Rapid CNC Prototyping for Automotive: A Strategic Edge

TL;DR

Rapid CNC prototyping for automotive applications is a subtractive manufacturing process that uses computer-controlled machines to quickly create high-precision parts from materials like metal and plastic. This technology is essential for the automotive industry because it dramatically accelerates development cycles, allowing engineers to test for fit, form, and function in days instead of months. The primary benefits include enhanced design validation, significant cost savings over traditional tooling, and the ability to rapidly iterate on complex components.

Understanding CNC Prototyping in the Automotive Sector

Computer Numerical Control (CNC) rapid prototyping is a manufacturing method that transforms digital designs into tangible, physical parts with exceptional accuracy. The process starts with a Computer-Aided Design (CAD) model, which is converted into machine-readable instructions (G-code). A CNC machine then follows these instructions to precisely cut away material from a solid block—a method known as subtractive manufacturing—until the final part is formed. This technique is capable of producing components with extremely tight tolerances, making it invaluable for industries where precision is non-negotiable.

In the highly competitive automotive industry, speed and innovation are paramount. Rapid CNC prototyping serves as a critical tool for accelerating the product development lifecycle. Before committing to expensive mass-production tooling, which can take months to create, automotive manufacturers use CNC prototyping to produce functional parts for testing and validation. This allows engineers to physically assess a component's design, check its fit within a larger assembly, and perform functional tests under real-world conditions. According to an article from Hidaka USA, Inc., this ability to quickly iterate helps identify and correct design flaws early, reducing the risk of costly errors down the line.

The relevance of CNC prototyping extends across the entire vehicle, from engine components to interior fittings. For example, engineers can machine a new piston design from aluminum to test its performance and durability or create a prototype of a dashboard console to evaluate its ergonomics and aesthetics. This capability enables a more dynamic and responsive design process, empowering automotive companies to innovate faster and bring safer, more reliable vehicles to market more quickly. The process is not just about creating a single model; it's about fostering an environment of continuous improvement and refinement.

Key Advantages Over Traditional Methods

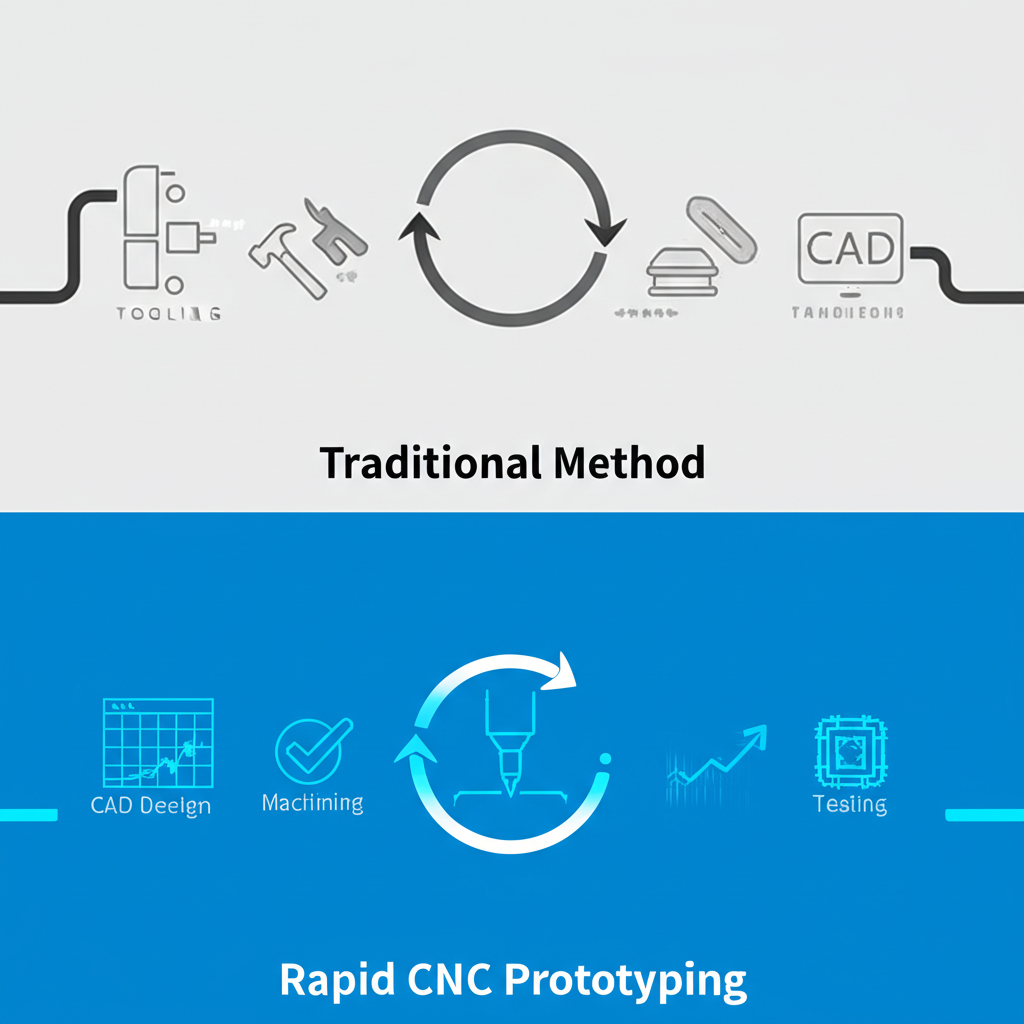

The adoption of rapid CNC prototyping in the automotive sector is driven by a clear set of advantages over traditional manufacturing methods like injection molding or casting for initial development stages. These benefits address the core industry pressures of time, cost, and quality, providing a strategic edge in a fast-paced market. The ability to move from a digital file to a functional part in a matter of hours or days fundamentally changes the development paradigm.

One of the most significant benefits is the dramatic reduction in lead time. Traditional prototyping methods often require the creation of custom tools, dies, or molds, a process that can be both time-consuming and expensive. As noted in multiple industry analyses, producing a prototype with these methods can take months. In contrast, CNC machining can produce parts directly from a CAD file within days or even hours, allowing for much faster design iteration and validation. This speed enables engineering teams to conduct more tests, gather more feedback, and refine designs more thoroughly in a shorter period.

Beyond speed, CNC prototyping offers superior precision and material versatility. The key benefits include:

- High Accuracy: CNC machines can achieve incredibly tight tolerances, often within a fraction of a millimeter, ensuring that the prototype accurately reflects the final product's intended dimensions. This precision is critical for testing the fit and function of components in complex assemblies like engines or transmissions.

- Material Authenticity: Unlike some other prototyping methods, CNC machining can use the same production-grade materials, from engineering plastics to high-strength metal alloys, that will be used in the final part. This allows for realistic functional testing of mechanical properties like strength, heat resistance, and durability.

- Cost-Effectiveness for Low Volumes: By eliminating the need for expensive, custom tooling, CNC prototyping significantly reduces upfront costs. This makes it economically viable to produce one or several iterations of a part, allowing for thorough testing without a massive financial commitment.

- Design Flexibility: Changes to a design can be implemented quickly by simply modifying the CAD file and running the program again. This agility allows engineers to experiment with different geometries and features, fostering innovation and optimizing performance without the delays associated with re-tooling.

Core Applications in the Automotive Lifecycle

Rapid CNC prototyping is not just a single-stage solution; it provides value throughout the entire automotive product development lifecycle. From initial concept validation to the creation of manufacturing aids, its applications are diverse and impactful. By enabling the creation of high-fidelity prototypes, it helps teams make informed decisions, mitigate risks, and ensure the final product meets stringent quality standards.

Functional and Fitment Testing

One of the most common applications is creating parts for functional testing and fitment validation. Before mass production, it is crucial to ensure that a newly designed component works as intended and fits perfectly within its designated assembly. CNC machining allows for the creation of prototypes from production-intent materials, such as aluminum or steel for engine parts, enabling engineers to test them under realistic operating conditions. This helps verify everything from mechanical strength and thermal resistance to clearances and assembly procedures, preventing costly errors from reaching the production line.

Engine and Powertrain Component Development

The powertrain is the heart of a vehicle, and its components demand the highest levels of precision and durability. CNC prototyping is instrumental in developing and iterating on parts like engine blocks, cylinder heads, pistons, and transmission casings. Jiga.io highlights that manufacturers can test new engine part designs for performance and efficiency gains by machining functional prototypes. This allows for rapid innovation in an area that directly impacts vehicle performance and fuel economy.

Custom Tooling and Jigs

Beyond prototyping the vehicle parts themselves, CNC machining is used to quickly create custom tools, jigs, and fixtures needed on the assembly line. These manufacturing aids are essential for holding parts in place during assembly, ensuring consistent quality and precision. Instead of waiting weeks for traditionally made tooling, assembly engineers can have custom jigs machined in days, helping to streamline the setup of new production lines and reduce manufacturing downtime.

Material Selection for Automotive Prototypes: From Plastics to Metals

Choosing the right material is a critical step in the rapid prototyping process, as it directly influences the prototype's functionality, durability, and ability to simulate the final product's performance. CNC machining offers a significant advantage by being compatible with a vast range of materials, from lightweight plastics to high-strength metal alloys. This versatility allows engineers to select a material that best matches the specific requirements of their application, whether for visual models, functional tests, or pre-production validation.

Common Plastic Materials

Engineering plastics are widely used for prototyping automotive components like interior trim, housings, and non-load-bearing parts. They offer a great balance of performance, weight, and cost.

- ABS (Acrylonitrile Butadiene Styrene): Known for its toughness and impact resistance, ABS is a popular choice for prototyping parts like dashboards, covers, and trim pieces.

- Polycarbonate (PC): Offering excellent strength, stiffness, and heat resistance, PC is ideal for components that require durability and transparency, such as headlight lenses or instrument panels.

- POM (Polyoxymethylene/Delrin®): This material provides high stiffness, low friction, and excellent dimensional stability, making it suitable for prototyping gears, bearings, and fuel system components.

- Nylon (PA): Valued for its strength, temperature resistance, and chemical resistance, Nylon is often used for under-the-hood components and parts exposed to wear.

Common Metal Materials

For functional prototypes that require high strength, thermal stability, and durability, metals are the preferred choice. These materials are essential for testing powertrain, chassis, and structural components.

- Aluminum (e.g., 6061, 7075): Offering an excellent strength-to-weight ratio, aluminum is widely used for prototyping engine parts, suspension components, and housings. It is easily machined and provides good thermal conductivity.

- Stainless Steel (e.g., 304, 316): Known for its corrosion resistance, high strength, and hardness, stainless steel is ideal for exhaust components, fasteners, and parts exposed to harsh environments.

- Titanium: While more expensive, titanium offers exceptional strength, low weight, and high-temperature resistance, making it suitable for high-performance applications in racing and aerospace-grade automotive parts.

For projects requiring high-precision parts across a wide range of materials, services from experienced providers are invaluable. For instance, some companies specialize in rapid prototyping with advanced capabilities. If you need high-precision custom parts fast, XTJ delivers rapid prototyping with lead times from just 3 days. They utilize advanced 4 and 5-axis CNC machines to handle over 30 materials with tolerances down to +/- 0.005mm, meeting demanding specifications for various industries.

Frequently Asked Questions

1. What is the main difference between CNC prototyping and 3D printing?

The primary difference lies in the manufacturing process. CNC machining is a subtractive process that carves a part out of a solid block of material, offering high precision and the ability to use production-grade metals and plastics. 3D printing, conversely, is an additive process that builds a part layer by layer. While 3D printing is often faster for complex geometries, CNC machining typically provides superior strength, surface finish, and dimensional accuracy, making it ideal for functional testing.

2. How quickly can an automotive prototype be made with CNC machining?

The turnaround time for a CNC-machined prototype depends on the part's complexity, size, and material. However, one of the key benefits of the technology is its speed compared to traditional methods. Simple parts can often be machined in a matter of hours, while more complex components can typically be produced within a few days. This is a significant reduction from the weeks or months required for traditional tooling.

3. Is CNC rapid prototyping expensive?

While the per-part cost of CNC prototyping can be higher than mass-production methods like injection molding, it is highly cost-effective for low-volume runs and one-off parts. It eliminates the substantial upfront investment in tooling, which can cost tens of thousands of dollars. By identifying design flaws early, CNC prototyping saves money by preventing costly changes to production tools later in the development cycle.

-

Posted in

automotive design, automotive manufacturing, cnc machining, CNC prototyping, rapid prototyping