Mastering CNC Workholding: Essential Strategies for Precision

TL;DR

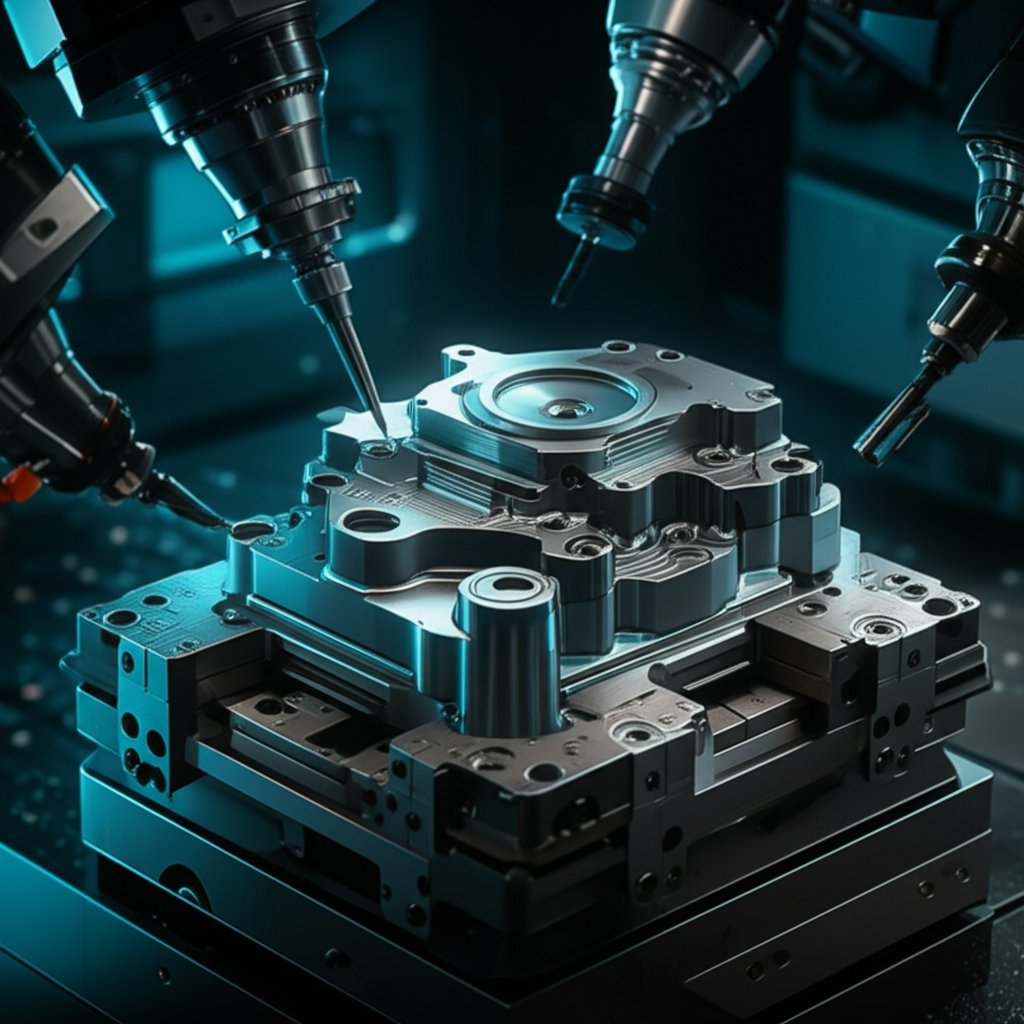

CNC workholding, often called fixturing, is the essential process of securely holding a workpiece in a fixed position during machining. Effective workholding strategies are critical for achieving rigidity, accuracy, and repeatability while ensuring operator and machine safety. Methods range from standard devices like vises and clamps for simple parts to complex, custom-designed jigs and modular fixture plates for high-volume production or complex geometries.

The Fundamentals of CNC Workholding: Why It's Critical for Machining Success

In the world of CNC machining, precision is paramount. However, even the most advanced machine and perfectly programmed toolpath are useless if the workpiece is not held securely. This is the fundamental role of workholding. As noted in educational guides, parts don't simply float in 3D space as they do in a CAD model; something must anchor them firmly against the powerful forces of machining. This anchoring process, also known as fixturing, is a critical link in what engineers call the “chain of stiffness,” which includes the machine, the cutting tool, the tool holder, and the workpiece itself. A weakness in any part of this chain, especially in the workholding, can lead to vibrations, poor surface finish, and dimensional inaccuracies.

The consequences of inadequate workholding can be severe. A part that shifts even slightly during an operation can be ruined, leading to wasted material and time. In more extreme cases, a workpiece can be ejected from the machine, posing a significant safety hazard to the operator and potentially causing catastrophic damage to the cutting tool, spindle, or machine bed. Therefore, a well-designed workholding setup is not just about precision; it's a cornerstone of safe and efficient manufacturing. It reduces non-cutting time, allows for more aggressive machining parameters, and ensures that every part produced is identical to the last.

Effective workholding strategies are built on a few core principles. A machinist must always consider how the chosen method will support the part and resist the cutting forces without distorting the workpiece itself. The primary goals of any workholding setup can be summarized as follows:

- Rigidity: The setup must prevent the workpiece from moving, vibrating, or deflecting under the load of the cutting tool.

- Repeatability: For production runs, the workholding must allow for subsequent parts to be located in the exact same position consistently and quickly.

- Accessibility: The fixture should secure the part while allowing the cutting tool maximum access to the areas that need to be machined, ideally minimizing the number of setups required.

- Security: The workpiece must be held in a way that is safe for both the operator and the machine throughout the entire machining cycle.

A Comprehensive Guide to Common Workholding Devices and Methods

A wide array of workholding devices have been developed to meet the diverse needs of CNC machining, each offering a unique balance of flexibility, precision, and speed. The most common solution is the machine vise, prized for its strength and simplicity when working with prismatic parts that have parallel surfaces. For parts with irregular or curved shapes, standard vises can be fitted with soft jaws—custom blocks, typically made of aluminum, that are machined to perfectly cradle the workpiece, providing a secure grip without marring finished surfaces.

When parts are too large or awkwardly shaped for a vise, machinists often turn to clamps. Step clamps (or toe clamps) are a fundamental method, using the T-slots on the machine table to bolt down a workpiece directly. While highly adaptable, this method can be slower to set up and less repeatable than other options. For higher volume and greater precision, fixture plates (also called tooling plates) are a superior solution. These plates, covered in a precise grid of threaded and locating holes, allow fixtures or parts to be mounted with exceptional speed and repeatability, protecting the machine table and streamlining job changes.

For thin, flat materials like sheet metal or plastics that could be warped by mechanical clamping pressure, vacuum chucks offer an elegant solution. By creating suction across the part's surface, they provide a uniform holding force with unobstructed access to the entire top face. Understanding the trade-offs between these common methods is key to efficient and precise machining.

| Device / Method | Pros | Cons | Best Use Cases |

|---|---|---|---|

| Machine Vise | Strong, simple, highly repeatable for standard shapes. | Limited by jaw capacity; requires parallel surfaces. | Prismatic (square/rectangular) parts in low to high volume. |

| Soft Jaws | Secures irregular or round parts; protects surfaces. | Custom-machined for specific parts; can wear out. | Complex geometries, delicate parts, and medium production runs. |

| Step Clamps | Highly versatile for large or odd shapes; strong grip. | Slow setup; low repeatability for multiple parts. | Large plates, one-off jobs, and securing other fixtures. |

| Fixture Plates | Excellent repeatability and speed for job changes; modular. | Higher initial cost; requires pre-planned setups. | High-mix, medium-volume production and modular fixturing. |

| Vacuum Chucks | Uniform pressure avoids part distortion; full top access. | Only for flat, non-porous materials; holding force depends on surface area. | Machining thin sheets of metal, plastic, or composites. |

Advanced Workholding Strategies for Efficiency and Complex Parts

Beyond basic devices, advanced workholding strategies focus on optimizing production efficiency and solving challenges posed by complex geometries or multi-axis machining. One of the most effective approaches for production is modular fixturing. Using a tooling plate as a base, machinists can assemble fixtures from a set of standardized components, creating a custom setup that can be quickly reconfigured for different jobs. This combines the precision of a custom fixture with the flexibility of general-purpose clamps, drastically reducing setup time.

For high-volume production, dedicated custom jigs and fixtures are often the most efficient solution. A custom fixture can be designed to hold multiple parts at once, allowing the machine to run for longer cycles with minimal operator intervention. This strategy, known as multi-part workholding, maximizes machine uptime and throughput. For example, a single fixture plate might be designed to hold ten small components, which are then all machined in one continuous operation. While the initial design and fabrication of a custom fixture requires investment, the savings in cycle time per part can be substantial over a long production run.

When developing new products, the ability to create custom workholding for prototypes is crucial. The rise of additive manufacturing has introduced 3D-printed fixtures, which can be produced quickly and cost-effectively for holding complex or organically shaped parts. For businesses needing to accelerate their development cycle, partnering with an expert service can be a strategic advantage. For instance, XTJ's comprehensive formative manufacturing services provide a reliable solution for high-quality rapid prototypes, offering expert Design for Manufacturability (DFM) feedback that can help optimize both the part and its corresponding workholding strategy from the very beginning.

Designing effective custom workholding requires careful planning. The process involves analyzing the part geometry, identifying stable clamping surfaces, and ensuring the fixture provides adequate support against cutting forces while maintaining tool clearance. A simplified process for designing a custom fixture might look like this:

- Analyze the Part: Identify the critical features, required tolerances, and the sequence of machining operations. Determine which surfaces can be used for locating and which for clamping.

- Establish a Datum Scheme: Define the primary locating points on the workpiece that will serve as the reference for all machining operations, ensuring repeatability.

- Design the Fixture Body: Create a rigid base, often a plate or block, that can be securely mounted to the machine table or a tooling plate.

- Incorporate Locating and Clamping Elements: Add dowel pins, stops, or nests to position the part accurately. Then, integrate clamps (such as toggle clamps or screw clamps) to secure the part, directing clamping forces into supported areas to avoid distortion.

- Verify Tool Clearance: Use CAD software to simulate the machining process, ensuring the cutting tool and tool holder will not collide with the fixture or clamps at any point.

How to Select the Best Workholding Strategy for Your Project

Choosing the 'best' workholding strategy is not a one-size-fits-all decision; it is a careful balancing act that depends on the unique requirements of each project. The optimal choice is the one that meets the technical requirements of the part while aligning with production and budget constraints. An incorrect choice can lead to scrapped parts, broken tools, or inefficient processes, while the right strategy ensures quality, safety, and profitability. The decision-making process should be guided by a systematic evaluation of several key factors.

The first factor is part geometry. Simple, prismatic parts are well-suited for a standard machine vise. However, as complexity increases—with curved surfaces, thin walls, or internal features—more specialized solutions like soft jaws or custom-machined fixtures become necessary. Production volume is another critical consideration. For a single prototype, a slower but flexible method like step clamps may be perfectly acceptable. For a run of thousands of parts, the initial investment in a custom multi-part fixture or a modular system will pay for itself through drastically reduced cycle times and improved consistency.

Material type and the anticipated machining forces also play a crucial role. Harder materials like stainless steel require a more rigid and secure clamping method than softer materials like aluminum or plastic. Likewise, aggressive roughing operations generate far greater forces than light finishing passes. Finally, the required tolerances of the finished part will dictate the necessary precision of the workholding. High-precision components demand a setup with high repeatability and minimal potential for part distortion. By thoughtfully considering these variables, a machinist can select a workholding method that is both effective and economical.

To guide your selection process, ask the following questions before starting any job:

- Material: How hard is the material? Is it prone to vibration or distortion under clamping pressure?

- Geometry: Are the clamping surfaces parallel and regular, or are they complex and contoured?

- Tolerances: How tight are the dimensional tolerances? Is high repeatability a critical requirement?

- Production Volume: Am I making one part, ten parts, or thousands of parts?

- Accessibility: How many sides of the part need to be machined? Can I complete it in a single setup?

- Budget: What is the trade-off between the upfront cost of the fixture and the long-term savings in cycle time?

Frequently Asked Questions About CNC Workholding

1. What is the difference between a jig and a fixture?

While often used interchangeably, there is a technical distinction. A fixture is a workholding device that holds a workpiece in a fixed location for machining; the CNC program guides the tool. A jig, on the other hand, not only holds the workpiece but also guides the cutting tool, a concept more common in manual machining than in CNC, where g-code handles tool guidance.

2. How does part material affect my workholding choice?

The material's hardness and stability directly influence the required clamping force and method. Hard materials like steel can withstand high clamping forces and are well-suited for robust methods like vises or step clamps. Softer materials like aluminum or plastics are prone to marring or distortion, often requiring lower clamping pressure, soft jaws, or methods that distribute force over a larger area, like a vacuum table. Thin or delicate materials also require care to avoid bending under pressure.

-

Posted in

cnc machining, CNC milling, fixturing, manufacturing, workholding