Exploring Formative Manufacturing Solutions and Processes

TL;DR

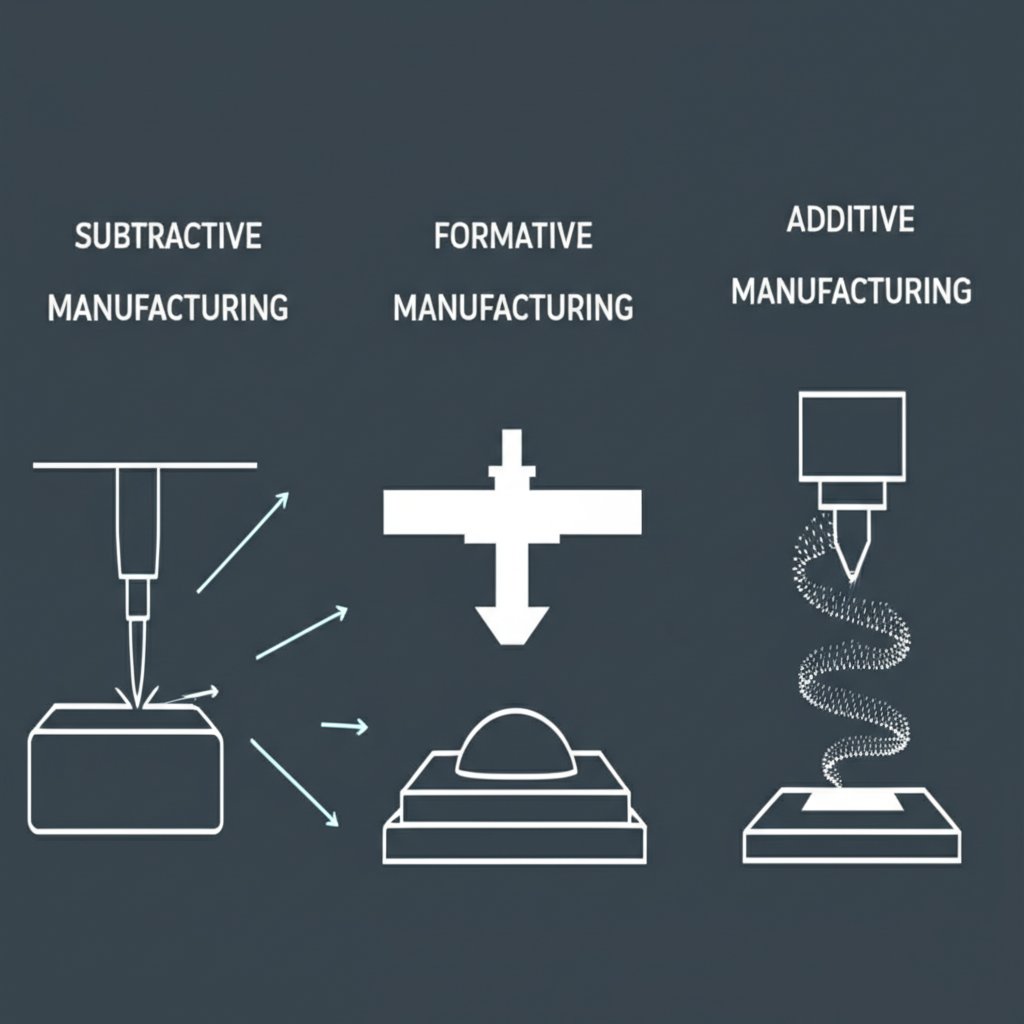

Formative manufacturing solutions involve shaping raw materials using force, pressure, or heat without adding or removing material. This category includes well-established processes like injection molding, die casting, and forging. Unlike additive manufacturing (3D printing) or subtractive manufacturing (CNC machining), formative methods are exceptionally cost-effective and repeatable for high-volume production, making them ideal for creating thousands or millions of identical, durable parts once the initial tooling is developed.

Understanding Formative Manufacturing: Core Principles and Processes

Formative manufacturing is a foundational category of production processes centered on a simple yet powerful principle: transforming the shape of a material without changing its mass. In these methods, production is achieved by applying external forces or heat to a workpiece, causing it to deform and take on a desired geometry. As explained by manufacturing resource electroforming.cz, this approach fundamentally differs from its counterparts. It does not add material layer by layer like 3D printing, nor does it carve away material from a solid block as in machining.

The core mechanism involves plastic deformation, where a material is stressed beyond its elastic limit to create a permanent new shape. This can be achieved with molten materials, as in casting, or with solid materials, as in forging. The defining characteristic is that the original volume of the material is preserved, significantly reducing waste compared to subtractive techniques. This efficiency is a key reason why formative processes are a cornerstone of mass production, where material costs are a critical factor.

Simple, everyday examples help illustrate the concept. Pouring liquid wax into a mold to make a candle or filling a tray with batter to bake cupcakes are basic forms of formative manufacturing. On an industrial scale, these principles are applied with much greater precision and force. Common formative manufacturing solutions include:

- Injection Molding: Forcing molten plastic into a custom-made mold to create complex parts, from bottle caps to automotive dashboards.

- Die Casting: A similar process to injection molding but used for metals, where molten metal is forced into a steel mold (a die) under high pressure.

- Forging: Shaping metal by hammering or pressing it, which aligns the material's grain structure and results in exceptionally strong and durable parts like wrenches or engine components.

- Stamping: Using a die to press a sheet of metal into a specific shape, commonly used for car body panels and appliance housings.

- Extrusion: Pushing material through a shaped die to create long, continuous profiles, such as aluminum window frames or plastic pipes.

These methods are chosen when a design is finalized and the goal is to produce a large quantity of parts with high consistency and at a low per-unit cost. The initial investment in tooling, such as molds and dies, is often substantial, but this cost is amortized over the large production run, making it highly economical at scale.

The Spectrum of Formative Manufacturing Solutions: Key Technologies Explored

The term "formative manufacturing solutions" encompasses a wide range of technologies, each tailored to specific materials, production volumes, and part complexities. These processes are the workhorses of modern industry, responsible for producing countless consumer and industrial goods. Understanding the primary technologies is key to leveraging their benefits for scalability and efficiency. Providers in this space, such as XTJ, often offer a comprehensive suite of these services to take products from prototype to mass production.

Injection Molding is arguably the most common formative process for plastics. It involves heating a polymer to a molten state and injecting it under high pressure into a precisely machined mold cavity. Once the plastic cools and solidifies, the mold opens to eject the finished part. This method is prized for its ability to produce complex and intricate components with high repeatability and at incredible speeds, often in cycles of just a few seconds. It is the go-to solution for high-volume plastic parts.

Die Casting operates on a similar principle but is used for non-ferrous metals like aluminum, zinc, and magnesium. Molten metal is forced into a hardened steel die, creating parts that are both dimensionally accurate and possess a high-quality surface finish. Die casting is essential for manufacturing lightweight yet strong metal components, such as engine blocks, electronics enclosures, and hardware fixtures.

Other key technologies include Compression Molding, where a pre-measured amount of material (often a thermoset plastic or rubber) is placed into a heated mold and compressed into shape, and Vacuum Casting, which uses silicone molds to create high-quality, short-run plastic prototypes. To help clarify their applications, the table below compares these primary formative technologies.

| Technology | Typical Materials | Ideal Production Volume | Key Advantages |

|---|---|---|---|

| Injection Molding | Thermoplastics (ABS, PC, PP, Nylon) | 10,000 - 1,000,000+ | Low cost per part at scale, high complexity, excellent repeatability. |

| Die Casting | Aluminum, Zinc, Magnesium | 5,000 - 1,000,000+ | High strength, dimensional accuracy, excellent surface finish. |

| Compression Molding | Thermoset Plastics, Silicone, Rubber | 1,000 - 100,000+ | Lower tooling costs than injection molding, ideal for bulky parts. |

| Vacuum Casting | Polyurethanes (simulating production plastics) | 10 - 100 | Excellent for high-fidelity prototypes, fast turnaround for low volumes. |

| Thermoforming | Plastic Sheets (ABS, PETG, Polystyrene) | 500 - 50,000+ | Very low tooling cost, fast setup, ideal for large, thin-walled parts like packaging. |

Formative vs. Additive vs. Subtractive: A Comparative Analysis

To fully appreciate the role of formative manufacturing, it's crucial to compare it with the other two primary manufacturing paradigms: additive and subtractive. Each approach has a distinct methodology that makes it suitable for different stages of product development and production. As detailed by manufacturing experts at Formlabs, additive processes build objects layer by layer, while subtractive methods remove material to reveal a final shape.

Additive manufacturing, or 3D printing, starts with nothing and adds material sequentially from a digital file. This method offers unparalleled design freedom, allowing for the creation of incredibly complex geometries that would be impossible to produce otherwise. It is ideal for rapid prototyping, custom one-off parts, and low-volume production where speed to first part and design flexibility are paramount. However, it is often slower and more expensive on a per-part basis for large quantities.

Subtractive manufacturing, such as CNC machining, begins with a solid block of material and uses cutting tools to remove material until the desired part is formed. This process is known for its high precision, tight tolerances, and ability to work with a vast range of materials, especially metals. It is excellent for creating high-strength functional prototypes and end-use parts, but it can generate significant material waste.

Formative manufacturing occupies a unique space. It reshapes existing material, offering a balance of speed, material efficiency, and cost-effectiveness at scale. While it requires a significant upfront investment in tooling and offers less design flexibility than 3D printing, its per-part cost for high volumes is unmatched. In an innovative development, researchers at Johns Hopkins University have introduced a hybrid method called HyFAM, which combines additive and formative techniques to accelerate production by using casting to fill bulk sections while 3D printing intricate details, aiming to get the best of both worlds. This highlights a growing trend of integrating different manufacturing approaches to optimize production. This hybrid approach speeds up production significantly, showcasing the future of manufacturing.

| Attribute | Formative Manufacturing | Additive Manufacturing (3D Printing) | Subtractive Manufacturing (CNC) |

|---|---|---|---|

| Process | Shaping material with force/heat | Adding material layer-by-layer | Removing material from a solid block |

| Key Technologies | Injection Molding, Forging, Casting | FDM, SLA, SLS, DMLS | Milling, Turning, Drilling, Grinding |

| Best For | High-volume mass production | Prototyping, complex geometries, custom parts | High-precision parts, functional prototypes |

| Pros | Lowest cost per part at scale, high speed, low waste | High design freedom, fast initial part, no tooling | Excellent precision, wide material choice, great surface finish |

| Cons | High initial tooling cost, limited design flexibility | Higher cost per part at scale, slower for volume | Material waste, some geometric limitations |

Advantages and Limitations: When to Choose Formative Manufacturing

Choosing the right manufacturing process is a critical decision that impacts cost, quality, and time to market. Formative manufacturing solutions offer a compelling set of benefits, but they also come with specific limitations. Understanding this trade-off is essential for engineers, product designers, and procurement leaders. The primary driver for selecting a formative process is almost always scalability.

Key Advantages

Formative manufacturing truly shines when production volumes enter the thousands or millions. Its benefits are directly tied to the economics of scale.

- Cost-Effective Scalability: While the initial tooling investment can be high, the cost per part becomes extremely low in mass production. Automated processes and rapid cycle times make it the most economical choice for large orders.

- High Precision and Repeatability: Once a mold or die is perfected, it can produce millions of identical parts with extremely tight tolerances. This consistency is crucial for products requiring interchangeability and reliable performance.

- Reduced Material Waste: Unlike subtractive methods that can waste up to 90% of the initial material block, formative processes reshape the material, generating very little scrap. This not only saves costs but is also more environmentally sustainable.

- Superior Part Strength: Certain formative processes, like forging, align the internal grain structure of the metal, resulting in parts that are significantly stronger and more durable than their machined or cast counterparts.

Primary Limitations

Despite its strengths, formative manufacturing is not suitable for every application. Its constraints are primarily related to cost and flexibility.

- High Initial Tooling Costs: The design and fabrication of a high-quality steel mold or die can cost tens of thousands of dollars and take weeks or months to complete. This makes it prohibitive for prototyping and low-volume production.

- Limited Design Flexibility: Once a tool is made, modifying the part design is difficult and expensive. This lack of flexibility makes formative processes ill-suited for products still in the iterative design phase.

- Longer Setup Times: The lead time to produce the first part is significantly longer than with 3D printing or CNC machining due to the need for tool manufacturing. This can delay market entry for new products.

In summary, the ideal project for formative manufacturing is one with a stable, validated design that needs to be produced in high volumes. For applications like prototyping, custom parts, or low-volume runs, additive or subtractive methods remain the superior choice.

Frequently Asked Questions

1. What is an example of formative manufacturing?

A classic industrial example of formative manufacturing is injection molding. In this process, molten plastic is injected into a mold cavity to create parts like LEGO bricks, computer mouse casings, or car bumpers. Simple, non-industrial examples include pouring liquid chocolate into a shaped tray to make candies or using a cookie cutter to shape dough—both involve giving a material a new shape without adding or removing it.

2. What is the difference between additive and formative manufacturing?

The primary difference lies in how the part is created. Additive manufacturing, or 3D printing, builds a part from the ground up by adding material one layer at a time. In contrast, formative manufacturing takes a volume of material (liquid or solid) and reshapes it using force or heat, such as by pressing it in a mold. No material is added or removed in the formative process; it is simply reformed.

3. What are the 7 types of additive manufacturing techniques?

While this article focuses on formative manufacturing, it's helpful to know its counterparts. The seven official categories of additive manufacturing as defined by ASTM are: Vat Photopolymerization (e.g., SLA), Material Jetting, Binder Jetting, Material Extrusion (e.g., FDM), Powder Bed Fusion (e.g., SLS, DMLS), Sheet Lamination, and Directed Energy Deposition.

-

Posted in

additive manufacturing, die casting, formative manufacturing, injection molding, manufacturing processes