Sustainable CNC Machining: Core Practices for Efficiency

TL;DR

Sustainable CNC machining encompasses a range of practices designed to minimize environmental impact. It strategically focuses on reducing material waste through methods like recycling and process optimization, while also lowering energy consumption with efficient technologies and operational improvements. Adopting these practices not only supports environmental stewardship but also leads to significant cost savings and enhanced operational efficiency.

Understanding the Core Principles of Sustainable CNC Machining

Sustainable CNC machining represents a critical evolution in modern manufacturing, moving beyond traditional production metrics to integrate environmental responsibility at every stage. At its core, it is an approach that uses technology and processes to reduce the ecological footprint of creating precision components. This involves a conscious effort to minimize waste, decrease energy consumption, and utilize eco-friendly materials, aligning high-precision engineering with long-term environmental health. As industries face increasing pressure to adopt greener practices, understanding these principles is no longer optional but essential for competitive and responsible operation.

The importance of this shift is twofold. Firstly, it addresses the significant environmental impact of traditional machining, which is often resource-intensive. By focusing on sustainability, companies can drastically cut down on scrap material, lower their carbon footprint from energy usage, and reduce reliance on virgin raw materials. Secondly, these practices deliver tangible business benefits. According to an article from American Micro Industries, reducing waste directly translates to lower material purchasing costs and reduced energy bills. Furthermore, a commitment to sustainability enhances brand reputation, attracting environmentally conscious customers and partners, which can lead to increased revenue and a stronger market position.

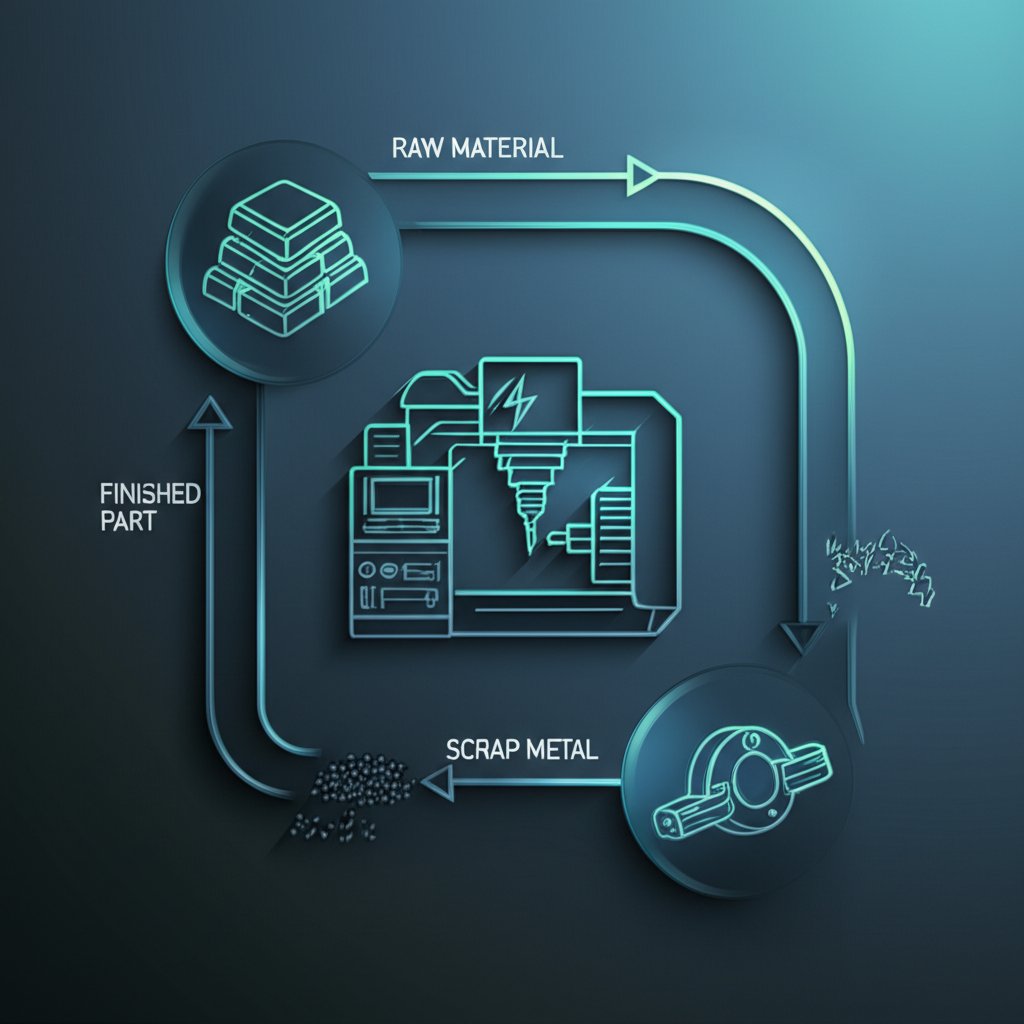

Traditional CNC machining, while precise, can be inherently wasteful. Its subtractive nature means that significant amounts of raw material are often cut away and discarded as chips or scrap. This process consumes large amounts of electricity to power spindles, servos, and cooling systems. The environmental impact is compounded by the use of petroleum-based coolants and lubricants, which can contaminate water and soil if not managed properly. In contrast, sustainable practices transform this model by treating waste as a resource, optimizing energy at every opportunity, and selecting materials with a lower life-cycle impact.

To better illustrate the differences, consider the goals and outcomes of each approach:

| Aspect | Traditional CNC Machining | Sustainable CNC Machining |

|---|---|---|

| Primary Goal | Part production speed and accuracy | Part production with minimal environmental impact |

| Material Usage | Focus on virgin materials; scrap is a byproduct | Prioritizes recycled and biodegradable materials; scrap is recycled in a closed-loop system |

| Energy Consumption | High, with machines often running idle | Minimized through energy-efficient machines, process optimization, and use of renewable sources |

| Waste Outcome | Scrap and used coolants often sent to landfills | Waste is minimized, recycled, and repurposed; coolants are filtered and reused |

| Business Focus | Short-term production costs | Long-term operational efficiency and brand value |

By implementing the principles of sustainability, machine shops can transition from a linear model of 'take, make, dispose' to a circular one that emphasizes efficiency and reuse. This strategic shift is fundamental to building a resilient and future-proof manufacturing operation.

Key Strategies for Material and Waste Reduction

Waste reduction is a cornerstone of sustainable CNC machining, offering one of the most direct paths to both environmental and economic benefits. It moves beyond simply discarding scrap to fundamentally rethinking how materials are sourced, used, and managed throughout the production cycle. The primary strategies revolve around intelligent material selection, comprehensive recycling programs, and the optimization of machining processes to prevent waste before it is even created. These efforts collectively reduce the demand for raw resources and minimize the volume of material sent to landfills.

A robust metal scrap recycling program is often the first and most impactful step. As highlighted by Zintilon, this involves a systematic process to accumulate, classify, and reuse the clippings and chips generated during machining. Common metals like aluminum, steel, brass, and copper are highly recyclable and retain their properties, making them ideal for reintroduction into the supply chain. Establishing a closed-loop system, where waste materials are collected and reprocessed, not only conserves natural resources but also reduces the significant energy and carbon emissions associated with producing metals from virgin ore.

Beyond recycling, optimizing the machining parameters is a proactive strategy to minimize waste. This involves fine-tuning elements like cutting speed, feed rate, and depth of cut to ensure parts are made correctly the first time, eliminating the need for rework or scrapping of components due to errors. Advanced software can simulate toolpaths to identify the most efficient cutting strategy, reducing material removal while maintaining part integrity. This precision ensures that only the necessary amount of material is used, preserving resources and reducing cycle times.

Integrating lean manufacturing principles provides a holistic framework for waste elimination. Lean manufacturing focuses on scaling production to meet demand, thereby preventing the overproduction of parts that may become obsolete. It also emphasizes continuous improvement, encouraging teams to regularly evaluate processes to identify and eliminate inefficiencies. A key tool in this approach is the 'waste walk,' a systematic review of the shop floor to identify sources of waste. To conduct an effective waste walk, follow these steps:

- Prepare and Plan: Define the process or area you want to analyze. Assemble a cross-functional team to bring different perspectives.

- Observe the Process in Action: Walk the actual path of material and information flow. Do not rely on assumptions.

- Identify the Eight Wastes: Look for evidence of defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, and extra-processing.

- Question Everything: Ask 'why' a certain step is performed. Challenge existing norms to uncover hidden inefficiencies.

- Document and Prioritize: Record your observations and brainstorm potential solutions. Prioritize actions based on their potential impact and ease of implementation.

Getting the design right from the start is another critical factor. Partnering with a manufacturing service that provides expert engineering feedback can prevent costly errors and material waste downstream. For instance, services that accelerate product development, such as those offered by XTJ's comprehensive formative manufacturing services, often include Design for Manufacturability (DFM) analysis. This feedback helps optimize designs for efficiency, ensuring materials are used effectively and reducing the risk of production issues.

Optimizing Energy Consumption in CNC Operations

Energy consumption is a major operational cost and a significant contributor to the environmental footprint of any CNC machine shop. The high power demands of spindles, motors, and auxiliary equipment make energy optimization a critical pillar of sustainable machining. Addressing this requires a dual approach: investing in energy-efficient technology and implementing smarter operational processes to eliminate energy waste. By focusing on how and when energy is used, manufacturers can achieve substantial cost savings and reduce their carbon emissions.

The first strategy involves upgrading to or properly maintaining energy-efficient equipment. Modern CNC machines are designed with sustainability in mind, incorporating features like high-efficiency motors, regenerative braking systems that recover energy, and intelligent power-down modes that automatically shut off non-essential components during idle periods. As noted by Wisconsin Metal Tech, investing in these technologies is a key part of minimizing environmental impact. While the upfront cost can be a consideration, the long-term savings in electricity bills often provide a rapid return on investment, making it an economically sound decision.

Process optimization offers another powerful lever for reducing energy consumption. This involves refining machining strategies to shorten cycle times, which directly correlates to less machine run-time and lower energy use. Techniques such as high-speed machining and optimizing toolpaths ensure that parts are produced as quickly and efficiently as possible. Furthermore, regular and proactive machine maintenance is essential. A well-maintained machine operates more efficiently, consumes less power, and is less prone to breakdowns that lead to energy-wasting downtime. Even the choice of coolants can play a role, as eco-friendly, high-performance fluids can reduce friction and thus the energy required for cutting.

For shops looking to make immediate progress, several 'quick wins' can be implemented with minimal investment. These practical steps help cultivate a culture of energy consciousness on the shop floor:

- Implement a Shutdown Policy: Ensure all machines and auxiliary equipment are fully powered down at the end of the day and during extended breaks, rather than left in standby mode.

- Optimize Compressed Air Systems: Regularly check for and repair leaks in compressed air lines, as these are a common source of significant energy waste.

- Maintain a Clean Environment: Keeping machines and the surrounding area clean ensures optimal performance and prevents components from overheating, which can increase energy draw.

- Schedule Efficiently: Group similar jobs together to reduce setup times and machine idling. Plan production to run on the most energy-efficient machines whenever possible.

- Use Smart Lighting: Switch to energy-efficient LED lighting in the facility and use motion sensors in less-frequented areas to reduce electricity consumption.

Looking ahead, advanced analytical techniques are emerging to further refine energy management. The concept of energy prediction for CNC machining using machine learning allows shops to forecast energy loads, identify peak consumption periods, and make data-driven decisions to optimize usage across the entire facility.

The Future: Leveraging AI and Machine Learning for Sustainable Machining

As the manufacturing industry moves beyond foundational sustainable practices, the next frontier lies in the integration of Artificial Intelligence (AI) and Machine Learning (ML). These advanced technologies are poised to revolutionize CNC machining by introducing a level of optimization and predictive capability that is impossible to achieve through manual adjustments alone. AI and ML are not just tools for enhancing productivity; they are becoming essential for unlocking new levels of sustainability by making processes hyper-efficient, predictive, and self-correcting.

The core mechanism behind this shift is data. AI and ML algorithms can analyze vast amounts of real-time data from sensors on a CNC machine—monitoring everything from spindle load and vibration to temperature and tool wear. By processing this information, machine learning models can create incredibly efficient toolpaths that minimize cutting forces, reduce cycle times, and extend tool life, all of which contribute to lower energy consumption and less material waste. This data-driven approach replaces traditional, experience-based methods with precise, calculated optimizations for every unique job.

A powerful application of this technology is in predictive maintenance. AI algorithms can detect subtle anomalies in a machine's performance that signal an impending failure. Instead of reacting to a breakdown—which causes costly downtime and wasted energy—shops can perform maintenance proactively. For example, an AI could predict that a specific bearing is wearing out and schedule a replacement before it fails, preventing a catastrophic event that could scrap a valuable part and waste significant resources. This shifts maintenance from a reactive or scheduled task to a predictive and highly efficient one.

To make this tangible, imagine a practical scenario: an AI-powered CAM software analyzes a complex part geometry and the properties of the material being machined. It then generates a unique toolpath that constantly adjusts the spindle speed and feed rate in real-time based on the tool's engagement with the material. As the tool enters a tight corner, the AI slows the feed rate to prevent tool breakage, and as it moves along a straight path, it accelerates to maximize efficiency. This dynamic optimization could result in a 15-20% reduction in cycle time and energy consumption per part compared to a static, pre-programmed approach.

For manufacturers looking to explore these technologies, the journey begins with data. The first step is to invest in systems for collecting and storing operational data from CNC machines. Many modern machines come equipped with sensors and connectivity features for this purpose. The next step is to explore CAM software and manufacturing execution systems (MES) that have built-in AI or ML features. Starting with a pilot project on a single machine or process can help demonstrate the value and build the expertise needed to scale these advanced sustainable practices across the entire operation.

Frequently Asked Questions About Sustainable CNC

1. What is the main goal of sustainable CNC machining?

The primary goal is to minimize the environmental impact of the manufacturing process. This is achieved by focusing on three key areas: reducing material waste through recycling and efficient processes, lowering energy consumption with modern technology and optimized operations, and using eco-friendly materials and fluids whenever possible.

2. Is sustainable machining more expensive to implement?

While some sustainable practices, like investing in new energy-efficient machinery, can have a higher upfront cost, many strategies lead to significant long-term savings. As noted in a study highlighted by AMFG, smaller companies can often recover their investment in green technology within months. Practices like waste reduction and energy conservation directly lower operational costs for materials and electricity, making sustainability an economically viable and often profitable strategy.

3. How can a small shop start implementing sustainable practices?

A small shop can begin with low-cost, high-impact changes. Start by establishing a comprehensive recycling program for all scrap metal and other waste materials. Conduct a 'waste walk' to identify and eliminate process inefficiencies. Implement a strict power-down policy for all machines at the end of the day. Regular machine maintenance is another crucial step that improves efficiency and reduces energy consumption. These foundational practices require minimal investment but can yield significant environmental and financial benefits.