Mastering CNC Surface Finishes: A Practical Guide

TL;DR

CNC machining surface finish refers to the texture and quality of a part's surface created during manufacturing. It is a critical specification determined by machining parameters (like tool selection and speed) and optional post-processing treatments. A controlled surface finish is essential for a part's appearance, wear resistance, corrosion protection, and overall functionality, directly impacting its performance and lifespan in its intended application.

Understanding the Fundamentals of CNC Surface Finish

In the world of precision manufacturing, the term "surface finish" describes the micro-level texture of a component after it has been machined. It's a measure of the fine peaks and valleys on a part's surface, often invisible to the naked eye but crucial to its performance. This is distinct from "surface finishing," which refers to the secondary processes, such as anodizing or bead blasting, applied after machining to alter these characteristics. A part's final surface finish is a critical engineering specification that dictates how it will interact with its environment and other components.

The importance of a well-defined surface finish cannot be overstated. It directly influences key performance attributes, including friction, wear resistance, and sealing capability. For example, parts that must slide against each other require a smoother finish to minimize friction and prevent premature failure. Conversely, a slightly rougher texture might be necessary for proper paint or adhesive bonding. A poor surface finish can create nucleation sites for corrosion and cracks, compromising the structural integrity and longevity of a component. Therefore, controlling the surface texture is fundamental to ensuring reliability and durability.

Several factors during the CNC machining process directly influence the resulting surface finish. Machinists carefully control these variables to achieve the desired texture specified in the design. Understanding these elements is key to producing parts that meet precise functional requirements. The primary factors include:

- Cutting Tool Selection: The geometry, material, and sharpness of the cutting tool play a significant role. A sharp, new tool with the correct nose radius will produce a much smoother finish than a worn one.

- Cutting Parameters: Spindle speed (how fast the tool rotates) and feed rate (how quickly the tool moves across the material) are critical. Generally, higher speeds and lower feed rates result in a finer finish.

- Toolpath Strategy: The path the cutting tool takes across the part's surface leaves behind marks. Optimized toolpaths, such as those used in finishing passes, are designed to minimize the height of these marks.

- Material Properties: The type of material being machined affects the achievable finish. Softer metals like aluminum are generally easier to machine to a smooth finish than harder alloys.

- Machine Rigidity and Vibration: A stable, rigid machine with minimal vibration is essential for achieving a high-quality surface finish, as any chatter can be transferred to the part's surface.

A Comprehensive Guide to Surface Finish Types and Processes

Beyond the initial "as-machined" state, a wide array of post-processing techniques are available to modify a part's surface for functional or aesthetic reasons. These processes can enhance properties like corrosion resistance, hardness, and visual appeal. Choosing the right finishing process is a critical design decision that balances performance, appearance, and cost.

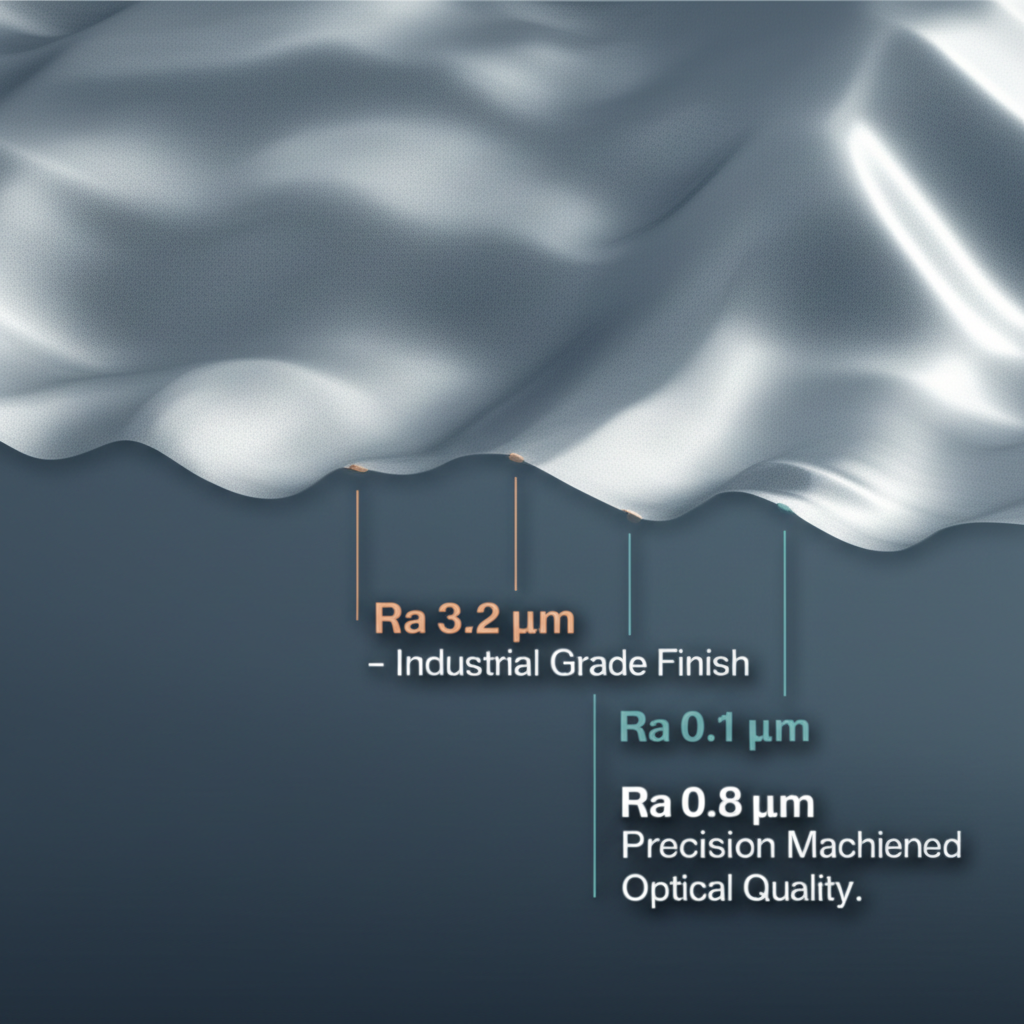

An "as-machined" finish is the surface texture left directly by the CNC machine's cutting tool. The standard roughness is typically 3.2 μm Ra, but finer finishes can be achieved with additional, more controlled machining passes. While this is the most cost-effective option, it leaves visible tool marks. For many applications, this is perfectly acceptable, but when enhanced properties are needed, secondary finishing processes are employed. These treatments range from simple mechanical abrasion to complex electrochemical conversions.

Common post-processing methods include mechanical techniques like bead blasting, which creates a uniform matte texture, and chemical processes like anodizing, which builds a durable, corrosion-resistant oxide layer on aluminum and titanium. Other options include plating, which deposits a layer of another metal (like nickel or zinc) onto the surface, and powder coating, which applies a durable polymer layer. Each method offers a unique combination of protection, appearance, and cost, as detailed in the table below.

| Finishing Process | Description | Best For | Relative Cost |

|---|---|---|---|

| As-Machined | Surface left by the final cutting pass. Tool marks are visible. | General-purpose parts where aesthetics are not critical. | $ |

| Bead Blasting | Propels glass beads to create a uniform, non-directional matte or satin finish. | Improving aesthetics and hiding tool marks. | $$ |

| Anodizing (Type II) | Creates a thin, corrosion-resistant oxide layer on aluminum or titanium. Can be dyed in various colors. | Cosmetic parts needing corrosion resistance and color. | $$$ |

| Anodizing (Type III / Hardcoat) | Creates a thicker, harder, and more wear-resistant oxide layer. | Functional parts in high-wear or harsh environments. | $$$$ |

| Powder Coating | A dry powder is electrostatically applied and cured to form a durable, impact-resistant polymer layer. | Parts requiring high durability, corrosion protection, and a wide range of colors. | $$$ |

| Electroless Nickel Plating | A uniform layer of nickel-phosphorus alloy is deposited chemically, providing excellent wear and corrosion resistance. | Complex parts needing uniform coverage and high hardness. | $$$$ |

| Passivation | A chemical treatment for stainless steel that removes free iron, enhancing its natural corrosion resistance. | Medical and food-grade stainless steel parts. | $$ |

| Black Oxide | A conversion coating for ferrous metals that provides mild corrosion resistance and a deep black finish. | Tools, firearms, and automotive components for a non-reflective finish. | $$ |

The selection of a finishing process often involves balancing multiple factors. For instance, while Type III hardcoat anodizing provides superior wear resistance, it is more expensive and can alter part dimensions more than Type II. Similarly, powder coating offers excellent impact resistance but may not be suitable for parts with very tight internal tolerances. For complex projects with demanding specifications, partnering with a capable manufacturing service is essential. Companies like XTJ, which offers advanced 4 and 5-axis CNC machining, can provide expert guidance and a wide range of finishing options to ensure components meet the highest standards for industries from aerospace to medical devices.

Decoding Surface Roughness: Understanding Ra Values

To communicate surface finish requirements precisely, engineers use standardized parameters. The most common of these is Ra (Roughness Average), which measures the arithmetic average of the absolute deviations of the surface profile from a mean line. It is typically measured in micrometers (μm) or microinches (μin). A lower Ra value indicates a smoother surface, while a higher value signifies a rougher one. Understanding common Ra values is essential for specifying a finish that is both functional and cost-effective.

Different Ra values are achieved through specific machining techniques and have distinct applications. Forcing an unnecessarily smooth finish can dramatically increase manufacturing time and cost, so it's crucial to match the Ra value to the part's actual needs. A standard machined part might be perfectly suitable for a structural bracket, whereas a high-performance bearing surface will require a much more refined, and therefore more expensive, finish.

Here is a breakdown of the most common Ra values specified in CNC machining and their typical applications:

- 12.5 μm Ra (Very Rough): This level of finish is typically the result of rapid machining operations where surface quality is not a primary concern. It is suitable for non-critical surfaces or clearance faces that do not contact other parts.

- 3.2 μm Ra (Standard Machined): This is the default, general-purpose machined finish for most applications. It provides a good balance of cost and quality and is suitable for many parts subject to stress, loads, and vibrations. Tool marks are clearly visible.

- 1.6 μm Ra (Fine Machined): Achieved with more controlled machining, such as slower feed rates and fine cuts. This finish is often specified for mating surfaces with slow movement and light loads, offering a good trade-off between performance and cost.

- 0.8 μm Ra (High-Grade Finish): This smooth finish is required for parts under high stress or load, or those with intermittent motion. It requires dedicated finishing passes and stricter quality control, making it ideal for components like bearings and tightly toleranced shafts.

- 0.4 μm Ra (Ultra-Smooth Finish): Often referred to as a near-mirror finish, this level of smoothness typically cannot be achieved by cutting alone. It requires secondary processes like grinding, lapping, or polishing. It is reserved for high-performance applications like precision bearings, optical components, and sealing surfaces where minimal friction is critical.

How to Select the Right Surface Finish for Your Application

Choosing the appropriate surface finish is a critical decision that impacts a part's performance, lifespan, and cost. A systematic approach that considers all relevant factors ensures that the selected finish meets the application's demands without unnecessary expense. The ideal choice is rarely the smoothest or most durable option, but rather the one that provides the necessary properties in the most economical way. The selection process should begin early in the design phase to account for any dimensional changes or material limitations associated with certain finishes.

The first step is to clearly define the part's role. Is it a purely cosmetic component, a high-wear structural part, or something in between? Answering this question will help prioritize the criteria for selection. For example, a front panel on a piece of consumer electronics will prioritize aesthetics and fingerprint resistance, while an internal gear will prioritize hardness and low friction. By methodically evaluating each criterion, you can narrow down the options to the most suitable choice.

Consider the following key criteria when selecting a CNC machining surface finish:

- Functional Requirements: This is the most important factor. Does the part require high wear resistance, corrosion protection, low friction (lubricity), or specific electrical properties? For parts exposed to harsh environments, a protective coating like hardcoat anodizing or electroless nickel plating is essential. For sliding components, a smooth, hard surface is paramount.

- Aesthetic Appearance: For consumer-facing products, the look and feel of a part are critical. Finishes like bead blasting followed by color anodizing can create a premium matte appearance. Polishing can provide a high-gloss, reflective surface. The desired color, texture, and reflectivity will heavily influence the choice of finishing process.

- Material Compatibility: Not all finishing processes are compatible with all materials. Anodizing, for instance, is primarily for aluminum and titanium. Plating processes work on most metals, but may require specific surface preparation. Always ensure the chosen base material is suitable for the desired finishing treatment.

- Cost and Budget Constraints: Finishing processes vary significantly in cost. A standard as-machined finish adds no extra cost, while multi-step processes like hardcoat anodizing or electropolishing can be expensive. It is crucial to balance the required performance with the project's budget. Often, a less expensive finish can meet all necessary requirements if chosen carefully.

- Dimensional Tolerances: Many finishing processes add or remove material, which can affect a part's final dimensions. Anodizing and plating add thickness, while processes like electropolishing remove it. If a part has features with tight tolerances, these changes must be accounted for in the initial design, or those features must be masked during the finishing process.

Making an Informed Decision on Surface Finishes

Selecting the right CNC machining surface finish is a crucial engineering decision that extends beyond mere aesthetics. It is a fundamental aspect of part design that directly influences functionality, durability, and cost. By understanding the interplay between machining parameters, surface roughness values like Ra, and the wide array of available post-processing treatments, designers and engineers can specify finishes that are perfectly tailored to their application's needs. The key is to move from a general desire for a "good finish" to a precise specification based on functional requirements, material properties, and budget constraints.

The journey from a raw block of material to a finished component involves a series of deliberate choices. A standard as-machined finish might be sufficient for a hidden structural part, while a component exposed to wear and corrosive elements will demand a more robust solution like hardcoat anodizing or nickel plating. Ultimately, a well-chosen surface finish ensures that a part not only fits and functions correctly on day one but continues to perform reliably throughout its intended service life. This thoughtful consideration is the hallmark of quality manufacturing and robust product design.

Frequently Asked Questions

1. What does 0.8 surface finish mean?

A 0.8 µm Ra surface finish is considered a high-grade, smooth finish. It is typically achieved through controlled finishing passes during CNC machining. This level of smoothness is specified for parts that are subject to stress, fatigue, or loading, as well as for moving components where reduced friction is important. It provides a good balance between performance and the added cost of the extra machining steps required.

2. What does 3.2 surface finish mean?

A 3.2 µm Ra surface finish is the standard, most common finish for CNC machined parts. It is the default quality produced by normal machining operations without extra finishing passes. While tool marks are visible, it is a cost-effective and functional finish suitable for a wide range of applications, including parts that are not aesthetically critical or do not have demanding wear requirements.

3. What does 12.5 RA surface finish mean?

A 12.5 µm Ra surface finish is a very rough finish, typically resulting from high-speed roughing operations where material removal rate is prioritized over surface quality. This finish is generally acceptable only for surfaces that will be further machined or for non-critical areas that have no functional or cosmetic requirements.

4. What is a 0.4 surface finish?

A 0.4 µm Ra surface finish is an ultra-smooth, fine finish that often approaches a mirror-like appearance. Achieving this level of smoothness usually requires secondary processes beyond standard machining, such as precision grinding, honing, or lapping. It is reserved for high-performance, critical applications where extremely low friction and high precision are necessary, such as in optical instruments or high-speed bearings.

-

Posted in

Anodizing, cnc machining, manufacturing, Surface Finish, Surface Roughness