Essential Surface Finishes for Aluminum Parts

TL;DR

A surface finish for aluminum parts is a secondary process that enhances a component's properties, including its durability, corrosion resistance, and appearance. These treatments range from electrochemical processes to applied coatings and mechanical texturing. The most common and effective types of aluminum finishes include anodizing, which thickens the natural protective oxide layer, and powder coating, which applies a durable decorative layer.

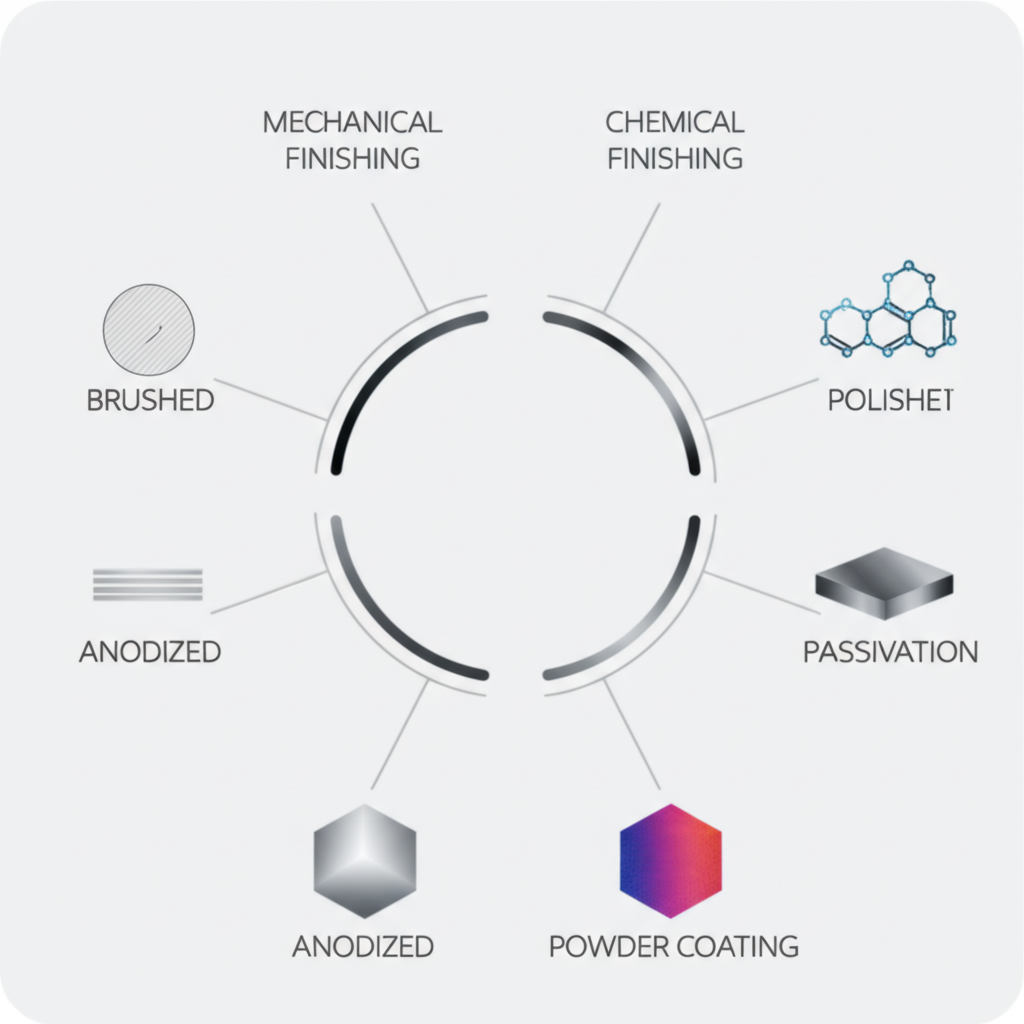

The Primary Categories of Aluminum Surface Finishes

Selecting the appropriate surface finish is a critical decision in product design and manufacturing, as it directly impacts the part's performance, lifespan, and aesthetics. Aluminum finishes are broadly categorized into chemical processes, which alter the surface of the metal itself, and coating processes, which add a new layer on top. Each category offers distinct advantages depending on the application's requirements.

Anodizing

Anodizing is an electrochemical process that enhances aluminum's natural oxide layer, making it significantly thicker, harder, and more durable. Unlike paint, this anodic layer is an integral part of the metal, meaning it won't chip or peel. The process involves submerging the aluminum part in an acid electrolyte bath and passing an electric current through it. The resulting porous layer is excellent for corrosion and wear resistance and can be dyed in various colors before being sealed, offering both protection and aesthetic flexibility. According to a guide from Yijin Hardware, there are different types of anodizing, such as Type I (Chromic acid), Type II (Sulfuric acid), and Type III (Hard anodize), each suited for specific applications from aerospace to consumer electronics.

Powder Coating

Powder coating provides a decorative and highly protective finish by applying a dry powder electrostatically to the aluminum surface. The part is then cured in an oven, which causes the powder to melt and flow into a durable, uniform coating. This method is renowned for its wide range of colors and textures, from high gloss to matte and metallic finishes. As noted by experts at Gabrian, powder coating is more environmentally friendly than traditional liquid painting because it contains no solvents and releases minimal volatile organic compounds (VOCs). It offers excellent resistance to chipping, scratching, and fading, making it ideal for outdoor furniture and automotive parts.

Liquid Painting (including PVDF)

Liquid painting offers the most extensive color selection and is ideal for projects requiring very specific hues, especially in smaller batches. A high-performance subset of liquid paint is Polyvinylidene Fluoride (PVDF), a resin-based coating known for its exceptional resistance to weathering, fading, and chemicals. This makes PVDF an excellent choice for architectural applications like exterior wall panels and window frames. While effective, traditional liquid paints often involve solvents with VOCs, requiring special handling and abatement systems to mitigate environmental and health risks.

Mechanical Finishing

Mechanical finishes physically alter the surface of the aluminum to achieve a desired texture or appearance. These methods do not add a protective layer but are often used to prepare the surface for other treatments or as a final aesthetic touch. Common techniques include blasting with media like glass beads to create a uniform matte finish, polishing to achieve a mirror-like shine, and brushing to create a directional satin texture. These processes are crucial for removing imperfections from manufacturing and achieving specific visual effects that enhance a product's appeal.

Chemical Conversion Coatings (Alodine/Chem Film)

Chemical conversion coatings, often known by the brand name Alodine, create a thin, protective film on the aluminum through a chemical reaction. This process, also called chem film, is a cost-effective alternative to anodizing for improving corrosion resistance and creating an excellent primer for paint adhesion. A key advantage highlighted by multiple sources is that, unlike anodizing, a chem film maintains the electrical conductivity of the aluminum. This property makes it indispensable for applications in electronics and aerospace where grounding is required.

How to Select the Right Finish for Your Application

Choosing the best surface finish for aluminum parts is not about finding a single superior option but rather matching the finish's properties to the specific demands of the application. The "best" finish is entirely dependent on context. Factors like environmental exposure, wear and tear, aesthetic requirements, and budget all play a critical role in the decision-making process. A finish that is perfect for an indoor decorative piece would likely fail on an exterior architectural component exposed to harsh weather.

Key criteria to consider include corrosion resistance, durability, visual appeal, and cost. For example, if the part will be used in a marine environment, a finish with superior corrosion protection like Type II anodizing or a high-performance powder coat is essential. If the component is subject to significant abrasion, a Type III hard anodize offers maximum surface hardness. For consumer electronics, aesthetics may be the primary driver, making the color consistency of anodizing or the vibrant options of powder coating more attractive.

The manufacturing process itself also influences the final finish. High-quality preparation is fundamental to a successful coating. The precision of the initial manufacturing, such as that achieved through advanced CNC machining, ensures a smooth and uniform surface that is ready for finishing. For projects requiring tight tolerances and complex geometries, it’s beneficial to work with a service that understands the entire lifecycle of a part. If you need high-precision custom parts fast, companies like XTJ deliver rapid prototyping and production with advanced 4 and 5-axis CNC machining, ensuring components meet demanding specifications before the finishing stage even begins.

To simplify the selection, the following table compares common finishes across key decision-making factors:

| Finish Type | Corrosion Resistance | Wear Resistance | Aesthetic Options | Relative Cost |

|---|---|---|---|---|

| Anodizing (Type II) | Excellent | Good | Good (metallic colors) | Moderate |

| Hard Anodizing (Type III) | Excellent | Excellent | Limited (darker shades) | High |

| Powder Coating | Very Good | Good | Excellent (wide color/texture range) | Moderate |

| Liquid Paint / PVDF | Very Good | Poor to Good | Excellent (unlimited colors) | Moderate to High |

| Chem Film (Alodine) | Good | Fair | Poor (primarily functional) | Low |

| Mechanical (Polished/Brushed) | Poor (requires secondary protection) | Poor | Excellent (texture-based) | Low to Moderate |

Making the Final Finishing Decision

Ultimately, the selection of a surface finish for aluminum parts is a balancing act between performance, appearance, and cost. By carefully evaluating the end-use environment and the specific functional requirements of your component, you can narrow down the options to the most suitable candidates. Whether the priority is the extreme hardness of a Type III anodize for industrial machinery, the vibrant color of a powder coat for a consumer product, or the conductive and corrosion-resistant properties of a chem film for an electronic enclosure, a well-chosen finish will ensure your aluminum parts perform reliably and look exceptional for years to come.

Frequently Asked Questions

1. What is the best surface finish for aluminum?

There is no single "best" surface finish; the ideal choice depends entirely on the application. For superior durability and corrosion resistance, especially in harsh environments, anodizing (particularly Type III hard coat) is often considered the most robust option. For decorative purposes with a wide range of color choices, powder coating is an excellent and durable alternative. The best finish is one that meets the specific performance, aesthetic, and budget requirements of your project.

2. What is the most durable finish for aluminum?

Hard anodizing (Type III) is generally regarded as the most durable and wear-resistant finish for aluminum. The process creates an exceptionally hard, thick layer of aluminum oxide that is integrated into the surface, providing outstanding resistance to abrasion, scratching, and corrosion. This makes it a preferred choice for high-performance applications in industries like aerospace, military, and industrial machinery where parts are subjected to extreme conditions.

3. How to surface finish aluminum?

Surface finishing aluminum involves a series of steps, starting with thorough cleaning and surface preparation to remove oils, dirt, and oxides. After preparation, a specific finishing process is applied. This could be a mechanical method like blasting or polishing, an electrochemical process like anodizing, or the application of a coating like powder coating or liquid paint. Each process has its own detailed procedure, such as immersing the part in chemical baths for anodizing or using an electrostatic gun and curing oven for powder coating.

4. What finish is used on aluminium?

A wide variety of finishes are used on aluminum, tailored to different needs. Anodizing is extremely common for its balance of durability, corrosion resistance, and metallic appearance. Powder coating is also widely used for its vast color options and protective qualities. Other common finishes include liquid painting, chemical conversion coatings (chem film) for corrosion resistance and conductivity, and mechanical finishes like brushing and polishing for purely aesthetic textures.