Find Top Custom CNC Machining Near You

TL;DR

Finding the right custom CNC machining service near you requires evaluating a shop's specific capabilities, material expertise, and precision standards. Top local and national providers offer a range of services, including multi-axis milling and turning for materials like aluminum, steel, iron, and plastics. The key is to match your project's complexity, volume, and material requirements with a provider that has the right equipment and experience to deliver high-quality parts on time and within budget.

What to Look for in a Custom CNC Machining Service

Selecting a partner for custom CNC machining is a critical decision that impacts the quality, cost, and timeline of your project. Before engaging a service, it's essential to assess their capabilities to ensure they align with your specific needs. A thorough evaluation will help you find a reliable shop that can produce parts to your exact specifications.

Focus on providers who are transparent about their equipment, processes, and quality control measures. An ideal partner not only manufactures your parts but also offers expertise that can potentially improve your design for better manufacturability and cost-efficiency. Look for clear communication and a willingness to discuss your project's technical details.

To make an informed choice, consider the following key criteria:

- Core Capabilities: Verify that the shop offers the specific services you need. This includes processes like CNC milling (for complex shapes and features), CNC turning (for cylindrical parts), and Swiss turning (for small, intricate, high-volume parts). Some shops also provide value-added services like drilling, tapping, welding, and assembly.

- Material Specialization: Ensure the provider has experience working with your chosen material. Common materials include various grades of aluminum, stainless steel, carbon steel, and plastics. Specialized shops may focus on materials like ductile iron castings or high-performance alloys.

- Precision and Tolerances: Ask about the level of precision they can achieve. Look for terms like "close tolerance" or specific measurements (e.g., +/- 0.005mm). The required tolerance depends entirely on your part's application.

- Industries Served: A shop with experience in your industry (e.g., aerospace, medical, automotive) will be more familiar with its specific standards, documentation requirements, and quality expectations.

- Quality Certifications: Certifications like ISO 9001 or AS9100D indicate a commitment to standardized quality management systems, which is a strong signal of reliability and process control.

Top Custom CNC Machining Providers

When you need custom parts, choosing the right provider is crucial. Whether you prioritize speed, local collaboration, or specialized material expertise, there are excellent options available. Here is a look at several providers that serve a range of needs, from rapid online services to specialized local shops.

XTJ

For projects demanding speed and high precision, XTJ stands out as a leading provider of rapid prototyping and volume production. They offer advanced 4 and 5-axis CNC machining with exceptionally fast lead times, starting from just 3 days. Specializing in tolerances as tight as +/- 0.005mm, XTJ works with over 30 materials, making them a versatile choice for demanding industries like aerospace and medical. Their ISO 9001 certification underscores a commitment to quality, providing a reliable option for businesses that need certified parts delivered quickly.

Enterprise CNC Machining

A prominent local provider, Enterprise CNC Machining offers a comprehensive suite of services including CNC milling, turning with 5-axis capability, and Swiss turning. They are experienced with a variety of materials such as aluminum, steel, iron, and plastics, working from bar stock, plates, and castings. Their AS9100D certification highlights a rigorous commitment to quality assurance, making them a trusted partner for precision parts. The shop also provides value-added services like welding, light assembly, and finishing to deliver a more complete product.

MPS Mankato (Dotson)

Specializing in machined iron castings, MPS Mankato is the go-to expert for projects involving ductile and austempered ductile iron. With a skilled team of machinists, they are equipped to handle any casting their foundry produces, focusing on parts weighing between 2 and 50 pounds. Their promise to deliver machined castings in 21 days or less makes them a reliable choice for projects requiring robust, specialized iron components.

Associated Machining & Design

Located in North Mankato, Associated Machining & Design is another local option for general machining needs. While their online presence is minimal, their local establishment makes them an accessible choice for businesses in the area looking for direct collaboration and service. Contacting them directly is the best way to explore their specific capabilities and services for your project.

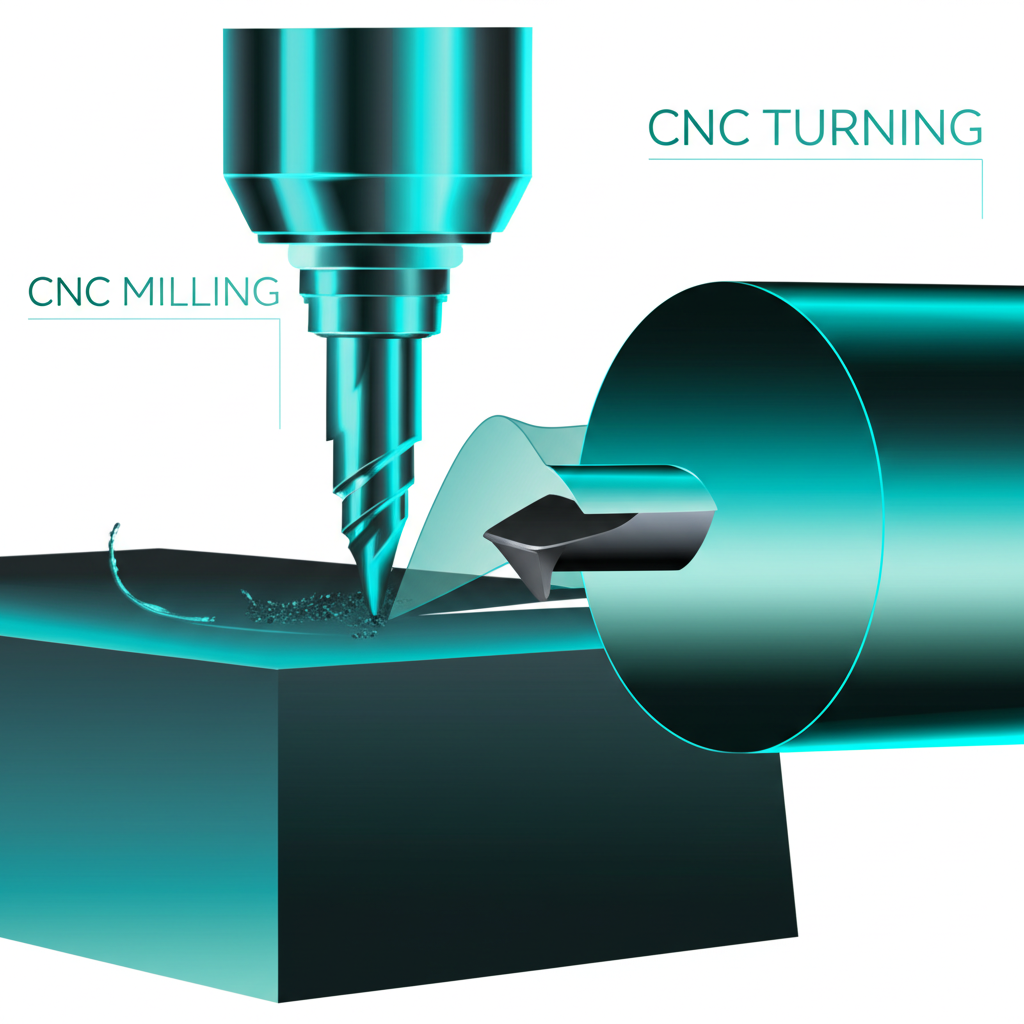

Understanding Core CNC Machining Capabilities

To have an informed conversation with a potential supplier, it helps to understand the basic services they offer. While the technology is complex, the core concepts are straightforward. Each process is suited for creating different types of parts and features, and knowing the difference will help you identify which service your project requires.

CNC Milling: This is a subtractive process where rotating multi-point cutting tools remove material from a stationary workpiece to create a part. It is highly versatile and ideal for producing complex shapes, slots, holes, and three-dimensional contours. Think of it as a highly precise, automated sculpting process for metal or plastic blocks.

CNC Turning: In this process, the workpiece rotates while a single-point cutting tool moves along its surface to shape it. Turning is used to create cylindrical or conical parts, such as shafts, pins, and rings. Lathes and turning centers are the primary machines used for this, and modern equipment can perform secondary operations like drilling and milling in the same setup.

Swiss Turning (Swiss Screw Machining): This is a specialized type of turning designed for producing small, long, and intricate parts with very high precision. The workpiece moves through a guide bushing, and the cutting tools work close to that bushing, providing excellent support and minimizing deflection. This makes it perfect for high-volume production of components like medical implants and electronic connectors.

Common Questions About CNC Machining Costs

Understanding the cost of custom CNC machining is a primary concern for anyone sourcing parts. While a simple hourly rate is often mentioned, the final price is determined by a combination of factors. Giving a single, universal price is impossible, as every project is unique. However, understanding the key cost drivers can help you manage your budget and optimize your design for affordability.

The most significant factors influencing cost are the complexity of the part, the material chosen, and the quantity of the order. A part with intricate geometries and tight tolerances will require more programming and machine time than a simple one. Likewise, exotic materials are more expensive and may be harder to machine than common aluminum or steel. Below are the primary elements that contribute to the total cost of a CNC-machined part.

- Machine Time: This is often calculated at an hourly rate, which covers the cost of running the machine, labor, and overhead. The more complex the part, the longer it takes to machine, increasing this cost.

- Material Costs: The price of the raw material billet or bar stock directly impacts the final cost. The amount of material wasted as chips during machining is also a factor.

- Part Complexity: Designs with intricate features, multiple surfaces, and tight tolerances require more advanced machinery (like 5-axis mills), more programming time, and longer machining cycles.

- Order Volume (Quantity): Setup costs (programming, tooling, fixturing) are amortized across the entire batch. Therefore, the price per part is significantly lower for high-volume production runs compared to one-off prototypes.

- Finishing and Post-Processing: Services like anodizing, painting, heat treating, or polishing add to the final cost and production time.

Frequently Asked Questions

1. What is the hourly rate for a CNC machine?

While rates vary based on location, machine type, and shop overhead, a general average hourly rate for CNC machining can be around $75 to $150 per hour in the United States. However, this figure is just one component of the total cost, which also includes materials, setup time, and any post-processing requirements.

2. Do CNC machinists make a lot of money?

The salary for CNC machinists depends on their skill level, experience, and geographic location. According to SERP data, the average salary in the USA is around $46,800 per year. Entry-level positions start lower, while experienced machinists, especially those who can program and operate complex multi-axis machines, can earn significantly more, with salaries reaching up to $58,500 or higher.