Titanium Grade 5 CNC Parts: A Professional Machining Guide

TL;DR

Titanium Grade 5 (Ti-6Al-4V) CNC parts are components machined from the most popular titanium alloy, renowned for its exceptional strength-to-weight ratio, durability, and corrosion resistance. This makes it a premier material for high-performance applications. Industries like aerospace, medical, and automotive rely on Grade 5 titanium for critical parts, including aircraft components, surgical implants, and high-performance engine parts where failure is not an option.

Understanding Grade 5 Titanium (Ti-6Al-4V): Properties and Benefits

Grade 5 titanium, also known by its chemical designation Ti-6Al-4V, is the most widely used titanium alloy in the world. The name itself reveals its composition: an alloy of titanium with approximately 6% aluminum and 4% vanadium. This specific blend classifies it as an alpha-beta alloy, giving it a balanced set of properties that are superior to commercially pure titanium grades. It's crucial to note that the terms 'Grade 5 titanium' and 'Ti-6Al-4V' are used interchangeably in the industry to refer to the exact same material.

The primary advantage of Grade 5 titanium lies in its remarkable material characteristics. It offers the tensile strength of many steels but at roughly half the weight, providing an unparalleled strength-to-weight ratio. This property alone makes it indispensable for applications where minimizing weight is as critical as maximizing strength. Furthermore, its ability to form a stable, protective oxide layer on its surface grants it outstanding corrosion resistance, particularly against seawater and various chemical agents. Unlike commercially pure titanium, Grade 5 can also be heat-treated to further increase its strength.

To provide a clearer picture for engineers and designers, here are some of the key mechanical properties of Ti-6Al-4V:

| Property | Value |

|---|---|

| Ultimate Tensile Strength | ~138 ksi (950 MPa) |

| Yield Strength | ~128 ksi (880 MPa) |

| Density | ~4.43 g/cm³ |

| Hardness | ~36 HRC (Rockwell C) |

| Modulus of Elasticity | ~16,500 ksi (113.8 GPa) |

Note: Exact values can vary based on processing and heat treatment.

These properties translate into tangible benefits: parts that are lightweight yet incredibly strong, durable enough to withstand extreme environments, and biocompatible, making them safe for medical use inside the human body. This combination of features justifies its use in some of the most demanding fields of engineering and manufacturing.

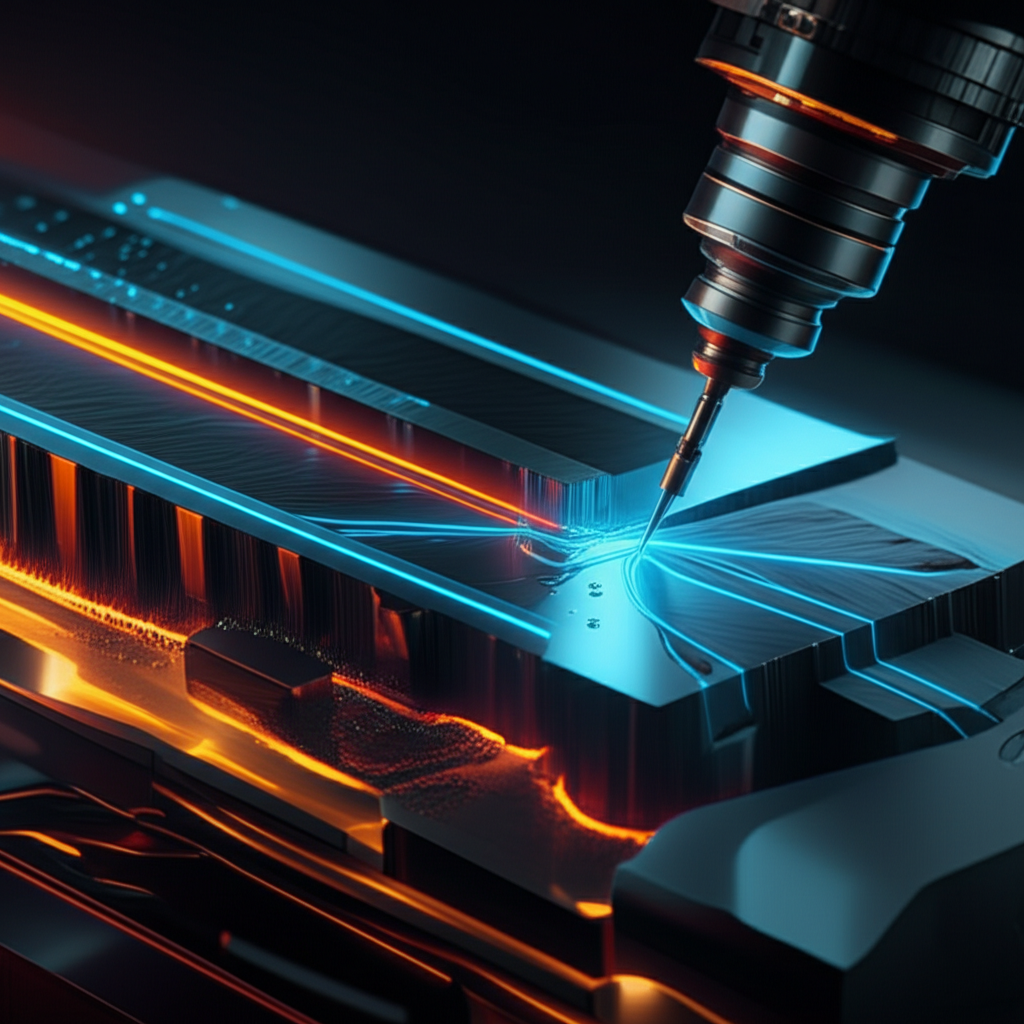

The CNC Machining Process for Grade 5 Titanium

While the properties of Grade 5 titanium are exceptional, they also make it a challenging material to machine. Its high strength, low thermal conductivity, and chemical reactivity at high temperatures require specialized knowledge, tools, and techniques. The material's low thermal conductivity is a primary concern; heat generated during cutting does not dissipate quickly through the workpiece or chips, instead concentrating on the cutting tool. This can lead to rapid tool wear, deformation, and even welding of chips to the tool edge.

Successfully machining titanium involves a careful balance of several factors. Key strategies include using low cutting speeds but maintaining high feed rates to minimize heat buildup. It is also critical to use sharp, tough cutting tools, often made from specific carbide grades with specialized coatings, to withstand the abrasive nature of the material. A constant and high-volume flow of coolant is essential to manage temperature at the cutting interface and flush away chips effectively. Furthermore, the machine tool itself must be rigid and robust to handle the high cutting forces and prevent vibrations that can compromise surface finish and dimensional accuracy.

Given these complexities, partnering with an experienced manufacturing service is crucial for achieving high-quality results. For projects requiring rapid turnaround without compromising on precision, services like XTJ offer advanced capabilities. They utilize 4 and 5-axis CNC machining centers to produce complex parts with tight tolerances, often with lead times as short as a few days. Their expertise in handling difficult materials like titanium ensures that components for demanding sectors such as aerospace and medical meet stringent quality standards.

Common Applications and Industries for Grade 5 Titanium Parts

The unique combination of high strength, low weight, and excellent corrosion resistance makes Grade 5 titanium the material of choice for numerous critical applications across various industries. Its performance under extreme conditions ensures reliability where other materials would fail.

In the aerospace and defense sector, Ti-6Al-4V is extensively used for airframe structural components, landing gear, and high-performance engine parts like blades, discs, and rings. Every pound saved on an aircraft translates to increased payload capacity and fuel efficiency, making titanium's strength-to-weight ratio invaluable. Its ability to withstand high temperatures also makes it suitable for components in and around the engine.

The medical industry relies heavily on Grade 5 titanium for its biocompatibility and non-toxic nature. The material does not react with the human body, making it ideal for surgical implants such as hip and knee replacements, bone screws and plates, and dental implants. Its strength ensures these implants can withstand the stresses of daily life for decades.

In the automotive world, particularly in high-performance and racing vehicles, Grade 5 titanium is used for components like connecting rods, valves, and exhaust systems. These parts reduce overall vehicle weight and reciprocating mass in the engine, allowing for higher RPMs and improved performance. Its durability and heat resistance are also beneficial in these demanding environments. Finally, its superior resistance to saltwater makes it a prime material for marine applications, including propeller shafts, rigging, and subsea equipment that face constant corrosive exposure.

Design Considerations for Optimal Grade 5 CNC Parts

Designing parts for manufacturability (DFM) is always important, but it becomes critical when working with a challenging and costly material like Grade 5 titanium. Adhering to specific design principles can significantly reduce machining time, lower costs, and improve the final quality of the component. Engineers and designers should consider the following points to optimize their designs for titanium CNC machining.

- Generous Corner Radii: Sharp internal corners are difficult and time-consuming to machine and create stress concentrations in the final part. Using the largest possible corner radii reduces tool stress, allows for faster cutting speeds, and results in a stronger component.

- Maintain Uniform Wall Thickness: Thin walls can be prone to vibration and warping during machining due to heat buildup. Designing parts with consistent and sufficient wall thickness (a common recommendation is a minimum of 0.75-1.0 mm) helps ensure stability and dimensional accuracy.

- Avoid Deep, Narrow Pockets: Machining deep and narrow features requires long, slender tools that are susceptible to deflection and breakage. This slows down the machining process significantly. Whenever possible, design pockets to be wider and shallower to allow for the use of more rigid cutting tools.

- Specify Tolerances Wisely: While CNC machining can achieve very tight tolerances, not every feature requires them. Unnecessarily tight tolerances dramatically increase machining time and inspection costs. Apply precision only where it is functionally necessary to keep the part cost-effective.

- Consider Surface Finish Requirements: A standard machined finish is often sufficient for many applications. Requesting highly polished or exceptionally smooth surfaces adds significant time and cost through additional machining passes or post-processing steps. Specify a higher-grade finish only when required for functional or aesthetic reasons.

Achieving Excellence with Titanium Machining

Successfully producing high-quality titanium Grade 5 CNC parts is a testament to engineering and manufacturing excellence. It requires a deep understanding of the material's unique properties, a mastery of specialized machining techniques, and a design-for-manufacturability approach. From its foundational role in aerospace to its life-changing applications in medicine, Ti-6Al-4V continues to be a cornerstone of modern high-performance technology.

By appreciating both its benefits and its challenges, engineers can fully leverage this remarkable alloy. Partnering with a skilled machining provider who possesses the right equipment and expertise is the final, critical step in transforming a complex design into a durable, lightweight, and precise component ready to perform in the most demanding environments.

Frequently Asked Questions

1. What is the difference between Ti-6Al-4V and Grade 5 titanium?

There is no difference; the terms are synonymous. Ti-6Al-4V is the chemical name for the alloy, indicating it is composed of approximately 6% aluminum and 4% vanadium. Grade 5 is the most common industry designation for this specific alloy, recognized as the workhorse of the titanium industry.

2. Is Grade 5 titanium hard to machine?

Yes, Grade 5 titanium is considered difficult to machine compared to materials like aluminum or steel. Its hardness, low thermal conductivity (which traps heat in the cutting zone), and tendency to work-harden present significant challenges. Successful machining requires specialized tools, rigid machinery, low cutting speeds, and aggressive cooling strategies to manage heat and prevent premature tool failure.

3. What makes Grade 5 different from other titanium grades?

The primary difference lies in composition and properties. Grades 1 and 2, for example, are commercially pure titanium, which makes them more ductile and easier to form but lower in strength. Grade 5 is an alloy that includes aluminum and vanadium, which significantly increases its strength and allows it to be heat-treated for even higher performance, while still retaining excellent corrosion resistance and a favorable strength-to-weight ratio.