Scrap Copper Price Truth: Grades, Tests, And Real Yard Offers

Understand the Real Meaning of Scrap Copper Price

What Scrap Copper Price Really Means

Ever wondered why the amount you get for your copper at the yard is different from what you see on financial news tickers? The term scrap copper price refers to the real-world amount a local recycler or scrap yard pays for your copper, based on its grade and condition. It’s not the same as the headline copper price you might see on commodity exchanges. Instead, it’s a practical, on-the-ground offer—usually quoted per pound—that reflects what you’ll actually be paid at the scale, after all adjustments and deductions.

- Scrap Copper Price: The actual payout offered by a local yard for your specific material and grade.

- Commodity Exchange Price: The global benchmark price for refined copper, used as a market reference but not a guaranteed payout.

- Grade: The purity and condition of your copper (like bare bright, #1, or #2) which heavily influences the offer.

- Gross Weight: The total weight of your material, including any containers or attachments.

- Net Weight: The weight of copper alone, after subtracting tare (container weight) and any non-copper material.

- Ticket: The slip or receipt you receive after your copper is weighed and graded, showing details of your transaction.

- Downgrade: A reduction in grade (and price) due to contamination, attachments, or mixed loads.

Market Index vs Yard Offer

Sounds complex? Here’s the key: while commodity exchanges set a reference price for copper, the copper scrap price you’re offered at the yard is based on more than just that index. Local yards adjust their offers based on:

- Current market trends and global copper demand

- The grade and cleanliness of your copper

- The volume you bring in—bulk can sometimes earn better rates

- Regional logistics and transport costs

- Yard-specific overheads and risk tolerance

Two yards just a few blocks apart may offer different prices on the same day, even for similar material. That’s why it’s smart to check multiple yards and always note the time and date of any quote you receive. This helps you track changes and negotiate with confidence.

| Exchange Benchmarks | Local Yard Offers |

|---|---|

| Global, standardized, and updated frequently on financial markets | Local, specific to grade and condition, updated daily or weekly |

| Reflects refined copper, not scrap | Reflects what you actually receive for your scrap at the scale |

| Reference only—no guarantee of actual payout | Real offer, subject to inspection and possible downgrades |

Yard offers are local, grade-specific, and time-stamped; exchange prices are global references, not guaranteed payouts.

Per Pound, Per Ton, and Net Pay

Most yards quote the scrap copper price per pound, but you might also see offers per ton, especially for commercial loads. Always clarify whether the price is for gross or net weight, and whether any fees or deductions apply. The cost of scrap copper to you as a seller is not just the headline price, but also the impact of grading, potential downgrades, and any handling fees. By understanding these factors, you can better compare offers and make sure you’re getting the best value for your material. Remember, the scrap cost of copper is ultimately determined by what you take home after all adjustments—so keep those tickets and timestamps handy for your records.

By knowing how copper scrap prices are set and what influences them, you’ll be better equipped to navigate the market and maximize your payout. In the next section, we’ll break down the different copper grades and how they affect your offer at the yard.

Copper Grades and Acceptance Criteria Made Simple

How Copper Grades Are Determined

When you walk into a scrap yard with a bucket of copper wire or pipes, you might wonder: What decides the price of scrap copper you’ll actually get? The answer is grading. Scrap yards use established grading systems to evaluate the purity and cleanliness of your copper, which directly impacts your payout. Higher grades mean higher value, while impurities or mixed materials lead to downgrades and lower offers. Understanding these grades—and how yards test for them—helps you sort smarter and avoid surprises at the scale.

What Counts as Bare Bright, #1, and #2?

Let’s break down the most common copper grades you’ll encounter at the yard. Each grade has specific visual and physical criteria, and knowing these can help you maximize your return, especially if you’re bringing in high-value items like 6 awg wire or thick copper wires.

| Grade | Visual Criteria | Common Sources | Common Downgrades |

|---|---|---|---|

| Bare Bright | Uncoated, shiny, no oxidation, no insulation or solder | Thick copper wire (e.g., 6 awg wire), stripped electrical wires | Any tarnish, paint, solder, or insulation |

| #1 Copper | Clean, unalloyed, no heavy corrosion, may have slight tarnish | Clean copper pipes, bus bars, large copper wires | Paint, oil, light solder, minor oxidation |

| #2 Copper | Painted, soldered, lightly tarnished, minor attachments | Older plumbing, copper with fittings, lightly corroded wires | Excessive corrosion, heavy solder, mixed metals |

| Insulated Wire | Wire with insulation, graded by copper recovery % | Household electrical wire, appliance cords | Low copper content, mixed insulation, moisture |

| Magnet Wire | Thin enamel-coated wire, usually from motors | Electric motors, transformers | Mixed metals, excessive insulation |

| Mixed Copper | Various grades combined, includes non-copper attachments | Demolition scrap, mixed wire bins | Heavy contamination, unknown materials |

As you can see, the bare bright copper price is reserved for the cleanest, shiniest, and uncoated copper wires—think freshly stripped, thick gauge electrical wire. #1 copper is also valuable, but even a little paint or solder can bump it down to #2, which fetches a lower no1 copper price at the yard.

Insulated Wire, Magnet Wire, and Mixed Copper

Insulated copper wire is graded by how much pure copper can be recovered after stripping the insulation. Yards may do a cut-and-weigh test or estimate based on the type of wire you bring—thick, single-strand wires like 6 awg wire generally have a higher copper recovery percentage than thin, multi-strand cables. Magnet wire, often found in motors, is coated in enamel and is usually treated as a separate grade. Mixed copper (like bins of various wires and pipes) will almost always be downgraded to the lowest common denominator.

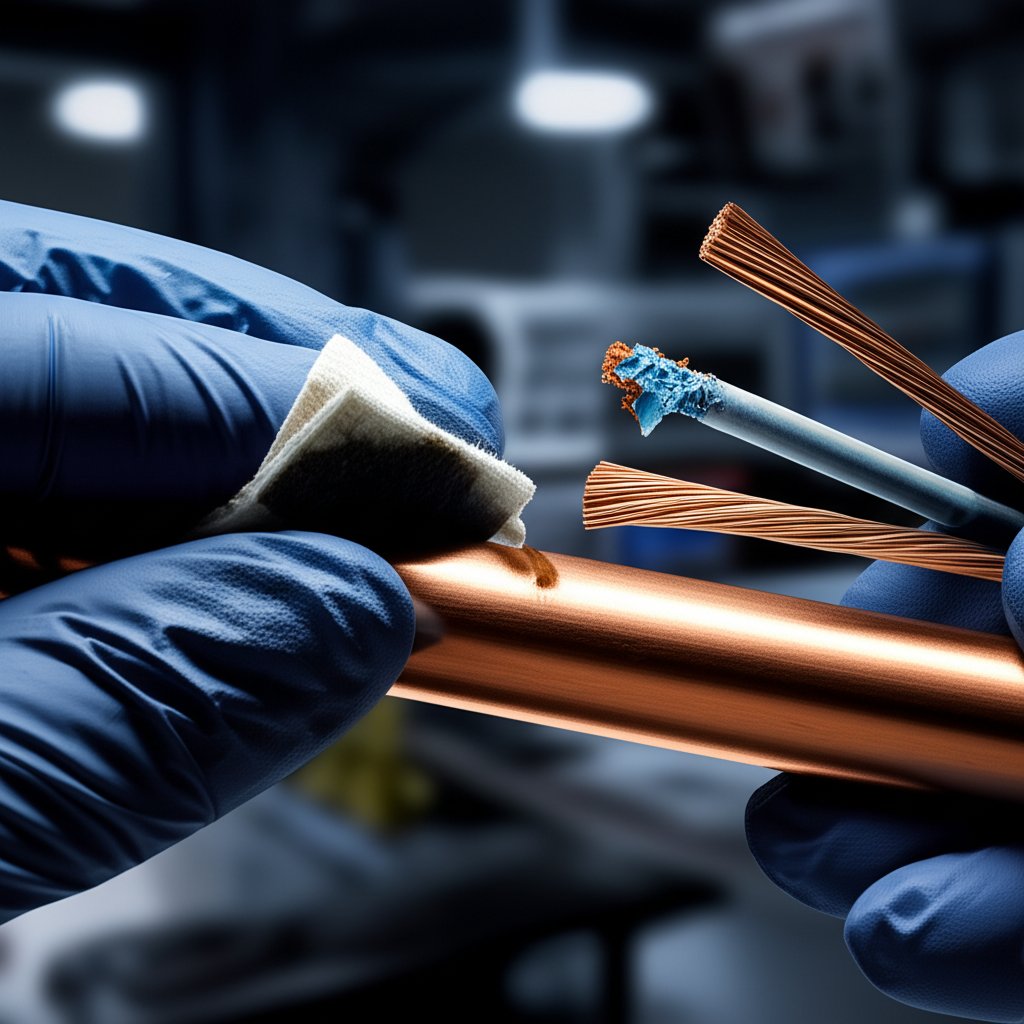

How Yards Test and Downgrade Copper

Scrap yards use quick tests to grade your copper:

- Scrape Test: Scraping the surface to check for coatings or oxidation.

- Magnet Test: Pure copper is not magnetic; if a magnet sticks, it’s likely contaminated or alloyed.

- Spark Test: Used to check for alloys in questionable material.

- Cut-and-Weigh: For insulated wire, a small section is stripped to estimate copper content.

Downgrades happen fast—just a bit of solder, oil, paint, or attached fittings can move your copper from #1 to #2 or even lower. Moisture and mixed loads (like copper wire tangled with steel or aluminum) are other common triggers for a lower payout.

- Sort copper wires by grade before loading

- Remove all insulation for bare bright

- Keep pipes and wires free of paint, solder, and fittings

- Separate mixed loads into single-grade bins

- Keep everything dry and free of oil or grease

Consistent sorting and clean presentation not only help you get the best copper wire scrap price but also reduce disputes at the yard. Imagine the difference: a neatly separated bin of shiny, thick copper wire versus a tangled, mixed mess. The first gets top dollar; the second gets downgraded. Next, we’ll see how these grades and tests translate into real offers when you visit your local yard.

How Local Yards Translate Markets Into Offers

How Yards Set Offers From Market Signals

Ever wondered why the scrap copper price today at your local yard can shift even when you haven’t seen any big news about copper? That’s because yards don’t just pull numbers from thin air—they follow a chain of signals that starts with global commodity markets and trickles down to what you see on the scale ticket. Here’s how it works:

- Commodity Benchmarks: Yards watch global copper prices on exchanges like the LME or Comex, which update in real time.

- Wholesale Buyers: Mills and exporters set their own buy prices, factoring in international demand, shipping costs, and regulatory changes.

- Yard Adjustments: Local yards adjust for grade, recovery risk, their own overhead, and transportation logistics. They also consider their ability to move material quickly or store it if prices drop.

- Public Offers: Yards post buy prices (often per pound) on boards, websites, or over the phone. These are regularly updated—sometimes intra-day, daily, or weekly—depending on how volatile the market is.

- Final Inspection: When you bring your copper in, the yard inspects and grades it. The final payout is determined only after this step, so posted prices are always subject to change if the material is downgraded.

Update Frequency and Price Notices

If you’re tracking the current copper price per pound, you’ll notice that not all yards update at the same pace. Some adjust prices several times a day as markets move, while others might stick to daily or weekly updates. It’s smart to ask the yard:

- How often do you update your scrap copper prices?

- Are posted prices before or after any deductions or fees?

- What happens if the market shifts between my quote and my delivery?

Remember, a quote you get over the phone or online isn’t binding. The real offer comes after your copper is weighed and inspected on-site.

| Signal | Local Adjustment |

|---|---|

| Global copper market price | Adjusted for yard overhead, transport, and risk |

| Wholesale buyer demand | Volume incentives or penalties |

| Material grade & recovery risk | Downgrade or upgrade applied after inspection |

| Regional logistics | Local supply/demand, storage capacity |

Gross vs Net and Documenting Your Ticket

When you receive your payout, always check if the price was applied to gross or net weight. Gross weight includes all containers and possible attachments, while net weight is just the copper itself. The copper value per pound you actually get depends on this distinction, as well as any downgrades for contamination or mixed loads.

To protect yourself and track your earnings, keep detailed records for every transaction. Here’s what to document:

- Timestamped quote (date and time)

- Yard name and contact

- Material description and grade assessed

- Any downgrade or deduction notes (often on the scale ticket)

Request whether the posted price is gross or net and how downgrades are noted on the ticket.

Staying organized helps you spot trends, dispute errors, and get the best deal the next time scrap copper price today shifts. Up next, we’ll look at the factors you can control to boost your copper payout, from cleaning to sorting and beyond.

What Boosts or Reduces Your Copper Payout

Cleanliness and Downgrade Triggers

When you’re hoping for the best copper recycling prices, it’s tempting to think all copper is created equal. In reality, the difference between a top-dollar payout and a disappointing offer usually comes down to details you can control. Imagine two sellers: one brings in a bin of clean, shiny 8 awg wire with every last bit of insulation removed, while the other shows up with tangled, dirty cables and pipes still dripping water. Who do you think gets the better deal?

- Insulation: Leftover plastic or rubber reduces grade—stripped wire pays more than insulated.

- Coatings: Paint, lacquer, or enamel (like on magnet wire) can trigger downgrades.

- Solder and Attachments: Soldered joints, fittings, or connectors lower purity and value.

- Oxidation: Tarnish or corrosion means your copper is less desirable for recycling.

- Mixed Loads: Combining copper with other metals or trash can downgrade an entire batch.

- Moisture: Wet pipes, coils, or wire (even from rain or residual water) are often penalized.

Wire Types and Recovery Expectations

Scrap yards judge wire by the percentage of pure copper they can recover after processing. For example, THHN wire (a common electrical wire) typically yields around 74–78% copper by weight, while thicker cables like 8 awg wire may offer higher recovery. On the other hand, thin multi-strand wires or cables with heavy insulation—such as those found in electronics or coaxial cable scrap—tend to have lower copper content, which impacts the scrap copper per pound rate you’ll be offered (source).

| Wire Category | Typical Recovery | Common Use | Downgrade Risk |

|---|---|---|---|

| THHN Wire | 74–78% copper | Household/building electrical wiring | Insulation left on, mixed metals |

| 8 AWG Wire | High (thick, single strand) | Main power feeds, heavy circuits | Paint, connectors, partial insulation |

| Coaxial Cable | Low (thin copper, heavy shielding) | TV, internet wiring | Plastic, aluminum shielding |

Knowing these differences helps you sort and prioritize your material. Clean, stripped wire fetches a much better copper value per pound scrap than tangled, insulated, or mixed wires. Always check with your yard about their recovery rates for each wire type—they may even have a posted chart or reference.

Moisture, Attachments, and Mixed Loads

Moisture is an often-overlooked penalty trigger. Wet copper can be heavier (affecting net weight) and may corrode during storage. If you bring in pipe or coil with water inside, expect a deduction. Likewise, fittings, screws, or even a stray steel staple mixed in with your copper can downgrade your entire load. Mixing different grades or types together makes it harder for the yard to sort, which usually means they’ll pay the lower copper price scrap for the whole batch.

- Sort your copper by grade and wire type before leaving home.

- Remove all insulation, fittings, and connectors from wires and pipes.

- Wipe or air-dry material to eliminate moisture.

- Keep bins clearly labeled and avoid mixing metals or grades.

- Double-check for stray non-copper items before loading up.

By controlling these factors, you’ll consistently get the best scrap copper per pound payout and avoid the frustration of unexpected downgrades. Up next, we’ll cover practical steps for prepping, stripping, and presenting your copper to maximize its value at the yard.

Step-by-Step Prep to Maximize Copper Value

Sorting Checklist Before You Drive

When you’re ready to cash in on your copper, a little preparation goes a long way in boosting your payout. Ever wondered why two people with the same amount of copper walk away with different checks? It’s all about sorting and presentation. Before heading to the yard, ask yourself: Is my copper clean, dry, and separated by grade?

- Separate Bare Bright, #1, #2, and insulated copper wire into clearly labeled bins or bags.

- Remove all non-copper attachments—think screws, steel fittings, or plastic connectors.

- Keep pipes and wires free of paint, solder, or oil residue.

- Double-check for moisture—wet copper can mean deductions or downgrades.

- Store your sorted copper in a dry area to prevent oxidation and preserve its value.

Taking these steps helps you avoid the frustration of seeing your load downgraded to a lower scrap copper prices per pound bracket simply because of a few overlooked details. The more organized your load, the faster and smoother your yard visit will be.

Safe, Efficient Wire Stripping

Stripping insulation off copper wire can dramatically increase your copper wire price, but only if done safely and efficiently. Sounds simple, but using the wrong tool or technique can damage the copper, lower its grade, or even cause injury. Here’s a practical workflow:

- Safety Check: Always wear gloves and eye protection. Never strip wire with a knife—use a dedicated copper wire stripper suited to your volume and wire type.

- Blade Setup: Adjust the stripping machine blade depth for your wire’s insulation thickness. Start shallow; gradually increase until you can peel the insulation without scoring the copper.

- Feed Rate: Test a short section first. Feed wire steadily—too fast or too slow can lead to jams or uneven cuts.

- Offcut Disposal: Collect stripped insulation for recycling if your yard accepts it, or dispose of it according to local regulations.

- Sort Again: After stripping, visually inspect copper for cleanliness. Separate any wire that shows oxidation or damage, as this can affect your price per pound scrap copper.

Remember, not all wire is worth stripping. Thin or heavily oxidized wire might fetch a better price left insulated—when in doubt, check with your yard or bring a sample for advice (source).

Labeling and Load Presentation

Imagine the difference between a tangled pile of mixed wires and a set of clearly labeled bins, each with a single copper grade. Which one do you think the yard will process—and pay for—faster? Here are some tips for smooth inspections and fewer disputes:

- Label each bin or bag with the copper grade and wire type.

- Keep receipts or records of where your material came from, especially for larger or recurring loads.

- Don’t mix grades or types in the same container—yards usually pay based on the lowest grade present.

- Keep everything dry and covered until delivery.

- If unsure about a batch, ask the yard ahead of time for their preferred sorting method.

When in doubt on insulated wire, ask the yard which categories they recognize and how they prefer material presented.

By following these steps, you’ll be better equipped to get the best how much is copper per pound rate available. And if you’re new to using a copper wire stripper, remember: clean, safe, and sorted beats quick and careless every time. Next, we’ll walk through the math of conversions and scale tickets so you know exactly what to expect at payout.

Conversions, Tare Weight, and Easy Payout Math

Converting Units With Confidence

Ever looked at your scale ticket and wondered if you’re really getting the payout you expect? With scrap copper, understanding units and conversions is essential. Yards might quote a copper price per lb, but sometimes you’ll see copper prices per pound, per kilogram, or even per ton. Knowing how to convert between these units ensures you can compare offers fairly and calculate your true payout.

| Unit | Common Use | Conversion Formula |

|---|---|---|

| Pound (lb) | Most U.S. scrap yards (copper price per lb) | — |

| Kilogram (kg) | International/metric yards | [lb] = [kg] × 2.2046 |

| Short Ton (U.S. ton) | Bulk/commercial loads | [ton] = [lb] / 2000 [lb] = [ton] × 2000 |

| Ounce (oz) | Refined copper, small quantities | [oz] = [lb] × 16 [lb] = [oz] / 16 |

Remember, regional variations may apply, especially if you’re dealing with international buyers or metric-only facilities. When comparing offers, always confirm the unit and double-check the math. For large loads, understanding lbs/ton is vital—most U.S. yards use 2,000 lbs per ton, but this can differ abroad.

Understanding Scale Tickets and Tare

When you bring in your copper, the yard weighs everything together first. This is your Gross Weight—the total weight of your material plus any containers, bins, or non-copper attachments. Next comes the Tare Weight—the weight of those containers or anything that isn’t copper. The difference between these two is your Net Weight—the number that matters for your payout. Here’s the formula:

- Net Weight = Gross Weight – Tare Weight

For example, if your barrels and bins add up to 50 lbs (Tare), and your total load weighs 350 lbs (Gross), your Net Weight is 300 lbs. That’s the number used to calculate your payment (reference).

Worked Examples Without Specific Prices

Let’s walk through a typical payout calculation. Imagine you’ve brought in a batch of copper, and you want to know what you’ll earn. Here’s a step-by-step guide using variables, so you can plug in your own numbers from your ticket or quote:

- Record your Gross Weight (total weight on the scale): [Gross_lb]

- Subtract the Tare Weight (weight of bins/containers): [Tare_lb]

- Calculate the Net Weight: [Net_lb] = [Gross_lb] – [Tare_lb]

- Find your price per pound from the yard: [Price_per_lb]

- If your copper isn’t bare bright (the highest grade), apply a grade factor (e.g., 0.85 for #2 copper): [Grade_factor]

- Calculate your payout:

- Payout = [Net_lb] × [Price_per_lb] × [Grade_factor]

If you want to compare with the cost per ounce of copper (useful for small lots or jewelry-grade material), simply convert pounds to ounces using the table above, then multiply by the appropriate price per ounce.

Always ask the yard if your quoted copper price per lb is before or after deductions for tare, moisture, or downgrade. This ensures your payout math matches what you actually receive.

Understanding these basics helps you spot errors, dispute discrepancies, and make smarter selling decisions. Next, we’ll look at how regional differences and local yard policies can further impact your bottom line, so you’re never caught off guard when comparing the copper per pound price in your area.

Regional Price Differences and Finding the Best Local Deal

Why Prices Differ by Region

Ever notice how scrap copper prices near me can be higher or lower than those in the next city or state? That’s because the price of copper in minnesota—or anywhere else—depends on more than just the global market. Regional factors play a big role in what you’ll actually get paid. Let’s break down the main drivers:

- Proximity to Mills or Export Routes: Yards closer to copper mills or major shipping hubs can often pay more, since their transport costs are lower.

- Number of Local Scrap Yards: More competition among yards in a city or region usually means better prices for sellers. Fewer yards can lead to lower offers.

- Local Demand and Industrial Activity: Areas with active construction, manufacturing, or green energy projects tend to have higher scrap copper prices in minnesota and other industrial hubs.

- Transportation Costs: The farther your copper needs to travel, the more those costs eat into your payout.

- Volume of Material: Larger loads may earn you a better rate, especially if you’re willing to drive a bit further for the best scrap copper prices near me.

For example, regional price ranges show that Midwest cities often pay differently than the West Coast or Southeast, reflecting these local dynamics.

How to Validate Local Offers

So, how do you make sure you’re getting a fair deal? The answer: compare, confirm, and document. Here’s a practical checklist for calling around and checking local yards:

- Ask for the current price and how often it’s updated (daily, weekly, etc.).

- Request their grade definitions—what counts as #1 or bare bright?

- Check if posted prices are before or after deductions (tare, downgrade, fees).

- Ask about ID requirements and what documentation you’ll need.

- Verify payment options: cash, check, or electronic transfer.

- Clarify minimum load thresholds for the best rates.

Don’t forget: the price quoted on the phone or website is only final after your copper is inspected and graded on-site. Two yards just a few miles apart can offer different rates, so it pays to check more than one location, especially when searching for scrap copper prices mn or the most competitive copper prices in minnesota.

The best offer on paper may not win after fuel, time, and potential downgrades are considered.

| Yard | Update Frequency | Accepted Grades | Convenience |

|---|---|---|---|

| Downtown Metals | Daily | Bare Bright, #1, #2, Insulated | Central, easy access |

| Suburban Recycling | Weekly | #1, #2, Mixed Copper | Ample parking, flexible hours |

| Lakeside Scrap | Intra-day (as market shifts) | Bare Bright, Insulated, Specialty Grades | Near highway, quick unloading |

When Transportation Costs Change the Best Choice

Imagine you find a yard offering a slightly higher scrap copper prices in minnesota, but it’s an hour away. Is it worth the drive? Factor in fuel costs, your time, and the possibility of your load being downgraded upon inspection. Sometimes, a slightly lower offer closer to home nets you more after expenses. Also, check for minimum load requirements—some yards only pay top rates for larger quantities.

In short, don’t just chase the headline number. Weigh all factors, including convenience, reliability, and your own costs, when choosing where to sell. By following these steps, you’ll be able to confidently navigate regional differences and secure the best deal for your copper—whether you’re searching for scrap copper prices mn or just trying to maximize your payout locally.

Next, we’ll look at how to read price trends over time so you can choose the best moment to sell your copper for maximum value.

Historical Context and How to Read Copper Price Trends

Reading Copper Price Trends

Ever wondered why the scrap copper price per pound today can shift even when there’s no headline news? Understanding copper price trends is about more than just watching daily numbers. It’s about recognizing the patterns behind the ups and downs so you know how much is copper worth—and when to sell for the best return. Tracking price history from trusted sources, like commodity exchanges or reputable recyclers such as Rockaway Recycling, gives you a reliable snapshot of the market’s direction.

Short vs Medium-Term Signals

Short-term copper price movements often reflect quick changes in supply and demand, such as a sudden surge in construction projects or a temporary mine closure. Medium-term trends, on the other hand, are shaped by broader forces—think global economic cycles, new technology rollouts, or shifts in government policy. For example, as noted by Fastmarkets, geopolitical events, regulatory changes, and sustainability initiatives have all played a role in recent market swings. If you’re asking, “how much is a pound of copper worth this month versus last?”—look for published historical charts or 30-day averages from established sources.

| Period | Direction/Pattern | Commentary |

|---|---|---|

| Recent Weeks | Stable to Slightly Volatile | Domestic demand steady; export uncertainties due to tariffs. |

| Past Month | Widening Export Grade Spreads | No. 2 copper discounts narrowed; domestic demand stable. |

| Past Year | Growth with Fluctuations | Supply constraints, geopolitical shifts, and sustainability policies influenced volatility. |

Events That Commonly Drive Volatility

The answer to “how much is copper going for a pound” can change quickly due to a handful of recurring catalysts. Here are some of the most common drivers that impact current price per pound for copper:

- Manufacturing Demand Shifts: Surges in construction or electronics production can push prices up.

- Supply Chain Disruptions: Mine strikes, natural disasters, or transport bottlenecks can limit available copper.

- Geopolitical Events: Trade tariffs, policy changes, or international conflicts can alter export/import flows.

- Seasonality: Construction booms in certain months often increase scrap demand and value.

- Monetary Policy: Currency fluctuations and central bank actions can make copper more or less expensive on the global market (reference).

- Sustainability Initiatives: Government incentives for recycling can increase the value of scrap and change what is recycled copper worth.

Always timestamp price snapshots you save or compare. Even a few days can make a big difference in how much does copper sell for at the yard.

By tracking these patterns and using historical data from authoritative sources, you’ll be better equipped to decide when to sell and how to interpret the scrap copper price per pound today. Up next, we’ll explore the best tools and resources to help you track prices and plan your material strategy with confidence.

Tools and Resources to Track Prices and Plan Materials

Trusted Tools for Tracking and Planning

Ever wish you had a toolkit to help you make sense of scrap metal prices or to plan your next big copper sale or project? Whether you’re a homeowner looking for scrap metal prices near me or an engineer weighing copper for prototypes, the right resources can save time and boost your bottom line. Here’s a scannable list of essential tools and services that can help you track scrap prices, compare offers, and make smart material decisions:

- XTJ Rapid Prototyping Services — Ideal for anyone prototyping copper or copper-alloy parts. XTJ offers complimentary DFM (Design for Manufacturability) feedback, helping you select the right material and optimize your design to reduce manufacturing costs and scrap. Their broad material selection and fast turnaround are especially valuable when evaluating copper versus alternatives. This guidance can help you minimize waste that would otherwise enter the scrap stream, directly impacting your understanding of copper pipe recycling prices and total project costs.

- London Metal Exchange (LME) — The global benchmark for real-time copper and other metal prices. Use this for trend tracking and to anchor your negotiations with local yards.

- Rockaway Recycling — A reputable U.S. recycler that publishes daily updates on copper grades, pricing, and preparation tips. Their site is a valuable reference for understanding what local yards pay and for clarifying grade definitions.

- Fastmarkets — For in-depth market analysis and historical data on copper scrap prices. Fastmarkets helps you interpret broader trends and anticipate changes in the market.

- Global Ardour Recycling — Offers practical guides and news on predicting scrap prices, plus tips on working with recyclers and staying compliant with industry regulations.

- EPA Recycling Reports — For methodology, terminology, and regulatory updates on copper and other scrap metals. Useful for aligning your process with industry best practices.

When Prototyping Intersects With Scrap Value

Imagine you’re designing a new electrical component and debating whether to use copper or an alternative alloy. The scrap copper price isn’t just a selling concern—it’s a key factor in your total cost of ownership. By understanding the scrap value of copper, you can make smarter decisions during the prototyping phase, potentially recovering more value from offcuts or rejected parts. Services like XTJ Rapid Prototyping stand out because their DFM feedback helps you avoid design pitfalls that generate excess scrap, while their material selection guidance ensures you’re not overpaying for performance you don’t need.

| Tool/Service | Best For | Value Notes |

|---|---|---|

| XTJ Rapid Prototyping | DFM feedback, material selection, fast-turn prototyping | Reduces waste, optimizes design for cost and recyclability, supports both copper and alternatives |

| London Metal Exchange | Market trend tracking | Industry-standard for global copper and scrap metal prices |

| Rockaway Recycling | Daily price checks, grade definitions | Real-time updates for "where to sell copper near me" queries; trusted U.S. resource |

| Global Ardour Recycling | Market prediction, compliance guidance | Practical tips for maximizing scrap metal value and staying ahead of market shifts |

| EPA Recycling Reports | Regulatory updates, methodology | Ensures you’re using the correct terminology and following best practices |

Material Selection and DFM Support

When you’re planning a manufacturing project—whether it’s a one-off prototype or a full production run—material choice is everything. Copper’s recyclability and high scrap value can offset initial costs, but only if you design with manufacturing and end-of-life recovery in mind. That’s where DFM (Design for Manufacturability) comes in. Early DFM input helps you avoid overengineering, minimize waste, and ensure that offcuts or rejected parts retain value in the scrap stream (reference).

In summary, leveraging the right tools and services—from daily price trackers like Rockaway Recycling to DFM-focused prototyping partners—empowers you to get the best deal whether you’re selling scrap or planning your next copper-based project. Up next, we’ll pull all these insights together into an actionable plan so you can maximize copper value and make smarter material decisions every time.

Action Plan to Get the Best Price and Plan Smarter

Your Next Steps to Maximize Copper Value

When you’re ready to turn your copper into cash, having a clear action plan can make all the difference. Whether you’re a homeowner, contractor, or an engineer planning a new product, knowing how much is the copper worth starts with a few practical habits. Here’s a step-by-step workflow to help you get the most from every pound, every time:

- Sort and Organize by Grade: Before you leave home, separate your copper into bare bright, #1, #2, and insulated wire. Remove all non-copper attachments and keep everything dry. Clean, sorted copper consistently commands the best scrap copper price per pound.

- Call at Least Three Local Yards the Same Day: Ask for their current scrap copper prices per pound, how often they update rates, and what their grade definitions are. Record the time and details of each quote for accurate comparison.

- Confirm Gross vs Net Pricing: Always clarify if the quoted price is for gross or net weight. This avoids surprises at payout and helps you accurately calculate copper salvage price.

- Document Each Transaction: Keep every scale ticket, receipt, and grading note. Note the date, yard name, copper grade, and any deductions. Organized records make it easier to track trends, dispute discrepancies, and answer the question, “how much is the copper worth this month compared to last?”

- Monitor Market Trends: Regularly check reputable sources for current scrap metal prices and copper market updates. Use this information to time your sales for the best possible return.

- Review and Adjust: After each sale, review your process. Did a certain yard consistently offer better rates? Were you downgraded for something you can control next time? Small tweaks can add up to bigger payouts over time.

Consistency in sorting, documentation, and yard comparison will earn you more over time than chasing one-off price spikes.

From Scrap Seller to Informed Material Planner

Imagine you’re not just selling scrap, but also designing new copper-based parts. Understanding scrap value isn’t only about maximizing today’s payout—it’s about smarter planning for tomorrow. If you’re developing prototypes or evaluating whether to use copper versus another alloy, knowing the scrap copper price per pound can help you forecast total material costs and potential recovery value.

For engineers and manufacturers, services like XTJ Rapid Prototyping offer complimentary DFM (Design for Manufacturability) feedback. This helps you optimize your design to reduce waste, select the right material, and understand how scrap recovery will affect the total cost of your project. By factoring in scrap value early, you’re not just saving money—you’re making your process more sustainable and efficient.

Keep Records and Iterate

Finally, keep a running log of every sale and every quote. Over time, you’ll build a personal database that shows how current scrap copper prices per pound fluctuate in your area, which yards are most reliable, and what preparation steps yield the best results. This record-keeping turns you from a casual seller into a savvy planner—one who always knows how much is the copper worth before hauling a load or launching a new project.

By following these steps, you’ll maximize your copper returns, avoid common pitfalls, and make smarter decisions—whether you’re cashing in scrap or designing the next generation of copper parts. Ready to put your plan into action?

Frequently Asked Questions About Scrap Copper Price

1. How much is #1 scrap copper worth?

The value of #1 scrap copper depends on its purity, cleanliness, and local market conditions. Yards typically pay more for shiny, uncoated copper wire or pipe, but actual payouts can differ from exchange rates due to grading, fees, and regional factors. Always check with several local recyclers for their current offers and ensure your copper meets the highest grade criteria to maximize your return.

2. Why does the price I get at the yard differ from the copper price on the market?

Scrap yard prices reflect local demand, copper grade, and handling costs, while market prices are global benchmarks for refined copper. Yards adjust their offers based on contamination, volume, and regional logistics, so your payout is tailored to your specific material and location, not just the headline market rate.

3. What factors affect the scrap copper price I receive?

Key factors include the grade and cleanliness of your copper, local competition among yards, current global copper demand, and the presence of contaminants like insulation, solder, or moisture. Sorting, cleaning, and presenting your copper properly can help you secure the best possible price.

4. How can I prepare copper to get the best price at the scrap yard?

Separate copper by grade (bare bright, #1, #2, insulated wire), remove all attachments and moisture, and keep materials clean and dry. Label your bins and keep records of weights and grades. Stripping insulation from copper wire, when safe and worthwhile, can also increase your payout.

5. Are there tools or services that help with copper scrap value and material planning?

Yes. Use daily price trackers like Rockaway Recycling for real-time updates, and consider services like XTJ Rapid Prototyping for DFM feedback and material selection if you’re designing copper parts. These resources help you track trends, optimize design, reduce waste, and plan material costs more effectively.