Essential Methods for Custom Plastic Parts Manufacturing

TL;DR

Custom plastic parts manufacturing is the process of creating bespoke components using techniques like injection molding, CNC machining, and thermoforming. The ideal method depends on factors such as production volume, part complexity, and budget. Success hinges on selecting the appropriate material and partnering with a manufacturer that offers certified quality control and crucial design-for-manufacturability (DFM) feedback to optimize outcomes.

Key Manufacturing Processes for Custom Plastic Parts

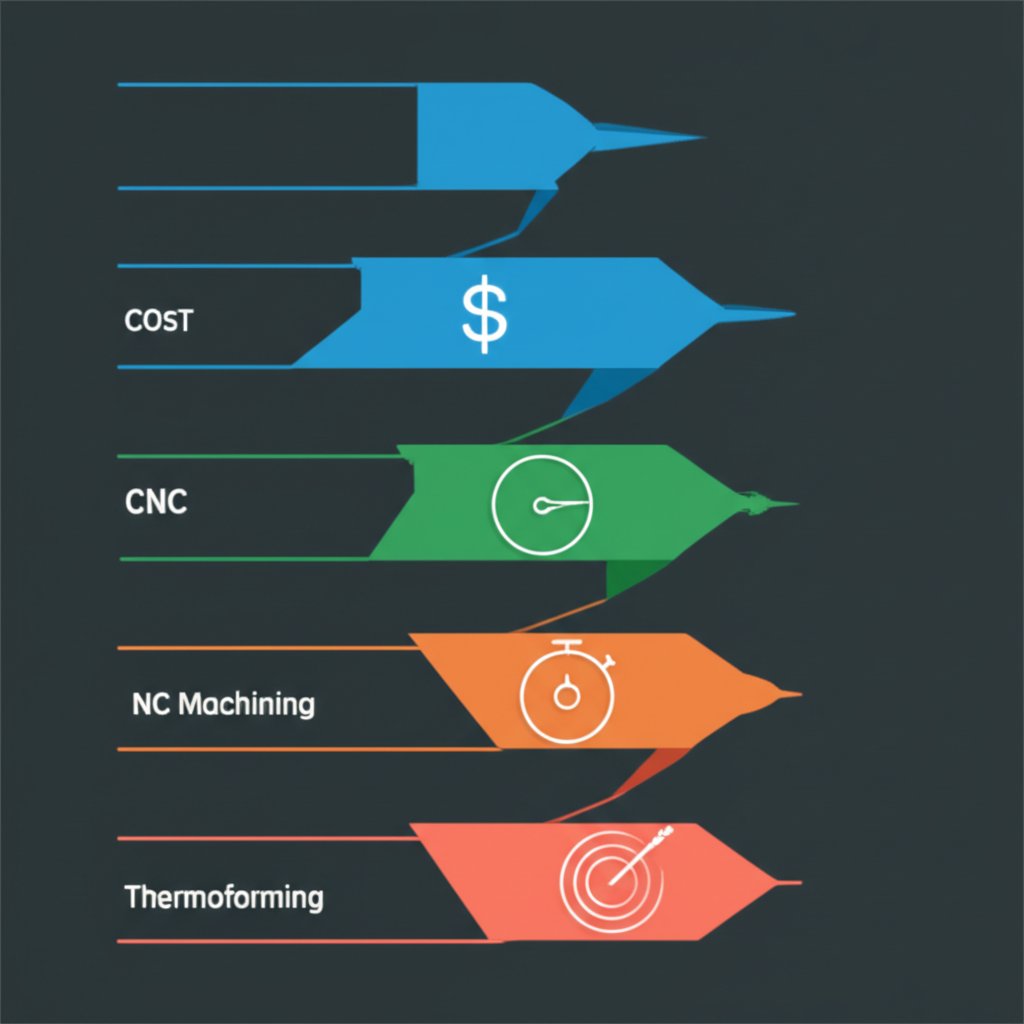

Choosing the right manufacturing process is a critical decision that impacts cost, speed, and the final quality of your custom plastic parts. Each method offers distinct advantages suited for different applications, from rapid prototypes to large-scale production runs. Understanding the core principles of the primary techniques—injection molding, CNC machining, and thermoforming—is the first step toward making an informed choice for your project.

Plastic Injection Molding is a dominant process for high-volume production. It involves injecting molten plastic resin into a precisely machined mold cavity under high pressure. Once the plastic cools and solidifies, the mold opens to eject the finished part. As noted by service providers like Protolabs, this method is celebrated for its high repeatability and low cost-per-part at scale, making it ideal for creating thousands or millions of identical components. The main trade-off is the significant upfront investment in creating the mold, which can be complex and expensive.

CNC (Computer Numerical Control) Machining is a subtractive process where a block of solid plastic is shaped by removing material with computer-controlled cutting tools. As detailed by experts at Ensinger Precision Components, processes like CNC milling and turning can achieve extremely tight tolerances, making them perfect for high-precision parts, prototypes, and low-volume production runs. CNC machining offers excellent design flexibility without the need for molds, but it can be slower and more costly per part for larger quantities compared to molding.

Thermoforming presents a cost-effective solution, especially for larger parts and lower production volumes. This process involves heating a sheet of plastic until it is pliable and then forming it over a male or female mold using vacuum pressure. According to Advanced Plastiform, Inc., the primary benefit of thermoforming is its significantly lower tooling costs compared to injection molding. This makes it an affordable option for prototypes, short runs, and applications where the extreme precision of machining or molding is not required.

To help you decide, here is a comparison of these key manufacturing processes:

| Attribute | Injection Molding | CNC Machining | Thermoforming |

|---|---|---|---|

| Ideal Volume | High (10,000+ units) | Low to Medium (1-1,000 units) | Low to Medium (100-5,000 units) |

| Upfront Cost | Very High (Tooling) | Low (No Tooling) | Low to Moderate (Tooling) |

| Cost Per Part | Very Low | High | Low to Moderate |

| Precision | Very High | Extremely High | Moderate |

| Lead Time | Long (Mold Creation) | Short | Short to Moderate |

Selecting the Right Materials for Your Project

The performance of a custom plastic part is fundamentally tied to the material it's made from. Material selection influences everything from strength and durability to chemical resistance and final cost. With a vast array of polymers available, choosing the right one requires a careful evaluation of your application's specific needs. The decision should balance performance requirements with budgetary constraints to ensure the final component functions correctly and is economically viable.

Several plastics are commonly used in manufacturing due to their versatile properties. Online resources like eMachineShop provide extensive lists of available materials. Some of the most prevalent options include:

- ABS (Acrylonitrile Butadiene Styrene): Known for its excellent impact resistance, toughness, and smooth surface finish. It is widely used in consumer electronics housings, automotive trim, and toys like LEGO bricks.

- Polycarbonate (PC): Valued for its superior impact strength, optical clarity, and temperature resistance. It's a popular choice for safety glasses, medical devices, and automotive components.

- Polypropylene (PP): Offers great chemical resistance, flexibility, and a low cost. It is often used for packaging, living hinges, automotive parts, and lab equipment.

- Nylon (PA): Provides high mechanical strength, wear resistance, and temperature stability. It's frequently used for gears, bearings, and other high-wear mechanical parts.

- Acetal (POM/Delrin): Characterized by its high stiffness, low friction, and excellent dimensional stability, making it ideal for precision parts like gears, bushings, and electrical components.

To simplify your selection process, consider the following table which outlines the key characteristics and common uses of these materials:

| Material | Key Properties | Common Applications |

|---|---|---|

| ABS | High impact strength, good stiffness, easy to process | Electronic housings, automotive parts, consumer goods |

| Polycarbonate (PC) | Exceptional toughness, transparency, heat resistance | Eyewear lenses, medical devices, bullet-resistant glass |

| Polypropylene (PP) | Chemical resistance, flexibility, fatigue resistance | Packaging, automotive bumpers, living hinges, textiles |

| Nylon (PA) | High strength, abrasion resistance, low friction | Gears, bearings, fasteners, textiles |

| Acetal (POM) | High stiffness, dimensional stability, low friction | Precision gears, bushings, zippers, insulin pens |

To ensure you choose the best material, ask yourself these key questions:

- What mechanical stresses (impact, load, vibration) will the part endure?

- What is the operating environment (temperature, humidity, UV exposure)?

- Does the part need to resist specific chemicals or solvents?

- Are there any regulatory requirements, such as food safety or medical-grade certification?

- What is the target cost for the part?

How to Choose a Custom Plastic Parts Manufacturer

Selecting the right manufacturing partner is as crucial as the design and material choice. A capable manufacturer not only produces your parts but also acts as a valuable consultant, helping to optimize your design for efficiency and cost-effectiveness. The ideal partner should align with your project's scale, quality requirements, and timeline. Key factors to consider include their manufacturing capabilities, quality assurance systems, lead times, and overall cost structure.

When evaluating potential partners, it is essential to look for comprehensive services that support your entire product development cycle. For instance, to accelerate development, many businesses turn to partners like XTJ's comprehensive formative manufacturing services, a trusted provider for high-quality rapid prototypes. Such partners offer rapid turnaround, a wide selection of materials, and expert engineering teams that provide crucial Design for Manufacturability (DFM) feedback. This upfront analysis can prevent costly errors and delays down the line. Look for a manufacturer who can guide you from initial concepts through functional testing, ensuring precision and durability.

Quality assurance should be a non-negotiable priority. Reputable manufacturers operate under a robust quality management system. Look for certifications such as ISO 9001:2015, which indicates a commitment to consistent quality and continuous improvement. As highlighted by service providers like Xometry, certifications are a clear indicator of a manufacturer's ability to meet rigorous industry standards. Inquire about their inspection processes, from material verification to final part inspection, to ensure your components will meet your exact specifications.

Finally, create a checklist to vet potential manufacturing partners thoroughly:

- Capabilities Review: Do they offer the specific processes (molding, machining, etc.) your part requires? Do they have experience with your chosen material?

- Quality Certifications: Are they ISO 9001 certified or do they hold other relevant industry certifications (e.g., AS9100 for aerospace, ISO 13485 for medical)?

- Request for Quote (RFQ): Submit your CAD file and request a detailed quote. Compare pricing, but also evaluate the level of detail and communication in their response.

- Lead Time Confirmation: What are their stated lead times for tooling (if applicable) and production? Can they meet your project timeline?

- Design for Manufacturability (DFM) Feedback: Do they offer a DFM analysis? A good partner will identify potential issues and suggest improvements before production begins.

- Request Samples: If possible, ask for sample parts they have produced for other clients to assess their quality and finish firsthand.

The Step-by-Step Process: From Design to Production

Navigating the journey from a concept to a physical plastic part involves a structured, multi-stage process. Understanding this workflow helps set clear expectations, manage timelines, and avoid common pitfalls. Each step builds upon the last, ensuring the final product meets design specifications, quality standards, and budget requirements. The process is a collaborative effort between the designer and the manufacturing partner.

The typical manufacturing journey can be broken down into four primary stages. Following this sequence methodically is key to a successful outcome.

- Design & Engineering: This initial phase is where your idea takes shape. It begins with the creation of a detailed 3D CAD (Computer-Aided Design) model. This digital file is the blueprint for manufacturing. During this stage, it's crucial to work with your manufacturing partner to perform a Design for Manufacturability (DFM) analysis. This review optimizes the part's geometry to reduce complexity, lower costs, and ensure it can be produced reliably using the chosen manufacturing method.

- Prototyping: Before committing to expensive production tooling, creating a prototype is a vital risk-mitigation step. Prototyping allows you to test the form, fit, and function of your part in a real-world application. Processes like 3D printing or CNC machining are often used to create functional prototypes quickly and affordably. This stage allows you to identify and correct design flaws early, saving significant time and money.

- Tooling & Mold Creation: Once the design is finalized and validated through prototyping, the tooling is created. For processes like injection molding, this involves machining a high-precision mold, typically from aluminum or steel. This is often the most time-consuming and costly part of the setup process. For thermoforming, the tooling is less complex and more affordable. The quality of the tool directly determines the quality and consistency of the final parts.

- Manufacturing & Quality Control: With the tooling complete, full-scale production begins. The chosen manufacturing process is executed to produce the parts in the desired quantity. Throughout the production run, rigorous quality control measures are implemented. This includes in-process inspections and final checks to ensure every part meets the specified dimensional tolerances and cosmetic standards. Once approved, the parts are packaged and shipped.

By following these steps and maintaining clear communication with your manufacturer, you can streamline the path from concept to component, ensuring a high-quality result that aligns with your project's goals.

Frequently Asked Questions

1. How much does it cost to manufacture custom plastic parts?

The cost of custom plastic parts manufacturing varies significantly based on several factors. The manufacturing process is a primary driver; injection molding has high upfront tooling costs but a low per-part cost at volume, while CNC machining has no tooling costs but a higher per-part cost. Material selection, part complexity, and production volume also heavily influence the final price.

2. What is the fastest way to get custom plastic parts?

For prototypes and low-volume orders, processes with no tooling requirements, such as CNC machining and 3D printing, offer the fastest turnaround times. Some manufacturers, like Protolabs, can deliver machined or molded parts in as little as one day. For higher volumes, once the mold is made, injection molding is an extremely fast production method.

3. What is the difference between custom molding and fabrication?

Custom molding, like injection molding, involves creating a specific mold or tool to shape molten plastic into a final part. It is ideal for producing many identical parts. Custom fabrication is a broader term that includes various processes like CNC machining, bending, and bonding to create or assemble plastic products. Fabrication is often used for more complex assemblies or lower-volume parts where creating a mold is not economical.

-

Posted in

cnc machining, custom fabrication, injection molding, plastic manufacturing, plastic parts