Unlock Precision: 5-Axis CNC Machining Benefits Explained

TL;DR

5-axis CNC machining provides major advantages over traditional 3-axis methods by enabling the production of highly complex parts with superior precision and efficiency. The core benefits include drastically fewer machine setups, faster cycle times, and the ability to create intricate geometries with an improved surface finish. This technology is a game-changer for demanding industries like aerospace, medical, and automotive manufacturing.

The Core Advantages of 5-Axis Machining

Transitioning to 5-axis CNC machining unlocks a range of operational benefits that translate directly to higher quality parts, reduced lead times, and increased profitability. By moving a tool or part on five different axes simultaneously, these machines overcome the limitations inherent in conventional 3-axis systems. This capability allows for more efficient processes and opens the door to manufacturing opportunities that were previously impractical or impossible.

1. Fewer Setups and Increased Efficiency

One of the most significant benefits is the ability to machine complex shapes in a single setup. Traditional 3-axis machining often requires multiple setups, where the workpiece must be manually repositioned to access different sides. Each new setup introduces the potential for human error, increasing scrap rates and extending production time. With a 5-axis machine, the cutting tool can approach the workpiece from multiple directions without manual intervention, consolidating operations and minimizing the risk of alignment errors. This “done-in-one” approach, as described by experts at Okuma, dramatically reduces setup time and increases spindle uptime, leading to faster overall production.

2. Higher Precision and Accuracy

By eliminating the need to move a part across multiple workstations or re-clamp it for different operations, 5-axis machining inherently improves accuracy. Each time a part is moved, the risk of losing precise alignment increases. A single setup ensures that all features are machined in relation to each other with exceptional precision. Furthermore, 5-axis machines can use shorter, more rigid cutting tools because the head or table can be tilted to maintain an optimal cutting position. Shorter tools are less susceptible to vibration and deflection, which results in a higher quality surface finish and the ability to hold tighter tolerances, a key advantage highlighted by Methods Machine Tools.

3. Machining of Complex Geometries

The primary driver for adopting 5-axis technology is often the need to produce parts with complex curves and intricate features. The two additional rotational axes allow the tool to follow complex contours and machine deep cavities or undercuts that would be impossible on a 3-axis machine. This capability is essential for manufacturing components like turbine blades, impellers, and medical implants, which feature organic shapes and multi-faceted surfaces. As noted by Xometry, the full range of motion allows these machines to create intricate parts with smooth, seamless surfaces.

4. Improved Tool Life and Surface Finish

5-axis machining allows the tool to be held in a position that is tangential to the cutting surface. This orientation enables a more efficient cutting process, spreading wear across the side of the tool rather than concentrating it on the tip. The result is a significant increase in tool lifespan and reduced tooling costs. This optimal tool orientation also allows for higher cutting speeds without sacrificing surface finish quality. Because the tool can maintain the best angle relative to the material, it produces a smoother finish, often eliminating the need for secondary finishing processes.

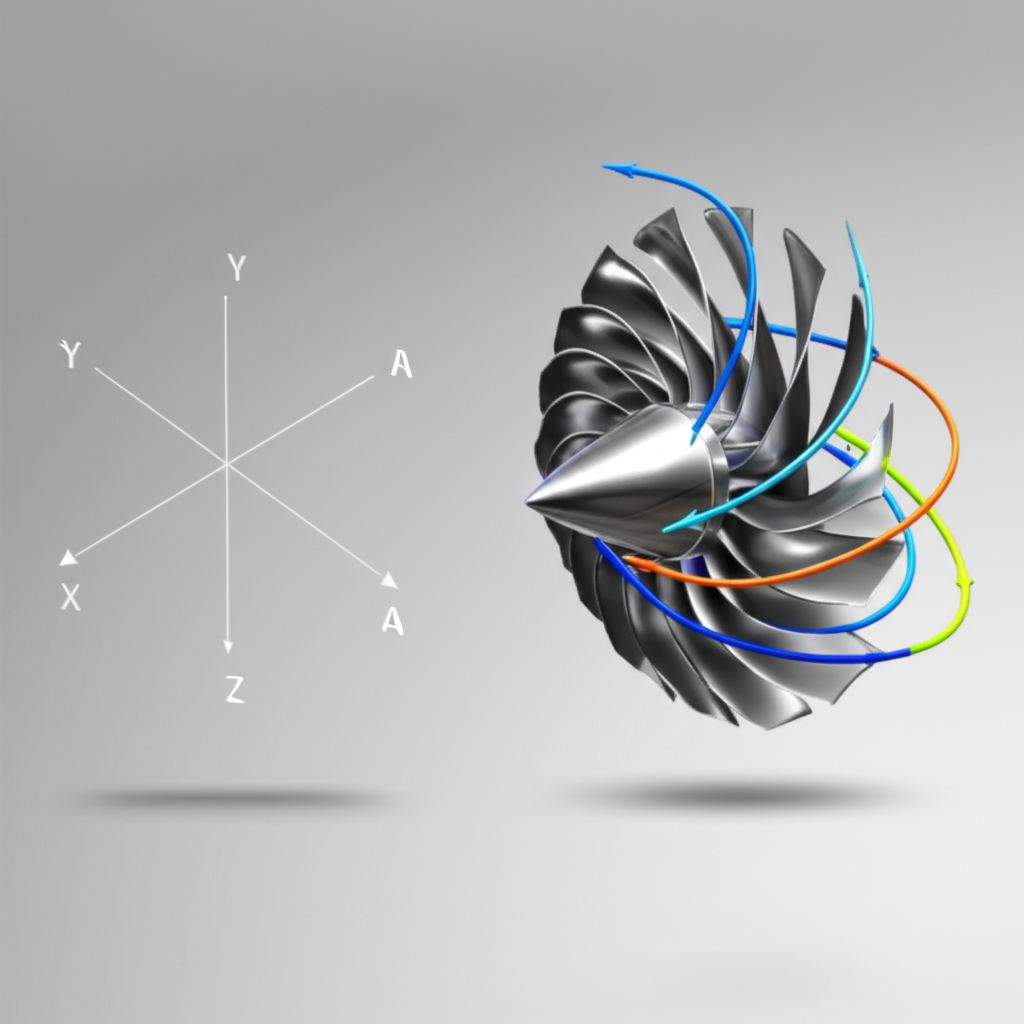

3-Axis vs. 5-Axis: Understanding the Key Differences

While both 3-axis and 5-axis machines are foundational to modern manufacturing, the addition of two rotational axes in a 5-axis system creates a world of difference in capability and efficiency. A 3-axis machine operates on the linear X, Y, and Z axes, moving the cutting tool left-to-right, front-to-back, and up-and-down. This is ideal for simpler, prismatic parts. A 5-axis machine adds two rotational axes (typically A and B, or A and C), allowing the tool or workpiece to tilt and rotate, enabling access to five sides of a part in a single clamping.

This distinction is crucial for understanding which technology is right for a given application. The choice impacts everything from part complexity and production speed to overall cost and operational efficiency. The following table provides a clear comparison of their core attributes.

| Factor | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

| Axes of Motion | Linear movement along X, Y, and Z axes. | Linear movement along X, Y, Z axes, plus two rotational axes (A and B/C). |

| Part Complexity | Best for simple, 2.5D parts, flat surfaces, drilling, and shallow cavities. | Ideal for complex, multi-faceted parts, deep cavities, undercuts, and smooth contours. |

| Setup Time | Requires multiple setups and manual repositioning for multi-sided parts. | Machines five sides of a part in a single setup, drastically reducing setup time. |

| Accuracy | Good, but accuracy can be lost with each manual repositioning. | Excellent, as single-setup machining eliminates errors from re-fixturing. |

| Ideal Applications | Housings, panels, brackets, and other parts with straightforward geometries. | Aerospace components, medical implants, complex molds, and automotive parts. |

Ultimately, the decision to use 5-axis machining comes down to balancing complexity and cost. While 3-axis machines are more affordable and simpler to program for basic jobs, 5-axis technology provides an unparalleled return on investment for complex, high-value components by reducing lead times, improving quality, and expanding a shop's manufacturing capabilities.

Common Industries and Applications

The unique capabilities of 5-axis CNC machining have made it indispensable in industries where precision, complexity, and reliability are non-negotiable. Its ability to produce intricate parts from tough materials with exceptional accuracy has driven innovation across several key sectors.

Aerospace and Defense

The aerospace industry was an early adopter of 5-axis technology and remains one of its biggest users. Components like turbine blades (blisks), impellers, and complex structural airframe parts require smooth, contoured surfaces and are often made from difficult-to-machine superalloys. 5-axis machines can create these aerodynamic shapes with the required precision and surface integrity, which is critical for performance and safety. The ability to machine a complex part in a single setup ensures dimensional stability and reduces the risk of defects.

Medical and Dental

In the medical field, 5-axis machining is used to create custom surgical implants, prosthetics, and complex medical instruments. These parts must often be tailored to a patient's specific anatomy and are made from biocompatible materials like titanium and specialized polymers. The technology's precision is vital for producing devices like artificial joints and dental implants that require a perfect fit and a high-quality surface finish to ensure biocompatibility and longevity. The complex, organic shapes of these components make 5-axis machining the ideal manufacturing method.

Automotive and Motorsports

From high-performance engine components to intricate molds for interior parts, the automotive industry leverages 5-axis machining for both prototyping and production. In motorsports, teams use it to create lightweight, high-strength parts like engine blocks, cylinder heads, and suspension components with complex geometries designed to maximize performance. The speed and accuracy of 5-axis machines also accelerate the development of prototypes, allowing for faster design iteration. For companies requiring such high-spec components, specialized providers can be invaluable. For instance, services like XTJ offer advanced 4 and 5-axis capabilities for industries like aerospace and medical, delivering rapid prototyping and production with tight tolerances.

Challenges and Considerations Before Investing

While the benefits of 5-axis CNC machining are substantial, adopting the technology requires careful consideration of its associated challenges. A balanced perspective is crucial for any shop evaluating this significant investment. The primary hurdles include the higher initial cost, increased programming complexity, and the need for skilled personnel.

The initial capital outlay for a 5-axis machine is significantly higher than for a 3-axis machine. This cost extends beyond the machine itself to include specialized tooling, workholding fixtures, and post-processors. Businesses must conduct a thorough return on investment (ROI) analysis, as detailed by resources like 5-axis.org, to ensure that the potential gains in efficiency and capability justify the expense. The higher cost per part for simpler jobs means that a 5-axis machine may not be economical without a consistent stream of complex work.

Programming for simultaneous 5-axis motion is also far more complex than for 3-axis operations. It requires advanced Computer-Aided Manufacturing (CAM) software and a deep understanding of toolpaths, machine kinematics, and collision avoidance. As noted in the SERP, this complexity is a significant challenge. Machine shops must invest in powerful software and, more importantly, in training for their programmers and operators. Without the right skills, it is impossible to leverage the full potential of the machine, and the risk of costly errors or crashes increases dramatically.

Finally, finding and retaining operators and programmers with 5-axis experience can be difficult. The learning curve is steep, and it takes time to develop the expertise needed to run complex jobs efficiently and safely. However, modern CNC controls and software are becoming more user-friendly, with features like dynamic fixture offsets and automated tuning to simplify setups and reduce the need for highly specialized labor. Investing in ongoing training is essential to overcome this challenge and maximize the machine's productivity.

Frequently Asked Questions

1. What are the main benefits of 5-axis CNC?

The primary benefits of 5-axis CNC machining are the ability to produce highly complex parts in a single setup, leading to increased accuracy, faster production times, and reduced labor costs. It also allows for the use of shorter, more rigid tools, which improves surface finish and extends tool life.

2. Is 5-axis CNC worth the investment?

For shops that regularly produce parts with complex geometries or require machining on multiple sides, a 5-axis CNC machine is often a worthwhile investment. The reduction in setup time, manual labor, and potential for error can lead to a significant return on investment. It also expands a shop's capabilities, allowing it to take on more advanced and profitable work.

3. What are the disadvantages of a 5-axis CNC machine?

The main disadvantages are the higher initial purchase price, the complexity of programming (requiring advanced CAM software and skilled programmers), and the higher maintenance costs associated with more moving parts. The learning curve for operators can also be steep, requiring significant investment in training.

4. What can I make with a 5-axis CNC machine?

A 5-axis CNC machine is ideal for creating parts with complex, multi-faceted geometries. Common examples include aerospace components like turbine blades and impellers, medical items such as custom implants and prosthetics, automotive parts like engine blocks and high-performance pistons, and intricate molds for various industries.

-

Posted in

5-axis machining, CAM programming, cnc machining, Manufacturing Technology, precision engineering