Choosing Your First CNC Machine: A Beginner's Guide

TL;DR

Choosing the best CNC machine for a beginner involves balancing affordability, user-friendly software, and strong community support. For most hobbyists starting out, top contenders like the Shapeoko 4, Sienci LongMill MK2, and Onefinity Woodworker consistently stand out. These models are highly recommended for their robust build, accessible software, and helpful user communities, making them ideal for tackling your first woodworking projects.

Key Decision Factors for Your First CNC

Diving into the world of CNC can feel overwhelming, but understanding a few core concepts will empower you to make a confident choice. Instead of just picking a popular name, it’s crucial to match the machine’s capabilities to your project goals and budget. Think of this as learning the language of CNC so you can find the machine that speaks to you.

Your budget is the most practical starting point. While entry-level machines can be found for under $1,000, most highly-recommended beginner kits range from $1,500 to $3,000. It’s a significant investment, but as the adage goes, "Buy the best and you'll only cry once." A slightly higher initial cost often translates to greater precision, better reliability, and less frustration down the road. Also, remember to factor in the "hidden costs" of software, router bits, and accessories, which we'll cover later.

Next, consider the work area, or "envelope," which defines the maximum size of material you can cut. This is expressed in X (side-to-side), Y (front-to-back), and Z (up-and-down) travel. If you plan on making small signs and engravings, a smaller envelope will suffice. However, if you dream of crafting larger items like cabinet doors or furniture parts, a machine with a larger X and Y travel is essential. While some software allows for "tiling"—cutting a large project in sections—it can be a fussy process. If you anticipate working on large pieces regularly, investing in a bigger machine from the start will save you a lot of hassle.

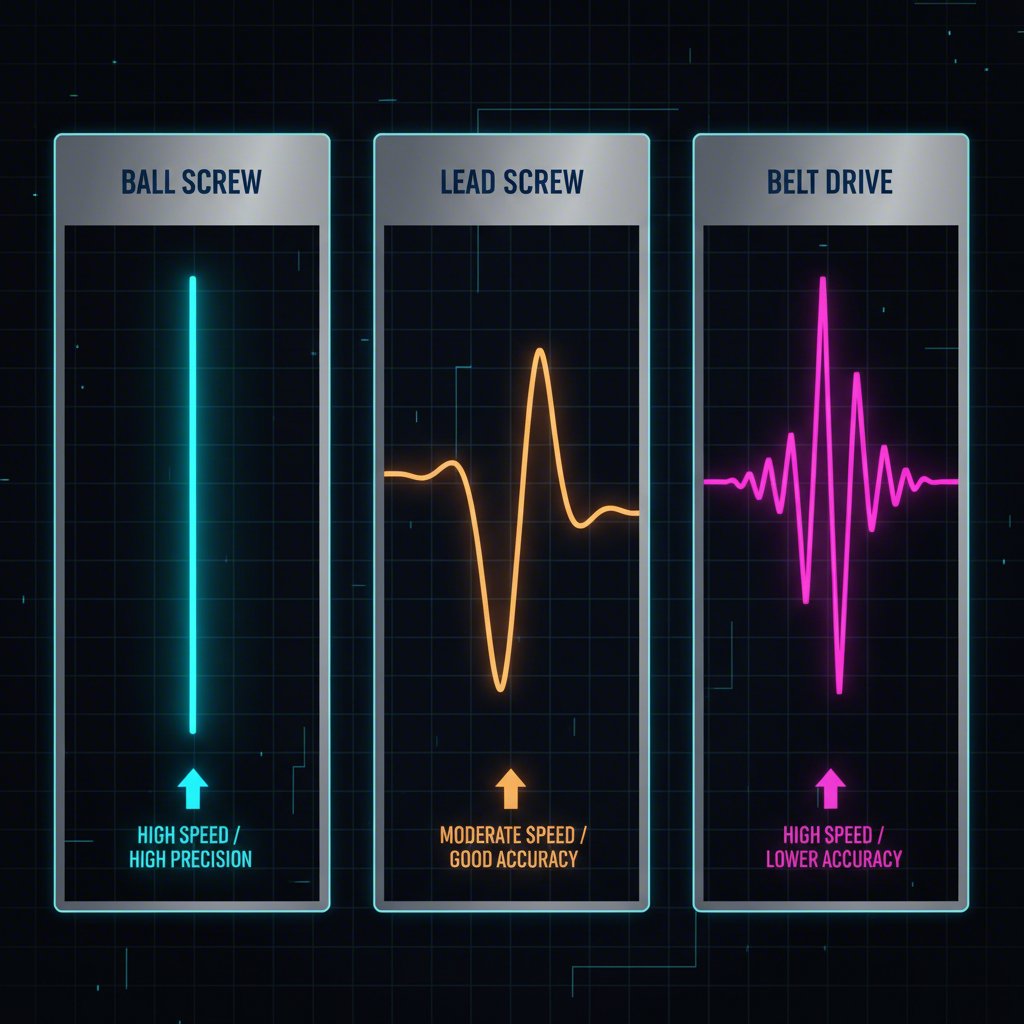

The drive system is the heart of a CNC machine, translating digital commands into physical movement. There are three common types on benchtop machines: belt drive, lead screw, and ball screw. Each offers a different balance of speed, precision, and cost. Understanding these differences is key to choosing a machine that will perform as you expect.

| Drive System | How It Works | Pros | Cons |

|---|---|---|---|

| Belt Drive | A cogged belt runs over pulleys to move the gantry. | Fast movement speeds, lower cost, easy to replace. | Belts can stretch over time affecting accuracy, less able to handle heavy cutting loads. |

| Lead Screw | A threaded rod turns to move a corresponding nut along the axis. | More precise than belts, good for moderate loads. | Slower than belts, creates more friction, can have backlash (minor play). |

| Ball Screw | A screw with ball bearings rolling in the threads to move the nut. | Highest precision and efficiency, minimal backlash, can handle heavy loads. | Most expensive option, often found on higher-end machines. |

Finally, you'll need to choose between a dedicated spindle or a standard woodworking router to do the cutting. A router is a cost-effective option and works well, but a spindle is quieter, offers more precise speed control (especially at lower RPMs for cutting plastics or soft metals), and is designed for the long run times common in CNC work. For most beginners working with wood, a quality trim router is a perfectly acceptable starting point.

Top-Rated CNC Machines for Beginners

Navigating the market for your first CNC machine can be a challenge, but a few models consistently rise to the top in community discussions and expert reviews for their reliability, support, and beginner-friendly features. These machines provide a solid foundation for learning and growing in the hobby. Below is a comparison of the most frequently recommended options.

| Model | Drive System | Best For | Key Feature |

|---|---|---|---|

| Shapeoko 4/Pro | Belt Drive (X & Y), Lead Screw (Z) | Absolute beginners wanting an all-in-one software and hardware package. | Excellent Carbide Create software and strong community support. |

| Sienci LongMill MK2 | Lead Screw (All Axes) | Hobbyists on a budget who want rigidity and upgrade potential. | Great value for its robust, all-screw construction. |

| Onefinity Woodworker | Ball Screw (All Axes) | Serious hobbyists prioritizing precision and ease of assembly. | High-precision ball screws on all axes for minimal backlash. |

Shapeoko 4 and Pro

The Shapeoko series from Carbide 3D is often considered the gold standard for beginner CNCs. Its biggest strength is the seamless integration of hardware and software. The included Carbide Create software is intuitive for designing projects, and Carbide Motion reliably controls the machine. This ecosystem removes a lot of the initial technical hurdles. The machine itself is robust, and the company is known for its fantastic customer support. The Shapeoko is an excellent choice if you want a machine that simply works out of the box with a gentle learning curve.

Sienci Labs LongMill MK2

For those who want maximum rigidity for their dollar, the LongMill MK2 is a fantastic option. It uses lead screws on all axes, providing more stiffness than belt-driven competitors, which is great for cutting harder woods and achieving finer detail. The LongMill has a reputation for being a workhorse and is backed by a passionate company and community. While the software side is more open-ended (you'll pair it with free or paid third-party programs), it offers incredible performance for its price point, making it a favorite among value-conscious woodworkers.

Onefinity Woodworker

The Onefinity Woodworker sets itself apart by using ball screws on all axes, a feature typically found on more expensive, professional machines. This results in exceptional accuracy and smooth movement. Another unique feature is its fast assembly time; you can often have it up and running in under an hour. While it's a premium option in the beginner space, its rigidity and precision make it a machine you won't outgrow quickly. It's an ideal choice for the serious hobbyist who is willing to invest a bit more for top-tier performance from the start.

The Hidden Costs: Budgeting for Software & Accessories

A common surprise for newcomers is that the price of the CNC machine is just the beginning. To actually turn a digital design into a physical object, you need a few more key ingredients. Budgeting for these "hidden costs" from the start will save you from the frustration of having an expensive machine sitting idle while you wait for essential components.

The most important additional cost is software. All CNC work starts with Computer-Aided Design (CAD) to create your 2D or 3D model, followed by Computer-Aided Manufacturing (CAM) to generate the "toolpaths"—the G-code instructions the machine follows. Some machines, like the Shapeoko, come with user-friendly software like Carbide Create. For others, you'll need to choose a program. Vectric VCarve Desktop ($349) and Pro ($699) are industry standards for hobbyists, known for their power and relative ease of use. Free options like Easel and the CAM functions in Autodesk Fusion 360 are also excellent starting points.

Next, you'll need things to actually cut with and hold your material down. A starter set of router bits (often called end mills) is essential. You'll want a variety of types, such as up-cut, down-cut, and V-groove bits, for different applications. Workholding is another critical piece; you need a way to securely clamp your material to the machine's bed. This can range from simple screw-in clamps to more complex T-track systems. Finally, CNC routing creates an enormous amount of fine dust. A dust collection system, consisting of a shop vacuum connected to a dust boot that surrounds the bit, is not just a nice-to-have—it's essential for your health and the longevity of your machine.

Here is a basic shopping list to help you budget for the essentials:

- CAD/CAM Software: $0 - $700 (depending on whether you use free options or purchase a license like VCarve).

- Router/Spindle: $70 - $300 (if not included with the machine).

- Starter Router Bit Set: $50 - $150.

- Workholding Clamps: $30 - $100.

- Spoilboard: A piece of MDF to protect your machine bed, typically around $20.

- Dust Collection System: $100 - $300 (for a good shop vacuum and dust boot).

DIY vs. Pre-Built: Should You Build Your Own CNC?

For the technically inclined, the idea of building a CNC machine from scratch can be tempting. The question often comes up: "Is it cheaper to build your own CNC?" The simple answer is yes, the raw material costs might be lower. However, the true cost is measured in more than just dollars. Building a CNC from plans or sourcing individual parts requires a significant investment of time, electrical knowledge, and a willingness to troubleshoot complex mechanical and software issues.

When you buy a kit from a reputable company like Shapeoko or Sienci, you're not just buying parts; you're buying a proven design, comprehensive instructions, and, most importantly, customer support. If a motor doesn't work or you can't get the software configured, there's a team of experts ready to help. With a DIY build, you are the support team. Calibrating a homemade machine for accuracy can be a long and frustrating process, delaying the moment you actually get to make things. For projects that require guaranteed high precision, many professionals and businesses choose to bypass this entirely and use specialized services. For instance, if a design calls for extremely tight tolerances, a service like XTJ CNC milling can deliver parts with precision far beyond what most hobbyist machines can achieve, saving immense time and effort.

For the vast majority of beginners, the goal is to start learning and creating as quickly as possible. A well-supported kit provides the most reliable and efficient path to success. The time you save on building and troubleshooting is time you can spend mastering design software and bringing your ideas to life.

| Approach | Pros | Cons |

|---|---|---|

| Buying a Kit | Proven design, faster assembly, customer support, strong user communities, gets you making things faster. | Higher initial financial cost compared to raw parts. |

| Building from Scratch (DIY) | Lower material cost, complete customization, deep learning experience of how CNCs work. | Massive time commitment, requires advanced technical skill, no dedicated support, troubleshooting can be very difficult. |

Frequently Asked Questions

1. How much is an entry level CNC machine?

While some very basic CNC kits can be found for under $500, most reputable, high-quality entry-level machines for hobbyists and small shops typically cost between $1,500 and $3,000. This price point generally includes a more rigid frame, reliable components, and better customer support, which are crucial for a positive beginner experience.

2. What kind of CNC machine do I need?

For most beginners interested in woodworking, sign-making, or carving softer materials, a CNC Router is the perfect choice. These machines are versatile and excel at cutting wood, plastics, and some soft metals like aluminum. Other types, like CNC Laser Cutters or Plasma Cutters, are specialized for different materials and applications and are generally not the starting point for a typical hobbyist.

3. Is it cheaper to build your own CNC?

While the cost of raw materials to build a CNC may be less than buying a kit, the total investment is much higher when you factor in your time. Building from scratch requires significant technical expertise, effort in sourcing parts, and extensive troubleshooting. For beginners, buying a well-supported kit is almost always a better value, as it allows you to start learning and creating much faster.

-

Posted in

cnc for beginners, cnc machine, cnc router, hobby cnc, woodworking