Quote Price Increases: 10 Details May You Ignore in CNC Machining

-

Internal Corner Radii : Your 3D drawings might show a perfectly sharp internal corner, but in machining, it is not easy to do. Because cutting tools are round. Overlooked Impact: Attempting a zero-radius corner forces undersized tools, increases passes (time/cost), risks tool breakage, vibration, and leaves unintended radii anyway. Pro Tip: Design with realistic radii slightly larger than the tool diameter you expect to use. Communicate with your machinist early!

-

Toolpath Strategy - It's Not Just the Destination: How the tool gets to the final shape matters immensely. Roughing vs. finishing paths, climb vs. conventional milling, stepover percentages, and entry/exit strategies are crucial. Overlooked Impact: Poor toolpaths cause excessive tool wear, chatter (vibration marks), poor surface finish, dimensional inaccuracy, and can even warp thin parts. Pro Tip: Discuss toolpath optimization with your machinist; sometimes a slightly longer path yields a far superior finish.

-

Fixturing: The Silent Foundation: How the part is held is paramount. Every clamp, vise jaw, or custom fixture introduces potential for distortion, vibration, or limited tool access. Overlooked Impact: Weak fixturing causes part movement (scrap!), chatter, tool deflection, and limits machining orientations. Overly aggressive clamping can bend thin parts. Pro Tip: Consider fixturing early in design. Allow space for clamps. Use soft jaws or custom fixtures for complex parts. Trust your machinist's fixturing expertise.

-

The Deburring: CNC machining inherently creates burrs – sharp, unwanted edges. Removing them isn't glamorous, but it's essential. Overlooked Impact: Left-on burrs are safety hazards, interfere with assembly, affect sealing surfaces, accelerate wear, and make parts look unprofessional. Pro Tip: Specify deburring requirements clearly. Understand the methods (manual, tumbling, thermal, cryogenic) and their cost/time implications. Design features that minimize burr formation where possible.

-

Material Grain Direction (Especially Metals): Metals like aluminum have a grain structure, similar to wood. Overlooked Impact: Machining against the grain can cause tear-out, poor surface finish, and accelerated tool wear. Machining with the grain yields smoother results. Pro Tip: For critical cosmetic or functional surfaces, discuss grain direction orientation with your machinist during material selection and setup.

-

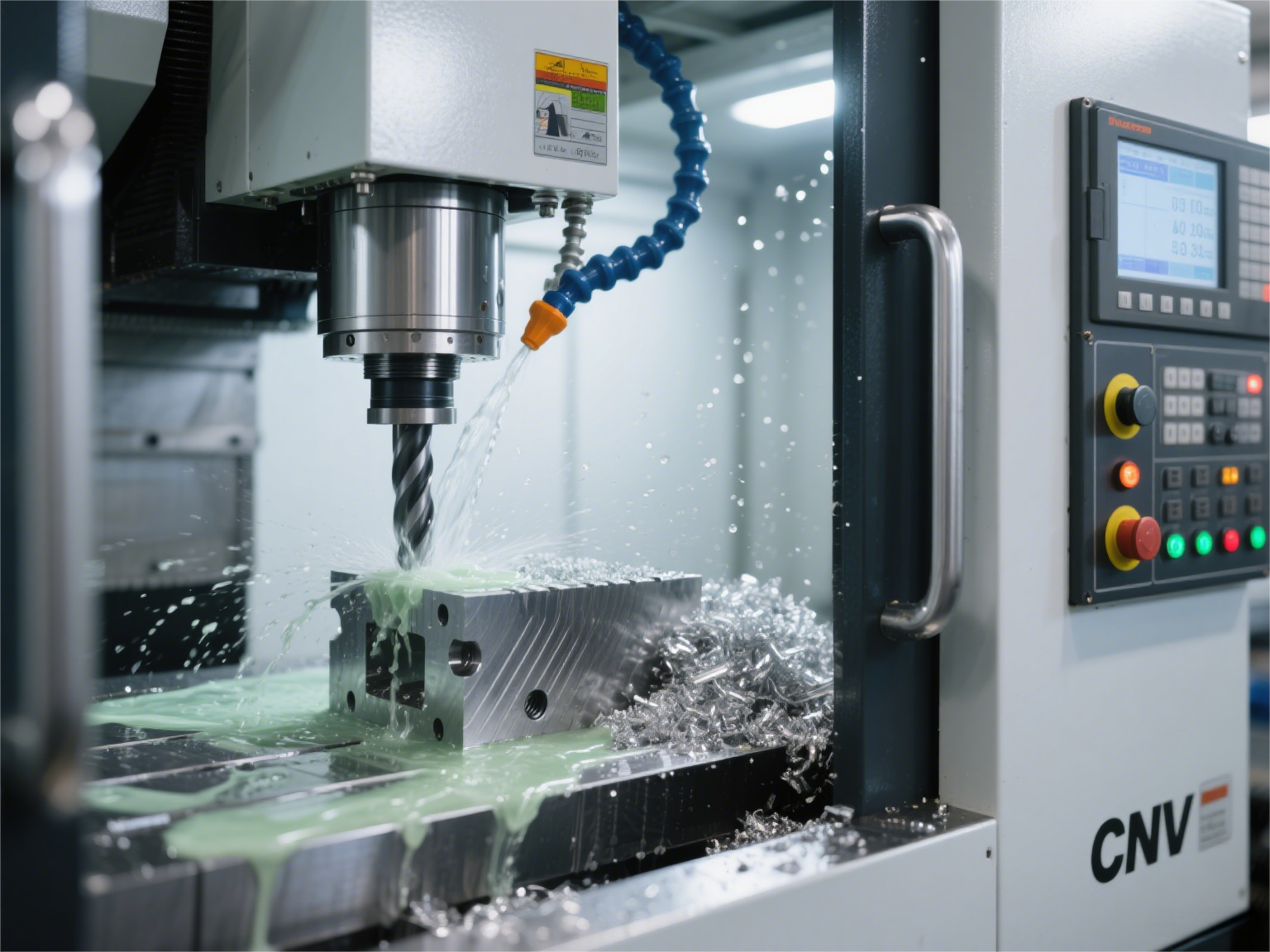

Coolant Concentration & Flow: More Than Just Cooling: Coolant lubricates, cools, and flushes chips. Its concentration and pressure are critical. Overlooked Impact: Incorrect concentration reduces lubricity (increasing tool wear) or cooling efficiency (risking part warping or tool failure). Inadequate flow leads to chip recutting (poor finish, tool damage). Pro Tip: Ensure your shop meticulously monitors and maintains coolant systems – it's not just water!

-

Chip Evacuation: Clear the Path: Removing swarf (chips) from the cutting zone is vital. Overlooked Impact: Accumulated chips get recut by the tool, destroying surface finish, dulling tools rapidly, and potentially jamming or damaging the machine. They can also scratch finished surfaces. Pro Tip: Design parts and select toolpaths that facilitate chip flow. Use adequate coolant pressure or air blast. Machinists must monitor and clear chips effectively.

-

Surface Finish Specifications: Beyond "Machined": "As Machined" covers a vast range. Specifying a required Ra (Roughness Average) value or a visual standard (e.g., SPI A-1) is crucial. Overlooked Impact: Unspecified finish leads to inconsistency. A finish suitable for a hidden bracket might be unacceptable for a cosmetic bezel, leading to rejections or costly secondary operations. Pro Tip: Always specify your required surface finish on the drawing for critical features.

-

Thermal Expansion & Machining Environment: Metal expands when hot. The machine itself generates heat, and ambient temperature fluctuates. Overlooked Impact: Machining a part warm and measuring it cold (or vice versa) leads to dimensional inaccuracies. Lack of shop temperature control exacerbates this. Pro Tip: High-precision shops control ambient temperature. Allow parts to normalize to room temp before final inspection. Consider thermal effects when specifying tight tolerances.

-

Operator Skill & Attention: The Human Element: Even the most automated CNC cell relies on skilled programmers and operators for setup, tool selection, probing, in-process checks, and listening/observing the machine. Overlooked Impact: Lack of experience can lead to poor toolpath choices, missed signs of tool wear (causing bad parts), improper fixturing, and failure to catch issues early. Pro Tip: Partner with a shop that values and invests in experienced personnel. Communication with the team making your part is invaluable.

-

Posted in

cnc machining, machining cost, Milling, precision machining, R&D, rapid prototyping, Turning