CNC Milling vs EDM: Which Process Is Right for You?

TL;DR

CNC milling is a subtractive manufacturing process that uses rotating cutting tools to physically remove material, making it generally faster for simpler parts. In contrast, Electrical Discharge Machining (EDM) is a non-contact thermal process that employs electrical sparks to erode conductive materials. EDM offers superior precision, especially for complex geometries, sharp internal corners, and extremely hard metals where conventional tools would fail.

Core Principles: Understanding CNC Milling and EDM

To make an informed decision between CNC milling and Electrical Discharge Machining (EDM), it's essential to understand the fundamental mechanics of each process. While both are used to shape materials with high precision, their methods are fundamentally different, leading to distinct advantages and applications in modern manufacturing.

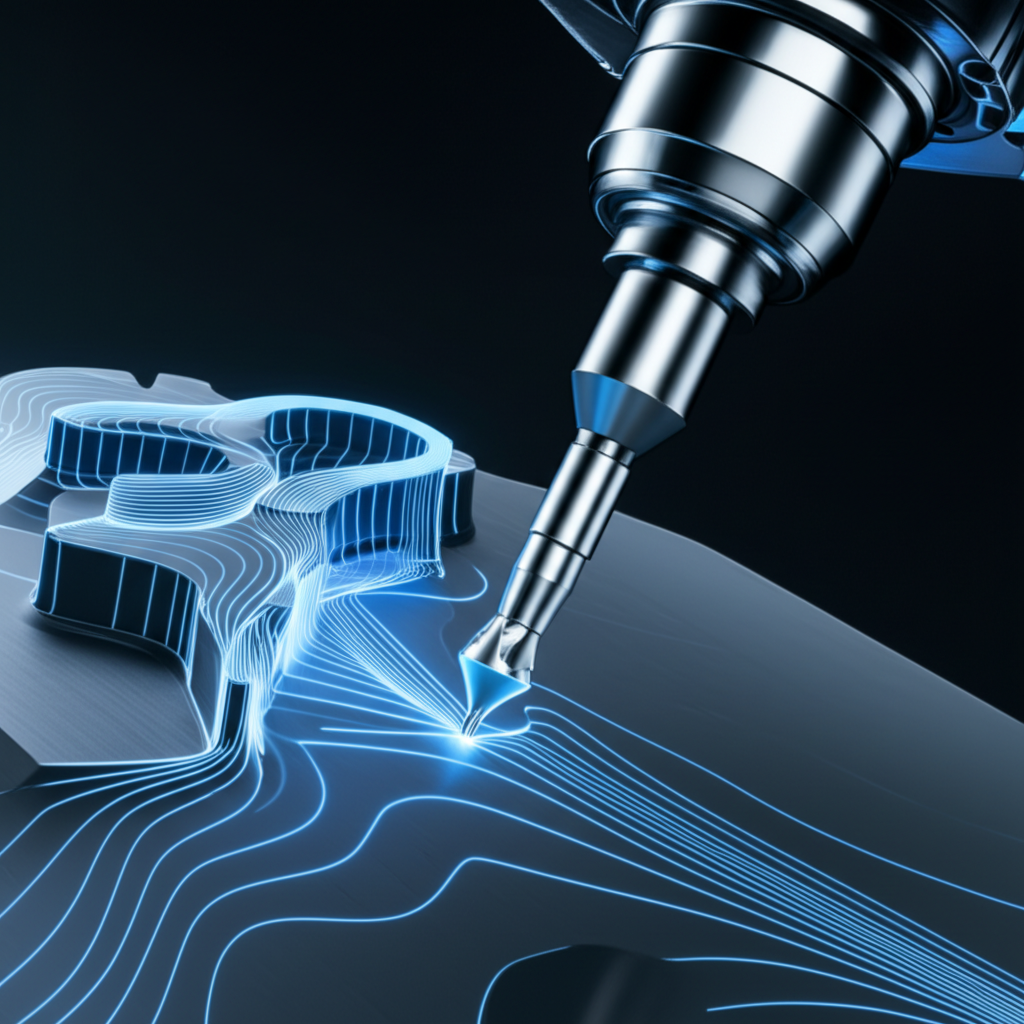

Understanding CNC Milling

Computer Numerical Control (CNC) milling is a subtractive, contact-based machining process. It involves a computer-controlled cutting tool that rotates at high speeds to remove material from a stationary workpiece. The process is highly versatile and can work with a wide range of materials, including metals, plastics, and wood. Because it relies on physical force to shear material away, its effectiveness can be limited by the hardness of the workpiece and the geometry of the part, especially when dealing with deep cavities or sharp internal corners.

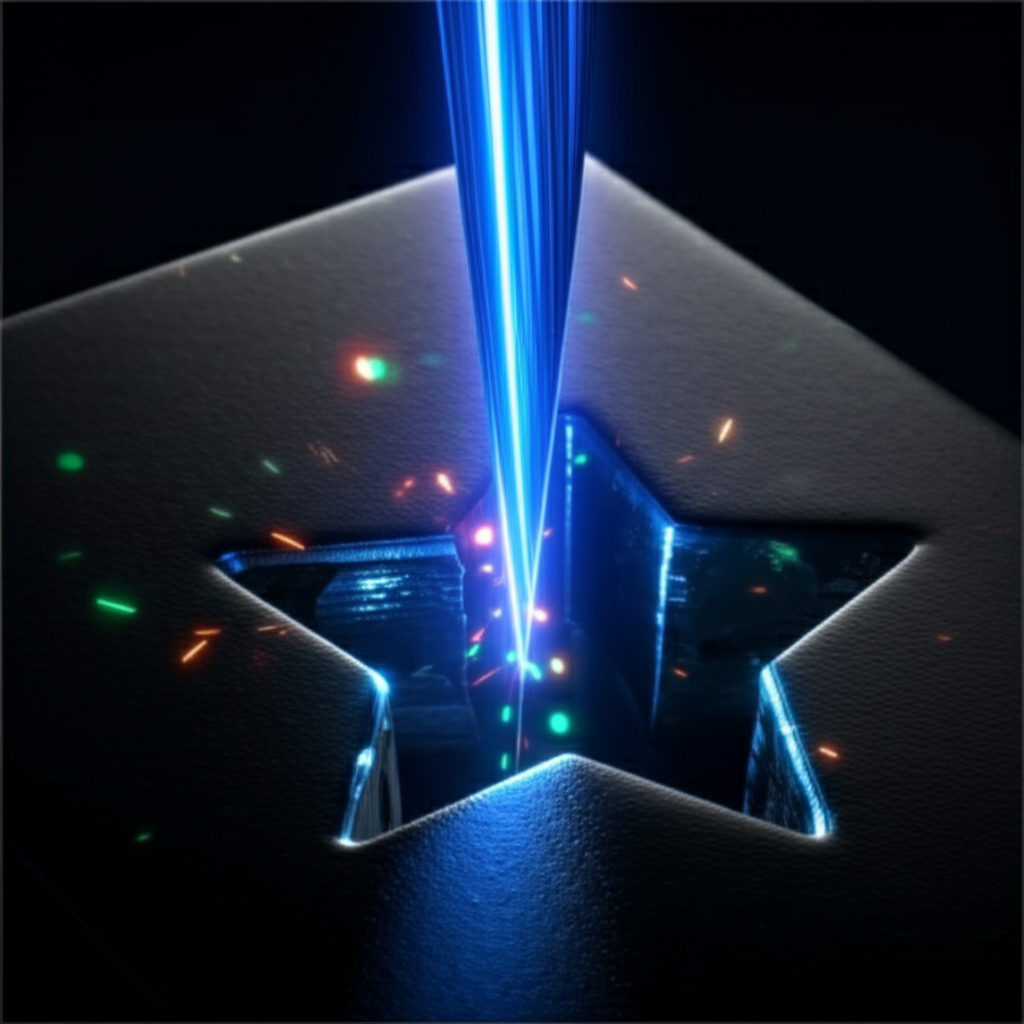

Understanding Electrical Discharge Machining (EDM)

Electrical Discharge Machining (EDM), also known as spark machining, is a non-contact, thermal erosion process. It works by creating a series of rapid, recurring electrical discharges (sparks) between an electrode and a workpiece, all submerged in a dielectric fluid. According to Xometry, each spark generates intense heat (up to 12,000 °C) that melts and vaporizes a tiny amount of material, which is then flushed away by the fluid. This method is only suitable for electrically conductive materials. Since there is no physical contact, the process imparts virtually no mechanical stress on the workpiece, making it ideal for delicate parts and extremely hard materials like hardened steel or titanium.

Head-to-Head Comparison: Key Differentiators

Choosing between CNC milling and EDM requires a direct comparison of their capabilities across several critical factors. The optimal choice depends entirely on the specific requirements of the project, including material, complexity, speed, and required precision.

| Factor | CNC Milling | Electrical Discharge Machining (EDM) |

|---|---|---|

| Process Type | Subtractive (Mechanical Force) | Thermal Erosion (Electrical Sparks) |

| Speed | Generally faster material removal rates. | Slower process, but can run unattended for long periods. |

| Precision & Tolerance | High precision, but can be limited by tool deflection and wear. | Exceptional precision, capable of tolerances as tight as +/- 0.0002”. |

| Material Compatibility | Wide range of materials including metals, plastics, and composites. | Only electrically conductive materials (e.g., steel, titanium, copper). |

| Geometric Complexity | Limited by tool size; struggles with sharp internal corners. | Excels at creating sharp internal corners, deep ribs, and intricate shapes. |

| Surface Finish | Good finish, but may show tool marks (swirls). | Superior, uniform finish often requiring no secondary polishing. |

| Tooling | Various cutting tools (end mills, drills) that experience wear. | Custom electrodes (sinker EDM) or a thin wire (wire EDM). |

The most significant trade-off is often speed versus complexity. As noted by Autodesk, CNC milling is typically a faster process overall because it removes material more quickly. However, this speed advantage diminishes as part complexity and material hardness increase. EDM, while slower, can achieve geometries that are difficult or impossible with a conventional mill. The non-contact nature of EDM also eliminates tool pressure, chatter, and vibration, allowing for the machining of very thin or fragile parts without distortion.

Optimal Use Cases: When to Choose One Over the Other

Understanding the theoretical differences is one thing; applying them to real-world manufacturing scenarios is another. The decision to use CNC milling or EDM is driven by the specific demands of the component being produced.

When to Use CNC Milling

CNC milling remains the go-to process for a vast array of applications due to its speed, versatility, and cost-effectiveness for less complex parts. It excels in situations such as:

- Rapid Prototyping: When speed is critical for producing initial design concepts and functional prototypes from plastics or aluminum.

- General Fabrication: For standard components, brackets, enclosures, and parts with relatively simple geometries.

- High-Volume Production: Its faster cycle times make it more economical for producing large quantities of identical parts.

- Working with Non-Conductive Materials: CNC milling is the only option for materials like plastics, wood, and composites that cannot be processed by EDM.

For businesses needing high-quality machined parts with fast turnarounds, specialized service providers are invaluable. For instance, XTJ offers advanced 4 and 5-axis CNC machining for both rapid prototyping and volume production, handling over 30 materials with tight tolerances. Their capabilities in aerospace, medical, and other demanding sectors highlight the power of modern CNC technology for bringing complex designs to life, which you can explore further at their CNC machining services page.

When to Use EDM

EDM is the superior choice when precision and complexity outweigh the need for speed. As detailed by manufacturing experts at 3ERP, its unique capabilities make it indispensable in several key scenarios:

- Machining Extremely Hard Materials: EDM easily cuts through hardened tool steels, titanium, tungsten carbide, and other superalloys that would quickly wear down or break conventional cutting tools.

- Creating Sharp Internal Corners: Wire EDM can produce virtually square internal corners with radii as small as 0.005 inches, a feat impossible for rotating CNC tools.

- Intricate and Complex Geometries: It is ideal for producing complex shapes, thin walls, and deep, narrow cavities (ribs) that are inaccessible to milling cutters.

- Mold and Die Making: EDM is a cornerstone of the tool and die industry, used to create the precise, high-finish cavities required for injection molding and die casting.

- No-Stress Machining: For delicate or thin-walled components that could be distorted or damaged by the mechanical force of a milling cutter, EDM's non-contact nature is a significant advantage.

A Symbiotic Relationship: Advantages and Disadvantages

Ultimately, CNC milling and EDM are not just competitors; they are often complementary technologies in a modern machine shop. Many complex projects, particularly in mold making, utilize both processes to achieve the final product efficiently. A part may be roughed out quickly with CNC milling, while the fine details, sharp corners, and final finish are completed with EDM.

CNC Milling: Pros & Cons

Advantages

- High material removal rates and faster cycle times for simpler parts.

- Versatility to machine a wide range of materials, including non-conductors.

- Generally lower operational costs for standard jobs.

Disadvantages

- Difficulty machining very hard materials.

- Inability to create sharp internal corners (leaves a radius).

- Mechanical stress and vibration can distort fragile parts.

- Tool wear is a constant factor that must be managed.

EDM: Pros & Cons

Advantages

- Exceptional precision and ability to hold extremely tight tolerances.

- Can machine any conductive material regardless of its hardness.

- Produces superior surface finishes without mechanical stress.

- Ideal for complex shapes, deep cavities, and sharp corners.

Disadvantages

- Significantly slower material removal rates compared to milling.

- Limited to electrically conductive materials only.

- Can be a more expensive process, especially due to the need for custom electrodes in sinker EDM.

- Sinker EDM requires a preliminary step to create a custom electrode.

Frequently Asked Questions

1. What is the difference between milling and EDM?

The primary difference lies in the material removal method. Milling is a mechanical process that uses a sharp, rotating cutting tool to physically chip away material. EDM is a thermal process that uses controlled electrical sparks to melt and vaporize conductive material without any physical contact, allowing it to work on harder materials and create more complex shapes. While milling is generally faster, EDM provides superior precision and can create features impossible for a mill, such as sharp internal corners.

2. What are the disadvantages of CNC milling?

The main disadvantages of CNC milling include high initial investment costs for the machinery and ongoing expenses for maintenance and tooling. It requires skilled operators and programmers to function effectively. The process is limited by tool geometry, making it difficult to machine very hard materials or create sharp internal corners. Furthermore, the mechanical forces involved can cause stress and potential distortion in thin or delicate workpieces, and tool wear is a constant factor that can affect accuracy over time.