Consumer Goods Manufacturing: From Concept to Customer

TL;DR

Consumer goods manufacturing is the large-scale industrial process of producing, packaging, and distributing finished products intended for direct sale to and use by individuals and households. This vast sector covers everything from food and beverages to electronics and personal care items. Success in this industry hinges on efficient production processes, robust supply chains, and powerful brand marketing to stand out in a competitive market.

What is Consumer Goods (CPG) Manufacturing?

At its core, consumer goods manufacturing is the engine that creates the products people buy for their own use. It represents the sector of stocks and companies that transform raw materials into items found in homes, on tables, and in daily routines. Unlike industrial goods, which are used to produce other items, consumer goods are the final product purchased by the end-user. The industry is a cornerstone of the modern economy, directly reflecting consumer spending habits and trends.

The consumer goods sector is broadly divided into two primary categories based on product lifespan. Durable goods are products with a long useful life, typically lasting three years or more, such as appliances, furniture, and electronics. In contrast, non-durable goods are consumed in one or a few uses, including items like food, beverages, cleaning supplies, and cosmetics. This distinction is critical as it influences manufacturing cycles, marketing strategies, and consumer purchasing frequency.

Beyond durability, consumer goods are also classified by purchasing habits into four key types:

- Convenience Goods: Items purchased frequently with minimal effort, like milk, bread, and soap.

- Shopping Goods: Products bought less often, where consumers compare features, quality, and price, such as clothing, cars, and flights.

- Specialty Goods: Unique items with strong brand identification that consumers are willing to make a special effort to purchase, like luxury watches or high-end electronics.

- Unsought Goods: Products that consumers do not normally think of buying, such as life insurance or funeral services.

This diverse landscape means CPG manufacturing encompasses a massive range of products. According to an industry overview by Wonnda, major categories include food and beverages, beauty and personal care, health and wellness, and home cleaning products. Because of this direct-to-consumer relationship, brand differentiation, advertising, and marketing are not just important—they are essential for survival and growth in this crowded marketplace, as highlighted by Investopedia.

The End-to-End CPG Manufacturing Process

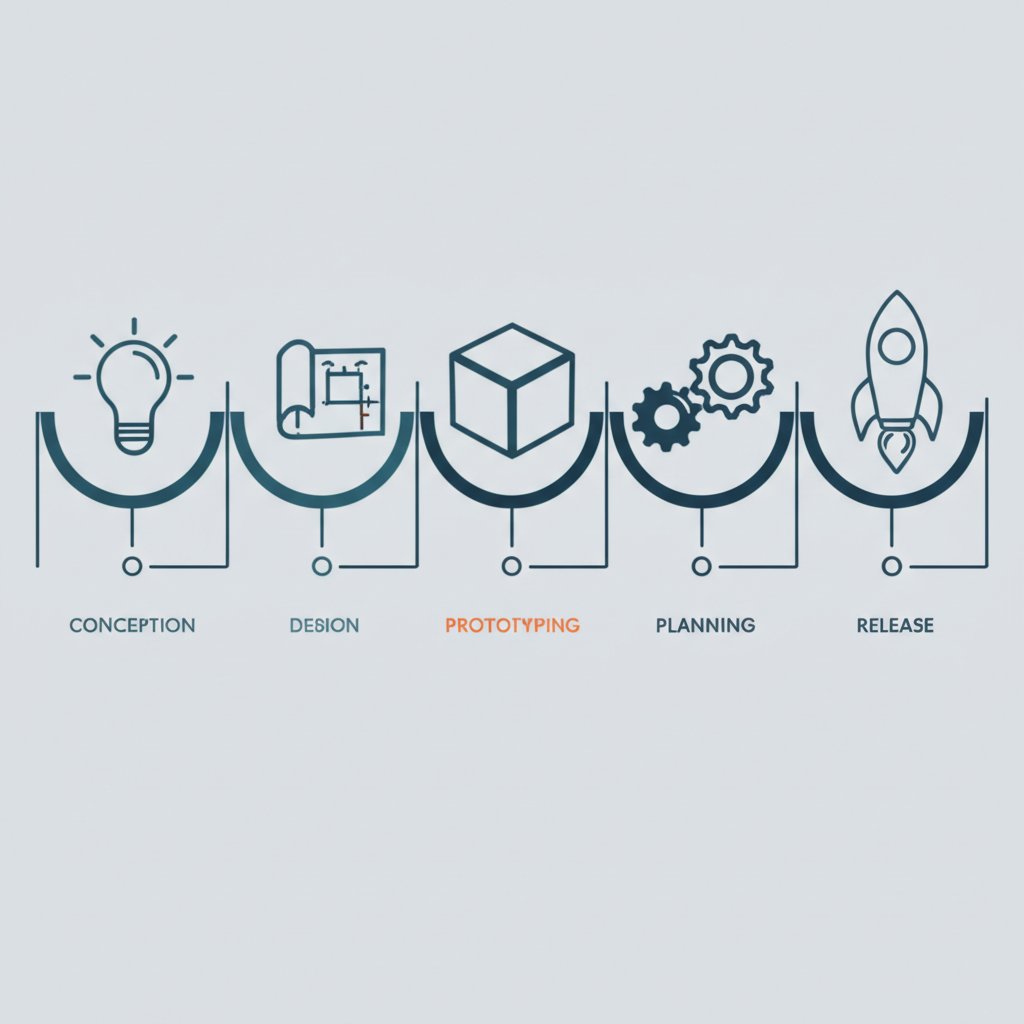

Bringing a consumer product from a simple idea to a store shelf is a complex, multi-stage journey. This process requires a careful balance of creativity, engineering, and strategic planning to ensure the final product is desirable, functional, and profitable. While specifics vary by product, the lifecycle generally follows a structured path from initial concept to market release.

The business side of the process can be broken down into five core stages, providing a roadmap for development:

- Product Conception: This initial phase involves brainstorming and market research to identify a consumer need or a gap in the market. Ideas are generated, vetted for viability, and refined into a solid product concept.

- Product Design: Here, the concept is turned into a tangible design. Engineers and designers create detailed specifications, sketches, and digital models (CAD) that define the product's form, function, and materials.

- Finalized Design & Prototyping: The design is refined and tested through prototyping. This crucial step validates functionality and manufacturability before committing to mass production. For instance, companies specializing in formative manufacturing, like XTJ, offer rapid prototyping and provide crucial Design for Manufacturability (DFM) feedback to optimize designs for efficiency and cost-effectiveness.

- Manufacturing Planning: With a finalized design, the focus shifts to logistics. This includes sourcing raw materials, setting up the production line, establishing quality control protocols, and planning the supply chain.

- Product Release: The product is manufactured at scale, packaged, and distributed to retailers or directly to consumers. This final stage is supported by marketing and sales campaigns to drive adoption.

On the technical side, various manufacturing methods are employed to create the physical product. The choice of method depends on the material, complexity, and production volume. According to manufacturing resource Protolabs Network, some of the most common techniques include:

| Manufacturing Method | Typical Application in Consumer Goods |

|---|---|

| Injection Molding | Creating plastic parts like casings, containers, buttons, and toys. |

| Sheet Metal Fabrication | Forming metal enclosures for appliances, brackets, and chassis. |

| Casting | Producing complex metal parts like engine components or cookware. |

| Additive Manufacturing (3D Printing) | Rapid prototyping, custom parts, and low-volume production runs. |

Integrating Design for Manufacturability (DFM) early in the process is critical. By simplifying designs and selecting appropriate materials and methods from the start, companies can significantly reduce production costs, minimize errors, and accelerate their time to market.

Industry Leaders: Top Consumer Goods Companies

The consumer goods landscape is dominated by a handful of multinational corporations whose brands are household names across the globe. These giants have built their empires on vast product portfolios, powerful marketing, and incredibly efficient global supply chains. Their scale allows them to influence market trends, innovate constantly, and maintain a strong presence in the daily lives of billions of people.

These companies are masters of brand loyalty, often owning dozens of individual brands that cater to different market segments. This strategy allows them to capture a wide consumer base while benefiting from centralized manufacturing and distribution. Their success is a testament to the power of understanding consumer needs and delivering consistent quality at a massive scale.

While the list of influential companies is long, a few consistently rank at the top in terms of revenue and market capitalization. Here are some of the key players shaping the industry, as noted by sources like Manufacturing Digital:

- Procter & Gamble (P&G): A powerhouse in home and personal care, known for iconic brands like Tide, Pampers, and Gillette.

- Nestlé S.A.: The world's largest food company, famous for products ranging from Nescafé coffee to Kit Kat chocolate bars.

- The Coca-Cola Company: The global leader in the beverage industry, with its flagship soda and a vast portfolio of other drinks.

- PepsiCo, Inc.: A major competitor in beverages and a leader in snack foods, owning brands like Pepsi, Lay's, and Doritos.

- Unilever: A British multinational with a strong presence in food, refreshments, home care, and personal care, with brands like Dove, Lipton, and Ben & Jerry's.

- Johnson & Johnson: A leader in health and wellness, producing everything from Band-Aids and baby shampoo to pharmaceuticals.

The enduring success of these CPG titans is built on a foundation of continuous innovation, strategic acquisitions, and a deep-seated ability to connect with consumers through advertising. Many are also increasingly focused on sustainability, with goals to reduce their environmental impact and meet the demands of a more conscious consumer base.

Choosing Your Manufacturing Partner & Model

For any brand entering the consumer goods space, one of the most critical strategic decisions is how to manufacture its products. The choice of manufacturing partner and model directly impacts cost, quality, speed to market, and scalability. Understanding the different options available is essential for building a resilient and successful business.

There are three primary manufacturing models that brands can consider, each with distinct advantages and use cases:

- Private Label Manufacturers: These partners offer pre-developed, market-tested formulas that brands can label with their own branding. It's the fastest and often most cost-effective way to launch a product, as the research and development are already done.

- Contract Manufacturers: These facilities produce goods based on a brand's unique, custom-developed formula. This model offers full control over the product's composition and uniqueness but requires the brand to handle its own R&D.

- Full-Service (Turnkey) Manufacturers: As the name implies, these partners offer an all-in-one solution. They can assist with everything from formula development and sourcing to manufacturing, packaging, and even logistics, providing a comprehensive, hands-off approach.

Selecting the right model depends entirely on a brand's specific needs, budget, and long-term goals. To help clarify this decision, consider the following breakdown:

| Model Type | Best For... | Key Benefit |

|---|---|---|

| Private Label | New brands wanting maximum speed to market and lower risk. | Low initial investment and proven product formulas. |

| Contract | Brands with a proprietary formula seeking quality production. | Full control over product uniqueness and intellectual property. |

| Full-Service | Brands that want to focus on marketing and sales, not operations. | Streamlined process with expert guidance at every stage. |

When evaluating potential partners, it's crucial to look beyond the cost. Key factors to assess include their minimum order quantity (MOQ), their specific experience in your product category, relevant certifications (e.g., GMP, organic), and their level of transparency. A strong manufacturing partner is more than a vendor; they are a critical component of your brand's success.

Frequently Asked Questions

1. What is the consumer goods manufacturing industry?

The consumer goods manufacturing industry, or CPG sector, consists of companies that produce and sell products intended for use by individuals and households. This diverse sector includes everything from food and clothing to electronics and cleaning supplies. Its success is closely tied to consumer spending, and key business strategies revolve around effective marketing, branding, and supply chain management.

2. What is the meaning of manufacturing consumer goods?

Manufacturing consumer goods refers to the entire process of transforming raw materials into finished products that are sold directly to end-users for personal consumption. These goods are the final output of the production process and are not used to create other products. They are typically categorized as durable (long-lasting) or non-durable (consumed quickly).

3. What are the 4 types of consumer goods?

Consumer goods are generally classified into four main types based on consumer buying behavior: convenience goods (frequent, low-effort purchases like soap), shopping goods (less frequent, comparison-based purchases like furniture), specialty goods (unique, high-effort purchases like luxury cars), and unsought goods (products not actively sought out, like insurance).

4. Who is the biggest CPG company?

While rankings can fluctuate, the biggest CPG companies are typically measured by market capitalization or revenue. As of recent analyses, giants like Procter & Gamble (P&G), Nestlé, and The Coca-Cola Company are consistently among the largest in the world due to their extensive brand portfolios and global reach.

-

Posted in

consumer goods, cpg manufacturing, manufacturing process, product development, supply chain