CNC Milling vs Turning: Which Service Your Project Needs

TL;DR

The core difference between CNC milling vs turning services lies in which part moves. In CNC turning, the workpiece rotates at high speed while a stationary cutting tool removes material, making it ideal for creating cylindrical parts like shafts and bushings. Conversely, CNC milling keeps the workpiece stationary while a multi-point cutting tool rotates and moves around it, a process perfectly suited for producing complex, non-cylindrical shapes with features like slots, pockets, and flat surfaces.

The Fundamental Difference: Rotating Workpiece vs. Rotating Tool

Understanding the distinction between CNC milling and turning begins with one simple mechanical principle: what is spinning? This single difference dictates the type of machine used, the tools required, and ultimately, the geometry of the parts each process can create. Both are forms of subtractive manufacturing, where material is precisely removed from a solid block to achieve a final design, but they arrive at the result from opposite approaches.

CNC turning is performed on a machine called a lathe. In this process, the raw material, typically a round bar stock, is held firmly in a chuck which then rotates at high speeds. A stationary, single-point cutting tool is then moved along the rotating workpiece to shave away material. This method is inherently designed for creating parts with rotational symmetry. Think of a potter shaping clay on a wheel—the principle is analogous, but with metal or plastic and extreme precision.

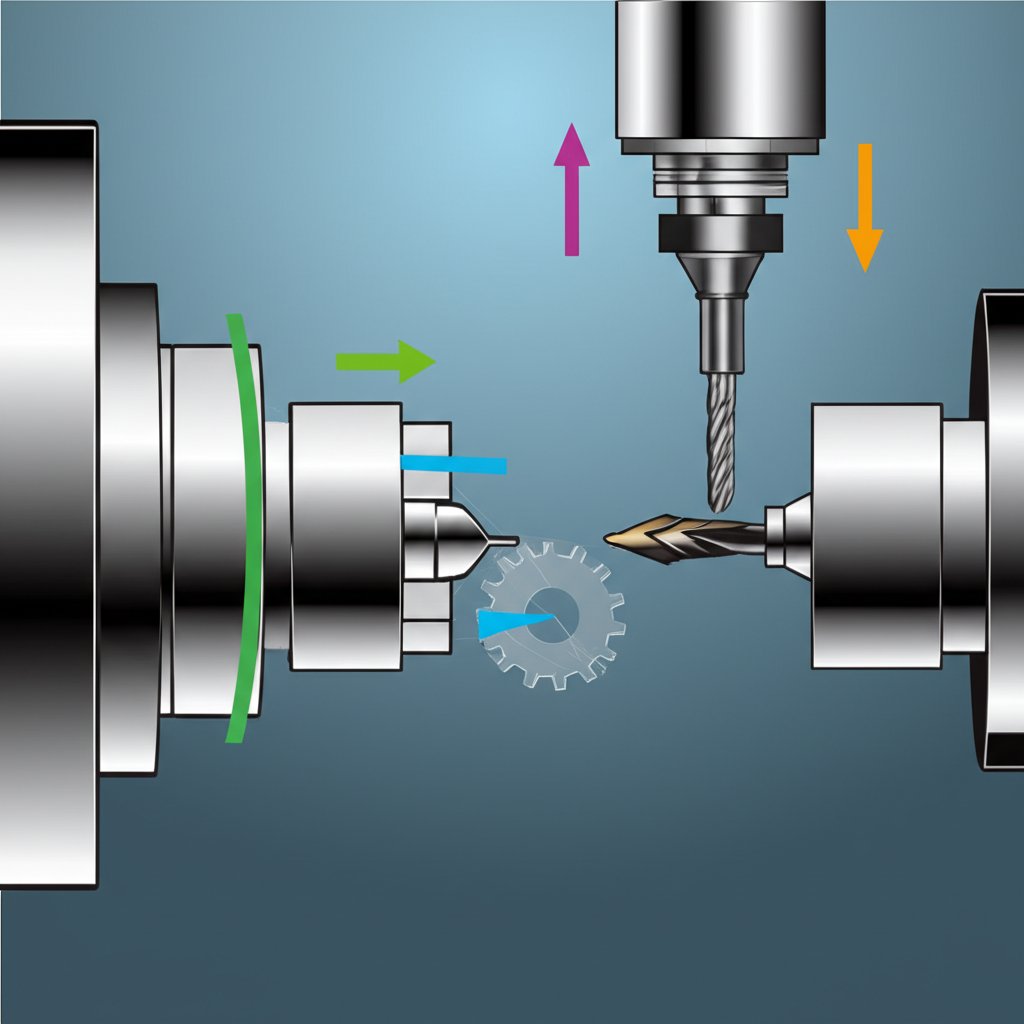

On the other hand, CNC milling involves securing the workpiece to a machine bed so that it remains stationary. The cutting tool, which is a multi-point tool like an end mill or drill, is held in a spindle that rotates at high speeds. The machine then moves this spinning tool along multiple axes (X, Y, and Z) to cut into the workpiece and carve out the desired shape. This allows for the creation of far more complex and varied geometries, including flat surfaces, pockets, holes, and intricate 3D contours.

This fundamental operational difference also affects aspects like chip formation. Turning, with its continuous contact between the tool and workpiece, can produce long, stringy chips, while the intermittent cutting action of milling typically creates smaller, discontinuous chips. Ultimately, this core distinction is the first and most important factor in deciding which service is appropriate for a given component.

| Feature | CNC Turning | CNC Milling |

|---|---|---|

| Primary Motion | Workpiece rotates | Cutting tool rotates |

| Workpiece State | In motion (spinning) | Stationary |

| Machine Used | Lathe / Turning Center | Milling Machine / Machining Center |

| Ideal Part Shape | Cylindrical, conical, round | Complex, prismatic, flat |

Typical Applications & Part Geometry: When to Use Milling vs. Turning

The geometry of your part is the single most important factor when choosing between CNC milling and turning services. While both create precision components, their applications are dictated by the shapes they produce most efficiently. Understanding these typical use cases helps clarify which process aligns with your project's needs.

Ideal Scenarios for CNC Turning

CNC turning excels at manufacturing any component that is cylindrical or has rotational symmetry. Because the workpiece itself spins, creating perfectly round and concentric features is fast and highly repeatable. This makes turning the go-to process for high-volume production of symmetrical parts. According to Komacut, it is particularly effective for projects requiring symmetrical parts like rods, shafts, and bushings. If your part can be made from round bar stock with features cut along its axis, turning is almost always the most efficient and cost-effective choice.

- Shafts: Long, cylindrical rods used to transmit power in machinery.

- Bushings: Cylindrical linings that reduce friction between moving parts.

- Flanges: Rims or collars used to connect pipes and other components.

- Knobs and Dials: Symmetrical control elements for various devices.

- Pins and Dowels: Precision cylindrical fasteners used for alignment.

- Valves and Hydraulic Components: Many internal parts of these systems are cylindrical.

- Rings and Spacers: Circular components used for sealing or maintaining distance.

Ideal Scenarios for CNC Milling

CNC milling is the solution for parts with non-cylindrical, complex, or flat geometries. Its ability to move a cutting tool along multiple axes allows it to create intricate features that are impossible for a standard lathe. As noted by Fluorocarbon, milling is used for everything from engine components to medical devices. If your design includes pockets, slots, complex contours, or features on multiple faces, milling is the necessary process.

- Engine Components: Such as engine blocks, cylinder heads, and pistons with complex cutouts.

- Enclosures and Housings: Boxes for electronics or machinery with precise cutouts and mounting points.

- Custom Gears: The detailed profiles of gear teeth require the precision of milling.

- Brackets and Mounts: Structural parts with complex shapes and hole patterns.

- Molds and Tooling: Creating cavities for injection molding or other manufacturing processes.

- Aerospace Structural Parts: Components with high strength-to-weight ratios and complex geometries.

- Medical Implants: Custom-shaped implants like those for knees or hips.

It's also important to note the rise of hybrid or multi-tasking machines. These advanced systems, often called mill-turn centers, combine the capabilities of both a lathe and a milling machine. They can turn a cylindrical part and then use live, rotating tools to add milled features like slots or holes in a single setup, offering the best of both worlds for highly complex components.

Advantages and Disadvantages of Each Process

Choosing the right manufacturing process requires a balanced understanding of its strengths and weaknesses. Both CNC turning and milling offer high precision, but their advantages and disadvantages become clear when evaluated against specific project requirements like geometry, volume, and cost.

CNC Turning

Advantages:

- Cost and Speed Efficiency: For cylindrical parts, turning is generally faster and more economical than milling. The setup is often simpler, and material removal rates can be very high, making it ideal for high-volume production runs.

- Excellent Surface Finish: The continuous cutting action on a rotating workpiece can produce very smooth and consistent surface finishes on cylindrical surfaces.

- Lower Tooling Costs: Turning primarily uses single-point cutting tools, often with replaceable inserts, which are typically less expensive than the complex multi-point tools used in milling.

Disadvantages:

- Geometric Limitations: The biggest drawback is its limitation to cylindrical or symmetrical shapes. Creating prismatic features like square pockets or complex contours is not possible on a standard lathe.

- Chip Management: When machining ductile materials, the continuous cutting can produce long, stringy chips that can become entangled and require careful management to avoid damaging the part or tool.

CNC Milling

Advantages:

- Geometric Versatility: Milling's primary advantage is its ability to produce highly complex and intricate shapes. With multi-axis machines (3, 4, or 5-axis), it can create virtually any geometry, including complex curves, undercuts, and features on multiple faces.

- Broad Application Range: Because of its flexibility, milling is used across a vast range of applications, from one-off prototypes to complex aerospace components.

- High Precision on Complex Features: Milling can achieve very tight tolerances on non-cylindrical features like slots, pockets, and contoured surfaces.

Disadvantages:

- Higher Cost and Complexity: Milling setups can be more complex and time-consuming, especially for multi-axis jobs. This often results in higher initial setup costs and longer cycle times for simple parts compared to turning. The machinery itself is also generally more expensive.

- Slower for Simple Round Parts: Using a milling machine to produce a simple cylindrical part is highly inefficient and would be much slower and more expensive than using a lathe.

Making the Right Choice for Your Project

Selecting between CNC milling and turning services ultimately comes down to a careful evaluation of your part's design, production volume, and budget. The decision is not about which process is universally "better," but which is optimally suited for your specific needs. For parts that are primarily cylindrical, such as shafts, pins, or flanges, CNC turning is almost always the faster, more cost-effective solution. Its efficiency in creating symmetrical forms is unmatched, especially in high-volume production.

Conversely, if your component features complex geometries, flat surfaces, pockets, or intricate details, CNC milling is the clear choice. Its versatility allows for the creation of shapes that are simply impossible to produce on a lathe. While potentially more expensive and complex in its setup, milling provides the design freedom necessary for a vast array of modern components, from engine blocks to custom enclosures.

For complex projects, partnering with a service provider that offers comprehensive manufacturing solutions is key. For instance, providers of formative manufacturing services like XTJ can offer expert Design for Manufacturability (DFM) feedback. This guidance can help you optimize your design for either milling or turning, ensuring you achieve the desired quality, precision, and cost-efficiency for your rapid prototypes and production parts.

Frequently Asked Questions

1. What is the difference between CNC milling and turning?

The primary difference is the motion of the workpiece and the tool. In CNC turning, the workpiece rotates while the cutting tool is stationary, ideal for cylindrical parts. In CNC milling, the cutting tool rotates while the workpiece is stationary, which is suited for creating complex, non-cylindrical shapes.

2. Is milling or turning harder?

Milling is generally considered harder and more complex to master. It often requires advanced programming and setup skills, especially for 4- and 5-axis machines, to manage complex toolpaths and fixtures. Turning, particularly for simple 2-axis operations, is often easier for novice operators to learn.

3. What are the disadvantages of CNC milling?

The main disadvantages of CNC milling include higher initial setup costs for machines and fixtures, potentially longer cycle times for simple parts compared to turning, and greater programming complexity. For simple cylindrical parts, it is a less efficient and more expensive process.

4. Can a mill do everything a lathe can?

While a CNC mill is incredibly versatile and can produce cylindrical features, it cannot do everything a lathe can with the same efficiency or precision. A lathe excels at creating perfectly concentric and round parts quickly and cost-effectively. While a mill can create a round shape, achieving the same surface finish and concentricity is often more challenging and time-consuming. For parts that are fundamentally cylindrical, a lathe remains the superior tool.