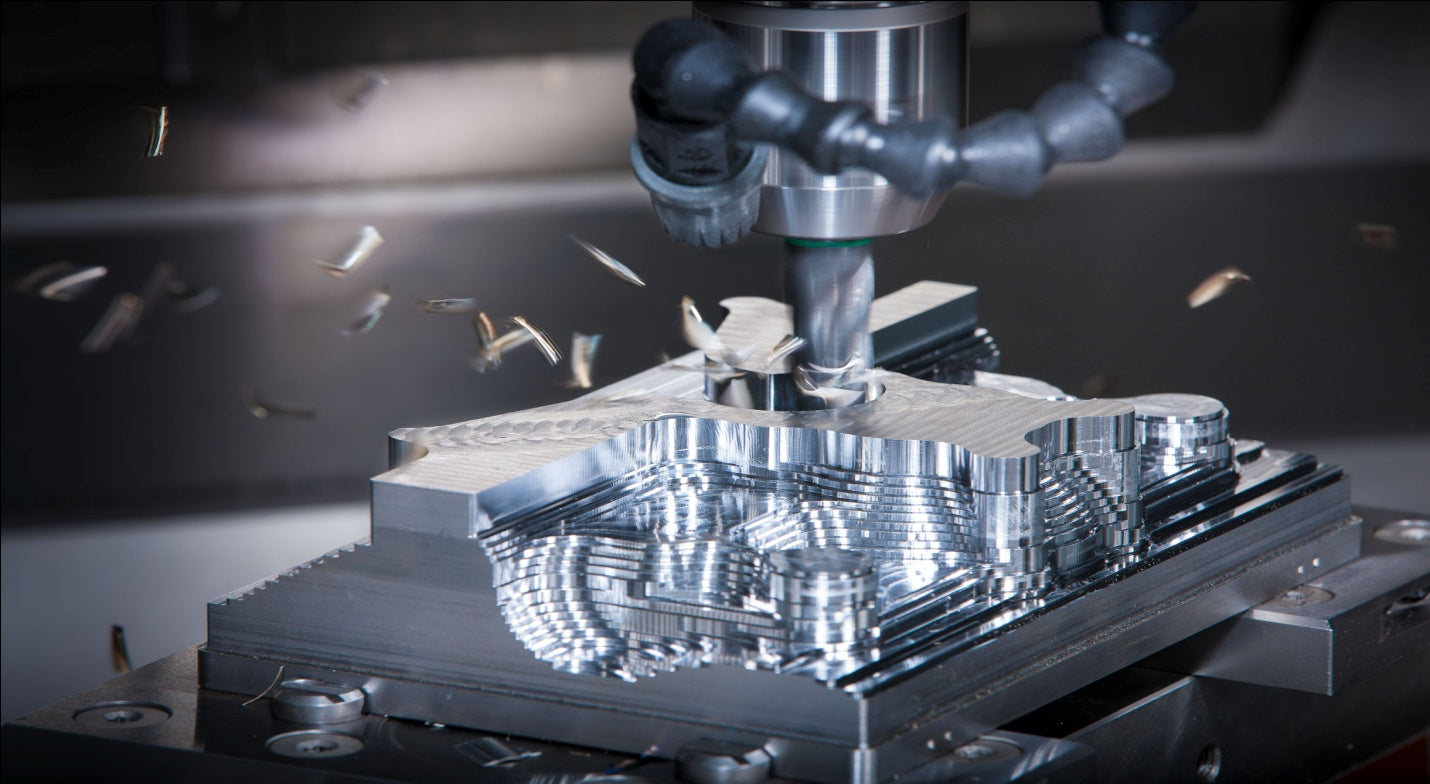

The Advantages of High-Speed Milling Aluminum

Higher Efficiency

By tripling cutting speeds compared to conventional aluminum milling, feed rates can be doubled (for softer aluminum alloys). Machining feed rate is recognized as the defining parameter for overall milling process productivity. Consequently, high-speed machining demonstrates significantly higher efficiency versus conventional milling. The machinability of aluminum allows spindle speeds reaching 18,000 rpm or beyond.

Such high material removal rates (MRR) position aluminum machining services as highly profitable solutions for automotive and aerospace industries. In automotive applications, prototype manufacturing requires extensive material removal with minimal milling setups. For aerospace components, numerous large-scale parts feature deep pockets and thin-walled structures – with aluminum alloys constituting up to 80% of aircraft and rocket components.

Lower Cutting Temperature

It has been empirically demonstrated that cutting temperature exhibits nonlinear variation with increasing speed. Initially, temperature rises proportionally to speed elevation. However, as speeds continue beyond a critical threshold, temperature plummets precipitously until stabilizing asymptotically. Further speed increases yield diminishing thermal reduction returns.

For illustration:

-

At 300-500 m/min milling speeds, temperatures reach 600-800°C

-

When speed increases to 1200 m/min, temperature drops below 200°C

-

At 1800 m/min, temperature stabilizes at merely 150°C

Beyond this velocity plateau, additional acceleration becomes thermodynamically impractical.

Consider the implications: a remarkable 150-200°C range! This enables:

① Prevention of material property alterations in cutting zones (eliminating localized heat treatment effects)

② Suppression of metal grain growth

③ Drastically reduced coolant requirements

This represents a significant technological advantage.

Longer Cutting Tools Life

This phenomenon appears counterintuitive – conventional wisdom suggests higher cutting speeds should accelerate tool wear. However, when comparing the actual volume of aluminum removed per tool in HSM versus conventional milling, the disparity becomes evident. Rather than reducing tool life to minutes, HSM demonstrates superior longevity. The underlying mechanisms include:

-

Thermal Advantage:

Reduced cutting temperatures (150-200°C vs. 600-800°C) preserve tool material integrity:-

Hardness retention of carbide substrates above 85% (vs. <60% at 800°C)

-

Prevention of diffusion wear mechanisms

-

-

Chip Geometry Transformation:

-

Radically thinner chips despite increased feed rates:

Chip thickness (h<sub>m</sub>) ∝ Feed per tooth (f<sub>z</sub>) / Cutting speed (V<sub>c</sub>) -

At 3× speed with doubled feed:

*h<sub>m_HSM</sub> ≈ (2f<sub>z</sub>) / (3V<sub>c</sub>) = 0.67 × h<sub>m_conventional</sub>*

-

-

Tribological Effects:

-

Reduced tool-chip contact time (< 0.1 ms at 18,000 rpm)

-

Lower coefficient of friction at elevated sliding velocities

-

Engineering Analysis:

▶️Thermal Management Mechanism

| Parameter | Conventional Milling | HSM Aluminum | Benefit |

|---|---|---|---|

| Cutting Temp | 600-800°C | 150-200°C | ↓ 70-75% thermal softening |

| Tool Hardness | < 60% of room temp | > 85% of room temp | ↓ Abrasive wear |

| Diffusion Rate | High (TiC dissolution) | Negligible | ↓ Crater wear |

▶️ Chip Thinning Dynamics

-

Mathematical Model:

h_m = f_z \cdot \sin(\kappa) \cdot \left[ \frac{V_c}{N \cdot z \cdot \pi D} \right]

-

Where:

-

κ = Approach angle (typically 90°)

-

N = Spindle speed (rpm)

-

z = Number of teeth

-

D = Tool diameter

-

-

Operational Impact:

-

67% thinner chips reduce cutting forces by 40-50%

-

Lower shear plane energy dissipation

-

▶️ Wear-Reduction Synergy

On the other hand, a critical challenge in aluminum machining is material adhesion – the soft alloy tends to weld onto cutting edges, forming built-up edges (BUE). This compromises tool sharpness, increases cutting forces, and accelerates tool failure. Significantly, this phenomenon is substantially suppressed under high-speed conditions.

Higher Precision

We all assume that higher feed rates produce a less polished surface finish on aluminum because the tool's cutting edge travels farther while the tool turns and cuts off. This typically results in wider chips, higher cutting forces, and a poorer surface finish. However, in HSM, despite the high feed rate, the tool speed is higher, so the chips are actually thinner than in conventional milling.

Constant Tool Engagement Angle

One of the main challenges when milling cavities with end mills is creating the cavity angle. The end mill must rotate 90 degrees to create the cavity, and in doing so, it must remove twice as much material (from both sides of the cavity). This results in locally increased cutting forces, which is detrimental to tool life and part accuracy. However, HSM aluminum milling features a number of predefined toolpath generation strategies, including one with a constant tool engagement angle. This means the tool gradually approaches the angle while machining all material around it in a circular trajectory. This keeps cutting forces constant, maintaining accuracy, and extending tool life.

Less Cooling Usage

Some HSM strategies for aluminum machining use no coolant at all. Machining at 200 degrees Celsius requires virtually no cooling of the material or tool. However, some extremely precise operations still use coolant to improve part quality, but the amount is much smaller than in conventional machining. Some aluminum high-speed milling processes use so-called minimum quantity lubrication. The amount of coolant applied is just enough to form a thin film, thereby reducing friction and providing some cooling.

Thus, it's clear that high-speed aluminum milling is an innovative production method for manufacturing custom parts, aluminum prototypes, and small-batch production.