Anodizing Type II Finish: A Technical Specification Guide

TL;DR

Anodizing Type II finish, commonly known as sulfuric acid anodizing, is an electrochemical process governed by the MIL-A-8625 standard. It creates a durable, corrosion-resistant, and aesthetically versatile oxide layer on aluminum surfaces. This finish is prized for its balance of protection and decorative possibilities, offering good wear resistance and an ideal surface for a wide range of colors.

What Is Type II Anodizing? (MIL-A-8625)

Type II anodizing is an electrochemical process that enhances the natural oxide layer on aluminum parts to provide superior protection and an improved surface for finishing. Often referred to as 'conventional' or 'sulfuric acid' anodizing, the process is precisely defined under the military specification MIL-A-8625. This standard is the benchmark for ensuring quality and consistency in the aerospace, military, and commercial industries.

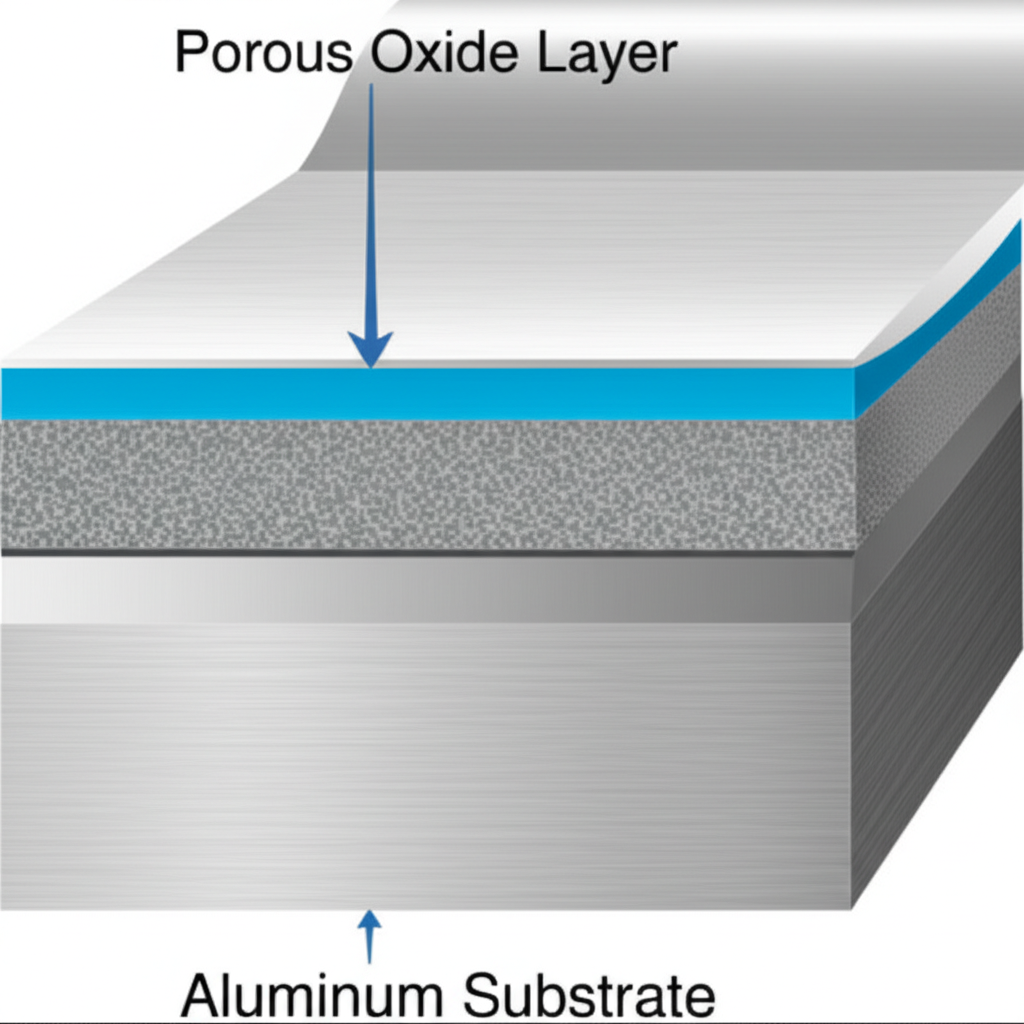

The process involves immersing an aluminum component into a bath of sulfuric acid electrolyte. The aluminum part acts as the anode (the positive electrode), and when a direct electrical current is passed through the bath, an anodic oxide finish begins to form. This controlled oxidation builds a porous, highly regular layer of aluminum oxide that is integral to the substrate. As detailed in a guide by PFI Inc., this layer grows both into the aluminum and out from its surface, ensuring exceptional adhesion and durability.

Unlike a simple coating like paint, the anodized layer is a conversion of the base metal itself, making it far more resistant to chipping and peeling. The entire process is typically conducted at a controlled temperature, around 70°F (21°C), which allows for the formation of a moderately thick, yet highly functional, protective layer.

Key Characteristics: Thickness, Corrosion Resistance, and Aesthetics

The performance and application of a Type II anodizing finish are defined by a few critical characteristics. These properties make it one of the most versatile and widely specified finishes for aluminum components across various industries.

Coating Thickness

A primary specification for Type II anodizing is its coating thickness. The oxide layer typically ranges from 2.5 to 25 micrometers (µm), which is equivalent to 0.0001 to 0.001 inches. According to Precision Coating, this thickness is sufficient to provide significant protection without drastically altering the part's final dimensions, a crucial factor for components with tight tolerances.

Corrosion and Wear Resistance

The primary function of anodizing is to protect the underlying aluminum from corrosion. The dense, hard layer of aluminum oxide acts as a robust barrier against moisture, salt spray, and other environmental factors that would otherwise cause the metal to degrade. While not as hard as Type III hardcoat, a Type II finish offers good wear resistance suitable for most consumer and industrial applications, protecting parts from scratches and minor abrasion during normal use.

Aesthetic and Decorative Options

One of the most significant advantages of Type II anodizing is its suitability for coloring. The porous structure of the newly formed oxide layer is excellent at absorbing and retaining dyes. This allows for an almost limitless spectrum of colors, from clear and black to vibrant reds, blues, and golds. This decorative flexibility makes it a popular choice for consumer electronics, architectural elements, and sporting goods where brand identity and appearance are paramount.

Comparison: Type II vs. Type III Anodizing

While both Type II and Type III anodizing use a sulfuric acid process under the MIL-A-8625 specification, they produce fundamentally different outcomes. Type II is considered conventional or decorative, while Type III is known as hardcoat anodizing, engineered for extreme performance. The choice between them depends entirely on the application's demands for hardness, wear resistance, and appearance.

The primary differences stem from the process parameters. Type III hardcoat anodizing is performed at lower temperatures (near freezing) and higher current densities. This creates a much thicker, denser, and harder oxide layer. Below is a direct comparison of their key attributes.

| Attribute | Type II Anodizing (Conventional) | Type III Anodizing (Hardcoat) |

|---|---|---|

| Process | Sulfuric acid bath at ambient temperature (~70°F) | Sulfuric acid bath at low temperature (~32°F) with higher voltage |

| Typical Thickness | 0.0001" – 0.001" (2.5 – 25 µm) | 0.001" – 0.004" (25 – 100 µm) |

| Hardness & Wear Resistance | Good; suitable for moderate wear applications | Excellent; approaches the hardness of case-hardened steel |

| Appearance & Color | Excellent for dyeing; wide range of vibrant colors available | Limited color options, often resulting in dark gray or bronze tones |

As outlined in a detailed comparison by Protolabs Network, Type II is ideal for applications where aesthetics and corrosion resistance are the primary goals. In contrast, Type III is specified for components in high-wear environments, such as pistons, gears, and military hardware, where mechanical durability is more critical than color options.

Understanding Anodizing Classes: Class 1 vs. Class 2

Within the Type II anodizing specification, there is a further distinction between Class 1 and Class 2. This classification does not relate to the anodizing process itself but rather to the final finish—specifically, whether it is dyed or not. Understanding this difference is crucial for accurately specifying a finish for a project.

- Class 1 - Non-dyed: A Class 1 finish is clear or undyed. The final appearance is a natural, frosty metallic look that showcases the aluminum itself. This class is often chosen for its excellent UV resistance and when the natural appearance of the metal is desired.

- Class 2 - Dyed: A Class 2 finish is one that has been colored using organic or inorganic dyes. This is the classification for all colored anodized parts, from standard black to custom hues. The dye is absorbed into the pores of the oxide layer and then sealed in, providing a durable and attractive color.

It's important not to confuse these MIL-A-8625 classes with the architectural designations from the Aluminum Association, which define Class I and Class II based on coating thickness for exterior durability. For parts specified under MIL-A-8625, the distinction is simply clear (Class 1) versus colored (Class 2).

Common Applications of Type II Anodized Finishes

The unique combination of durability, corrosion resistance, and aesthetic flexibility makes Type II anodizing a preferred finish across a vast range of industries and products. Its ability to provide reliable protection while enhancing visual appeal ensures its use in both functional and decorative roles.

- Architectural Components: Used on window frames, facades, and building trim for long-lasting color and resistance to weathering.

- Electronics: Found on the casings of laptops, smartphones, and other devices, providing a durable, non-conductive, and premium-feeling finish.

- Automotive Parts: Applied to trim, wheels, and various engine components for a combination of corrosion protection and aesthetic appeal.

- Medical Devices: Used for instrument housings and components that require sterilization and resistance to corrosion from cleaning agents.

- Consumer Goods: Widely used on products like high-end flashlights, cookware, sporting equipment, and keychains for its vibrant color options and durability.

For instance, high-precision manufacturers of custom components for these industries often specify Type II finishes. Companies like XTJ CNC Machining rely on this process for parts requiring both protection and a high-quality appearance on materials handled by their advanced machining centers.

Frequently Asked Questions

1. What is the difference between Class 1 and Class 2 anodized finish?

Under the MIL-A-8625 standard, the difference is straightforward: Class 1 refers to a non-dyed, clear anodized coating, while Class 2 refers to a coating that has been dyed with a specific color. Class 1 is valued for UV stability, whereas Class 2 offers broad aesthetic options.

2. What is the difference between Type II and Type III anodizing?

The main difference lies in the thickness and hardness of the coating. Type II is a conventional anodize with a thinner coating suitable for decoration and general corrosion resistance. Type III, or hardcoat, is produced at colder temperatures to create a much thicker, harder, and more wear-resistant layer for high-performance applications, though it has limited color options.

3. How thick is Type II Class 2 anodizing?

The thickness for a Type II anodized finish, whether it's Class 1 (clear) or Class 2 (dyed), typically ranges from 2.5 micrometers to 25 micrometers (0.0001" to 0.001"). The specific thickness within this range is chosen based on the part's application and required level of corrosion resistance.