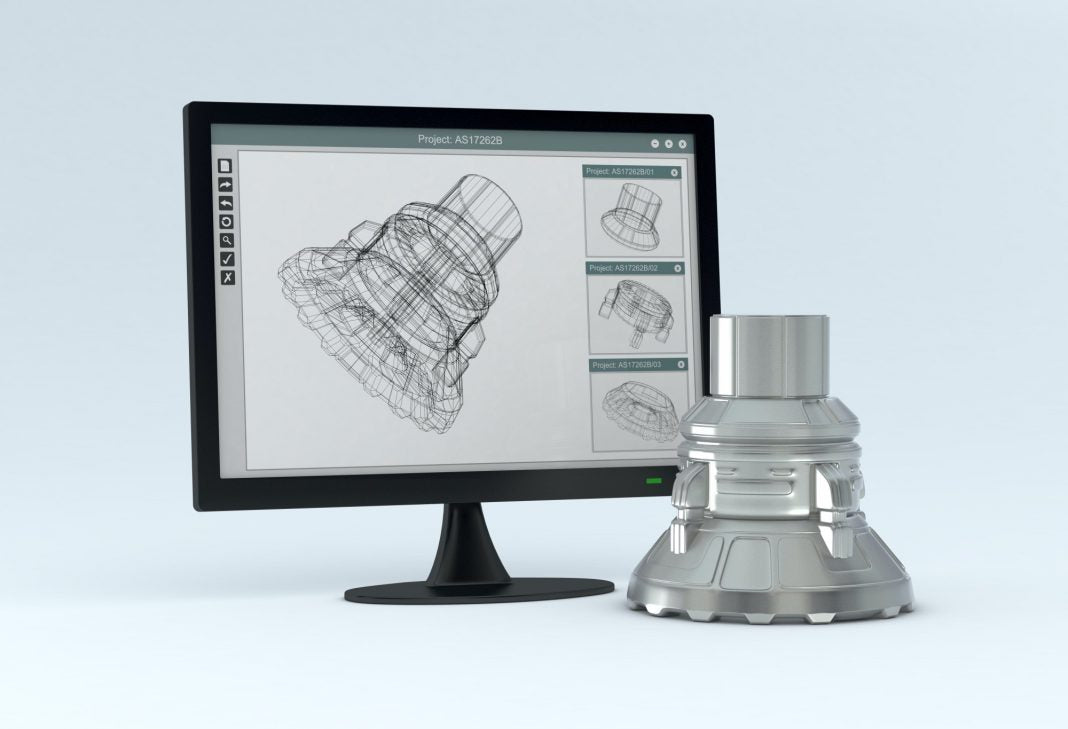

Rapid Prototyping-CNC Aluminum Machining

What is Aluminum Prototyping?

Modern design constraints and market demands compel engineers and companies to minimize both time-to-market and development costs while achieving final product validation. To meet these requirements, rapid prototyping has become indispensable.

For aluminum components, rapid prototyping employs two principal technologies:

Additive Manufacturing (AM)

-

-

Process: Layer-by-layer deposition of aluminum powder via 3D printing (e.g., SLM/DMLS)

-

Characteristics:

-

Net-shape fabrication from digital models

-

Supports complex internal geometries

-

Typical surface finish: Ra 10–15μm

-

-

Subtractive Manufacturing

-

-

Process: CNC machining (milling, turning, drilling)

-

Characteristics:

-

Material removal from solid billets

-

Achieves Ra 0.8–3.2μm surface finish

-

Tolerances down to ±0.025mm

-

-

Introduction to Aluminum and its Alloys

Aluminum exhibits low density yet high strength-to-weight ratios, with certain alloys surpassing the mechanical properties of premium steels. Its material advantages include:

Superior Workability

-

-

Malleability: Elongation up to 25% (6061-O temper)

-

Corrosion resistance: Salt spray >1000hrs (per ASTM B117)

-

Weldability: ER4043 filler compatibility (AWS D1.2 compliant)

-

Economic & Sustainable Benefits

-

-

Material cost: $2.1–3.8/kg (vs. steel at $0.8–1.5/kg)

-

Recyclability: >95% energy savings vs. primary production

-

Prototyping waste reduction: 60–70% lower than steel

-

Precision Manufacturing Advantages

-

-

Post-machining distortion: <0.1mm/m (ISO 230-1 tested)

-

Ideal for:

-

Functional prototypes

-

Jigs & fixtures

-

Low-volume end-use parts

-

-

Shenzhen XTJ Aluminum Parts CNC Machining

At XTJ, aluminum machining processes are optimized to ensure:

- Superior Chip Evacuation – Prevents built-up edge (BUE) and minimizes aluminum adhesion to cutting tools.

- Tool Core Strength – Maintains rigidity to withstand cutting forces without deflection or fracture.

Tooling Solutions:

-

Carbide Grades (K-series) – For general machining (e.g., Kennametal K68)

-

High-Speed Steel (HSS) – For intricate geometries

-

Polycrystalline Diamond (PCD) – For high-volume, high-precision finishing

Machining Technology:

-

Industrial-Grade 5-Axis CNC – Enables complex contouring with ≤0.01mm positional accuracy

-

High-Pressure Coolant (70+ bar) – Enhances tool life by 30–40%

Aluminum Alloy CNC Machining and Prototyping Industry

XTJ (Shenzhen) specializes in aluminum rapid prototyping, delivering:

-

Prototyping to Production: Seamless scaling from 1–10,000+ units

-

Precision Capabilities:

-

5-Axis CNC: ±0.02mm accuracy

-

Surface Finishes: Ra 0.8–3.2μm (mirror polish available)

-

-

Company Certification: ISO9001, IATF 16949 (automotive)

-

Posted in

Aluminum Alloy, cnc machining, precision machining, prototyping