From Prototype to Production: A Step-by-Step Pathway

TL;DR

The transition from prototype to production is the essential process of evolving a single, experimental model into a product that can be manufactured reliably and consistently at scale. This journey involves several critical phases, including rigorous testing and validation, implementing Design for Manufacturability (DFM) principles, establishing a robust supply chain, and navigating the complexities of scaling up. Successfully managing this process is key to launching a market-ready product efficiently and cost-effectively.

Understanding the Core Transition: From One-Off Model to Mass-Market Product

The journey from a prototype to a production-ready product represents a fundamental shift in mindset, goals, and execution. A prototype is essentially a draft—a tangible concept used for experimentation, testing functionality, and gathering initial feedback. Its primary purpose is to validate a design and identify flaws early on. In contrast, a production unit is the final, market-ready version, engineered not just to work once, but to be manufactured consistently thousands or even millions of times while meeting strict quality and cost targets.

This transition is one of the most challenging phases in product development because it requires moving from a creative, flexible environment to a disciplined, process-driven one. According to Fictiv, a manufacturing partner, this involves deep considerations for material consistency, cost management, and maintaining design fidelity at scale. The materials and methods used for a one-off prototype, such as 3D printing or CNC machining, are often not viable for mass production. This is where the concept of Design for Manufacturability (DFM) becomes paramount. DFM is the practice of designing products in a way that optimizes them for ease of manufacturing, which is crucial for controlling costs and ensuring quality during large-scale production.

Failing to plan for this transition can lead to significant delays and budget overruns. A complex design that is easy to assemble by hand in a lab can become a logistical nightmare on an automated assembly line. Therefore, thinking about the end-product and its manufacturing requirements from the very beginning is a strategic advantage that streamlines the entire development lifecycle.

| Aspect | Prototype | Production Unit |

|---|---|---|

| Primary Goal | Validate design, test function, gather feedback. | Achieve consistent quality, cost-efficiency, and scalability. |

| Quantity | One to a few units. | Hundreds to millions of units. |

| Manufacturing Method | Often flexible and fast (e.g., 3D printing, CNC machining). | Optimized for scale (e.g., injection molding, die casting). |

| Cost Per Unit | High. | Low, due to economies of scale. |

| Design Focus | Functionality and user experience. | Manufacturability, assembly, and reliability. |

The Critical Stages of the Prototype-to-Production Pathway

Navigating the path from a finished prototype to a full production run involves a structured sequence of stages. While the process can be fluid, a well-defined framework helps ensure that no critical step is missed. Each phase builds upon the last, systematically de-risking the product and preparing it for the market.

- Design Refinement and Validation: Once a functional prototype exists, the design is far from final. This stage involves refining the product based on feedback from prototype testing. According to Pivot International, this is where usability concerns, structural flaws, and ergonomic issues are addressed. It's also where DFM principles are heavily applied to simplify the design, standardize components, and ensure it can be assembled efficiently.

- Rigorous Testing and Compliance: Before committing to expensive tooling, the refined prototype must undergo exhaustive testing. This goes beyond basic functionality to include stress tests, environmental simulations, and durability checks to expose any weaknesses. For many products, especially in the medical or electronics industries, this stage also involves navigating complex regulatory requirements and obtaining necessary certifications like FDA approval or CE marking.

- Manufacturing Partner Selection and Supply Chain Setup: Choosing the right manufacturing partner is a critical decision. It's best to involve them early in the process, as they can provide invaluable feedback on material selection and manufacturability. This phase involves vetting suppliers, establishing quality control standards, and building a resilient supply chain to source all the necessary components and raw materials consistently.

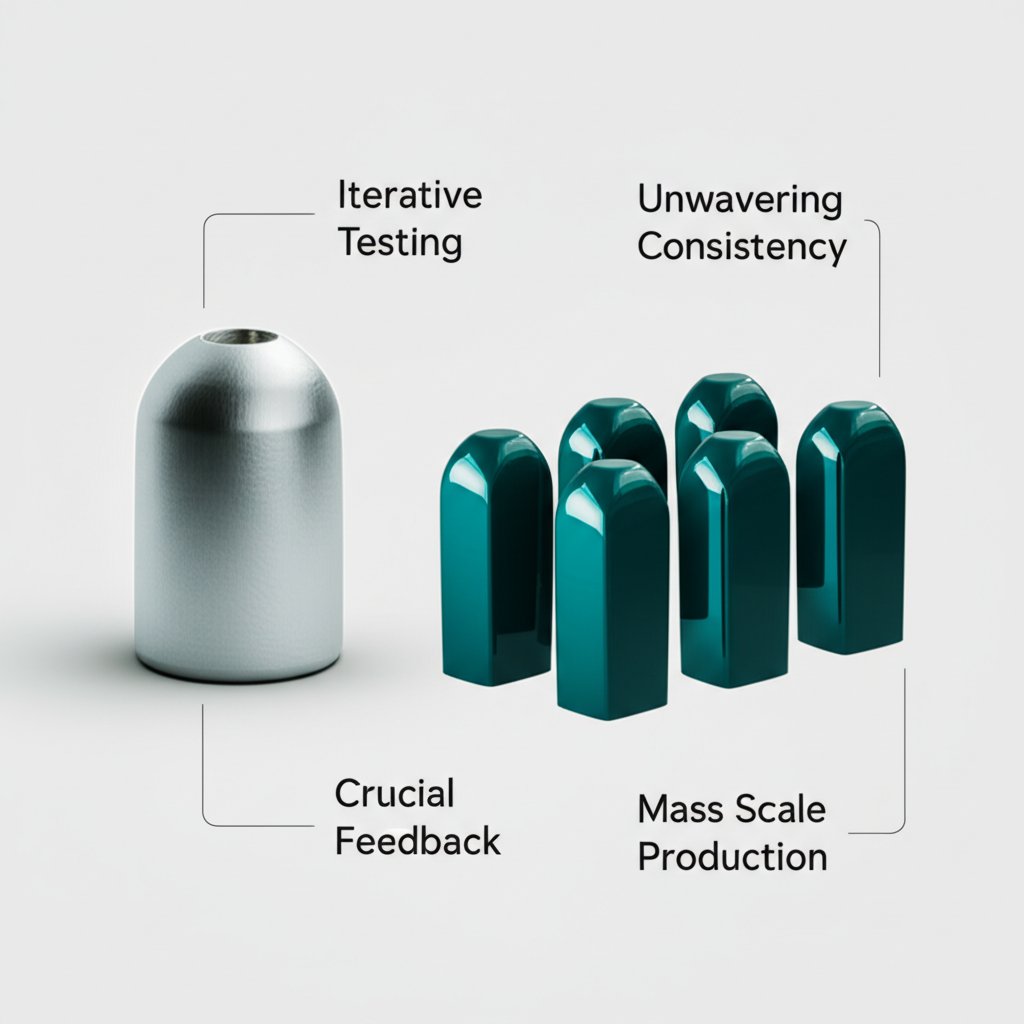

- Pilot Run or Low-Volume Production: Before scaling to mass production, a limited production run (often called a pilot or bridge run) is conducted. This crucial step validates not only the product design but also the manufacturing process itself. As explained by experts at Fictiv, it's a chance to identify any issues on the assembly line, refine quality control procedures, and train staff before a full-scale launch. This phase helps mitigate the risk of discovering a major flaw after thousands of units have already been produced.

- Final Adjustments and Mass Production: Based on the outcomes of the pilot run, final tweaks are made to the product design or manufacturing process. Once everything is optimized and validated, the green light is given for mass production. At this point, the focus shifts to scaling up operations, managing inventory, and ensuring consistent quality across tens of thousands or even millions of units.

Navigating Key Challenges: Scaling Costs, Manufacturing, and Quality Control

The transition from a single prototype to thousands of production units is fraught with challenges that can derail even the most innovative products. Anticipating and planning for these hurdles is essential for a smooth process. The three most common obstacles are managing costs, solving for manufacturability, and choosing the right partners.

Scaling costs often catch entrepreneurs by surprise. The cost to produce one unit is vastly different from the cost to produce 10,000. This involves significant investment in tooling (like injection molds), materials, and assembly line setup. Without careful financial planning and a detailed Bill of Materials (BOM), these costs can quickly spiral out of control. The entire process, from a near-final prototype to mass production, can take a significant amount of time, sometimes up to 18 months, which further impacts the budget.

Design for Manufacturability (DFM) is arguably the biggest technical hurdle. A design that works perfectly as a 3D-printed prototype may be impossible or prohibitively expensive to mass-produce using a method like injection molding. Optimizing for DFM means simplifying parts, minimizing assembly steps, and selecting materials that are both cost-effective and suitable for high-volume production. An experienced partner can be invaluable here; for instance, you can accelerate your product development with XTJ's comprehensive formative manufacturing services, which provide expert DFM feedback and rapid prototypes to ensure your design is ready for scale.

Finally, selecting and collaborating with manufacturing partners and suppliers is a logistical challenge. You must find partners who not only have the right technical capabilities but can also scale with your demand while consistently meeting quality standards. As recommended by OpenBOM, involving suppliers early helps align your design with their capabilities, preventing costly rework later. Clear communication and establishing a strong partnership are key to navigating this complex relationship successfully.

Best Practices for a Smoother Transition

- Engage Partners Early: Don't wait until your design is finalized. Bring in manufacturing experts and suppliers during the prototyping phase to get critical feedback on DFM, materials, and cost.

- Test Everything, Repeatedly: Rigorous testing at every stage is non-negotiable. Test for function, durability, environmental resistance, and regulatory compliance to catch flaws before they become expensive production problems.

- Define Your Goals Clearly: Before you begin, have a clear understanding of your target production volume, budget, and end-user experience. As Pacific Research Laboratories notes, ambiguity in these areas leads to delays and dead ends.

- Plan for Scalability: Design and select processes with the end goal in mind. Use materials and manufacturing methods in later-stage prototypes that are consistent with your plan for mass production.

Paving the Way for a Successful Product Launch

The journey from prototype to production is more than just a technical process; it's a strategic undertaking that bridges the gap between a creative idea and a commercially viable product. Success hinges on a forward-thinking approach that integrates manufacturing considerations into the earliest stages of design. By focusing on Design for Manufacturability, conducting relentless testing, and fostering strong partnerships with suppliers, companies can effectively de-risk this critical transition.

Ultimately, a smooth transition saves invaluable time and resources, prevents costly errors, and ensures the final product meets the high standards of quality and reliability that the market demands. Mastering this pathway is not just about making a product—it's about building a foundation for scalability and long-term success.

Frequently Asked Questions

1. How do you go from prototype to product?

The process involves several key steps: first, refining the design based on prototype testing and market research. Next, you select a manufacturing partner and optimize the design for manufacturability (DFM). This is followed by a low-volume production run to validate the process, making final changes before launching into full-scale mass production.

2. How long does it take to go from prototype to production?

The timeline can vary significantly based on product complexity, manufacturing methods, and regulatory requirements. A simple product using 3D printing or CNC machining might take a few weeks. However, a complex product requiring custom tooling, like plastic injection molding, can take several months. For reasonably complex products, the entire transition can often be around 12 to 18 months.

3. What is the transition from prototype to production?

This transition is the process of taking a single, often handcrafted, model (the prototype) and developing a repeatable, scalable system to manufacture it consistently and in large quantities. It involves shifting focus from just functionality to include manufacturability, cost-efficiency, quality control, and supply chain management.

4. What is prototype production?

Prototype production, or prototype manufacturing, is the process of creating early-stage test versions of a product. Its purpose is to evaluate and refine key aspects like form, function, and design before committing to the significant investment required for mass production. It's a crucial step for identifying and fixing issues early in the development cycle.

-

Posted in

DFM, manufacturing, mass production, product development, prototyping