Essential CNC Machining for Modern Robotics Components

TL;DR

CNC machining is a high-precision manufacturing process that is indispensable to the modern robotics industry. It enables the creation of critical, complex components such as joints, gears, and end-effectors with exceptional accuracy and consistency. This technology is vital for achieving the high performance, reliability, and repeatable motion that define advanced robotic systems, making it the foundation for innovation in automation.

The Indispensable Role of Precision: Why CNC Machining is Essential for Robotics

The field of robotics is built on a foundation of precision. For a robot to perform its tasks flawlessly, whether on an assembly line or in a surgical suite, every component must work in perfect harmony. This is where Computer Numerical Control (CNC) machining becomes a cornerstone technology. CNC robotics combines the programmability and accuracy of CNC machines with the flexibility of robotic systems, creating a powerful synergy for modern manufacturing. According to an explanation from Fictiv, this blend of technologies increases efficiency, enhances precision, and reduces labor costs. The reliance on CNC machining stems from its unparalleled ability to produce parts that meet exacting specifications, a non-negotiable requirement for the robotics industry.

The core value of CNC machining in robotics lies in its capacity to achieve incredibly tight tolerances, sometimes as fine as +/- 0.015mm. As highlighted by Wenext, this level of manufacturing precision is essential for the smooth, repeatable movements that robots are known for. Every gear, bearing, and housing must fit together perfectly to minimize friction and wear, ensuring the robot's longevity and reliability. Without this accuracy, a robot's movements could be jerky and unreliable, leading to errors in production or, in critical applications, catastrophic failures. The ability to create parts with excellent surface finishes also reduces friction between moving components, further enhancing performance.

This need for precision underpins the entire functionality of a robotic system. The main components, from the controller and drive train to manipulators and end-effectors, all depend on accurately manufactured parts. As detailed by Aztalan Engineering Inc., CNC machining is often the best choice for creating these parts from durable and diverse materials. This versatility allows engineers to design lightweight yet strong components, optimizing the robot's speed and efficiency. Ultimately, the precision afforded by CNC machining is what enables the development of more advanced, intelligent robots capable of performing increasingly complex and delicate tasks.

Anatomy of a Robot: Common Components Produced by CNC Machining

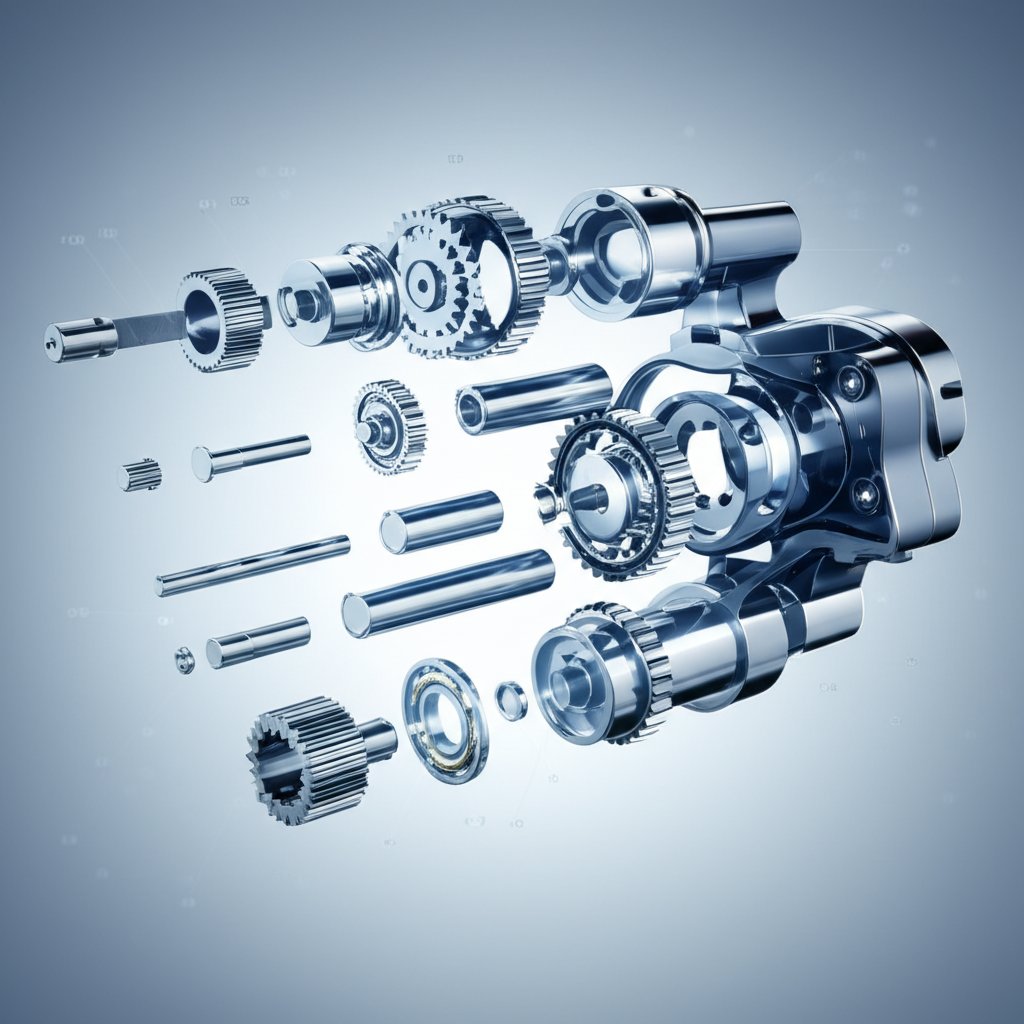

CNC machining is responsible for fabricating a wide array of components that form the skeleton and muscles of a robotic system. These parts range from large structural frames to minuscule, intricate gears. The most common components produced include joints, gears, bearings, shafts, fasteners, and brackets. Each of these parts plays a critical role in the robot's ability to move, interact with its environment, and perform its designated tasks with precision. As noted by 3erp, the exact specifications required for parts like robot arms, jigs, and end-effectors make CNC machining the ideal manufacturing method.

End-effectors, or the "hands" of the robot, are a prime example of components that benefit from CNC machining. These tools are customized for specific tasks like gripping, welding, or cutting and must be manufactured with extreme accuracy to function correctly. Similarly, the structural components of robotic arms require robust materials and complex geometries to withstand heavy loads and repetitive motion. CNC machining excels at creating these parts from materials like steel and aluminum. Other crucial parts include the housings for controllers and sensors, which protect the delicate electronics that serve as the robot's brain and senses.

The selection of materials for these components is just as critical as the manufacturing process itself. Different parts of a robot have different requirements for strength, weight, and durability. A comparison of common materials and their applications highlights the versatility that CNC machining offers.

| Component | Typical Material | Function & Rationale |

|---|---|---|

| Robotic Arms & Frames | Aluminum (e.g., 6061, 7075) | Provides an excellent strength-to-weight ratio, allowing for rapid movement without sacrificing structural integrity. |

| Gears & Shafts | Stainless Steel, Hardened Steel | Offers high durability and wear resistance, essential for power transmission and joints that undergo constant motion. |

| End-Effectors (Grippers) | Aluminum or Titanium | Requires a balance of strength, low weight, and the ability to be machined into complex shapes for specialized tasks. |

| Housings & Brackets | Plastics (e.g., PEEK, Delrin) or Aluminum | Plastics are used for insulating electronic components and reducing weight, while aluminum provides durable mounting points. |

Key Advantages: The Benefits of Using CNC Machining in Robotics Manufacturing

The integration of CNC machining into robotics manufacturing offers a host of advantages that directly impact efficiency, quality, and innovation. These benefits are the primary drivers behind its widespread adoption in the industry. The ability to automate repetitive tasks not only speeds up production but also ensures a level of consistency that is difficult to achieve with manual processes. This leads to higher quality products and a more predictable manufacturing workflow.

The core benefits of using CNC machining for robotic components can be summarized as follows:

- Unmatched Precision and Accuracy: CNC machines can produce parts with extremely tight tolerances, ensuring that every component functions as designed. This precision is fundamental to the reliable and smooth operation of any robotic system.

- Material Versatility: The process is compatible with a wide range of materials, from various metals like aluminum and steel to engineering-grade plastics. This allows designers to select the optimal material for each component based on its specific functional requirements, such as strength, weight, or electrical insulation.

- Enhanced Efficiency and Speed: Automation significantly reduces production time compared to manual methods. Once a design is programmed, a CNC machine can run continuously with minimal supervision, leading to faster turnaround times for both prototypes and production parts.

- Flexibility and Scalability: CNC machining is adaptable to different production volumes. It is cost-effective for creating one-off custom parts or prototypes and can be seamlessly scaled up for low- to mid-volume production runs, making it ideal for the evolving needs of the robotics market.

Furthermore, CNC machining facilitates rapid prototyping, a critical phase in robotics development. Engineers can quickly produce and test new designs, allowing for fast iteration and refinement. This accelerated development cycle is crucial in a competitive and fast-paced field. For companies looking to optimize this process, providers offering comprehensive formative manufacturing services can be invaluable partners, providing expert DFM feedback and rapid turnarounds to bring concepts to life efficiently.

Materials and Processes: A Look at CNC Machining Techniques for Robotics

The production of high-quality robotic components relies on a selection of specialized CNC machining processes and carefully chosen materials. Different techniques are suited for creating parts with varying geometries and complexities. For instance, 5-axis CNC milling is essential for producing intricate parts like end-effectors or sensor housings with a high degree of precision in a single setup. As JACO Machine Works points out, versatile methods like Vertical and Horizontal CNC Milling are used for a wide range of components, from detailed parts to larger structural frames.

Another crucial technique is CNC Swiss Screw Machining, which is ideal for manufacturing small, precise parts like fasteners, miniature gears, and precision shafts in high volumes. The choice of process often depends on the component's size, complexity, and the required production volume. These processes are complemented by a thoughtful selection of materials tailored to the demands of robotic applications.

While CNC machining is incredibly versatile, not all materials are suitable for this subtractive process. Materials that are too soft, brittle, or abrasive can be challenging or impossible to machine effectively. For example, soft rubbers and flexible polymers tend to deform under the cutting tool rather than being cleanly cut. Likewise, hard materials like ceramics and some composites can cause excessive tool wear, making the process inefficient. Understanding these limitations is crucial for proper material selection in the design phase.

Frequently Asked Questions

1. What is CNC in robotics?

CNC in robotics refers to the integration of Computer Numerical Control (CNC) machining principles with robotic technology. This can mean two things: using CNC machines to manufacture precise robot components, or using robots to automate CNC machine operations, such as loading and unloading parts (machine tending). This combination leverages the precision of CNC with the flexibility of robotics to enhance manufacturing efficiency and consistency.

2. What materials cannot be CNC machined?

Certain materials are generally unsuitable for CNC machining due to their physical properties. These include very soft or flexible materials like silicone rubber, which do not cut cleanly. Extremely hard or abrasive materials such as ceramics, hardened glass, and carbon fiber composites are also difficult to machine as they cause rapid tool wear. Other challenging materials include soft foams and inconsistent or unstable substances.

3. What are the big 4 of robotics?

The "Big Four" in the industrial robotics industry are four major companies that lead the market in automation solutions. These giants are generally recognized as ABB Robotics, FANUC, KUKA, and Yaskawa Motoman. They are known for their advanced robotic systems, wide range of product offerings, and significant influence on the future of industrial automation.

-

Posted in

automation, cnc machining, manufacturing, precision engineering, robotics