Bead Blasting Metal Finishing: A Guide to Satin Surfaces

TL;DR

Bead blasting is a metal finishing process that uses fine, spherical media like glass beads, propelled by high-pressure air, to clean or finish a surface. This technique creates a uniform, non-directional satin or matte finish by gently peening the surface rather than abrading it. It is highly effective for removing cosmetic defects, cleaning parts, and preparing surfaces for coatings without significantly altering a component's dimensions.

The Fundamentals of Bead Blasting: Process and Purpose

Bead blasting is a specialized abrasive blasting technique where fine, spherical media are propelled against a substrate to alter its surface characteristics. Unlike more aggressive methods that use sharp, angular abrasives, bead blasting employs round particles, such as glass beads, to create a smooth, clean, and uniform finish. The process works by creating thousands of tiny, consistent dimples on the surface, which scatters light to produce a distinctive satin or matte appearance. This method is valued for its ability to clean and finish parts without removing a significant amount of the underlying material, preserving critical dimensions and tolerances. According to experts at Xometry, this makes it ideal for finishing precision components.

The primary purpose of bead blasting extends beyond simple aesthetics. It is widely used for deburring, removing rust and scale, cleaning away contaminants, and hiding surface imperfections left by manufacturing processes like machining. The peening action of the spherical media can also impart a compressive stress layer on the surface of metal parts, which can increase resistance to fatigue and stress corrosion cracking. This makes the process not only a cosmetic treatment but also a functional one that can enhance the durability of components in demanding applications.

The operational sequence for bead blasting is straightforward yet requires careful control to achieve consistent results. The process typically involves these key stages:

- Surface Preparation: Before blasting, the component must be thoroughly cleaned to remove any oils, grease, or heavy dirt. For some materials, like aluminum, it's crucial to first strip away hard oxide layers using a sharper abrasive, as glass beads are designed to polish, not cut.

- Blasting: The part is placed inside an enclosed blast cabinet. The operator then directs a nozzle, which propels the bead media using compressed air, across the part's surfaces. Consistent motion and distance are key to achieving a uniform finish.

- Media Selection: The operator chooses the media type and size based on the material and desired finish. Finer beads create a smoother, more satin-like appearance, while coarser beads produce a rougher texture.

- Post-Treatment Cleaning: After blasting, the part is cleaned to remove any residual media particles. This is especially critical for components with internal passages or those that will be used in sensitive applications like medical devices or engines.

Equipment and Media: The Tools of the Trade

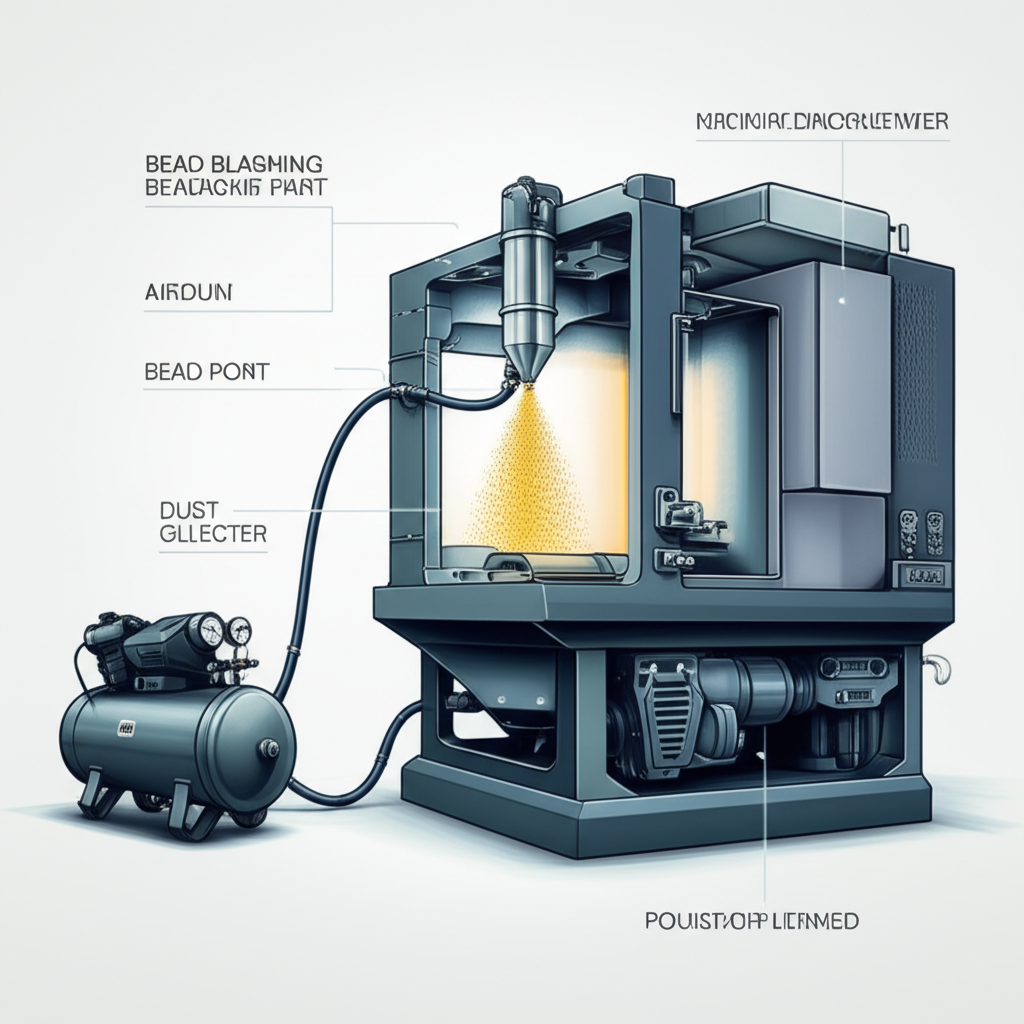

Achieving a high-quality bead blast finish depends on using the right equipment and selecting the appropriate blasting media. The central piece of equipment is the bead blaster cabinet, an enclosed system designed for safety and efficiency. These cabinets contain the abrasive media, prevent dust and debris from escaping into the workplace, and allow the operator to handle parts safely via integrated, heavy-duty gloves. High-quality cabinets are typically constructed from sturdy steel and feature a sealed environment, a dust collection system, and a large, protected viewing window to monitor the process.

The blasting itself is performed with a blast gun, which is connected to a compressed air source. The gun siphons media from a hopper and accelerates it toward the workpiece. Guns may be trigger-operated or controlled by a foot pedal, with foot-pedal systems often preferred for longer sessions to reduce operator fatigue. As highlighted by RapidDirect, controlling the air pressure is a critical factor; glass beads work most effectively at lower pressures (around 50 PSI), as high pressures can shatter the beads, reducing their lifespan and creating unnecessary dust.

The choice of media is arguably the most critical variable in the bead blasting process, as it directly determines the final surface texture and appearance. Several types of spherical or semi-spherical media are available:

- Glass Beads: The most common media, made from lead-free soda-lime glass. Glass beads are chemically inert and recyclable, making them an environmentally friendly option. They produce a clean, bright, satin finish and are excellent for light cleaning and cosmetic applications on materials like aluminum and stainless steel.

- Steel Shot: A harder, denser, and more durable media used for more aggressive applications like cleaning, deburring, and shot peening. Steel shot imparts significant compressive stress, enhancing fatigue life, but is typically reserved for robust materials like steel and cast iron.

- Ceramic Beads: A highly durable and long-lasting alternative to glass beads. They are less prone to shattering, create less dust, and can provide a very fine, smooth finish. Their hardness makes them suitable for peening and finishing harder metals.

- Plastic Media: Made from materials like urea, these are much softer and are used for delicate cleaning, paint stripping, and deflashing molded parts without damaging the substrate. They are not typically used for creating a cosmetic satin finish.

Bead Blasting vs. Sandblasting: A Comparative Analysis

While both bead blasting and sandblasting are forms of abrasive blasting, they serve fundamentally different purposes due to the nature of their media. The primary distinction lies in the shape of the particles: bead blasting uses round, spherical media, while sandblasting uses sharp, angular media like silica sand or aluminum oxide. This difference in geometry dictates how each process affects a surface. Bead blasting peens or burnishes the surface, creating a smooth, satin texture without significant material removal. In contrast, sandblasting acts like a chisel, cutting into and etching the surface, which is ideal for removing thick coatings or creating a rough profile for paint adhesion.

The resulting finish from each process is also markedly different. Bead blasting leaves a bright, uniform, and non-directional finish that is often desired for its cosmetic appeal. Sandblasting, however, typically produces a duller, rougher, matte finish. Because sandblasting is more aggressive, it can alter the dimensions of a part, making it unsuitable for components with tight tolerances. WayKen Manufacturing notes that bead blasting is much gentler, preserving the part's original dimensions and integrity.

Safety and environmental considerations also set the two processes apart. Traditional sandblasting with silica sand generates fine silica dust, which can cause silicosis, a serious lung disease, if inhaled. This has led to stricter regulations and a shift toward safer abrasives like aluminum oxide. Bead blasting with glass beads, which are chemically inert and don't contain free silica, is considered a much safer alternative. The media is also highly recyclable, reducing waste and operational costs.

| Feature | Bead Blasting | Sandblasting |

|---|---|---|

| Media Type | Spherical (e.g., glass beads, steel shot) | Angular (e.g., silica sand, aluminum oxide) |

| Surface Action | Peening / Burnishing | Etching / Abrading |

| Resulting Finish | Smooth, satin, or bright matte | Rough, dull matte |

| Material Removal | Minimal to none | Significant; can alter dimensions |

| Primary Use Case | Cosmetic finishing, cleaning, deburring | Heavy rust/paint removal, surface prep for coating |

| Safety | Safer; no free silica with glass beads | Potential health risks (silicosis) with silica sand |

Key Applications and Benefits in Metal Finishing

Bead blasting is a versatile finishing process valued across numerous industries, including aerospace, automotive, medical, and consumer electronics, for its ability to produce consistent, high-quality surfaces. Its applications are broad, ranging from purely cosmetic enhancements to critical functional improvements. By selecting the appropriate media size—from fine beads for delicate work to larger ones for aggressive cleaning—the process can be tailored to meet precise specifications for a variety of materials, including aluminum, stainless steel, titanium, and brass.

The ability to achieve precise, repeatable finishes is crucial for modern manufacturing. For companies that specialize in high-precision components, surface finishing is a critical final step. For instance, services that deliver rapid prototyping and volume production, such as the CNC machining services from XTJ, often rely on processes like bead blasting to meet the demanding cosmetic and functional specifications for parts used in industries from aerospace to medical devices.

Common Applications

- Cosmetic Finishing: It creates a uniform satin or matte finish that hides fingerprints, machining marks, and other surface imperfections, providing a clean, professional look.

- Deburring and Deflashing: The process effectively removes small burrs and sharp edges left from machining or molding without damaging the part's surface.

- Cleaning and Restoration: It is highly effective at removing rust, scale, paint, and other surface contaminants from metal parts, restoring them to a clean state.

- Surface Preparation: While not as effective as sandblasting for creating a rough profile, it provides a perfectly clean surface that is ideal for certain types of coatings, anodizing, or plating.

- Shot Peening: Using denser media like steel shot, the process can be used to induce compressive stress on a metal's surface, which significantly improves its fatigue strength and resistance to cracking.

Primary Benefits

- Uniformity: Bead blasting produces a non-directional, consistent finish across the entire surface of a part, even on complex geometries.

- Non-Damaging: The process is gentle and does not remove significant material, preserving the dimensional integrity of precision components. This is a key advantage noted by sources like Protolabs Network.

- Versatility: It is compatible with a wide range of metals and even some plastics, with different media types available to achieve various finishes.

- Environmentally Friendly: The most common media, glass beads, are non-toxic, chemically inert, and can be recycled multiple times, making it a more sustainable choice than many chemical finishing processes.

Frequently Asked Questions

1. What kind of finish does bead blasting produce on stainless steel?

On stainless steel, bead blasting typically produces a clean, bright, and uniform satin finish. It removes any discoloration from welding or heat treatment and hides minor scratches or tool marks, resulting in a consistent, non-reflective surface that is both aesthetically pleasing and functional. The exact texture can be controlled by the size of the glass beads used.

2. Is bead blasting effective for removing paint?

Bead blasting can remove paint, but it is a slower and gentler process compared to sandblasting. It is best suited for removing thin layers of paint or coatings from more delicate surfaces where preserving the underlying material is a priority. For thick, stubborn coatings, a more aggressive abrasive like aluminum oxide might be required first, followed by bead blasting for the final finish.

3. Can you bead blast aluminum parts?

Yes, bead blasting is an extremely popular finishing method for aluminum. It effectively removes the swirl marks left by CNC machining and creates a uniform, soft satin finish that is highly desirable for consumer electronics and automotive components. It's important to first ensure the aluminum is free of oils and that any heavy oxide layers are dealt with before blasting to achieve the best results.

-

Posted in

bead blasting, glass beads, metal finishing, sandblasting, surface treatment