn't stop once production begins. Continuous improvement engineers analyze ongoing processes to identify bottlenecks and inefficiencies, using root cause analysis to implement effective, lasting changes. A significant part of this involves designing and creating custom jigs, fixtures, and end-of-arm tooling. These manufacturing aids are essential for ensuring quality, improving worker safety, and boosting the overall efficiency of the assembly line.

Integrating Engineering Support with Your Team

The success of manufacturing engineering support hinges on seamless collaboration and clear communication between the external experts and your internal team. It is not about outsourcing a task but about building a strategic partnership. This relationship is most effective when it begins at the project's conception and continues through the entire product lifecycle. The process typically starts with an in-depth consultation where the support engineers work to understand the client's goals, challenges, and product requirements.

A typical workflow involves several key phases. First, the engineering team conducts a thorough design review, applying DFM principles and providing feedback for optimization. This is a highly interactive stage, filled with questions and discussions to ensure everyone is aligned. As the project moves into prototyping, the feedback loop continues, with physical models allowing for tangible evaluation and further refinement. This iterative process ensures that potential manufacturing issues are resolved long before mass production begins, saving significant time and money.

Throughout the production phase, the engineering support team remains engaged, overseeing the process, troubleshooting issues, and providing ongoing guidance. They act as a direct line of communication between the client and the production floor, ensuring that specifications are met and quality is maintained. This human-to-human interaction is vital for resolving issues quickly and adapting to any unforeseen challenges. By fostering a close, communicative relationship, engineering support becomes a true extension of your own team, dedicated to achieving your project's success.

FAQs About Manufacturing Engineering Support

1. What does a manufacturing support engineer do?

A manufacturing support engineer plays a multifaceted role in the production environment. They are responsible for supporting production planning, scheduling, and ensuring the technical application of products is sound. They also contribute to continuous improvement initiatives, investigate and resolve service issues, and produce detailed technical reports and documentation to support sales, purchasing, and product development teams.

2. What is a manufacturing support service?

Manufacturing support is a service where a company partners with a specialized third-party provider to handle specific parts of the manufacturing process. This can include a wide range of activities, from logistics and inventory management to quality control and process optimization. The goal is to leverage external expertise to improve efficiency, reduce costs, and enhance product quality without having to build those capabilities in-house.

3. What is the meaning of engineering support?

Engineering support refers to all expert activities related to a product's lifecycle. This includes modifying product designs, adjusting manufacturing processes, building and testing prototypes, and addressing quality issues. As defined by Swisher Inc., it's a comprehensive service designed to ensure a product is successfully developed, manufactured, and maintained to meet both customer expectations and industry standards.

-

Posted in

engineering services, manufacturing support, process optimization, product lifecycle, Quality Control