Powder Coating vs. Painting CNC Parts: A Pro's Analysis

TL;DR

When selecting a finish for CNC parts, the choice between powder coating vs. painting hinges on a trade-off between durability and flexibility. Powder coating provides a significantly more durable, thicker, and chip-resistant finish ideal for parts in demanding environments, offering superior long-term value. Painting, conversely, offers a lower initial cost, easier application for small-scale projects, and virtually limitless custom color-matching capabilities, making it suitable for less strenuous applications or when precise aesthetics are paramount.

The Core Showdown: Application Process and Methodology

Understanding the fundamental differences in how powder coating and paint are applied to CNC parts is crucial for making an informed decision. These are not just different materials; they are entirely different processes from preparation to final cure. The core distinction lies in their physical state and bonding mechanism: powder coating is a dry, thermal-bonding process, while painting is a wet, solvent-based process that relies on evaporation.

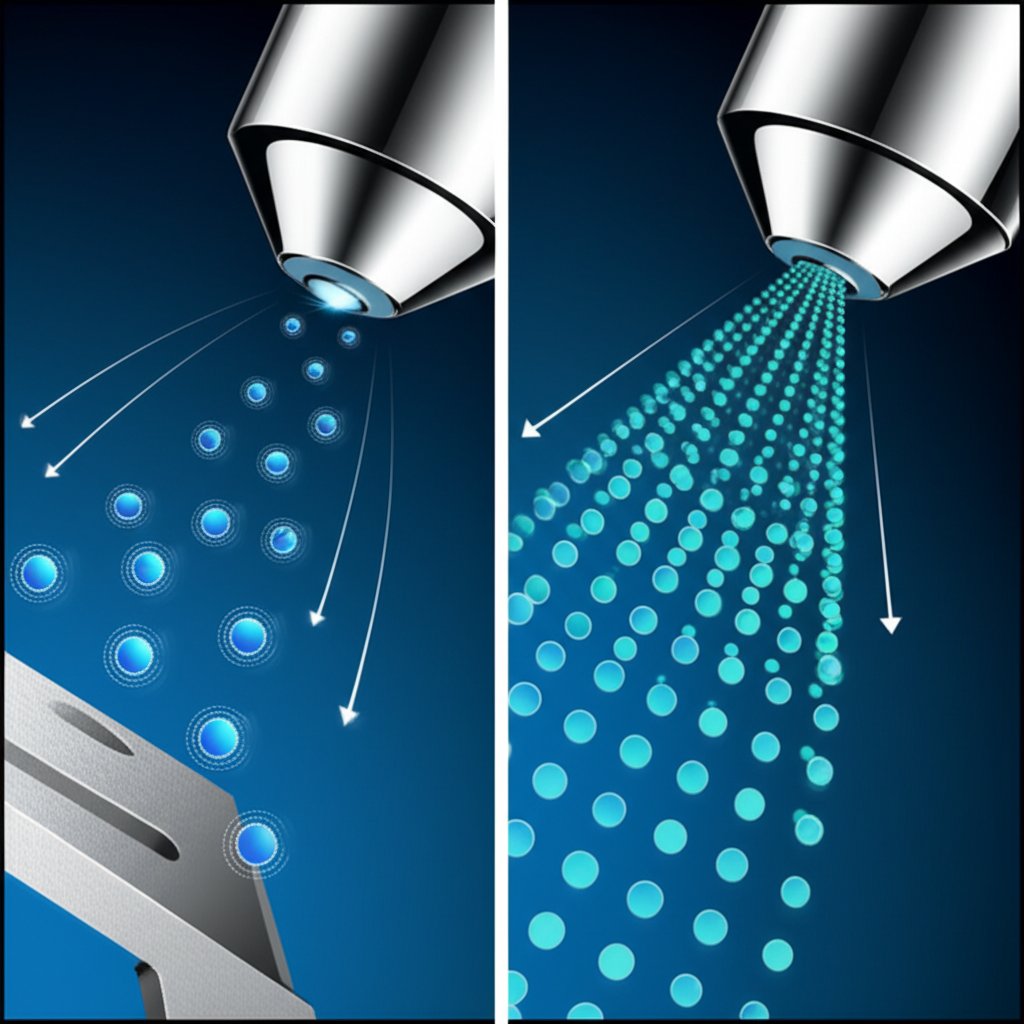

The powder coating process begins with meticulous surface preparation, typically involving degreasing and media blasting to ensure the surface is perfectly clean for adhesion. A dry powder, composed of polymer resins, pigments, and additives, is then applied using an electrostatic spray gun. The gun imparts a negative charge to the powder particles, which are then attracted to the grounded metal CNC part. This electrostatic attraction creates a remarkably uniform layer of powder that clings to the surface, even on complex geometries. Finally, the part is moved to a curing oven, where it is heated to approximately 350-450°F (175-230°C). The heat melts the powder, allowing it to flow and chemically cross-link into a hard, continuous, and highly durable film.

Painting follows a more traditional path. Like powder coating, it requires a thoroughly cleaned and often sanded surface, frequently with the application of a primer to enhance adhesion. The liquid paint—a mixture of pigments, binders, and a solvent—is then applied with a brush, roller, or, most commonly in industrial settings, a spray gun. As the solvent evaporates, the binders and pigments are left behind to form the solid colored film. This process often requires multiple coats to achieve a uniform and sufficiently thick finish, with drying time needed between each application. The complete hardening of some paints can take a day or more, a significant time difference compared to the rapid curing of powder coating, which is often ready for handling within an hour of leaving the oven. This efficiency is a major advantage in production environments.

The efficiency of the application processes also varies dramatically. As noted by experts at Kramer Industries, the electrostatic application of powder coating can reduce material waste by up to 95% because any oversprayed powder can be collected and reused. In contrast, a significant portion of liquid paint is lost to overspray and cannot be recovered.

Process Comparison at a Glance

| Factor | Powder Coating | Painting |

|---|---|---|

| Material State | Dry solid powder (polymer resins) | Liquid (pigments in a solvent) |

| Application Method | Electrostatic spray | Spray gun, brush, or roller |

| Curing/Drying | Thermal curing in an oven | Solvent evaporation (air drying) |

| Waste/Efficiency | High efficiency; overspray is reusable | Lower efficiency; overspray is lost |

Durability and Performance Under Stress

For most CNC-machined parts, particularly those intended for industrial, automotive, or outdoor use, durability is the most critical factor. In this arena, powder coating holds a distinct and measurable advantage over traditional painting. The consensus among manufacturers and finishing experts is clear: the thermal bonding process of powder coating creates a finish that is substantially tougher and more resilient to mechanical and environmental stress.

The superior durability stems directly from the application process. The heat-cured cross-linking of the polymer resins forms a thick, dense, and uniform layer that is chemically bonded to the metal substrate. This creates a hard shell that is far more resistant to chipping, scratching, and abrasion than a typical layer of paint. As detailed by finishing specialists at 3ERP, liquid paint is inherently less resistant to this kind of wear and tear. A painted surface, being thinner and relying on simple adhesion rather than thermal bonding, is more prone to flaking or being compromised by impact.

Corrosion resistance is another area where powder coating excels. The thick, non-porous finish provides an excellent barrier against moisture and oxygen, effectively sealing the metal from the elements that cause rust. While a high-quality paint job with a proper primer can offer good protection, any scratch or chip in the paint creates an entry point for corrosion to begin and spread underneath the finish. Powder coating's toughness makes such breaches less likely. According to industry resource Huyett, a well-applied powder coat can protect metal from corrosion for as long as two decades, a lifespan rarely achieved by paint in similar conditions.

When considering the performance of CNC parts, it is essential to match the finish to the application. For components exposed to harsh weather, frequent handling, chemical exposure, or potential impacts, the long-term protection offered by powder coating is unparalleled. For decorative parts, components used in controlled indoor environments, or items where easy touch-ups are valued over absolute resilience, painting remains a viable and effective solution.

Performance Feature Comparison

- Chip & Scratch Resistance: Powder coating offers high resistance due to its thickness and flexibility. Paint is moderately resistant but can chip or scratch more easily upon impact.

- Corrosion Protection: The seamless, non-porous barrier of powder coating provides excellent protection. Paint offers good protection, but is more vulnerable if the surface is breached.

- UV Resistance: Both finishes can be formulated for UV resistance, but powder coatings often retain their color and gloss for longer periods under direct sunlight, a process known as chalking.

- Chemical Resistance: The cross-linked polymer structure of powder coating generally provides better resistance to chemicals, fuels, and solvents than most standard paints.

Cost Analysis: Initial Investment vs. Long-Term Value

The financial calculation for powder coating versus painting is not a simple one-to-one comparison; it involves weighing upfront equipment and application costs against long-term durability and maintenance expenses. Generally, painting presents a lower barrier to entry, while powder coating often proves to be the more cost-effective choice over the lifespan of the product, especially for production runs of CNC parts.

The initial investment for powder coating is significantly higher. The process requires specialized equipment, including an electrostatic spray booth to contain the powder and a large industrial oven for curing. This makes it less accessible for hobbyists or small-scale, one-off projects. In contrast, painting can be done with relatively inexpensive equipment like a spray gun or even aerosol cans, making it the go-to choice for projects with tight upfront budgets or for DIY applications.

However, when moving from a single part to batch production, the economic model begins to shift. Powder coating is a more efficient process in terms of material usage and labor. As mentioned, the ability to reclaim and reuse oversprayed powder means very little material is wasted. Furthermore, it is typically a single-coat application that cures quickly, reducing labor time and increasing throughput. Painting often requires multiple coats with significant drying time in between, increasing both labor hours and the potential for application errors.

The most compelling financial argument for powder coating is its long-term value. Because the finish can last for up to 20 years without needing attention, it eliminates the recurring costs of maintenance, touch-ups, and complete repainting that are often necessary for painted parts, especially those exposed to the elements. A painted part might need to be refinished every few years, incurring repeated labor and material costs that can quickly surpass the initial savings over paint. For a commercial product, this durability translates into higher quality, better customer satisfaction, and a lower total cost of ownership.

Cost Factor Breakdown

| Cost Factor | Powder Coating | Painting |

|---|---|---|

| Initial Equipment Cost | High (Requires oven, spray booth) | Low (Requires spray gun, simple setup) |

| Per-Part Material Cost | Lower in production due to high transfer efficiency | Can be higher due to material waste (overspray) |

| Labor Cost | Often lower in production (single coat, fast cure) | Often higher (multiple coats, long dry times) |

| Long-Term Value | High (Less maintenance and recoating required) | Lower (Requires periodic touch-ups and repainting) |

Aesthetics, Finish, and Customization Options

Beyond durability and cost, the final appearance of a CNC part is a critical consideration. Both powder coating and painting offer a wide array of aesthetic choices, but they excel in different areas. The choice often comes down to whether the priority is a perfectly uniform and textured finish or the flexibility of custom color mixing.

Powder coating is renowned for its ability to create a thick, smooth, and exceptionally consistent finish. The electrostatic application process ensures that the powder is drawn evenly across the entire surface of the part, wrapping around edges and covering complex geometries without the risk of drips, runs, or sags that can plague liquid paint applications. This results in a high-quality, professional look that is difficult to replicate with paint without significant skill. Furthermore, powder coating offers a unique range of specialty finishes that are not easily achieved with paint, such as textured surfaces (wrinkle, sand), metallic effects, and clear coats.

Painting, however, holds a decisive advantage in color flexibility. While powder coating comes in thousands of colors, the colors are pre-formulated by the manufacturer. Mixing powders to create a custom shade is not feasible on-site and can result in an inconsistent, marbled effect. Liquid paint, on the other hand, can be mixed to match virtually any color standard, such as a specific Pantone or RAL code, offering near-infinite possibilities for branding and design. This makes paint the superior choice when a highly specific, custom-matched color is a non-negotiable requirement for the project.

The thickness of the coating also impacts the final look. Powder coating's thicker layer can sometimes soften sharp edges or fill in very fine surface details on a CNC part. For most applications, this is not an issue and is often desirable for its smooth appearance. However, if preserving every minute detail of a machined surface is critical, the thinner layers achievable with paint may be preferable. As noted by manufacturing service SendCutSend, this thinner coating is a key differentiator for applications where tolerances are extremely tight.

Aesthetic Feature Comparison

- Finish Uniformity: Powder coating is superior, providing a consistent finish without drips or runs.

- Color Flexibility: Painting has the edge, allowing for nearly unlimited custom color mixing and matching.

- Specialty Finishes: Powder coating offers a wider range of unique textures like wrinkle and hammered finishes.

- Finish Thickness: Powder coating produces a thicker finish (typically 2-6 mils), while paint creates a thinner finish (1-2 mils per coat).

Making the Final Decision for Your CNC Parts

Choosing between powder coating and painting for CNC parts is a strategic decision that balances performance, cost, and aesthetics. Powder coating is the clear choice for applications demanding maximum durability, corrosion resistance, and a long, maintenance-free life. Its thick, resilient finish is ideal for automotive components, industrial equipment, and outdoor products. While the initial investment is higher, its efficiency in production and long-term value make it a superior financial choice for high-volume manufacturing.

Conversely, painting remains the optimal solution when custom color matching is critical, when the part cannot withstand the heat of a curing oven, or when upfront costs must be minimized for small-scale projects. Its versatility and accessibility make it a practical choice for prototypes, decorative items, and applications in less demanding environments. Ultimately, a thorough analysis of your part's end-use, production volume, and budget will guide you to the right finishing process.

For businesses in the product development phase, testing these options on physical prototypes is invaluable. Engaging with a partner that provides comprehensive manufacturing services can accelerate this process. For instance, working with a provider of XTJ's comprehensive formative manufacturing services allows you to access rapid prototyping with over 50 material options and receive expert Design for Manufacturability (DFM) feedback, helping you select the perfect finish for both performance and aesthetic excellence.

Frequently Asked Questions

1. What is the most common problem with powder coating?

The most common problems with powder coating typically stem from improper surface preparation or application technique, rather than a failure of the material itself. Issues can include incomplete coverage (leaving bare spots), pinholes (small craters in the finish), blistering, or an uneven, bumpy texture often described as 'orange peel'. These defects are usually preventable by ensuring the metal surface is immaculately cleaned and by using correct electrostatic application and curing procedures. Chipping can also occur, but it is far less common than with paint and usually results from a severe impact.

-

Posted in

cnc machining, metal finishing, painting, powder coating, surface treatment