Copper Pipe Decoded: Types, Sizes, And Joins That Pass Code

What Copper Pipe Is And Why It Matters

What Copper Pipe Means In Plumbing Specs

When you first encounter the term copper pipe in a plumbing specification, it might sound straightforward—but there’s more nuance than meets the eye. In North American plumbing, copper pipe, copper tube, and copper tubing are all manufactured to rigorous standards, but each term has a specific meaning and application. Understanding these differences is essential for anyone working with potable water, HVAC, or industrial systems, as the wrong choice can lead to sizing errors or compliance issues.

Tube Versus Pipe Terminology Explained

Let’s clear up a common point of confusion: the difference between copper pipe and copper tube. Imagine you’re at the supply house and you see two similar-looking products—one labeled as copper pipe, the other as copper tubing. What’s the difference?

- Copper Pipe is typically defined by its nominal pipe size (NPS), which often does not match the actual outside diameter (OD). For example, a 1/2-inch copper pipe actually has an OD of 0.625 inches. Copper pipes are made to standards like ASTM B42 and are widely used in plumbing and boiler feed lines.

- Copper Tube (or copper tubing) is sized by its actual outside diameter and wall thickness. Tubes are often used in HVAC, medical gas, and refrigeration, where precise sizing and flexibility are crucial. Standards like ASTM B88, B280, and B75 apply.

Why does this matter? Because matching the right type and size to your fittings and application is critical for leak-free, code-compliant installations. Sizing confusion is a top cause of installation errors, especially when transitioning between copper water pipe and refrigeration tubing.

Where Copper Shines And Where It Doesn’t

So, why does copper remain a preferred choice for so many applications, from copper water pipe in homes to copper tubes in commercial chillers? Here’s a quick snapshot:

- Durability: Withstands decades of use in water, heating, and gas systems.

- Antimicrobial Properties: Naturally resists bacterial growth, making it ideal for potable water lines.

- Heat Tolerance: Performs reliably in both hot and cold service, unlike some plastics.

- Recyclability: 100% recyclable, supporting sustainable building practices.

- Limitations:

- Cost volatility—prices can fluctuate with global copper markets.

- Susceptible to certain types of corrosion if water chemistry is aggressive.

- Requires careful joining and handling to avoid leaks or cracks.

The best copper pipe installations balance wall thickness and joining method to safely handle the system’s pressure and temperature—always check both before selecting materials and fittings.

In the sections ahead, you’ll learn how to identify the right types of copper piping, measure accurately, select compatible fittings, and ensure code compliance. This guide draws on industry standards like ASTM B88 for water tube, as well as the International Plumbing Code and Uniform Plumbing Code for installation guidance. For application-specific recommendations, always consult technical bulletins from reputable manufacturers.

Ready to decode copper tubing and pipe for your next project? Let’s map the journey from specification to successful installation—starting with types, sizing, joining, code checks, and finally, how to buy or specify the right copper water pipe for your needs.

Copper Pipe Types And Where To Use Them

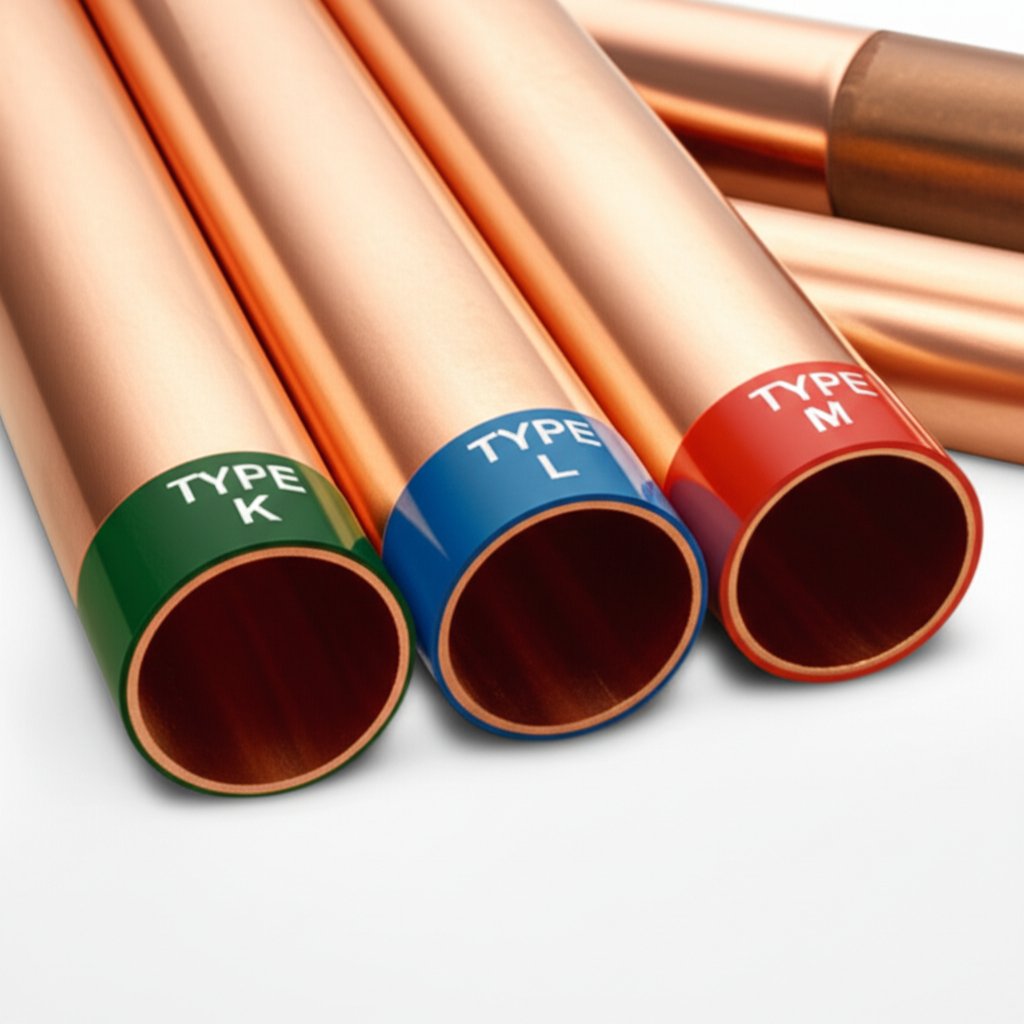

Type K, Type L, and Type M at a Glance

When you’re planning a plumbing or mechanical project, choosing the right types of copper pipe is a key decision. Sounds complex? Let’s break it down. The main types you’ll encounter are Type K, Type L, Type M, and DWV copper tubing. Each has a unique wall thickness, color code, and use case—so picking the wrong one can mean code issues or premature failure.

| Type | Wall Thickness (in.) Example (1/2" size) |

Temper Availability | Common Applications | Standard Reference | Notes |

|---|---|---|---|---|---|

| Type K | 0.049 (1/2") Thickest |

Hard, Soft (Coil) | Underground water service, heavy-duty HVAC, fire protection | ASTM B88 | Color: Green; Highest pressure rating; Suitable for direct burial |

| Type L | 0.040 (1/2") Medium |

Hard, Soft (Coil) | Interior potable water, general plumbing, HVAC linesets | ASTM B88 | Color: Blue; Most common for above-ground water supply |

| Type M | 0.028 (1/2") Thinnest |

Hard, Limited Soft | Low-pressure residential water, hydronic heating (where allowed) | ASTM B88 | Color: Red; Not always permitted by local code—verify first |

| DWV | 0.042 (2" size) Light |

Hard Only | Drain, waste, and vent (non-pressurized) | ASTM B306 | Color: Yellow; Never for pressurized water or gas |

DWV Copper and Where It Fits

Ever wonder why some copper pipes are stamped “DWV”? DWV copper tubing is designed strictly for drain, waste, and vent lines. Unlike Type K, L, or M, it’s not rated for pressure. Instead, it relies on gravity to move waste. You’ll mostly find DWV copper in older buildings, as newer construction often uses alternatives like PVC for these applications. Remember: never use DWV copper for pressurized supply lines—it’s not built for that job (WhyRepipe).

Hard Versus Soft Temper: What Changes On Site

Here’s a scenario: You’re running a water line through a crawlspace with lots of bends. Should you choose hard or soft copper? The answer depends on your installation needs:

- Hard Drawn (Rigid): Comes in straight lengths. Best for exposed runs—think risers, trunk lines, and where you want a neat, straight appearance. Joints are typically soldered or pressed.

- Soft Annealed (Coil): Supplied in rolls. Ideal for snaking through tight spaces or making long, continuous runs with minimal joints. Common for underground service (Type K) and some HVAC linesets.

Imagine uncoiling type k copper tubing for a direct-burial water service—it’s flexible enough to bend around obstacles, reducing the need for fittings underground. But for a crisp, exposed water line in a basement, rigid Type L or Type M might be your go-to.

How to Choose: Application Snapshots

- Type K copper pipe: Maximum strength and corrosion resistance. Underground mains, heavy-duty fire protection, and high-pressure HVAC lines.

- Type L: Versatile, code-approved for most interior potable water and HVAC supply lines. A safe bet for remodels and new builds alike.

- Type M copper: Lightweight and budget-friendly, but check your local code—some areas don’t allow it for potable water due to its thinner wall.

- DWV copper tubing: Only for gravity drains, waste, and vent systems—never for supply lines.

Always confirm with your local building department which types of copper pipe are approved for your application. Some municipalities restrict the use of Type M or DWV in potable water systems. For authoritative guidance, reference ASTM B88 (Types K, L, M) and ASTM B306 (DWV).

Now that you know how to match copper pipe types and temper to your project, let’s move on to sizing. Next, you’ll learn how to measure copper tube accurately and avoid the most common sizing mistakes.

Copper Pipe Sizes And Measuring Like A Pro

How To Measure Copper Pipe Size Accurately

Ever tried to match a copper pipe to a fitting, only to realize the size isn’t what you expected? You’re not alone. Getting copper pipe sizes right is critical for leak-free installations and code compliance. The trick is knowing how to measure, and understanding what those measurements actually mean.

When you’re sizing up a piece of copper tubing, always start with the outside diameter (OD). Most copper tube and pipe in North America is sized by its actual OD, not the nominal size printed on the label. For example, 1/2 copper pipe actually has an OD of 0.625 inches. This is the number you’ll use for selecting press jaws, flaring tools, and fittings. If you’re working with 1 2 copper tubing (that’s 1/2-inch nominal), remember: the OD matters more than the nominal size for compatibility.

Nominal Versus Actual OD And ID

Sounds confusing? Here’s how it breaks down:

- Nominal Size: The name of the pipe (e.g., 1/2 inch), but not the true OD.

- Outside Diameter (OD): The actual measurement across the pipe, critical for fitting selection.

- Inside Diameter (ID): The space inside the pipe—varies based on wall thickness (Type K, L, M, or DWV).

Why does this matter? Because the wall thickness changes by copper pipe type, so the same nominal size can have different IDs. That’s why you’ll see slight variations in charts and why referencing a copper pipe size chart or copper pipe dimensions chart is so important for field work and procurement.

Reading Size Charts Without Getting Burned

Ready to avoid the most common mistakes? Use the table below as your starting point. It covers the most-used copper tube sizes for Types K, L, M, and DWV. These values are based on industry standards (Engineers Edge). Always confirm with manufacturer datasheets or ASTM B88/B306 tables before finalizing your order or cut list.

| Nominal Size (inches) | OD (inches) | ID (inches) Type K | ID (inches) Type L | ID (inches) Type M | ID (inches) DWV |

|---|---|---|---|---|---|

| 1/4 | 0.375 | 0.305 | 0.315 | - | - |

| 3/8 | 0.500 | 0.402 | 0.430 | 0.450 | - |

| 1/2 | 0.625 | 0.527 | 0.545 | 0.569 | - |

| 3/4 | 0.875 | 0.745 | 0.785 | 0.811 | - |

| 1 | 1.125 | 0.995 | 1.025 | 1.055 | - |

| 1 1/4 | 1.375 | 1.245 | 1.265 | 1.291 | 1.295 |

| 1 1/2 | 1.625 | 1.481 | 1.505 | 1.527 | 1.541 |

| 2 | 2.125 | 1.959 | 1.985 | 2.009 | 2.041 |

| 2 1/2 | 2.625 | 2.435 | 2.465 | 2.495 | - |

| 3 | 3.125 | 2.907 | 2.945 | 2.981 | 3.030 |

| 4 | 4.125 | 3.857 | 3.897 | 3.935 | 4.009 |

Note: Always cross-check with the official copper pipe dimensions chart or manufacturer datasheets for exact values, especially for less common sizes or specialty applications.

Field Measurement Checklist: Avoid Sizing Mistakes

- De-burr the cut pipe end for a clean surface.

- Use a pipe caliper or digital caliper to measure the OD (not just a tape measure).

- Compare your OD to the copper pipe diameter chart above or the manufacturer’s chart.

- Check the fitting type—press, solder, flare, or compression—to match the correct size.

- Repeat the measurement if in doubt—consistency is key!

By following these steps and referencing a reliable copper pipe size chart, you’ll minimize errors, speed up procurement, and ensure your fittings and tools are always the right match. Next, we’ll show you how these sizing choices impact pressure ratings, joining methods, and code compliance—so you can build safe, long-lasting systems every time.

Pressure Temperature And Code Compliance Guidance

Pressure And Temperature Basics For Copper

When you’re specifying a copper water line, copper gas line, or any other copper pipe system, pressure and temperature ratings are more than just numbers—they’re the backbone of safe, code-compliant design. Sounds complex? Let’s break it down. The working pressure a copper pipe can handle depends on three main factors: wall thickness (Type K, L, or M), temper (hard or soft), and the joining method you select. For example, type l copper pipe is a popular choice for interior water supply because it balances strength and workability, but its pressure rating drops as pipe diameter increases or as service temperature climbs.

Joining Methods And What They Do To Ratings

Imagine you’ve picked the perfect copper pipe for your project. Now, the way you join those pipes—soldering, brazing, press-connect, or even threaded copper pipe—directly impacts the system’s overall rating. Here’s a quick comparison of common joining methods, their service ranges, and key code references. Always verify exact values with manufacturer datasheets or standards for your specific installation.

| Joining Method | Typical Service Temp (°F) | Max Working Pressure* (psi) | Common Applications | Code/Standard Reference |

|---|---|---|---|---|

| Soldered Joint (Sn50, 95-5, etc.) | 100–250 | Up to 200 (1/2" size, Sn50 @ 100°F) | Potable water, hydronics | Copper Dev. Assoc. Table 14.4a |

| Brazed Joint (Alloys ≥1100°F) | Up to 250+ | See tube rating (often higher than soldered) | HVAC, medical gas, high-temp water | ASTM B88 |

| Press-Connect Fitting (EPDM, FKM, HNBR seals) | EPDM: 0–250 FKM: 14–284 HNBR: -40–180 |

Per fitting/listing (typically up to 200–300 psi) | Potable water, gas, hydronics, compressed air | ICC CodeNotes |

| Threaded Copper Pipe | Ambient–moderate | Lower than soldered/press (due to reduced wall at threads) | Specialty, repairs (rare for water/gas lines) | Refer to IPC/UPC, manufacturer |

*Refer to official tables and manufacturer specs for your exact pipe size, type, and alloy. A system's maximum allowable working pressure is determined by its weakest link, which is usually the joint. For example, while a 1/2" Type M copper pipe by itself can withstand over 400 psi at 100°F, if standard lead-free solder is used to connect it, the overall system's pressure rating will be limited to the 200 psi that the solder joint can withstand.

Code Pathways And Where To Verify

Codes such as the International Plumbing Code (IPC), Uniform Plumbing Code (UPC), and International Fuel Gas Code (IFGC) spell out how copper water line and copper gas line systems must be joined and rated. For example, press-connect fittings must be listed to ANSI LC-4/CSA 6.32 for gas piping above certain pressures, and potable water joints must meet NSF 372 for lead content. Always check the latest code edition and your local Authority Having Jurisdiction (AHJ) for any amendments.

- Confirm copper pipe type and wall thickness per ASTM B88 (K, L, M) or B306 (DWV)

- Identify joining alloy or press-fitting seal material and its temperature/pressure limits

- Verify code section in IPC/UPC/IFGC for your application (water, gas, hydronics)

- Consult your local AHJ for regional requirements or special approvals

Remember: The allowable pressure of any copper pipe system is limited by its weakest component—often the joint. Always size and select both pipe and joining method to meet or exceed your maximum system demands.

Understanding these fundamentals ensures safer system design and helps you pass inspections with confidence. Up next, we’ll dive into hands-on joining techniques and pro prep steps that keep your copper pipe and fittings leak-free and code-compliant.

Joining Copper With Confidence

Choosing The Right Copper Pipe Fittings

When you’re faced with a maze of copper pipe and fittings at the supply house, it’s easy to wonder: which joining method is best for your job? The answer depends on the application, code requirements, and your comfort with the tools. Let’s break down the most common methods for connecting copper fitting pipe—soldering, brazing, press-fit, flare, and compression—so you can choose with confidence.

| Method | Where Used | Pros | Cons |

|---|---|---|---|

| Soldering | Potable water, hydronics, general plumbing |

|

|

| Brazing | HVAC, medical gas, high-temp or high-pressure lines |

|

|

| Press-Fit (Press-Connect) | Potable water, hydronics, gas (with listed fittings) |

|

|

| Flare | Refrigeration, gas lines, select water connections |

|

|

| Compression | Temporary repairs, appliances, small-diameter lines |

|

|

Pro Prep for Solder, Brazing, and Press Fittings

Success with copper pipe and fittings starts long before you strike a match or pick up a press tool. Here’s how the pros prep for leak-free, inspection-ready joints—whether you’re working on copper fitting pipe for water or 3 8 copper tube fittings for refrigeration:

Soldering & Brazing Prep Sequence

- Cut pipe square using a pipe cutter.

- Deburr inside and outside edges for smooth flow.

- Clean pipe exterior and fitting interior until shiny (use emery cloth or wire brush).

- Apply a thin, even layer of flux to both mating surfaces.

- Assemble joint fully—pipe must bottom out in fitting.

- Heat fitting evenly with torch; apply solder when hot enough (for brazing, use appropriate alloy and higher heat).

- Allow joint to cool, then wipe away excess flux with a clean rag.

Tip: For potable water, always use lead-free solder and flux.

Press-Fit Prep Sequence

- Deburr both pipe ends carefully—no sharp edges to damage O-rings.

- Clean outside of pipe where fitting will seat.

- Mark fitting insertion depth on pipe for visual check.

- Insert pipe into press fitting, ensuring full engagement with O-ring.

- Align press tool jaws squarely and activate tool to complete the crimp.

- Check for visible press marks and confirm fitting is secure.

Press-connect systems are especially helpful in occupied buildings or where open flames pose a risk.

Inspection Day: What Pros Expect

Wondering what inspectors look for on copper pipework fittings? Here’s what you can expect:

- Clean, properly prepped joints—no excess flux, solder blobs, or visible gaps

- Correct fitting type and alloy for the application

- Press fittings installed per manufacturer’s instructions (depth marks visible, no missed crimps)

- Proper support and alignment of all copper pipe and fittings

- Absence of leaks after pressure test

Failing to meet these standards can mean costly rework or delays in project sign-off.

Troubleshooting: Leaks at Copper Fittings

Even with careful prep, leaks can happen. Use this quick checklist to resolve issues with copper tubing fittings or copper pipework fittings:

- Isolate the leaking section and turn off the water.

- Inspect for contamination, debris, or insufficient heat/press cycle.

- Disassemble and clean both pipe and fitting as needed.

- Re-make the joint, following the correct prep and joining steps for your chosen method.

- Retest for leaks before restoring full service.

By mastering these joining techniques and preparation steps, you’ll not only pass inspections but also extend the lifespan of your copper pipe and fittings. Next, let’s explore best practices for working with soft copper coils and linesets—so you’re ready for any installation scenario.

Best Practices For Soft Copper And Coils

Working With Soft And Coiled Copper

Ever tried to uncoil soft copper tubing for a new HVAC copper line set or water service, only to end up with frustrating kinks or a tangled mess? You’re not alone. Soft copper coils—like 1/4 copper tubing, 5/16 copper tubing, and larger sizes such as 7/8 copper tubing and 1 1/8 copper tubing—are staples in refrigeration, air conditioning, and underground water lines. But working with these coils requires a different approach than rigid pipe.

Uncoiling, Bending, And Spring Back

Imagine you’re installing a lineset for a mini-split system. The goal is a smooth, kink-free run that preserves refrigerant flow and system efficiency. Here’s how to do it right:

- Uncoil in a controlled arc: Lay the coil on the ground and unwind it slowly, forming a large arc rather than pulling straight—this prevents sharp bends and kinks.

- Use the right bending tools: For small sizes (like 1/4 or 5/16 copper tubing), a lever-type or spring tube bender gives precise results. Larger sizes (up to 1 1/8 copper tubing) often require a ratcheting tube bender or a mandrel matched to the OD. This ensures a consistent radius and reduces the risk of collapse or flat spots. (AC Service Tech)

- Mind the minimum bend radius: As a rule of thumb, keep bends no tighter than three times the tube’s OD to avoid kinking and flow restriction. For example, a 7/8 copper tubing line should be bent with a radius of at least 2-5/8 inches. Always check manufacturer recommendations for the specific product you’re using.

- Manage spring-back: After bending, copper coils tend to spring back slightly. Always bend just past your target angle, then release slowly for an accurate finish.

- Avoid reverse bends near flare seats: Too many bends close together can weaken the tube, especially near connections.

Storage, Transport, And Finish Protection

Soft copper coils are easy to damage if handled carelessly. Picture a lineset left unprotected on a jobsite—dirt, moisture, or a stray footstep can ruin the finish or introduce debris. Here’s how to keep your copper coils in top shape:

- Protect from chemicals: Keep coils away from chloride cleaners, concrete, or corrosive materials that can cause pitting or stress corrosion.

- Cap ends immediately: After cutting, always cap both ends to prevent dirt or moisture from entering. This is especially critical for HVAC copper line sets, where even small contamination can impact long-term performance.

- Tag coils with type and size: Use a permanent marker or tag to identify the type (K, L, etc.) and nominal size. This helps avoid costly mix-ups on site.

- Store in a dry, secure area: Keep coils off the ground and covered to prevent accidental damage or corrosion.

Line cleanliness is critical: Any debris or contamination inside copper coils can lead to HVAC compressor failure or plumbing water quality issues. Always keep lines capped and clean from start to finish.

Proper handling of soft copper coils ensures every copper line set, from 1/4 copper tubing to 1 1/8 copper tubing, performs as designed—delivering reliable, efficient service for years. Next, we’ll help you match the right copper type and size to your application, so you can buy or specify with total confidence.

Buyer Guide And Sizing Decision Matrix

Decision Matrix For Copper And Alternatives

When you’re ready to buy copper pipe or specify a system, the options can seem overwhelming. Should you choose Type K, L, or M? Would PEX or CPVC be a better fit for your budget or installation needs? Let’s break it down so you can make the right call for your job—without second guessing your decision later.

| Material/Type | Common Applications | Joining Complexity | Typical Tools Needed | Service Temp. Range | Relative Material Cost | Notes |

|---|---|---|---|---|---|---|

| Type K Copper | Underground water service, high-pressure HVAC, fire protection | Moderate-High (solder, press, or flare) | Pipe cutter, torch/press tool, deburrer | -40°F to 400°F | $$$$ (Highest) | Thickest wall, longest lifespan, code-preferred for buried lines |

| Type L Copper | Interior potable water, hydronics, HVAC line sets | Moderate (solder, press, or flare) | Pipe cutter, torch/press tool, deburrer | -40°F to 400°F | $$$ | Balance of strength and cost, most common for above-ground use |

| Type M Copper | Residential potable water (where allowed), hydronic heating | Moderate (solder, press) | Pipe cutter, torch/press tool, deburrer | -40°F to 400°F | $$ | Thinnest wall, check local code before use |

| PEX | Potable water, radiant floor, service lines | Low (crimp, clamp, push-fit) | PEX cutter, crimp/clamp tool | -40°F to 200°F | $ | Flexible, fastest install, not UV stable |

| CPVC | Potable water, hydronics | Low (solvent weld) | Plastic cutter, solvent cement | Up to 200°F | $ | Lightweight, easy DIY, lower impact resistance |

Selecting Diameter For Flow And Pressure Drop

Sounds complex? Here’s a simple approach: start by counting the number of fixtures (sinks, showers, etc.) your pipe will serve. Use code tables to estimate the total flow demand in gallons per minute (GPM). Then, consult a pressure-loss chart for your chosen copper type and size—for example, from the Copper Tube Handbook—to ensure the pipe diameter you select will keep pressure loss within acceptable limits all the way to the farthest fixture. If the pressure drop is too high, upsize the pipe.

For critical applications, such as long runs or high-demand systems, always double-check your calculations and consider upsizing to maintain performance. This step helps you avoid callbacks and ensures your system passes inspection the first time.

Budgeting And Total Cost Considerations

Budget is often the deciding factor when you buy copper pipe or choose an alternative. But don’t just look at the sticker price—factor in installation, lifespan, and maintenance. Here’s a quick checklist to help you estimate the true cost of your plumbing system:

- Material cost: Copper pipe price per foot typically ranges from $2 to $4, while PEX and CPVC can cost less than $2 per foot. Always verify the latest copper pipe price with your supplier, as the cost of copper pipe per foot can fluctuate based on market demand and global supply chains.

- Labor cost: Copper installation requires skill (soldering, precise measurements), often resulting in higher labor charges compared to PEX or CPVC, which are easier and faster to install.

- Tool investment: Soldering and press tools for copper add upfront costs, while PEX and CPVC tools are generally less expensive.

- Longevity: Copper’s average lifespan is 50+ years, often outlasting PEX or CPVC (20–30 years). This means lower replacement frequency and better long-term value.

- Maintenance and repairs: Copper is less likely to leak or burst, especially in freezing conditions, and is more resistant to UV and chemical degradation than plastic alternatives.

- Health and environment: Copper is antimicrobial and recyclable, with minimal risk of water contamination or plastic leaching—important for potable water systems.

When comparing the copper plumbing pipe price to alternatives, remember that copper’s durability, reliability, and resale value may justify a higher initial investment. And if you’re looking to save, consider recycled copper for certain applications or check with local suppliers for the best copper pipe price per foot.

"Choosing the right copper pipe type and size means balancing up-front cost, installation complexity, and long-term reliability—always confirm copper tubing cost and code compliance before you buy."

With these considerations in mind, you’re ready to specify, budget, and buy copper pipe with confidence. Next, we’ll walk you through the actionable steps for prototyping and sourcing copper components to ensure your project is a success from design to installation.

Actionable Next Steps And Prototyping Resources

From Specification To Prototype And Production

When your copper pipe system design is nearly complete, the final steps can make or break your project’s success. Ever wondered how top pros ensure their installations go smoothly from the drawing board to the jobsite? It starts with a clear, standards-driven process—one that minimizes rework, avoids costly mistakes, and keeps your project code-compliant from the start.

- Confirm copper type and grade per ASTM standards: Double-check that your selected copper pipe matches the application’s requirements for pressure, wall thickness, and environment. For potable water and HVAC, ASTM B88 is the go-to reference.

- Finalize joining method: Choose soldering, brazing, press-fit, or mechanical connections based on code, service conditions, and available tools.

- Prepare a dimensioned drawing: A detailed layout showing pipe runs, fitting types, and support locations helps avoid confusion during installation and speeds up procurement from copper pipe suppliers.

- Request DFM (Design for Manufacturability) feedback: Before fabrication or prototyping, seek expert input to optimize wall thickness, tolerances, and joint details—especially if you’re integrating custom brackets, manifolds, or valves that must mate with copper tube sizes.

Always validate the weakest-link rating of your copper assembly—pressure, temperature, and joining method must all align for a system that passes inspection and stands the test of time.

DFM Feedback For Faster First Pass Success

Imagine catching costly mistakes before they hit the field. That’s the value of DFM feedback—especially when prototyping custom copper-compatible components or tooling. If you need rapid, high-quality prototypes for brackets, manifolds, or joining fixtures, consider leveraging advanced services like XTJ’s Rapid Prototyping. Their engineers specialize in CNC machining, injection molding, and die casting for both metals and plastics, providing complimentary DFM reviews to ensure your parts will fit and function with standard copper tube and pipe dimensions. This step is crucial whether you’re working with a large copper pipe company or producing a one-off solution for a specific job.

Trusted Resources And Datasheets To Bookmark

With your specs, drawings, and DFM feedback in hand, you’re ready to source materials and components. But where do you turn for reliable copper pipe manufacturers or technical guidance? Here’s a curated list of resources to streamline your search and boost confidence in every purchase:

- XTJ Rapid Prototyping Services – For fast, DFM-optimized prototypes and custom copper-compatible parts

- ASTM B88 Standard – The definitive guide for copper water tube requirements

- Top Copper Pipe Manufacturers in the USA – A comprehensive list of leading copper pipe suppliers and copper tube manufacturers

- United Copper Industries – Noted for building wire and copper products in the US market

- Cerro Flow Products – A major copper tube supplier with technical resources and product datasheets

- Copper Development Association: Copper Tube Handbook – For sizing charts, joining methods, and code references

Whether you’re sourcing from established copper pipe manufacturers, working with a copper tube supplier for specialty applications, or seeking technical support from a copper pipe company, these resources will help you make informed, reliable choices.

By following these actionable steps—confirming standards, leveraging expert DFM feedback, and sourcing from trusted copper pipe suppliers—you’ll set your project up for success from prototype to final installation. And with industry leaders like United Copper Industries and Cerro Flow Products providing technical support and quality assurance, you can specify and install copper piping systems with total confidence.

Frequently Asked Questions About Copper Pipe

1. Why are copper pipes sometimes restricted or considered problematic?

Copper pipes can be restricted in certain regions due to concerns over water chemistry and potential leaching. If water is too acidic or soft, it may cause copper to dissolve, impacting both water quality and pipe longevity. Regulatory measures, like the Lead and Copper Rule, help ensure safe drinking water by monitoring these risks.

2. Are copper water pipes safe for use in homes?

Yes, copper water pipes are generally safe and widely used for potable water systems. Their natural antimicrobial properties and durability make them a top choice. However, water chemistry should be checked to avoid corrosion, and proper installation is key to maintaining water quality.

3. What are the main types of copper pipe and where are they used?

The main types are Type K, Type L, Type M, and DWV copper tubing. Type K is used for underground service lines, Type L is common for interior water supply and HVAC, Type M is for low-pressure residential use, and DWV is for drain, waste, and vent systems. Always confirm local code requirements before selecting a type.

4. How do I choose the correct copper pipe size for my project?

Start by measuring the outside diameter (OD) of the pipe. Use a copper pipe size chart to match OD with the correct type and application. Consider flow requirements, pressure drop, and code compliance when selecting diameter, and always double-check with manufacturer datasheets for precise sizing.

5. Where can I find reliable copper pipe suppliers and technical resources?

Reputable copper pipe suppliers include United Copper Industries and Cerro Flow Products. For technical guidance, consult the Copper Development Association's Copper Tube Handbook or ASTM B88 standards. For rapid prototyping of custom copper-compatible parts, XTJ offers DFM-optimized solutions tailored to your needs.

-

Posted in

copper fittings, copper pipe, copper tubing, pipe sizing, plumbing materials